Edaphic Scientific ESRAD-200 User manual

Remote CO2 Storage Safety DualAlarm

with Oxygen Monitor

Operating Instructions

Model:

ES

RAD-200

Table of Contents

1. Product Instructions

2. Package Content Check & Main Unit View

3. LCD Display Symbol

4. SEU (Sensor Unit) Function Instructions

5. RDU (Remote Display Unit) Function Instructions

6. Safety Notes

7. Caring For Product

8. Installation Instructions

9. Customizing Settings

10. CO2 & O2 & Temperature Specifications

11. Relay Outputs

12. Weight & Dimensions

13. Fault Codes & Troubleshooting Guide

13. Support & Warranty

1. Product Instructions

Thank you for selecting the ESRAD-200 CO2 and O2 Monitor. It is designed

to detectthepresenceofcarbondioxideandoxygenintheambientairto

protectpeople in confined spaces. High concentrations ofCO2 or low

concentrations ofoxygeninconfinedspacesaredangerous,andmayleadto

healthproblems ranging from headaches and fatigue to asphyxiation and

death.

The RAD-0200 is widely used to protect workers and employees in CO2

storage areas, breweries, wineries, cellars, beverage dispensing areas, and

fast foodoutlets. Ithas both audible and visual alarms which activate when

CO2 or O2 concentrations reach user-defined levels. Detection of high levels

ofCO2willalsoactivate2relaysthatcouldbeusedfora fanorair-conditioning

system to ventilate the confined space, and reduce CO2 concentration and

add O2 concentration in the area.

The ESRAD-200 CO2 & O2 Monitor is cost-effective and has many features:

1.Dual Beam NDIR (Non-Dispersive Infrared) technology is used to

measure CO2concentration up to 50,000ppm (parts per million) and

electrochemical technology to measure O2 concentration up to 30%.

2.With the SEU (Sensor Unit) and RDU (Remote Display Unit), it can

connect multiple RDUs for safety notices.

3.Large LCD display clearly indicates ambient CO2& O2 concentrations.

4.Relay outputs can control a fan to ventilate confined spaces.

5.Audible and visual alarm indications.

6.IP65 Water Proof Protection of SEU (Sensor Unit).

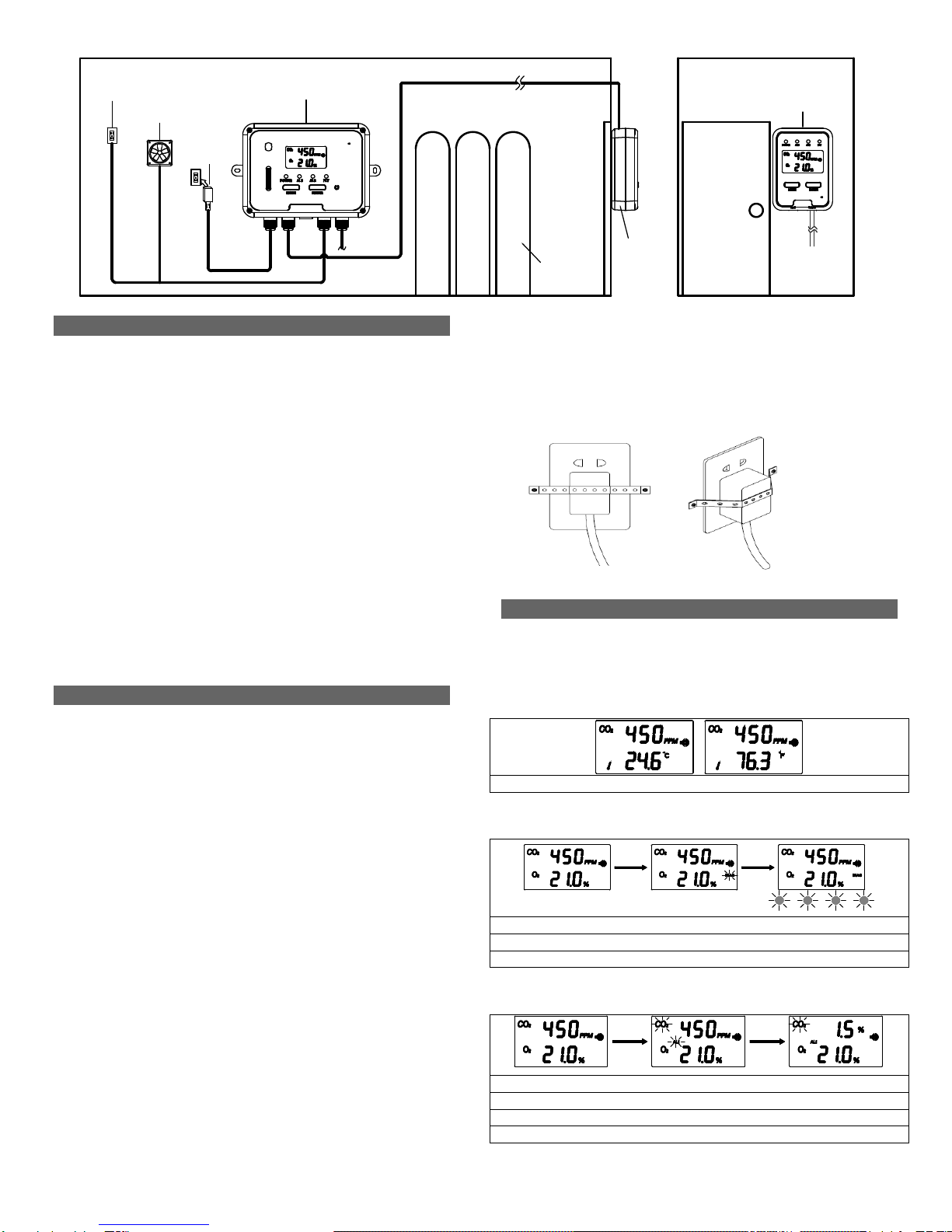

2. Package Content Check &Main Unit View

The ESRAD-200 package comprises the following parts:

