EDAC 320 User manual

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

1. Table of Contents

1. Table of Contents................................................................................................................ 2

2. Overview.............................................................................................................................. 4

2.1 About the EDAC 320.......................................................................................................................... 4

2.2 Specifications..................................................................................................................................... 4

3. Getting Started.................................................................................................................... 6

3.1 Network Connection........................................................................................................................... 6

3.1.1 Circuit Switched Data Number.................................................................................................................. 8

3.1.2 GPRS........................................................................................................................................................ 9

3.2 LED’s.................................................................................................................................................. 9

3.2.1 Power........................................................................................................................................................ 9

3.2.2 Active ........................................................................................................................................................ 9

3.2.3 Status........................................................................................................................................................ 9

4. Hardware Installation.........................................................................................................10

4.1 Power Supply................................................................................................................................... 10

4.1.1 Power Supply Selection Jumper ............................................................................................................. 10

4.1.2 DC Power Input....................................................................................................................................... 11

4.1.3 AC Power Input....................................................................................................................................... 11

4.2 Inputs ............................................................................................................................................... 12

4.2.1 Jumper configuration .............................................................................................................................. 12

4.2.2 Digital Input Configuration....................................................................................................................... 13

4.2.3 4-20mA Analog Input Configuration........................................................................................................ 14

4.2.4 0-5V Analog Input Configuration............................................................................................................. 15

4.3 Outputs............................................................................................................................................. 16

4.3.1 Direct Load Switching ............................................................................................................................. 16

4.3.2 Relay Switching ...................................................................................................................................... 17

4.4 Aerial Installation.............................................................................................................................. 17

4.4.1 Aerial Selection....................................................................................................................................... 17

4.4.2 Mounting ................................................................................................................................................. 18

4.4.3 Cable Length........................................................................................................................................... 18

4.5 Other ................................................................................................................................................ 18

4.5.1 RS232..................................................................................................................................................... 18

4.5.2 USB ........................................................................................................................................................ 18

5. Software Installation..........................................................................................................19

5.1 EDAC 320 Configuration Manager .................................................................................................. 19

5.2 EDAC 320 Remote Management .................................................................................................... 20

5.3 USB Drivers ..................................................................................................................................... 22

5.3.1 Windows © 98 / ME ................................................................................................................................ 22

5.3.2 Windows © 2000/XP/Server 2003 and Windows © XP/Server 2003 64bit edition .................................. 26

6. EDAC 320 Configuration Manager....................................................................................31

6.1 Setup................................................................................................................................................ 31

6.2 Main Features .................................................................................................................................. 31

6.3 Unit Page ......................................................................................................................................... 32

6.3.1 ‘General’ Tab .......................................................................................................................................... 33

6.3.2 ‘Connection’ Tab..................................................................................................................................... 33

6.3.3 ‘Email’ Tab .............................................................................................................................................. 35

6.3.4 ‘Logging’ Tab .......................................................................................................................................... 36

6.4 Inputs ............................................................................................................................................... 37

6.4.1 ‘Input’ tab ................................................................................................................................................ 37

6.4.2 ‘Alarm A’ Tab .......................................................................................................................................... 38

6.4.3 ‘Alarm B’ Tab .......................................................................................................................................... 39

6.5 Outputs............................................................................................................................................. 40

6.6 Diagnostics Interface ....................................................................................................................... 41

7. EDAC 320 Remote Management .......................................................................................42

7.1 Setup................................................................................................................................................ 42

7.1.1 Edit Connections..................................................................................................................................... 42

7.1.2 Modem.................................................................................................................................................... 43

7.2 Downloading Log Files..................................................................................................................... 44

7.3 Downloading/Uploading Contacts List ............................................................................................. 44

8. EDAC 320 – Notification, Control and Queries ................................................................46

8.1 Alarm Notification Messages ........................................................................................................... 46

8.2 Controlling Outputs .......................................................................................................................... 46

8.2.1 Switching Commands ............................................................................................................................. 46

8.2.2 Responses.............................................................................................................................................. 46

8.2.3 Multiple Output Commands..................................................................................................................... 47

8.3 Status Query .................................................................................................................................... 47

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

8.4 Advanced SMS Commands............................................................................................................. 48

8.4.1 System Queries ...................................................................................................................................... 48

8.4.2 Multiple Commands ................................................................................................................................ 48

8.4.3 SMS Forwarding to RS232 port .............................................................................................................. 48

8.4.4 Updating Contacts List via SMS.............................................................................................................. 49

8.5 Email Commands............................................................................................................................. 50

9. Data Logging......................................................................................................................51

9.1 Overview .......................................................................................................................................... 51

9.2 SD Data Card................................................................................................................................... 51

9.2.1 Supported Card Types............................................................................................................................ 51

9.2.2 Initialising/Formatting New Cards ........................................................................................................... 51

9.2.3 Installing/Removing SD cards................................................................................................................. 52

9.3 Log File Formats .............................................................................................................................. 54

9.3.1 LOG.CSV................................................................................................................................................ 54

9.3.2 ALARM.LOG ........................................................................................................................................... 55

9.3.3 SYSTEM.LOG......................................................................................................................................... 55

9.4 Retrieving Log Files ......................................................................................................................... 55

9.4.1 Locally..................................................................................................................................................... 55

9.4.2 Remotely................................................................................................................................................. 56

10. Application Notes / Advanced Features...........................................................................57

10.1 Through Mode Data Connection...................................................................................................... 57

10.2 Automatic Local Output Switching ................................................................................................... 57

10.3 Automatic Remote Output Switching ............................................................................................... 59

10.4 Power Supply Monitoring ................................................................................................................. 60

10.4.1 Hardware Setup ...................................................................................................................................... 60

10.4.2 Configuration Setup ................................................................................................................................ 61

10.5 RS232 AT Commands ..................................................................................................................... 62

11. Glossary .............................................................................................................................65

12. Product Support.................................................................................................................67

13. Notes...................................................................................................................................68

14. Document History ..............................................................................................................69

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

2. Overview

2.1 About the EDAC 320

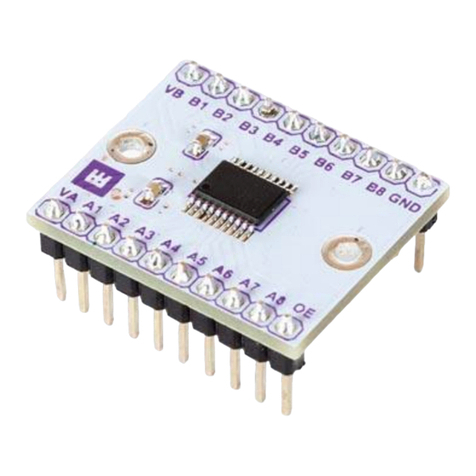

The EDAC 320 is a cost effective, cellular based remote monitoring control and logging system. Based off the

tried and true EDAC SMS 300 series product the EDAC 320 integrates all of the features of the SMS 300 as well

as adding some new ones.

