RJE ULB-350 Series User manual

03-TM-0046 Page 1 of 13

TECHNICAL MANUAL

ULB-350 SERIES

UNDERWATER ACOUSTIC BEACON

August 1, 2002

REV 00

RJE International, Inc.

15375 Barranca Pkwy, Suite B107,

Irvine, California 92618

Tel: (949) 727-9399 Fax: (949) 727-0070

DOCUMENT NO. 03-TM-0046

RJE International, Inc.

Irvine, California

03-TM-0046 Page 2 of 13

This manual should be read in its entirety

prior to using the ULB-350 Series

03-TM-0046 Page 3 of 13

SECTION I

INTRODUCTION

1.1. GENERAL. This manual contains the description, operation,

theory and maintenance procedures for the Underwater Acoustic

Beacon Model ULB-350 Series, hereafter referred in this manual as the

Model ULB-350.

1.1.1. The ULB-350 is a water switch activated underwater locating

device designed for use in marking applications. Housed in a water

tight case, the ULB-350 consists of an electronic module, transducer

and a self contained battery. The ULB-350 operates at depths down

to 4,000 feet (1216 m).

1.1.2. The ULB-350 will operate for a minimum of 20 days under

normal conditions.

FIGURE 1. ULB-350 UNDERWATER ACOUSTIC

BEACON

03-TM-0046 Page 4 of 13

TABLE 1. ULB-350 ACOUSTIC BEACON

SPECIFICATIONS

Operating Frequency ..................... 27 or 37kHz ± 1kHz

Operating ........................................ Depth Surface to 4,000 feet

(1216 meters)

Pulse Length .................................. 10 milliseconds ± 10%

Pulse Repetition Rate .................... Not less than 0.9 Pulses/Sec

Operating Life ................................. 20 Days (minimum)

Acoustic Output .............................. 163 db at 1 meter

Operating Temperature Range ....... +28°F to +100°F (-2°C to

+38°C)

Actuation ......................................... Fresh or salt water

Size ................................................. 1.70 inches (4.30 cm) diameter

x 3.1 inches (7.90 cm) long

Weight, Beacon ............................... 7.0 ounces (217 grams)

Storage Temperature ...................... -65°F (-54°C) to 160°F (71°C)

03-TM-0046 Page 5 of 13

SECTION II

BEACON MAINTENANCE

2.1. BEACON TESTING. The beacon should be tested prior to

each use.

2.1.1. Using the 42A12 Series Ultrasonic Test Sets, test the bea-

con in the following manner:

2.1.2. Turn the GAIN control to a fully clockwise position. A

pronounced background noise should be present. Lack of noise

may indicate a dead battery. Should this occur, replace battery in

the test set before resuming operational testing.

2.1.3. Set the TUNING control to approximately midscale. Rub-

bing fingers in front of microphone should produce a rushing noise

from the speaker.

2.1.4. Set the GAIN control at a comfortable listening level.

2.1.5. Point the microphone of the Test Set towards the water

switch end of the beacon for best results. If the beacon is mounted,

position the Test Set for maximum unobstructed signal. Beacon

operation will be indicated by an audible pulsing tone.

03-TM-0046 Page 6 of 13

SECTION II

MAINTENANCE

2.2. GENERAL. This section describes beacon cleaning, disassem-

bly, O-ring replacement, battery replacement and battery testing.

2.3. BEACON CLEANING. Clean the switch end of the beacon

with mild detergent then dry thoroughly with a clean cloth.

2.4. BEACON DISASSEMBLY. Disassembly of the beacon is

limited to battery replacement, as outlined in Section 2.5.

2.5. BATTERY REPLACEMENT AND TESTING.

2.5.1. GENERAL. Perform an operational test (Section 2.1.) to

determine if beacon is operational. If not, insert a new battery and run

the test again (Section 2.1.) Battery replacement should be done in a

maintenance shop under clean conditions to prevent dust from contami-

nating O-ring and lubricant. Because the old O-ring may have devel-

oped a set with age, a replacement is recommended at the time of

battery change. O-ring lubrication should be applied to the new O-ring

and threads before installation.