Main Unit:

Accessories:

Plug lock 1 pcs Screw 10pcs Expansion

plug 10 pcs

Nail cable clip 10 pcs Warning signs 2 pcs

SEU (Sensor Unit)

RDU (Remote Display Unit)

A

B

C

D

E

F

G

H

I

JKLM

N

O

QRS

T

U

V

W

X

Y

P

SEU( Sensor Unit) RDU (Remote Display Unit) Panel holders

User manual 8 meters (26 feet) communication cable

A. LCD display I. Mode Button

B. Buzzer J. Relay 2 output

(red &

white: NO,

Blue & white: NC)

C. Green LED (Power indication) K. Relay 1 output

(red & white: NO,

Blue & white: NC)

D. Red 1 LED( AL1 ) L. Communication Cable to RDU

E. Red 2 LED( AL2 ) M. Power Supply

F. Yellow LED( Fault indication) N. CO2 entry

G. Reset Button O. O2 entry

H. Enter Button Z. Gas Calibration Port

P. Green LED (Power indication) U. Mode Button

Q. Red 1 LED (AL1 ) V. Enter Button

R. Red 2 LED ( AL2) W. Buzzer

S. Yellow LED ( Fault indication) X. RJ45 Plug for next RDU (Output)

T. LCD display

Y

. RJ45 Plug for SEU

(Input)

|

Z

NOTE: RemoveAir Intake Plug (N) before

powering SEU. Use Plug when cleaning SEU.

3. LCD Display Symbol

Symbol Meaning Description

CO2

Concentration ppm

(Parts Per Million) Ambient CO2 concentration

O2 Concentration Ambient O2 concentration

Alarm Alarm

icon

Diagnostics Test communications between

the SEU and RDU

CO2/O2 First

Alarm level

Relay1willbetriggeredwhenthe

CO2 concentration exceeds the

first alarm level or O2

concentration drops below the

first alarm level, the Red 1 LED

will flash, and buzzer will sound.

CO2/O2 Second

Alarm level

Relay 2 will be triggered when

CO2 concentration exceeds the

second alarm level or O2

concentration drops below the

second alarm level. The Red 1 &

Red 2 LEDs will flash, and the

buzzer will sound.

Calibration Calibrate the CO2 / O2 sensors

when the accuracy deviates from

the actual concentration.

Recover Factory

Setting Recover factory default settings

and cancel customized settings.

ESC Indicate the CO2 leakage once

the CO2 level is above the

second alarm level.

Hi The CO2 concentration is above

5%, or the O2 concentration is

lower than 30%.

Fan If CO2 > CO2Alarm Level or

O2<O2Alarm Level, fan will run.

4. SEU (Sensor Unit) Function Instructions

The SEU (Sensor Unit) should be placed in a room where the CO2 is likely to

accumulate or O2 reduced, such as a room where CO2 canisters or tanks are

stored. The large LCD displays the ambient CO2 & O2 concentration.

The SEU has the “DIAG”, “AL1”, “AL2”“CALI”, “ReFactSet” function. The

“DIAG” function executes communication tests between the SEU and RDU.

The user can do the calibration under the “CALI” mode when necessary. If

data-setting is done incorrectly, the user can use the “ReFactSet” back to the

original factory setting.

There are two alarm levels: “AL1” and “AL2”. Both alarm levels are

adjustable. The first alarm level of CO2 can be set to 5,000ppm, 1%, 1.5%,

2%. The default first alarm level is 1.5%. The first alarm level of O2 can be

set to 18%, 18.5%, 19%, 19.5% or 20%. The default first alarm level is

19%.The second alarm level of CO2 can be set to 1.5%, 2%, 2.5%, 3%,

3.5% or 4% CO2. The default second alarm level is 3%. The second alarm

level for O2 can be set to 16%, 16.5%, 17%, 17.5% or 18%. The default

second alarm level for O2 is 17%.

When the RAD-0200 CO2 &O2 Monitor detects CO2 concentration exceeds

the first alarm level or O2 concentration drops the first alarm level, the red 1

LED will blink and the buzzer will sound intermittently, and the relay will be

triggered. When CO2 concentration drops below the first alarm level, or O2

concentration raises to the first alarm level, the red 1 LED will stop blinking

and the buzzer will stop beeping.

If the concentration of CO2 continues to rise above the second alarm level,

or the concentration of O2 drops below the second alarm level, the red 1 and

red 2 LED’s will both flash together, the tempo of the buzzer will increase,

and the second relay will be triggered. When the CO2 concentration drops

below the first alarm level the red 1 and red 2 LED’s will stop blinking, and

the buzzer will stop beeping. However, the yellow FLT LED will stay on to

show an event has occurred until the RAD-0200 is restarted with the reset

button RAD-0200 or theAC adapter is unplugged and reconnected.

The green LED will light continuously when the power is normally supplied.

Warning: If the ambient CO2 concentration reaches the second alarm level

on SEU & RDU, there will be a safety notice “ESC” displayed on the LCD.

Careful action, such as ventilating the space, must be taken before entering

the room where the SEU is placed.