The EDAC 320 connects to approved GSM cellular networks and uses this connection to deliver critical

information. The EDAC 320 employs SMS (Short Messaging Service), email via GPRS (General Packet Radio

Service) and CSD (Circuit Switched Data) technologies to report and deliver this information.

The EDAC 320 has the ability to monitor up to 8 inputs and send out messages via SMS or email when a

predefined alarm or reset condition occurs. The EDAC 320’s inputs can accept either digital, 4-20mA analog or

0-5V analog inputs.

The EDAC 320 also has four integrated relay outputs which can be used to control various pieces of equipment.

Any of the outputs can be switched either remotely via a user sending an SMS or email to the unit with the

command, or automatically depending on the state of an input (i.e. low temperature detected, turn heating on).

Notification of outputs switching can be sent to any of the EDC 320’s sixteen different programmable contact

slots.

Information from any of the EDAC 320’s inputs and outputs can be recorded to an onboard flash memory card,

where it can be retrieved and viewed either locally or remotely via cellular networks at any time. This information

can be useful for monitoring the performance of systems and equipment, recording/reporting of system faults as

well as recording/logging of information for compliance in processing or resource allocation.

Like its brother the SMS 300, the EDAC 320 is sturdily constructed and enclosed in an extruded aluminium case

ensuring maximum ruggedness and reliability.

2.2 Specifications

Power Supply 12-28V AC/DC supply

When in idle mode the EDAC 320 draws less than 100mA. The PSU must be

able to supply a peak current of up to 1A at 12VDC and 500mA at 24VDC

Fuse 1A Internal Fixed Re-settable Fuse.

Telephone Network Connection GSM – Telstra Australia or Vodafone NZ

Contact List capacity 16 entries consisting of either cellphone numbers (for SMS alarm messages),

or email addresses (for email messages). Each alarm can be sent to any

combination of these contacts. Cellphone numbers are programmed in

international format meaning SMS messages can be delivered to any cellular

network in the world that is interlinked with the host network.

Alarm Delivery Method Either via SMS or email

Inputs 8 user selectable 10bit Analog or Digital inputs. Sensor out of range warnings

Input scan rate < 0.5 second

De-bouncing Configurable between 0 and 10,000 seconds

Analog Input type Individually configurable 0-5V or 4-20mA

Analog Input Units Engineering units can be specified to match the sensor type

Analog Scaling Scaling and zero offset parameters for each input

Analog Alarming Hi-Alarm, Low-Alarm, Hi-Reset and Low-Reset parameters configurable in the

specified engineering units for each input

Control Outputs can be controlled manually via SMS or email. Outputs can also be

activated by being linked to alarm conditions, either internally or on another

EDAC 320 unit configured in the phone book.

Outputs Normally open relays. 2A max, 50V AC/DC

Data Logging Rates Globally configurable between 5 and 86,400 seconds (5 second resolution)

Data Card Type SD or MMC data cards up to 1 GB

Data Retrieval Methods Either via remote dial up connection or locally by inserting card into desktop

PC

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Other Interfaces RS-232 Serial and USB

Diagnostic interface Real time diagnostic interface showing condition of all I/O as well as signal

strength and network status

Configuration Interfaces Using the supplied windows configuration application via RS-232, USB or

remote dial up connection (limited to contacts list only).

Site Message 20 characters (max) which is attached to every alarm message

Alarm and Reset messages 40 characters (max) for each alarm.

Output Name 20 characters (max) for each output name. This can be used to control

switching of the output using an SMS.

Modem Through-mode The internal GSM modem can be used in through mode to provide a wireless

serial link to an external device (e.g. PLC) or the EDAC 320

SMS Command Mode The EDAC 320 can forward messages received via the serial port

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

3. Getting Started

3.1 Network Connection

The network connection is the first and most important part of setting up your new EDAC 320. It is also important

the once set up, the network connection is properly maintained. If the account lapses or the credit is used up, the

device will not be able to send any notification messages meaning that critical alarm events may be missed.

Below detailed in table 3.1 are the networks where the EDAC 320 is currently approved for connection, The

EDAC 320 should only be used on approved networks. Correct and reliable operation cannot be guaranteed

when connected to non-approved networks.

EDAC 320 Approved Networks

Telstra Aust – GSM

Vodafone NZ

Vodafone Aust

Table 3.1 Approved Networks

To start using the EDAC 320 it must be registered on an approved GSM cellular network. To do this the unit

must be fitted with a SIM (Subscriber Identity Module) card. This small card-like microchip contains information

about the account the unit is connected to. The EDAC 320 can work with pre-pay or contract SIM cards.

Visit your local GSM network provider’s store to obtain a SIM card. Note the phone number listed on the SIM

packaging as this will become the phone number of the EDAC 320 device.

Most SIM cards have a ‘SIM PIN’ feature. This is a PIN code that must be entered each time the SIM is powered

up. Normally this feature is disabled on new SIM cards. If the ‘SIM PIN’ is enabled this pin MUST be the same as

the EDAC 320’s ‘Unit PIN’ (see section 6.3.1 for more information on changing the ‘Unit PIN’). Failure to ensure

the two PIN’s match will result in the SIM being locked. If this occurs contact you local service provider for

information on unlocking SIM cards.