03-TM-0046 Page 7 of 13

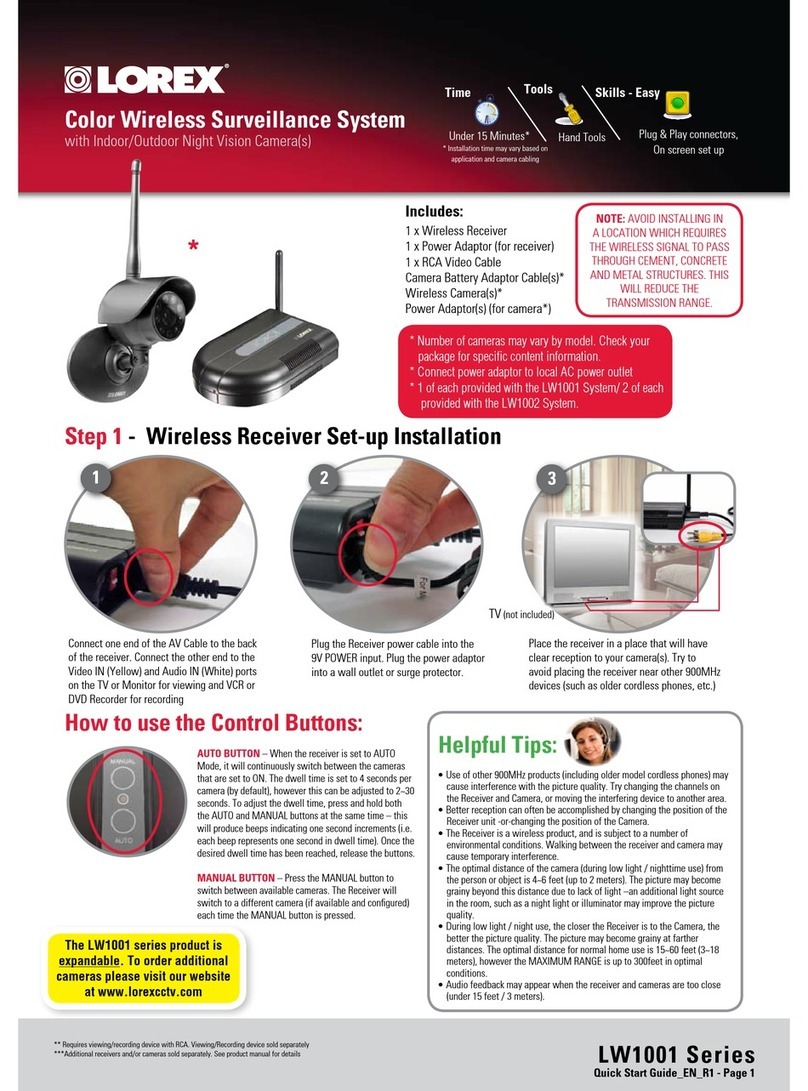

FIGURE 2. BATTERY END CAP REMOVAL

2.5.2. PROCEDURE. To replace the battery, remove battery end

cap from beacon as follows:

2.5.3. Remove the three brass 4-40 machine screws from the battey

end cap. Lift that battery end cap to access the battery.

2.5.4. Remove battery from beacon. Replace with battery a 9 Volt

Alkaline or Lithium Battery. Note: Battery orentation is based on the

battery contacts. If battery is installed the wrong way, then the battery

end cap will note seat on the beacon housing.