If the communication cable between the SEU& RDU isn’t connected properly,

thefaultLEDontheSEUwillblink.Tofix this,reconnectthecable. If the cable

is accidently inserted into the output port on the RDU, after one minute “Er7”

will flash on the LCD. Unplugging the cable and plugging it into the Input port

will normally correct the problem.

5. RDU (Remote Display Unit) Function Instructions

The RDU (Remote Display Unit) should be placed outside the CO2 storage

room during use. The RDU is connected to the SEU with a CAT5 cable.An 8

meter (26 ft.) cable is supplied, although up to 3 daisy-chained RDUs over 76

meters (250 ft.) using CAT5 cable has been tested. The RDU should be

placed where it can be conveniently observed before entering the room

where the SEU is located. The RDU is a repeater, and displays the

measurements made by the SEU on an easy-to-read digital LCD along with

important safety information.

The RDU has “DIAG” function. The “DIAG” can test the communication

between the SEU and RDU. Resetting the RAD-0200 CO2 and O2 Monitor is

only available from SEU.

6. Safety Notes

Warning: Your safety is very important to us. To ensure to use the product

correctly and safety, please read these warnings and the entire User Manual

beforeusingtheproduct. Otherwise,theprotection providedby the equipment

may be impaired. These warnings provide important safety information and

should be observed at all times.

1. Handle the device carefully; do not subject the product to impact or shock.

Otherwise, this may cause the accuracy to drift.

2. Do not place the unit or the adaptor near a heat source. Heat can cause

distortion of the unit, which may result in an explosion or fire.

3. Do not touch the exposed electronic circuitry of the device under

any circumstances, as there is danger of electric shocks.

4. Use only the included power adaptor. Improper power adaptors or power

sources can cause serious damage to the product, or result in injury or

death to the user.

5. Use the “DIAG” function to verify the communication between SEU and

RDU works normally.

6. Make sure that the power adaptor is secured tightly by a plug lock so the

power adapter cannot be disconnected accidently or by hand.

7. Do not enter into the room directly if there has safety notice “ESC”

displayed on the LCD of SEU & RDU. Careful and protective action must

be taken before entering the room where the SEU is installed.

8. Take care of cable connection between SEU and RDU. Make sure the

cable from SEU is connected into the INPUT port of RDU.

9. Ensure the external power supply to a ventilation fan is tested while the

relayisworking.If therehas no power tothe fan,therelay will not turn it on,

which may result in potentially dangerous high CO2 concentration or low

O2 concentration in a confined space.

Power

Adapter

Fan for

Ventilation

gas

tanks

SEU (Sensor unit)

RDU

Display

RDU

Display

Power Supply

for fan 8m(26ft) comm. cable

to the 2nd/3rd RDU

(optional,daisy chain)

Door

7. Caring For the Product

To receive the maximum benefit from using this product, please observe the

follow guidelines.

1. Repair - Do not attempt to repair the product or modify the circuitry by

yourself. Please contact your local dealer or a qualified repairman if the

product needs servicing, including the replacement or calibration of the

sensors.

2. Note -- The oxygen sensor must be replaced every 3 years.

3. Cleaning - Disconnect the power before cleaning. Clean with a damp cloth

only. Do not use liquid cleaning agents such as benzene, thinner or

aerosols, as these will damage the device.

4. Maintenance – We recommend testing the communication between the

SEU and RDU under the ‘DIAG” function to verify the SEU and RDU are

working properly. If the four LED’s blink and the buzzers sound

simultaneously, it indicates that SEU and RDU work normally.

When the LCD displays a safety icon “ESC”, please take immediate

protective action to check if a CO2 leak has occurred. We suggest a

calibration and thorough function check at least yearly to make sure that

the RAD-0200 CO2 and O2 Monitor is working properly.

8. Installation Instructions

Please carefully take out the SEU (Sensor Unit), RDU (Remote Display Unit),

panel holders, network cable connector, communication cable, user manual,

plug lock, screws, expansion plugs, nail cable clips, and warning poster from

the package.

Step-by-Step Installation:

1. Choose a suitable location to install the SEU. Fix a panel holder on the wall

with the four screws (included); the recommend installation height is about

0.45 meters (1.5 feet) from the floor and as close to the manifolds and

valves as possible.

2. Put the SEU on the panel holder. Remove the Air Entry Plug from the air

entry port (N). Save plug for use when cleaning SEU.

3. Fix another panel holder in a suitable location outside the monitored space

with screws (included). Push the RDU onto the panel holder, and stick the

warning poster next to RDU.

4. The communication cable is pre-wired to the SEU. Route the cable to the

RDU and fixed the communication cable to the wall by nail cable clips, and

then plug the cable into the input port on the RDU. Communication is now

ready between the SEU and RDU.

5. The RAD-0200 CO2 and O2 Monitor has two relay outputs: one is for AL1

and the other is for AL2. The relay cable is pre-wired to the SEU. Relays

can control a fan or blower to ventilate monitored space when necessary

andtherelaywillbetriggeredwhen theCO2concentrationexceedsthefirst

alarm level or O2 concentration drops below the first alarm level.

6. After finishing the installation, Connected the AC power adapter into the

electrical supply outlet. Mount the Plug lock by expansion plugs so that the

power adapter cannot be disconnected without use of tools.

7. When the power has been connected, The SEU and the RDU will begin to

work. Please use the “DIAG” function to verify the communication between

SEU and RDU, the four LED’s will blink and buzzer will sound on SEU &

RDU. Communication is ready when the information displayed is the same

on the SEU & RDU.

Mount the plug lock

9. Customizing Settings

Once power has been connected, the SEU and RDU will begin to monitor the

CO2&O2concentration.Inordertothegetthetimelyalarmsafetyinformation

or to meet personal requirements, you can customize the parameters as

necessary.