The SIM must be fitted into the unit before the EDAC 320 will operate. To do this the unit must be powered down

and end plate must be removed to expose the SIM connector. Remove the connector blocks from the end plate

(the end the aerial connects to) and remove the screws securing the end plate as detailed in Fig 3.1a.

Fig 3.1a Removing terminal blocks and end plate

Relocate the endplate to allow access to the SIM connector. The case lid may also be removed to allow easier

access to the SIM holder as shown in Fig 3.1b

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig 3.1b Removing the Case Lid

Slide the SIM connector back and lift to allow the SIM to be inserted as shown in Fig 3.1c

Fig 3.1c Unlocking SIM card holder

Insert the SIM into the holder as shown below in Fig 3.1d. Due to the shape of the SIM card itself it should not be

possible to insert the card in an incorrect manner.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig 3.1d Fitting SIM card

Place the SIM holder down flat and slide forward to lock into place as shown in Fig. 3.1e. Refit the lid, end plate

and connector blocks.

Fig 3.1e Locking SIM card in place

The unit should now be ready for use.

3.1.1 Circuit Switched Data Number

Some features of the EDAC 320 require a ‘Circuit Switched Data’ (or CSD) number to be enabled on the SIM to

function correctly.

Having a data number enabled means that the SIM card will have two different phone numbers associated with

it, one for voice/SMS and another for CSD communications. Dialling the CSD number ensures that modem calls

are routed through the network in the most appropriate and reliable way.

The following features require a data number on order to function correctly:

Through Mode Data Connection (see section 10.1)

Downloading Log Files (see section 7.2)

Downloading/Uploading Contacts List (see section 7.3)

Contact your local GSM network provider to have a data number enabled on your SIM card. Most network

providers will only enable a data number on post paid or contract accounts. Ensure the data number s recorded

and kept safe.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

3.1.2 GPRS

Some features of the EDAC 320 require ‘GPRS’ (short for General Packet Radio Service) to be enabled on the

SIM to function correctly. Put simply having a GPRS connection enabled allows the SIM to connect to the

internet through the cellular connection.

The following features/settings require a GPRS connection to function correctly:

Connection Settings (see section 6.3.2)

Email Configuration Settings (see section 6.3.3)

Email Log File Updates (see section 6.3.4)

Email Addresses as Unit Contacts (see section 6.3.1)

Contact you local GSM network provider to ensure GPRS is enabled on your SIM card. Most network providers

enable GPRS by default on all new SIM cards, as this is the framework behind premium mobile services such as

WAP, mobile video calling and mobile internet technologies.

3.2 LED’s

The status of the EDAC 320 is indicated externally by three green LED lights. Each of these lights, power, active

and status indicates the condition of different parts of the 320’s functionality.

3.2.1 Power

The power LED indicates if the EDAC 320 is powered up, and if it is the status of the SD/MMC data card.

On Powered up, data card inserted and accessible

Flashing Rapidly Powered up but unable to access data card

Off Not Powered

Off Momentarily Writing information to data card

Warning do not remove the data card while the ‘Power’ LED is off momentarily, this means

the 320 is writing information to the data card. Doing so may result in corruption of the file

system on the data card rendering the information stored unusable

3.2.2 Active

The active LED indicates if the EDAC 320 is actively processing incoming and outgoing messages.

On EDAC 320 is actively processing incoming/outgoing communications

Off EDAC 320 is idle

3.2.3 Status

The Status LED indicates the status of the EDAC 320’s connection to the cellular network

On The cellular and GPRS connection are active

Flashing Rapidly The cellular connection is active, but GPRS is inactive or currently connecting

Off No cellular or GPRS connection is available

See section 3.1.2 for more information on GPRS connections and its importance to the functionality of the EDAC

320.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

4. Hardware Installation

4.1 Power Supply

The EDAC 320 has a universal input power supply. The unit can accept AC or DC input power between 12 and

28 volts.

The EDAC 320’s idle current draw is quite low, however because of the nature of cellular radio communications,

peak current draw can be quite high, the average current draw also varies depending on the input voltage. Table

4.1 details the EDAC 320’s approximate current draw figures, when the unit is in different states.

All figures listed below are based on a supply voltage of +12VDC and an RSSI reading of 25 (very good signal).

These figures will vary depending on supply voltage and cellular signal strength.

State Approx current draw (mA)

Idle (no outputs active) 30-40 mA

Idle (all outputs active) 90-100 mA

Initialisation 60-100 mA

Sending 80-120 mA

Receiving 60-100 mA

Max 1000 mA

Table 4.1 EDAC 320 Current Draw

4.1.1 Power Supply Selection Jumper

The EDAC 320 has an internal power supply selection ‘jumper’ which designates which type of supply the 320 is

set up to run from, either AC or DC. It is very important that the power supply selection jumper is set correctly for

the type of supply that is to be used.

A jumper consists of a group of metal pins, protruding vertically from the circuit board, and a piece of plastic

coated metal that shorts one or more of these pins together, the position of the jumper on these pins designates

the type of power supply to be used.

Ensure the power supply selection Jumper is set correctly. Failure to do so may result in

undesired operation or irreversible damage to the product.

To set the power supply selection jumper the case end plate and the case lid must be removed from the product.

The diagram in Fig. 4.1.1a and 4.1.1b shows the location and configuration of the jumper.

Fig 4.1.1a Location of PSU Jumper

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig 4.1.1b Configuration of PSU Jumper

Position the jumper either in the DC position (closest to the power supply terminal block) or the AC position

(closest to the centre of the circuit board).

Extreme caution should be taken not to touch any of the internal components of the EDAC

320. Touching the components may cause a static discharge which could severely

damage the unit and void the warranty.

4.1.2 DC Power Input

The DC power supply input will accept voltage between 12 and 28V, and has reverse polarity protection up to

30VDC. The product is DC over current protected by an internal 1 Amp, self resetting fuse. The fuse will

disconnect the product if over current is detected, but will reset if voltage is removed and re-applied.

4.1.3 AC Power Input

The AC supply input will accept voltage between 12 and 28V.