03-TM-0046 Page 8 of 13

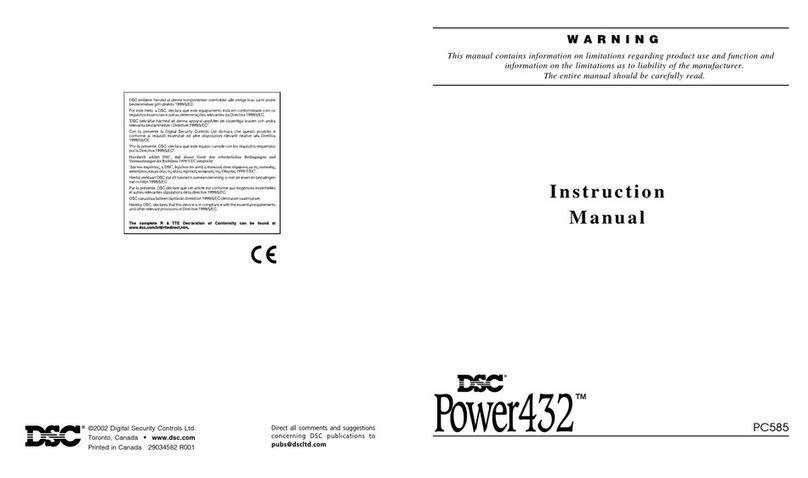

FIGURE 3. BEACON EXPLODED VIEW SHOWING

RELATIVE LOCATION OF BATTERY AND RELATED

PARTS

CAUTION

DIRT, LINT, SAND AND OTHER FOREIGN SUB-

STANCES IN LUBRICANT ON SEALING SURFACES

MAYALLOW WATER LEAKAGE THROUGH THE O-

RING SEAL. SCRATCHES OR GOUGES WILL ALSO

CAUSE WATER LEAKAGE.

2.5.5. Check O-ring for ware or damage. If it is necessary to replace

O-ring. remove the old O-ring from the battery end cap. Do not use

steel screwdriver or sharp tool because of danger to damaging O-ring

groove . Clean O-ring groove in the body and the threads on the cover

by wiping them thoroughly with mild soap and water.

2.5.6. Carefully install new O-ring on battery end cap. Apply a thin

coating of O-ring lubricant to O-ring and O-ring groove.

03-TM-0046 Page 9 of 13

2.5.9. Replace the battery end cap and install the three 4-40 brass

machine screws. Tighten until the cap flange contacts the body or leaves

less than a 0.003 inch (0.076 mm) gap. Use hand force only on the

brass screws. Clean beacon exterior of excess O-ring grease.

2.5.10. Perform operational test of beacon as outlined in Section 2.1.

3.0 Returning Product for Service

When shipping a product back to RJE from either inside or outside

the United States, the following instructions will help ensure the

equipment arrives with the minimum possible delay. Any deviation

from these instructions increases the potential for delay.

Step 1 - Get a Return Authorization

The best way to make sure RJE is aware of your intentions to ship

equipment is to obtain a Return Material Authorization (RMA)

before sending the shipment. Return Material Authorizations are

issued by Sales Administration or Customer Service and are used

to notify us of your needs in advance of arrival so we can provide a

faster turnaround. When requesting a Return Material

Authorization, please give us the following information.

•What is being shipped (include the serial number)

•When you plan to send the shipment

•What problem(s) need correction

•When you need the instrument returned

When the Return Material Authorization is issued, we will tell you

the RMA number. Please include this number on all packages and

correspondence.

Mark the Package(s)

To: RJE International, Inc. (RMA Number)

15375 Barranca Parkway, Suite B107

Irvine, California 92618

03-TM-0046 Page 10 of 13

Step 3 - Update RJE International

Send the following information by fax or telephone to RJE.

Attention: Sales Administration

Fax: (949) 727-0070

Phone: (949) 727-9399

• Detailed descriptions of what you are shipping

(number of packages, sizes, weights, and contents).

• The name of the freight carrier

• Master Air bill number

• Carrier route and flight numbers for all flights the

package will take

03-TM-0046 Page 11 of 13

SECTION III

WARRANTY

RJE International warrants that this equipment (referred to as the unit) will be

free from defects in materials and workmanship, when used under normal

operating conditions as determined solely by RJE International, for a period of

one (1) year from the date of shipment from RJE International.

As the sole remedy for breach of the foregoing warranty, RJE International shall

repair or replace, at RJE International’s option, any unit, component or part

thereof found defective or nonconforming within said one (1) year period from

the date of shipment. Customer shall give RJE International notice of any defect

or nonconformity and, if so instructed by RJE International, customer shall, at

its expense, ship the unit, component or part to RJE International. If RJE

International determines that the unit, component or part is actually defective or

nonconforming, it shall, at its expense, ship a new or a rebuilt unit, component

or part to the customer. The customer shall be responsible to perform, at its own

expense, any necessary installation work related to any defective or nonworking

unit, component or part. The functionality and operational aspects of the unit is

determined by the unit operating within the specifications and is dependent of

proper maintenance as required to be performed by the customer.

RJE International shall not be liable for any expense or damages resulting from

interruptions in the operation of the unit.

RJE International shall not be liable for the cost of any repairs undertaken by the

customer or any third party without RJE International prior written authoriza-

tion.