Temperature ºC/ºF:

Using the DIAG function:

1. Press Mode until the “DIAG” icon flashes

2. Press Enter, the four LED’s will blink on the SEU and the buzzer will sound

3. The four LED’s will blink and buzzer will sound simultaneously on the RDU

Setting the CO2 First Alarm parameter:

1. Press Mode until the “

A

L1”

icon flashes

2. Press Enter. The “

A

L1”

icon will show on the LCD

3. Press

Mode to go through

5,000ppm, 1%, 1.5%, 2%

CO2

alarm levels

4. Press Enter again to

save the setting

PRESS

MODE

PRESS

ENTER

PRESS

MODE

PRESS

ENTER

1. Press “Enter” to switch between ºC and ºF temperature.

Setting the CO2 Second Alarm parameter:

1. Press Mode until the “

A

L2” icon flashes

2. Press Enter. The “

A

L2” icon will show on the LCD

3. Press Mode to go through 1.5%, 2%, 2.5%, 3%, 3.5%, 4% CO2 alarm levels

4. Press Enter again to save the setting

Note: The second alarm level must always be higher than the first alarm level

when customizing the alarm level parameters.

Setting the O2 First Alarm parameter:

1. Press Mode until the “

A

L1” icon flashes

2. Press Enter. The “

A

L1” icon will show on the LCD

3. Press Mode to go through 18%, 18.5%, 19%, 19.5%, 20% O2 alarm levels

4. Press Enter again to save the setting

Setting the O2 Second Alarm parameter:

1. Press Mode until the “

A

L2” icon flashes

2. Press Enter, the “

A

L2” icon shows on LCD

3. Press Mode to go through 16%, 16.5%, 17%, 17.5%, 18% O2 alarm levels

4. Press Enter again to save the setting after selection

Note: The second alarm level for CO2 must be HIGHER than the first alarm level.

The second alarm level for O2 must be LOWER than the first alarm level.

Otherwise, the alarms will not function as expected.

Using the CO2 CALI function:

“ZEro” Calibration means theSEU is saturated in nitrogen (0% CO2) gas.

“SPAn” Calibration means the SEU is saturated in 40,00ppm (4%) CO2.

1. Press Mode until the CO2 and “CALI” icon flashes.

2. Press Enter. The “CO2”, “CALI” and “ZEro” icons will show on the LCD.

Press and hold Mode for at least 10 seconds, The “CALIBRATING” and “ZEro”

icons will flash simultaneously. The calibration will be done automatically.After

about 3 minutes the LCD will display “Pass” or “Fail”. If “Fail”, please try again.

3. Press Enter until the “CO2”, “CALI” and “SPAn” icons will show on the LCD.

Press and hold Mode for at least 10 seconds. The “CALIBRATING” and “SPAn”

icon will flash simultaneously and the calibration will be done automatically. After

about 3 minutes the LCD will display “Pass” or “Fail”. If your unit fails calibration,

please try again before calling support.

Note: Before starting either a “ZEro” or ”SPAn” calibration, wait at least 5 minutes

for the CO2 level inside the SEU to stabilize. For calibration, gas cylinders

connected to calibration port Z should be used.

Using the O2 CALI function:

“ZEr” Calibration means the SEU is saturated in nitrogen gas.

“SPA” Calibration means the SEU is saturated in 21% Oxygen (outdoor air).

The O2 CALI function is as same as CO2, except that the “O2” icon flashes to

signify calibration of the oxygen sensor.

Note: Before doing either a “ZEr” or ” SPA” calibration, wait at least 5 minutes for

the O2 level inside the SEU to stabilize. For Zero calibrations, a calibration bag

connected to a nitrogen gas cylinder is typically used

Using the ReFactSet function:

1. Press Mode until the “ReFactSet” icon flashes.

2. Press Enter, and then press Mode to choose either “Yes” or “No”.

3. Press Enter again to save the setting.

Note: If the user sets the data or calibrates the sensor incorrectly, use the

ReFactSet (recover the factory Setting) to come back the default factory

setting.

10 .Specifications

CO2 & O2 & Temperature specifications:

CO2 & O2 Specification

Measurement Range CO2: 0 - 50,000ppm (5%) display

O2: 0- 30% display

Display Resolution CO2: 10ppm at 0~10,000ppm;

100ppm at 10,001~50,000ppm

O2: 0.1%

Accuracy CO2: ±100ppm or ±5% of reading, whichever is

greater

O2: Better than ± 3% of FS over 0.1 to 30%

Repeatability CO2:±20ppm @400ppm

O2: Less than ±1.0%

Temperature

Dependence ±0.2% of reading per °C or ±2ppm

per °C, whichever

is greater, referenced to 25°C

Pressure

Dependence 0.13% of reading per mm Hg

Response Time CO2: <60 seconds for 90% response to step change

O2: <30 seconds for 90% response to step change

AL1 (FirstAlarm

Level) CO2: 5000ppm, 1 / 1.5 / 2 % , DefaultAL1= 1.5%

O2:18%,18.5%,19%,19.5%,20%, Default AL1=19%

AL2 (SecondAlarm

Level) CO2: 1.5 / 2 / 2.5/ 3 / 3.5 / 4 % , Default AL2= 3%

O2: 16%,16.5%,17%,17.5%,18%, DefaultAL2=17%

SoundAlarm 80db@10cm

Warm-UpTime <60secondsat22°C

Temperature Specifications:

Temperature Range 0°C to 50°C (32°F to 122°F)

Display Resolution 0.1°C (0.1°F)