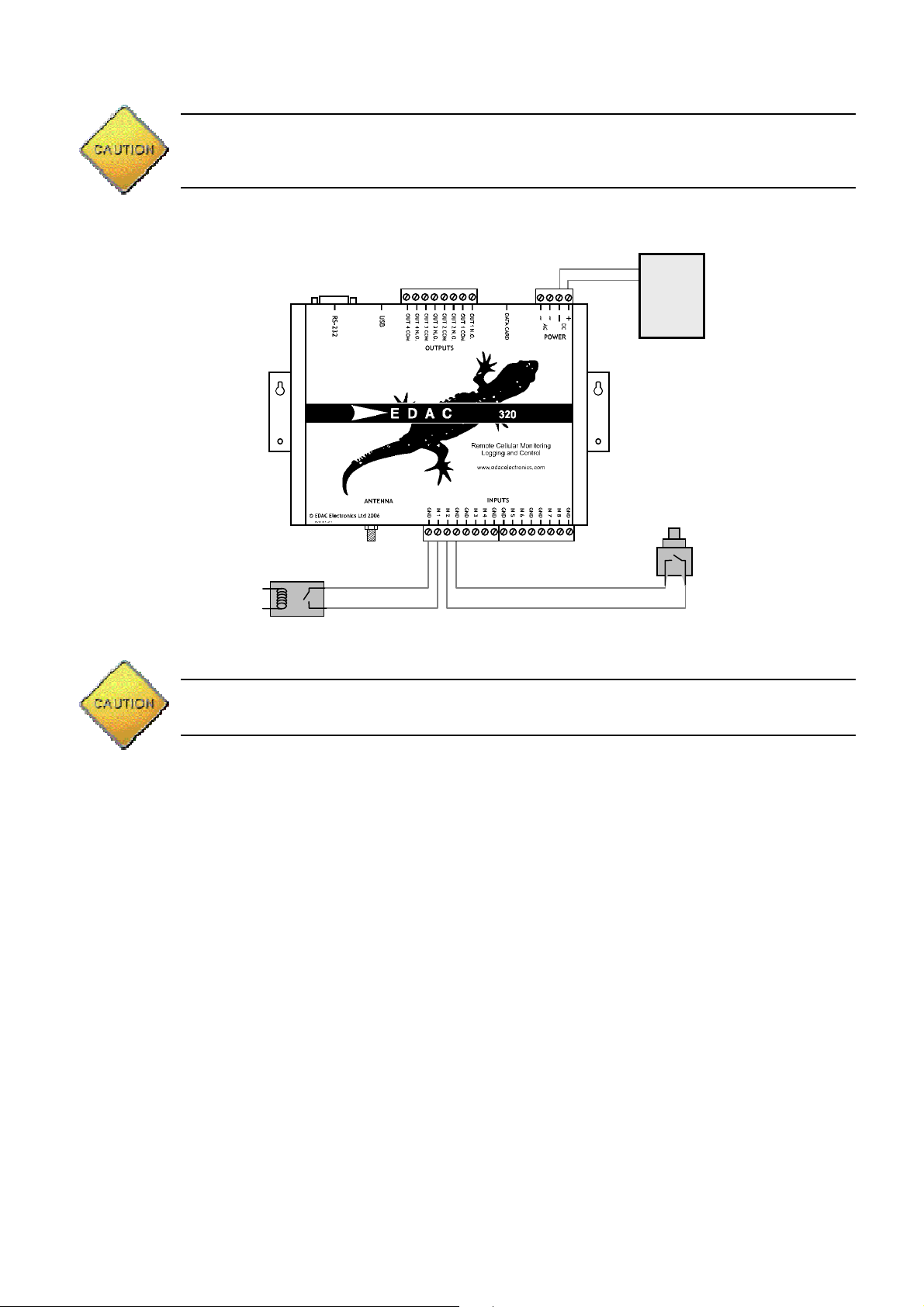

If an AC Power supply is used it MUST be fully isolated (floating). Use of a non-isolated AC

power supply may result in severe damage to the unit. If there is any doubt about the type

of AC power supply you intend to use, contact your supplier for more information.

It is required for warranty purposes that external fusing is fitted to the EDAC 320 when powered from AC

supplies. This prevents damage from ground loops and surges. Below Fig 4.1.3 details how the external fusing

should be connected.

Fig 4.1.3 Fitting external fuses to AC powered device

AC~ AC~

AC Power

Supply

Two 1A Fuses.

One connected

on each AC

supply input

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

4.2 Inputs

The EDAC 320 has eight fully configurable inputs, capable of accepting three different types of input signals,

Digital (N.O. or N.C.), 4-20mA analog and 0-5V analog. The following sections detail common configurations for

these types of inputs.

4.2.1 Jumper configuration

The unit has a series of ‘hardware jumpers’ which configure the internal sensing circuitry for the type of input

being used. The jumper for each input must be set correctly for the input to operate properly. A jumper consists

of a group of metal pins, protruding vertically from the circuit board; and a piece of plastic coated metal that

shorts one or more of these pins together.

By default all jumpers are set to ‘digital’. The following process need only be performed if

the setting needs to be changed from default, or to check the configuration of a particular

input.

To configure the jumpers first of all the case end plate and lid need to be removed. Remove the two input

terminal blocks from the unit, then the two screws securing the endplate as shown in Fig. 4.2.1a. Carefully move

the end plate aside.

Fig 4.2.1a Removing the input terminal blocks

The end plate will still be attached to the circuit board by the aerial cable, be careful not to

stress or break the aerial cable.

Slide the lid out from the extrusion and place to one side as shown in Fig 4.2.1b. The circuit board and

configuration jumpers should now be exposed.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig. 4.2.1b Removing the case lid

Extreme caution should be taken not to touch any of the internal components of the EDAC

320. Touching the components may cause a static discharge which could severely

damage the unit and void the warranty.