RJE International shall not be liable for any incidental, special consequential or

exemplary damages arising out of the installation, use, testing, servicing or

maintenance of any unit, component or part. This warranty is given in lieu of all

other warranties, expressed or implied, including the warranties of merchant-

ability or fitness for a particular purpose.

RJE International’s total liability under this warranty is limited to the

remanufacture or replacement of the unit, component or part.

03-TM-0046 Page 12 of 13

APPENDIX A

ULB-350/TD

A.1. GENERAL. The ULB-350/TD is configured with the time delay

option that is factory set. This configuration will delay the normal

underwater operation of the beacon based on the time set at the factory

(ie.., 8, 16, or 32 minutes).

A.2. BEACON DELAYING FUNCTION.

A.2.1. When the water switch is activated the beacon will ping several

times and then begin the selected delaying period. This function is

provided to verify the operation of the beacon and the delaying period.

A.2.2. Upon completion of the selected delaying period the beacon will

resume pinging for the live of the battery.

A.2.3. Removing the beacon from the water will reset the delaying

period.

Table of contents

Other RJE Security System manuals

Popular Security System manuals by other brands

Defender

Defender EL00147 quick start guide

FLAJZAR

FLAJZAR FISHTRON NEON TX3 Instructions for operation and use

Witura

Witura WT-1010SA User manual and installation instructions

Horizont Agrar

Horizont Agrar 10662 operating instructions

ON Control

ON Control AP01 manual

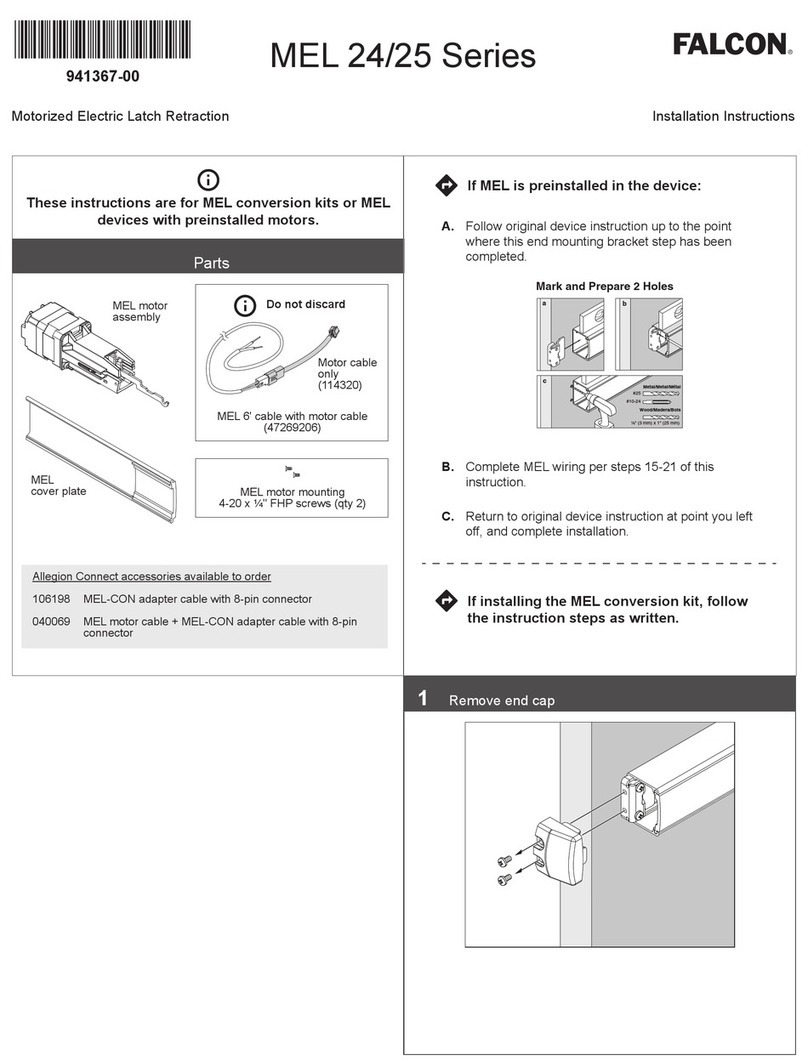

Falcon

Falcon MEL 24 Series installation instructions