Display Options °C/°F

Accuracy ±1°C(±2°F) when CO2 concentration is below first

alarm level

Response Time 20-30 minutes (case must equalize with environment)

PRESS

MODE

PRESS

ENTER

PRESS

MODE

PRESS

ENTER

PRESS

MODE

PRESS

ENTER

PRESS

MODE

PRESS

ENTER

PRESS

ENTER

PRESS

MODE 10s

PRESS

MODE

PRESS

ENTER

PRESS

ENTER

PRESS

MODE 10s

PRESS

MODE

PRESS

ENTER

PRESS

MODE

Operating Conditions:

Operating

Temperature 0°C to 40°C ( 32°F to 104°F)

Humidity Range 0 ~ 95% RH non-condensing

Storage Conditions:

Storage Temperature -20°C to 60 °C (-4°F to 140°F)

Power Supply & Relay Output:

Power Supply AC adapter 110/220 VAC

AC Input

Voltage 100 ~ 240 VAC

Frequency 50 / 60 Hz

Power

Requirement 1 W maximum @ 115 VAC 60 Hz

2 W maximum @ 230 VAC 50 Hz

AC/DC

Output Voltage 6VDC

Power 3.0 W

Peak Input Current 0.5Afrom 6 VDC

Relay Output Two Relay output: Relay 1 operates at alarm 1 for

CO2 or O2, Relay 2 operates at alarm 2 for CO2 or

O2. Peak Current< 2A@30 VDC or 250 VAC,SPDT.

11. Relay outputs

There are two relay output for this item. Relay 1 operates at alarm 1 for CO2

or O2, Relay 2 operates at alarm 2 for CO2 or O2. The relay 1 will be

triggered when CO2 concentration exceeds the first alarm level or O2

concentration drops the first alarm level. The relay 2 will be triggered when

CO2 concentration exceeds the second alarm level or O2 concentration

drops below the second alarm level.

12. Weight & Dimensions

Weight: SEU (Sensor Unit):1200 g (include cables)

RDU (Remote Display Unit): 120 g

Dimensions:

SEU (Sensor Unit)

RDU (Remote Display Unit)

13. Fault Codes &Troubleshooting Guide

This section includes a list of FrequentlyAsked Questions for problems you may

encounter with the RAD-0200 CO2 &O2 Monitor.

No

LCD

Fault

Icon

Description

(of the fault) SEU

Indication RDU

Indication

SuggestedActions

1 Er3

The ambient

temperature has

exceeded the

temperature

range 0°C to

50°C ( 32°F to

122°F)

“Er3” flash Fault

LED blink,

Buzzer beep

“Er3” flash

Fault LED

blink,

Buzzer

beep

This error will disappear

when the temperature

returns to the range

between 0°C and 50°C

( 32°F to 122°F)

2 Er4

some wrong

measurement or

the sensor has

exceeded its

expected life

“Er4” flash

Fault LED blink,

Buzzer beep

“Er7” flash

Fault LED

blink,

Buzzer

beep

Please unplug theAC

adapter and reconnect it. If

the “Er4” always appears,

please contact with the local

dealer.

3 Er5

Er6 EEPROM System

Problem

“Er5” & “Er6”

flash, Fault LED

blink, Buzzer

beep

“Er7” flash

Fault LED

blink,

Buzzer

beep

Please unplug theAC

adapter and reconnect it. If

the “Er5, Er6” always

appear, please contact with

the local dealer.

4 Er7

Internal Data

Transmission

Error

“Er7” flash,

Fault LED blink,

Buzzer beep

“Er7” flash,

Fault LED

Blink,

Buzzer

beep

①Please unplug theAC

adapter and reconnected

it.

②Check the RJ45 plug is

connected into the INPUT

port of RDU,if the “Er7”

displays on the RDU only.

5 Er8

The accuracy of

CO2& O2 sensor

may deviate from

the actual

concentration.

“Er8” flash Fault

LED blink,

Buzzer beep

“Er8” flash

Fault LED

blink,

Buzzer

beep

①Please unplug theAC

adapter and reconnect it If

the “Er8” still appears,

please contact with the

local dealer.

②Please calibrate the unit,

after the calibration, If the

“Er8” still appears, please

contact with the local

dealer.

14. Support & Warranty

Support

The quickest way toobtain technical support is via email. Please send all

clear, concise definition of the problem and any relevant troubleshooting

information or steps taken so far, sowe can duplicate the problem and

quickly respond to your inquiry.

Warranty

This unit comes with a 1YEAR (warranty period) limited manufacturer’s

warranty, starting from the date the unit was shipped to the buyer. During

this period of time, Edaphic Scientific warrants our products to be free from

defects in materials and workmanship when used for their intended purpose

and agrees to fix or replace (at our discretion) any part or product that fails

under normal use.

Totake advantage of this warranty, the product must be returned toEdaphic

Scientific at your expense. If, after examination, we determine the product is

defective, we will repair or replace it at no additional cost to you.

mm[inch]

mm[inch]

Liability

All liabilities under this agreement shall be limited tothe actual cost ofthe

product paid to Edaphic Scientific. In noevent shall Edaphic Scientific be

liable for any incidental or consequential damages, lost profits, loss of time,

lost sales or loss or damage to data, injury to person or personal property or

any other indirect damages as the result of use of our products.

Contact us: We’re here to help!

If the troubleshooting guide above doesn’t help you solving your problem or

for more information, please contact us using the information below.

www.edaphic.com.au

This warranty does not cover any products that have been subjected to

misuse, neglect, accident, modifications or repairs by you or by a third party.

No employee or reseller of Edaphic Scientific’s products may alter this

warranty verbally or in writing.