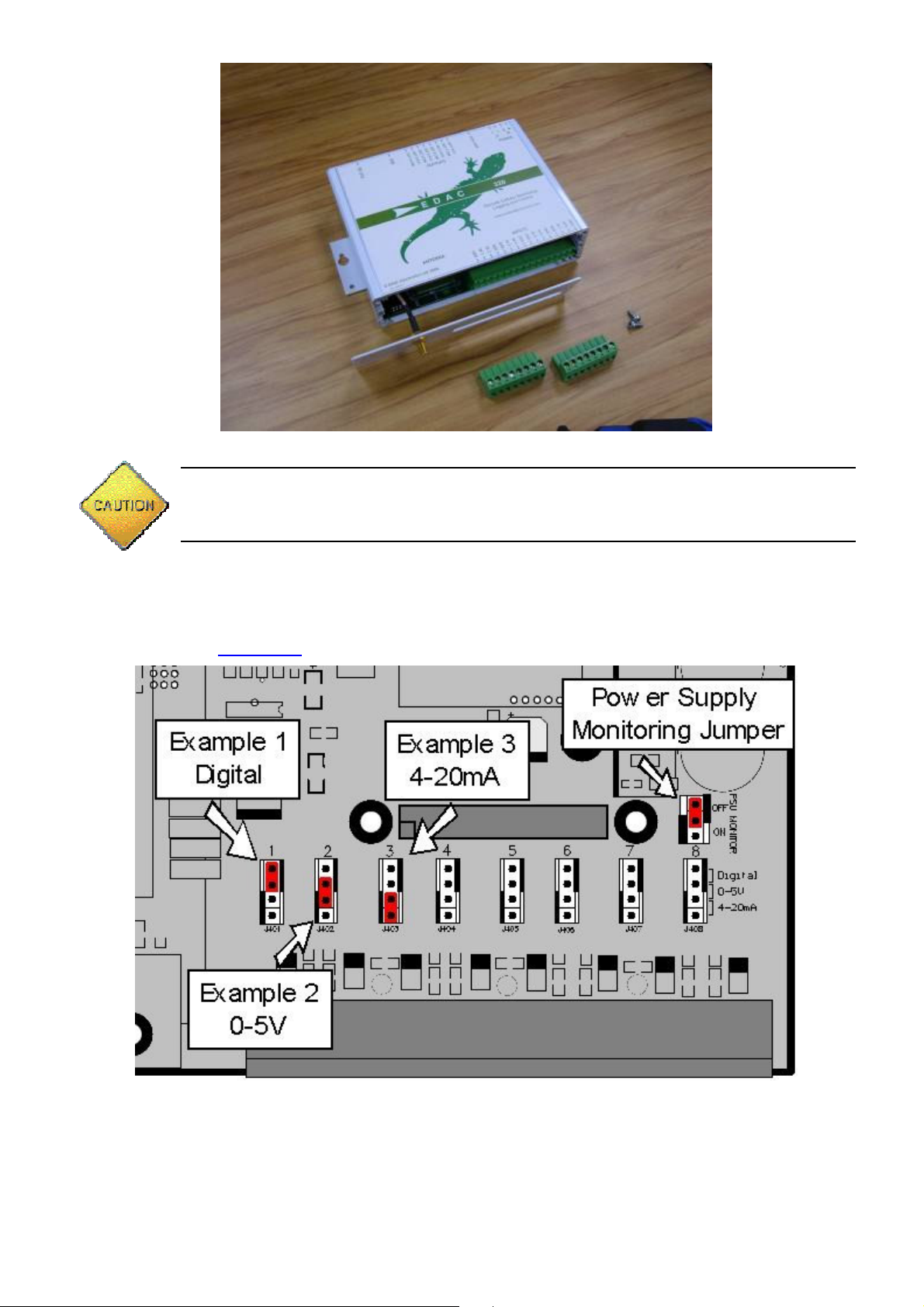

Fig 4.2.1c below details the jumper configuration setup. Note that there is one jumper for each input channel and

that there are three possible configurations: up for ‘Digital’, centre for ‘0-5V’ and down for ‘4-20mA’.

Also note that there is a ‘Power Supply Monitor’ jumper. Ensure this is set to ‘OFF’ if power supply monitoring is

not to be used. See section 10.4 for more information on Power Supply Monitoring.

Fig 4.2.1c Input Jumper Configuration

4.2.2 Digital Input Configuration

The EDAC 320 requires a ‘clean contact, voltage free’ digital input. Basically what this means is that the input

needs to be shorted to ground (for N.O.), or disconnected from ground (for N.C.) to indicate an alarm condition.

When configured as digital the input has an internal pull-up. This means that when the input is not connected to

anything (or floating) it sits at +5VDC. When the input is shorted to ground a small amount of current (around 10

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

micro amps) is allowed to flow, which pulls the input voltage down to 0VDC. The microprocessor in the EDAC

320 constantly monitors the voltage on the inputs checking if the input is shorted to ground or not.

No external voltage should be presented to the input terminals of the EDAC 320 when

configured as digital. If the device to be monitored has voltage driven digital or TTL

outputs, use a relay to interface them.

Normally the inputs are driven from a relay, microswitch, reed switch or contact output from another control

product (i.e. PLC or data logger). Fig 4.2.2 shows a typical wiring schematic.

Fig 4.2.2 Typical Digital Wiring

Note that if an AC power supply is being used the GND terminals on the input side must be

used for input signals, NOT the supply ground.

4.2.3 4-20mA Analog Input Configuration

Generally speaking there are two different types of 4-20mA sensors that are commonly used in industry. ‘Loop

powered’ and ‘Sensor powered’

Loop powered transmitters are often referred to as ‘parasitic powered’ sensors as the sensor transmitter draws

its power from the signal current loop. Fig. 4.2.3a shows a typical wiring diagram for a loop powered transmitter.

Micro-switch, reed-

switch or clean contact

interface

Voltage driven output

from external device

interfaced with relay.

-

+

Power

Supply

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig. 4.2.3a Typical 4-20mA Loop Wiring

Note that the power supply used should match the supply requirements of the loop powered transmitter. Loop

powered transmitters should generally only be used with D.C. power supplies. Also note that the ‘INP 1’ terminal

is internally connected to DC- which completes the loop circuit.