Returns

If the product fails under normal use during the warranty period, an RMA

(Return MaterialAuthorization) number must be obtained from

Edaphic Scientific.After the item is received, Edaphic Scientific will repair or

replace the item at our discretion.

Toobtain an RMAnumber, please call Edaphic Scientific at (61-2) 6584

5768. When requesting an RMAnumber, please provide the reason for

return and original order number.

If we determine that the product failed due to improper use (water damage,

dropping, tampering, electrical damage etc.) or abuse, or if it is beyond the

warranty period, we will inform you of the cost to fix or replace your device.

If you are returning your device due to a warranty claim (with an RMA

number) and you still have the unit original package, please use it to ship

your unit to us. Please makesure to include the provided RMAnumber on

the outside ofthe box, preferably onthe shipping label. Makesure you

secure the unit inside the package properly toprevent any damage during

transit that could void your device’s warranty.Finally, please ship your

device to the address shown under the “Contact Us”section below. Edaphic

Scientific will not, under any circumstances, be responsible for your shipment

expenses and no refund willbeissued for shipping charges necessary for

you to ship the unit to us.

Appendix A

CO2 level maximum standards inthe US and worldwide.

For workplaces that fall under OSHA guidelines, you should monitor the display to assure that the CO2 level over an 8-hour day does is not over the 5,000ppm TWA

exposure limit.

Note the 30,000ppm STEL exposure limit is the 2nd alarm level by default (3% CO2). This level can be lowered in the settings, but for worker and first-responder

safety should never be raised.

Ref. No.:012013

Appendix B

To conform with the National Boiler Inspection Code (NBIC) CO2 safety standards, 2 warning signs must be posted. You can download

them here for printing:

http://co2meters.com/Documentation/Other/NBIC-CO2-Warning-Sign.pdf

Appendix C

Wiring Diagram for Alarm 1 to control 120VAC, 10A exhaust fan.

Standards for Oxygen in the Workplace

OSHA does not have a permissible exposure limit (PEL) for oxygen.

Oxygen less than 19.5% OSHA regulations define an oxygen-deficient atmosphere as one

with an oxygen concentration less than 19.5%.

Oxygen less than 18% Progressive onset of fatigue and other symptoms, Effects

accelerate with exertion. O2 levels insufficient to sustain life

indefinitely.

Oxygen less than 15% Loss of reason, judgment, coordination. Dimming vision, nausea,

vomiting, gasping for breath.

Oxygen less than 12% Immediate unconsciousness.Asphyxiation within minutes.

Progressive brain damage leading to death unless rescued.

Table of contents

Popular Security System manuals by other brands

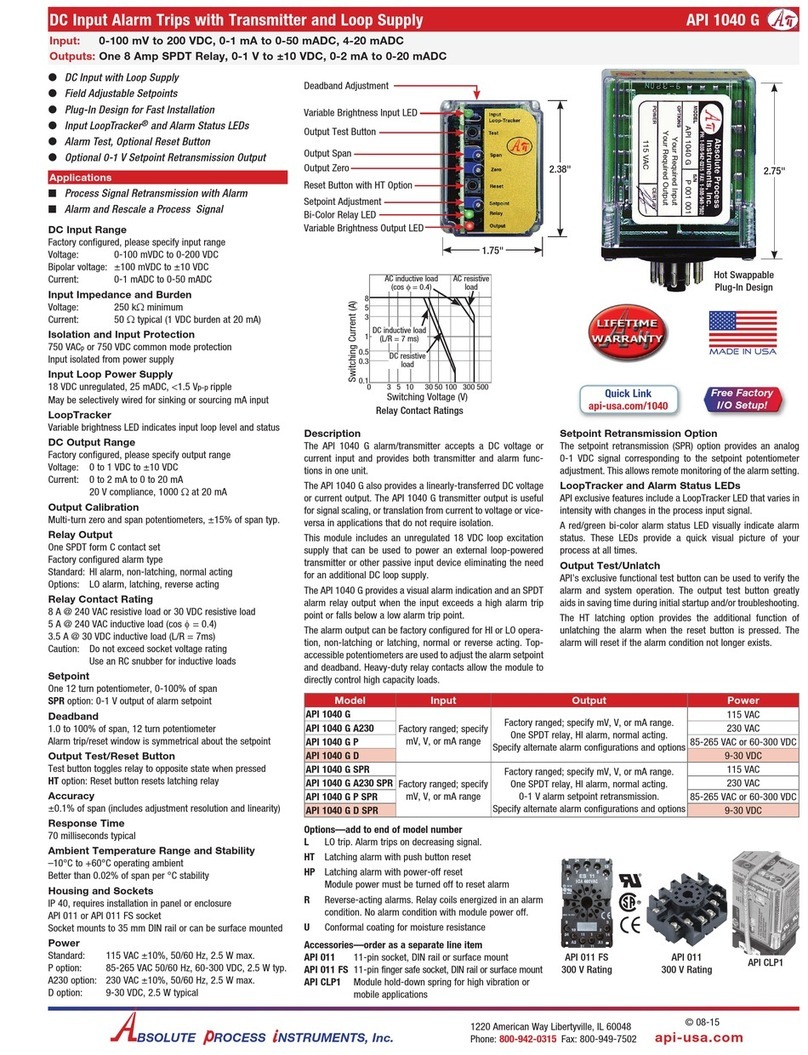

Absolute Process Instruments

Absolute Process Instruments API 1040 G Series quick start guide

Siemens

Siemens SIMATRIX NEO 2GF2211-8EA Quick start manual

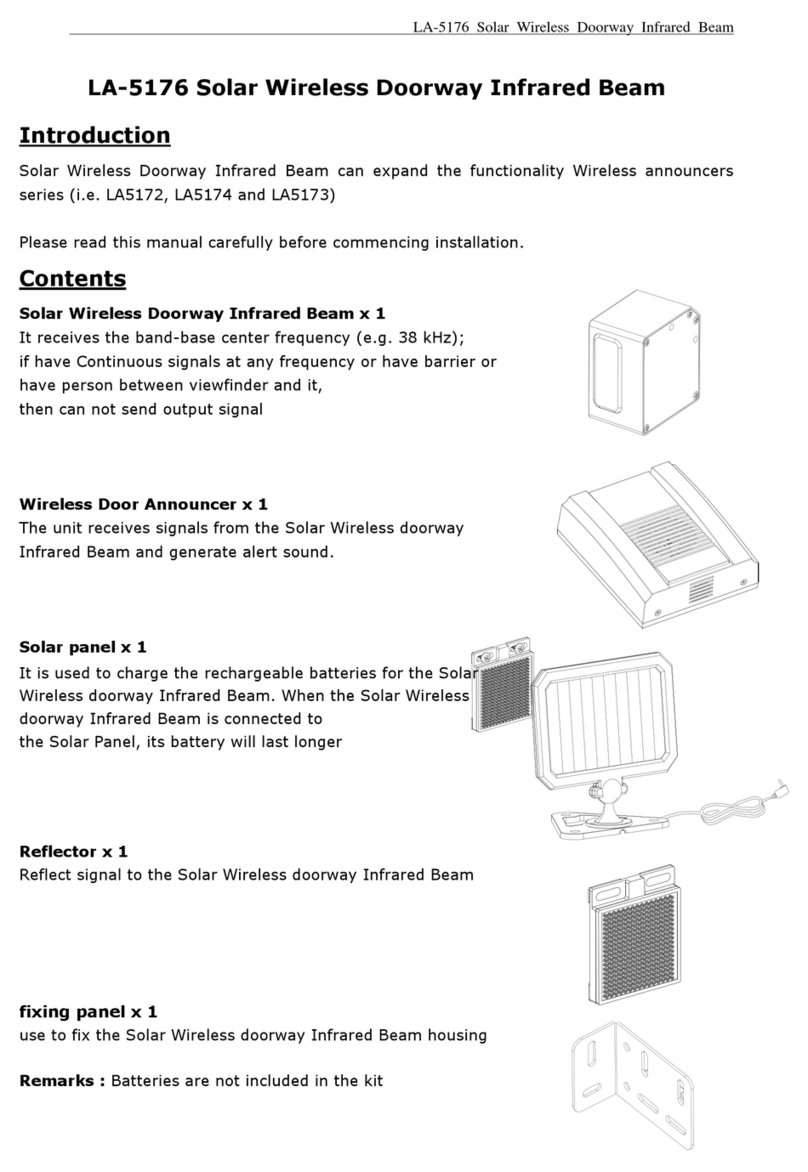

Jaycar

Jaycar LA-5176 manual

Gigaset

Gigaset Elements Alarm System M Easy installation

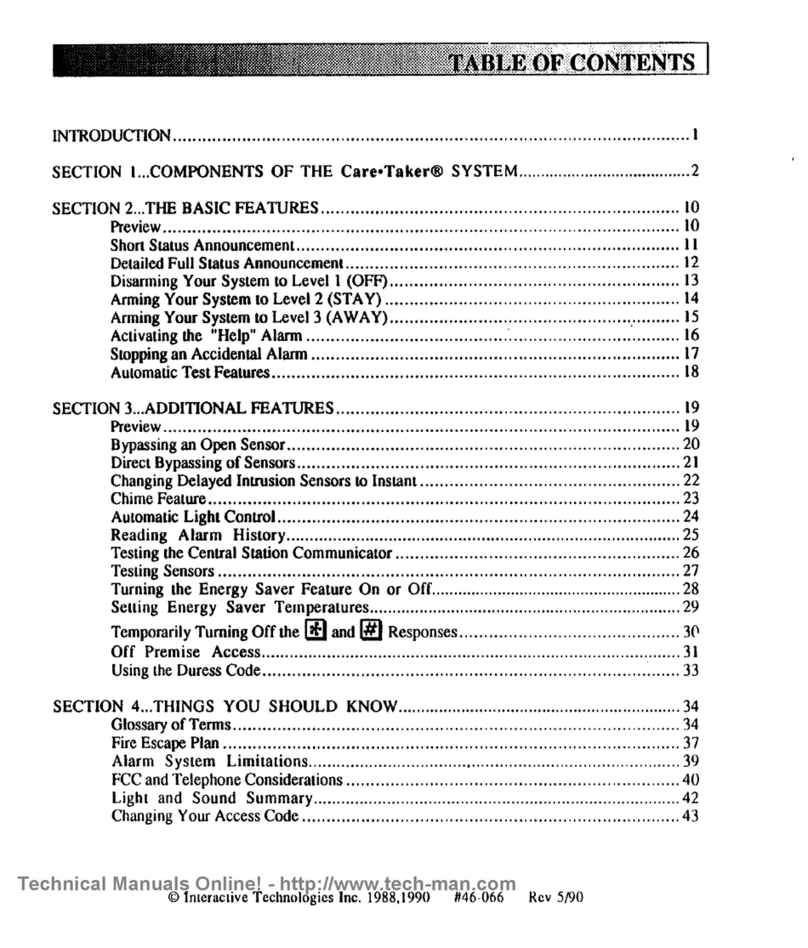

CareTaker

CareTaker Security System owner's manual