Sensor powered or four wire transmitters draw their power from an external power source. Fig. 4.2.3b shows a

typical wiring diagram.

Fig 4.2.3b Typical 4-20mA Sensor Wiring

Note again that the power supply used should match the requirements of the sensor transmitter. Also note that

the ‘IN’ terminals are internally connected to DC – which completes the loop circuit.

4.2.4 0-5V Analog Input Configuration

0-5V sensors are probably the least commonly used of the three types or sensors. This is due to the fact that

part of the signal voltage can be lost across long cable runs. A typical wiring schematic is shown in Fig 4.2.4.

-

+

Power

Supply

Loop

-

Loop +

GND

PWR

4-20mA Sensor Powered

Transmitter

Sensor or Transducer

(i.e. RTD Temp,

Pressure or Humidity

Sensor).

-

+

Power

Supply

-

+

Power

Supply

Loop

-

Loop

+

4-20mA Loop Powered

Transmitter

Sensor or Transducer

(i.e. RTD Temp,

Pressure or Humidity

Sensor).

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig 4.2.4 Typical 0-5V Wiring

Note that the power supply should match the requirements of the transmitter. One 0-5V transmitter can also

provide signal to multiple devices, such as PLCs or display units at the same time, this is the advantage of 0-5V

type sensors.

4.3 Outputs

The outputs on the EDAC 320 are of a relay type, meaning that they can switch small to medium voltages and

currents (Below 50V and 2A AC or DC). Where higher power is required the relays can be used to drive larger

relays.

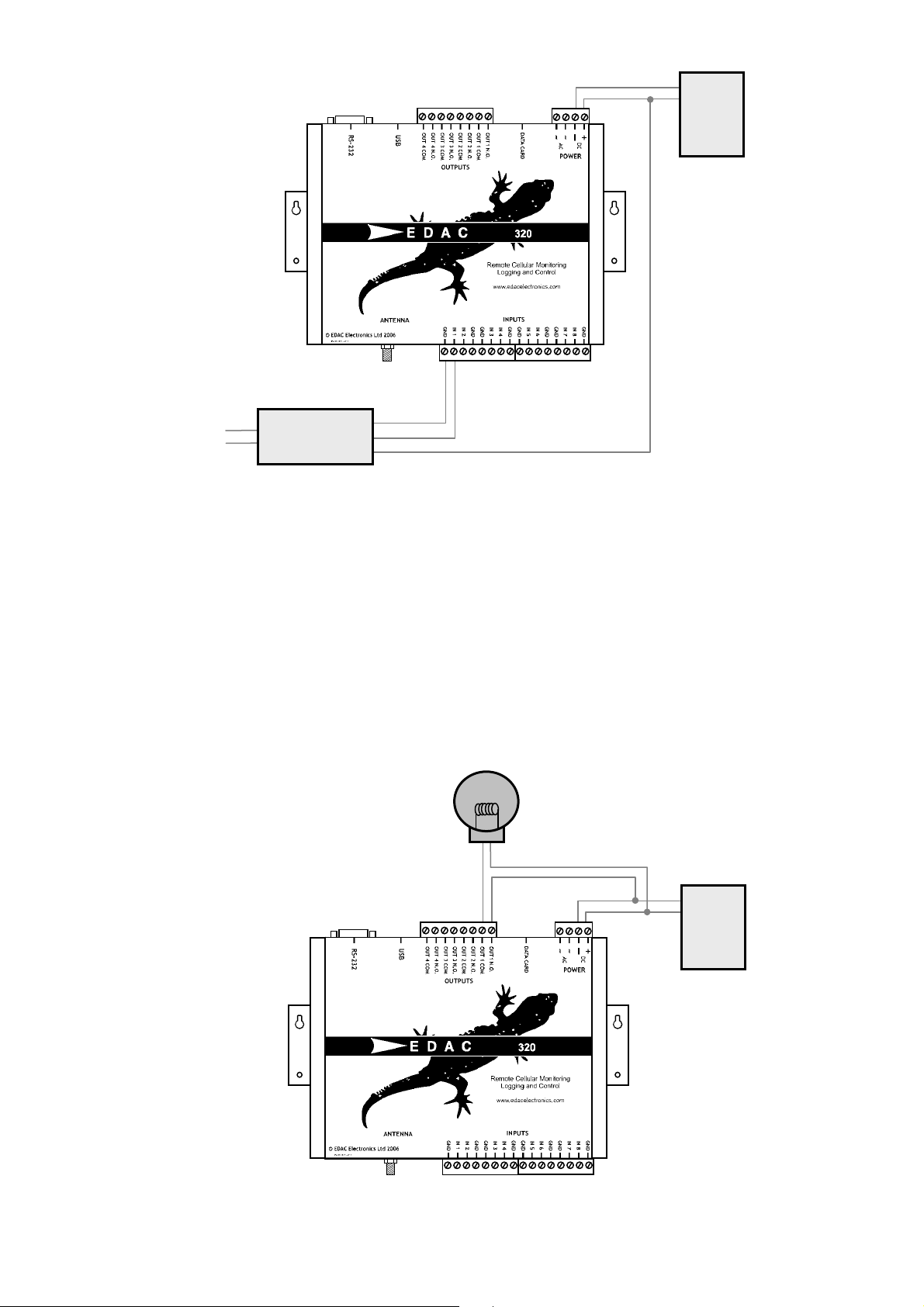

Below are typical wiring diagrams for both ‘Direct Load Switching’ (Fig. 4.3.1) and ‘Relay Switching’ (Fig. 4.3.2)

applications.

4.3.1 Direct Load Switching

Fig 4.3.1 Direct Load Switching

-

+

Power

Supply

GND

Signal

PWR

0-5V Sensor

Transmitter

Sensor or Transducer

(i.e. RTD Temp,

Pressure or Humidity

Sensor).

-

+

Power

Supply

Output Load. i.e. electric

motor, DC lighting, strobe

light or siren (below 50V

2A).

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Note that the load can be powered from the same power supply as the EDAC 320, however the supply will need

to match the voltage requirements of the load and will need to be able to supply enough current to power both

the EDAC 320 and the load. An additional external power supply can be used for the output load if required.

4.3.2 Relay Switching

Fig 4.3.2 Relay Switching

Note the use of an external power supply, also that the coil of the relay must be matched to the voltage of the

EDAC 320 power supply and the relay contacts must be matched to the voltage and current of the output load.

4.4 Aerial Installation

Aerial selection and installation needs to be carefully considered prior to commissioning. Selection and

positioning of the aerial can make the difference between a system that works perfectly and one that performs

poorly. The EDAC 320 has an SMA Female type aerial connector, allowing a wide variety of aerials to be fitted.

4.4.1 Aerial Selection

Not all aerials are created equal! Many different types of aerials are available on the market and each has its

own pro’s and con’s. EDAC generally recommends and supplies the ‘Pacific Aerials’ range of cellular aerials

because of their durability and performance at a budget price. Below the main type of aerials and the pro’s and

con’s of each are listed.

Stubby

The stubby aerial is a short ‘spike’ type aerial suitable for use in indoor installations in metropolitan

areas where good signal strength is available, or where mounting of an external aerial is not possible.

This aerial is mounted directly on the SMA connector of the unit. The stubby provides around 1-2dbi of

gain (depending on the type). A stubby aerial is not suitable where the unit is mounted inside a fully

enclosed metal or concrete structure.

1/2 Wave

Half wave aerials are a short screw base aerial that can be mounted on external horizontal or vertical

surfaces with the aid of a bracket. These aerial offer around 3-4dbi of gain, and are suited to

metropolitan areas or sites where good general cell coverage is available. Because of the high dome

shaped reception pattern of the ½ Wave it is quite well suited to hilly or obstructed areas also. The ½

Wave is an omni-directional aerial and will connect to the nearest available cell tower

Elevated Feed Colinear

The colinear is a larger screw base aerial at around 1m in height. The 1/4, 1/8, 1/4 element pattern

provides around 6.5dbi of gain. The elevated feed aids in clearing obstructions when mounting.

Because of the long flat reception pattern of the colinear it is suited to flat sites where the cell tower

AC~ AC~

Power Supply

-

+

Power

Supply

Relay

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

may be quite some distance away. The colinear is an omni-directional aerial and will connect to the

nearest available cell tower and can be mounted on horizontal or vertical surfaces with the aid of a

bracket

Yagi

The Yagi is a specialised aerial consisting of a number of receiving elements mounted on a horizontal

feed, much like a UHF TV aerial. The yagi can provide up to 22dbi of gain. The yagi is mounted on a

‘hockey stick’ pole affixed to an external structure. The Yagi provides excellent gain for the most

remote of sites HOWEVER it has an Achilles heel. The Yagi is a directional aerial, this has two major

implications. The first is that when the aerial is mounted, the location of the nearest cell tower needs to

be known and the aerial needs to be pointed directly at it for best performance. The second is that

because it is directional it can only communicate with the cell tower it is pointed at. If this cell tower is at

maximum capacity, or is non-operational when the device is trying to communicate, it is unable to roam

and find another available cell tower due to the directional nature of the aerial. The Yagi is best suited

to the most remote sites or where only one cell tower is within range and the signal strength is weak.

It is highly recommended that a site survey is undertaken by the installer before the aerial is selected

and installed. Using a test EDAC 320 and a selection of aerials and a laptop running ‘EDAC 320

Configuration Manager’ the installer can determine which type of aerial will give best performance. The

‘EDAC 320 Configuration Manager’ and its diagnostics interface can be used to obtain an ‘RSSI’

(Relative Signal Strength Indication) reading. This reading works on a scale of 0 to 31 (zero being no

signal, 31 being perfect). A minimum reading of 10 is recommended for reliable operation.

4.4.2 Mounting

Aerials need to be mounted in the highest possible position, clear of any obstructions, and preferably outside, on

the exterior of a structure. If any aerial is mounted inside a steel shed for example, performance will be severely

affected as the steel structure acts like a shield, blocking signal to and from the aerial. It is advisable to try the

aerial in several different positions, obtaining an RSSI reading from the unit each time.

4.4.3 Cable Length

Cable length can play a critical part in the performance of an aerial. Basically the coaxial cable that connects the

aerial to the device will ‘drop’ a portion of the signal that is transmitted. The longer the cable, the more signal will

be ‘dropped’. This is why keeping the cable as short as possible is important. RG58-AU coaxial will drop up to 35

percent of the signal across a 5 meter run at the common cellular frequencies. Generally we recommend using a

cable that is 5m or less in length. This of course is not always practical as many aerials come pre-fitted with a

length of cable. If there is spare cable left it is important to make sure this is not coiled or looped in any way, try

to avoid the cable crossing over itself or any high voltage or signal cables wherever possible. This will help

minimise cross-talk and interference and will maximise the performance of the aerial.

4.5 Other

4.5.1 RS232

The EDAC 320 has one RS-232 (serial) port which is used primarily for configuration of the unit using the ‘EDAC

320 Configuration Manager’ software (see section 6 for more information on using ‘320 Configuration Manager’.

The RS-232 port can also be used for remote communications to external devices such as PLCs, data loggers

and control panels (see section 10.1 for more information on using ‘Through Mode Data Connection).

The RS-232 interface is provided via a -standard DB9 connector and is fully configurable with speeds between

1200 and 19200 bps, 7 or 8 data bits, none, odd or even parity, and one or no stop bits. This allows flexibility in

the types of external devices the EDAC 320 can connect to (see section 10.5 for instructions on changing serial

port properties).

4.5.2 USB

One USB-B socket connector is provided as an alternative to the RS-232 port for programming the EDAC 320.

The EDAC 320 has an onboard USB to RS-232 conversion chipset, which when connected to a Windows based

PC via the USB port, emulates an RS-232 port on the PC This allows for communication between the ‘320

Configuration Manager’ software and the EDAC 320 on computers where no RS-232 port is available.