ProCurve

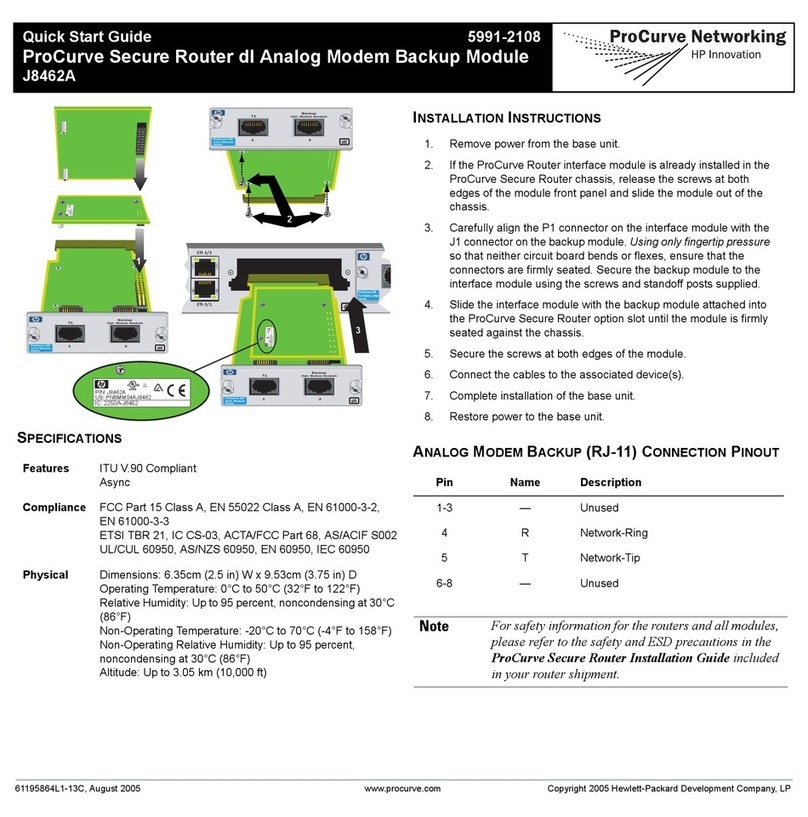

ProCurve J8462A quick start guide

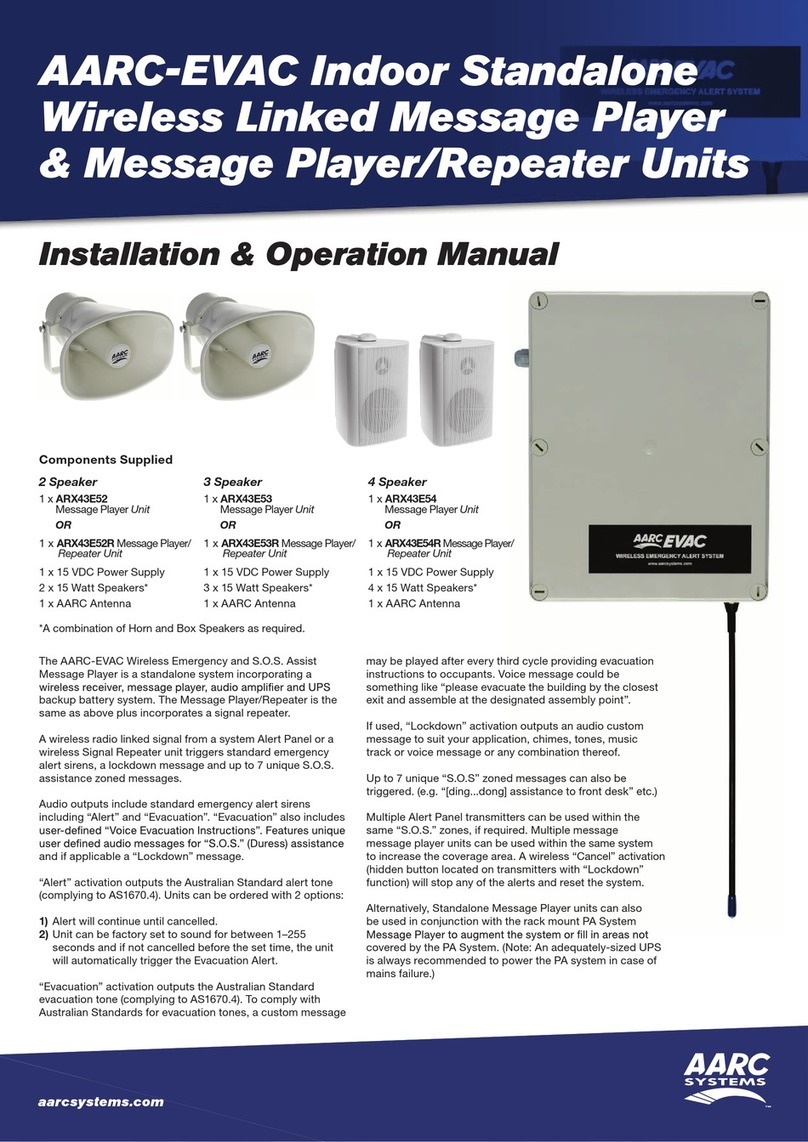

AARC Systems

AARC Systems EVAC ARX43E52 Installation & operation manual

ADEMCO

ADEMCO VISTA XM Series Technical reference manual

Siemens

Siemens FDAI91 Installation

Politec

Politec ALES Series installation manual

Alderon Industries

Alderon Industries Versa'larm 8124 Operation, maintenance and installation manual

TrackNet

TrackNet Tabs Push Button Get started