See section 5.3 for instructions on installing the USB drivers required to connect the EDAC 320 to a PC via a

USB port.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

5. Software Installation

The following section details the process to install the ‘EDAC 320 Configuration Manager’ and ‘EDAC 320

Remote Management’ software which is used to setup, configure and remotely manage the EDAC 320. Also

detailed is the process for correctly installing the EDAC 320 USB drivers.

For more information on using the ‘EDAC 320 Configuration Manager’ and ‘EDAC 320 Remote Management’

software see section 6 and section 7 respectively.

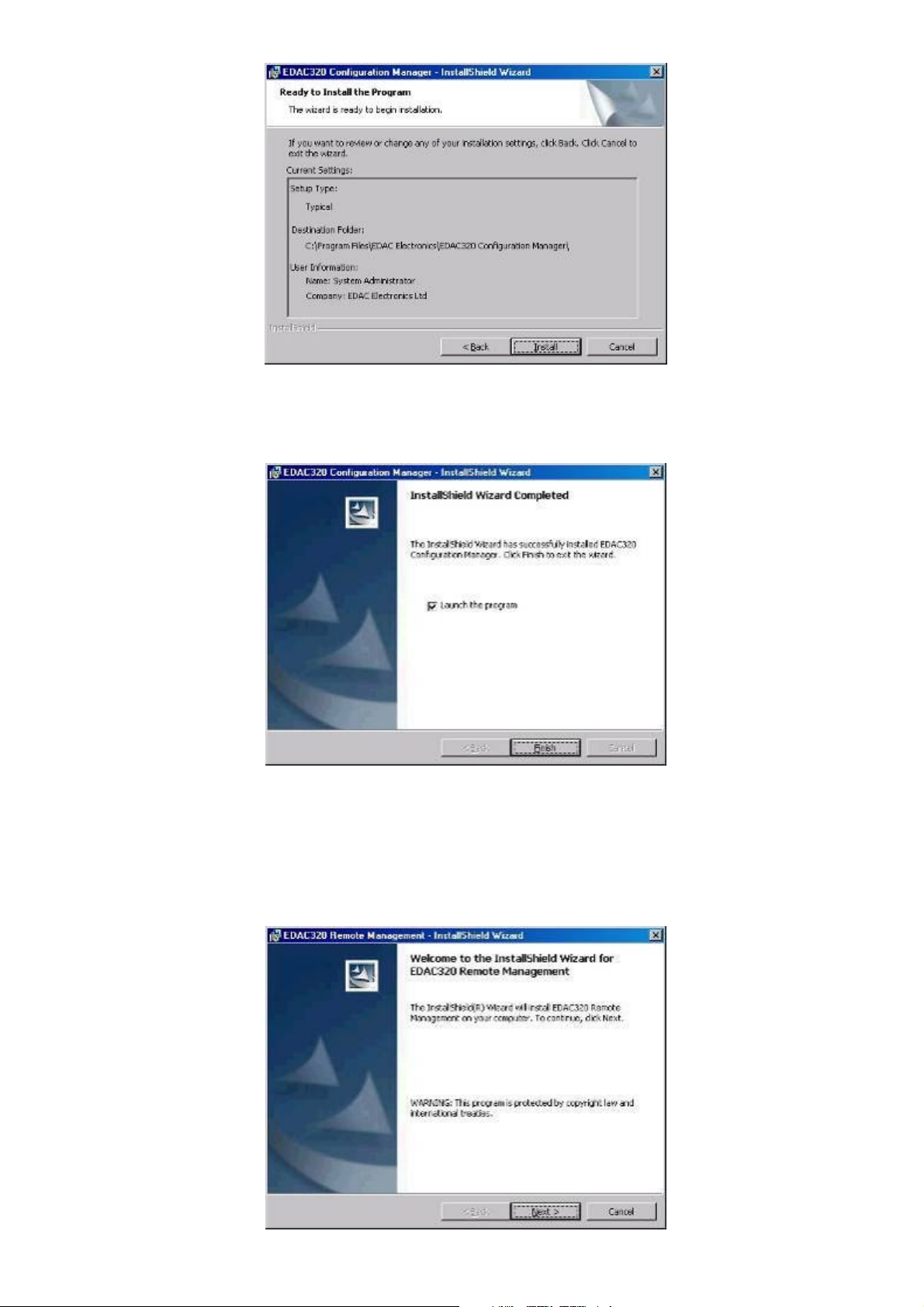

5.1 EDAC 320 Configuration Manager

To begin the installation process, execute the ‘EDAC320 Configuration Manager Installer.exe’ installation file

located in the ‘Configuration Manager’ folder on the CD-ROM supplied with the product. The window in Fig. 5.1a

should appear.

Fig 5.1a Software Installation - Starting

Click on the ‘Next’ button to proceed. The window shown below in Fig 5.1b will then appear.

Fig. 5.1 b Software Installation – Change Settings

On this window the destination directory for installation can be changed if desired. It is recommended that the

default setting is used. Click ‘Next’ to proceed. The window in Fig 5.1c will then appear.

www.edacelectronics.com

© 2005 EDAC Electronics Ltd

Fig 5.1c Software Installation – Check Settings

In this window the installation settings can be reviewed. Click ‘Back’ to go back and change any of these

settings. Click ‘Next’ to proceed and the software will be installed. The following window will appear when

installation is complete.

Fig. 5.1d Software Installation - Finish

Click on the ‘Finish’ button and the application will launch.

5.2 EDAC 320 Remote Management

To begin the installation process for the ‘EDAC 320 Remote Management’ software, execute the ‘EDAC 320

Remote Management Installer.exe’ file in the ‘Remote Management’ Folder, located on the CD-ROM supplied

with the product. The window shown in Fig 5.2a should appear.

Fig 5.2a Software Installation – Starting

Table of contents

Popular Control Unit manuals by other brands

National Instruments

National Instruments PXIe-5698 Getting started guide

Bosch

Bosch DCU 220 Repair instructions

Siemens

Siemens SINAMICS G130 operating instructions

EVERSPRING

EVERSPRING AC301 user manual

4EVAC

4EVAC SW6 Installation and user guide

Bull

Bull 1GB Intel Ethernet Switch Module Installation and user guide