Eddy TBE2 Instructions for use

Page | 1

Tile breaker model TBE2

Briseur de tuile modèle TBE2

Azulejo removerdor modelo TBE2

WARNING

For your safety, READ and UNDERSTAND before using. Save these instructions for future reference.

AVERTISSEMENT

Pour votre sécurité, LIRE et COMPRENDRE avant d’utiliser. Sauvegarder ces instructions pour référence future.

ADVERTENCIA

Para su seguridad, LEER y ENTENDER antes de usarlo. Guarde estas instrucciones para referencia en el futuro.

Ver. 2017-04

Page | 2

Page | 3

INSTRUCTION & MAINTENANCE MANUAL

MANUEL D’INSTRUCTIONS & D’ENTRETIEN

INSTRUCCIÓN Y MANTENIMIENTO MANUAL

Page | 4

Table of contents

English version......................................................................................................................................5

Introduction...........................................................................................................................................6

General safety rules..............................................................................................................................7

Additional safety rules...........................................................................................................................8

Unpacking...........................................................................................................................................10

Operating instructions.........................................................................................................................12

Maintenance .......................................................................................................................................15

Warranty.............................................................................................................................................18

Service................................................................................................................................................18

Version Francais.................................................................................................................................19

Introduction.........................................................................................................................................20

Règles de sécurité generales..............................................................................................................21

Règles additionnelles de sécurité .......................................................................................................23

Déballage............................................................................................................................................24

Mode d’emploi.....................................................................................................................................26

Entretien..............................................................................................................................................29

Garantie..............................................................................................................................................32

Service................................................................................................................................................32

Version en español.............................................................................................................................33

Introducción ........................................................................................................................................34

Reglas generales de seguridad ..........................................................................................................35

Reglas adicionales de seguridad........................................................................................................36

Desembalaje.......................................................................................................................................38

Instrucciones de uso...........................................................................................................................40

Mantenimiento ....................................................................................................................................43

Garantia..............................................................................................................................................46

Servicio...............................................................................................................................................46

Appendices.........................................................................................................................................47

SPECIFICATIONS / SPÉCIFICATIONS / ESPECIFICACIONES .......................................................47

EXPLODED VIEWS / VUES EN ÉCLATÉ / VISTAS DESARROLLADAS ..........................................48

PARTS LIST / LISTE DES PIÈCES / LISTA DE PIEZAS....................................................................50

Contact information.............................................................................................................................53

Purchase record / Record d’achat / Registro de la compra.................................................................54

Page | 5

English version

Page | 6

Introduction

RESUME

Due to prolonged and demanding physical effort that requires manual removal of ceramic tiles, cements and

glues, we have developed a tool allowing the operator to have a better posture and this for all phases and

materials to be removed.

ERGONOMICS

An ergonomic tool for removing ceramic floor covering whose design focuses on reducing physical effort and

prevention of professional injuries to the operator.

Thanks to its geometry allowing a wide variation of angles of attack on the various coatings to remove and its

minimum height of the handles, the tile breaker tool provides a comfortable position to the operator.

GENERAL DESCRIPTION

The system consists of a percussion tool, system of positioning and adjustment of angles, handle with a switch

and control knobs, folding column and fork, wheels and chisels 1’’, 2’’ and 3’’.

ANGLE ADJUSTMENT

The electric actuator allows the positioning of the tool to the different necessary angles for the work to be done.

On the opposite side of the actuator, we have added a graduated sticker and needle showing the degrees of the

tool to the operator. For example, an angle of + or –30 degrees is used for the removal of ceramic tiles rather

than an angle of 70 degrees used to remove the grout. This rule then becomes a reference point for the operator.

The electric actuator is connected to a control Up & Down integrated in the handle which allows the safe

positioning of the tool without manual effort.

Page | 7

General safety rules

WARNING!

Read all instructions.

Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury. The term

’’power tool’’ in all the warnings listed below refers to your mains-operated (corded) power tool.

SAVE THESE INSTRUCTIONS

This equipment should be operated in compliance with all OSHA regulations.

Work area

Keep work area clean and well lit. Cluttered and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids,

gases or dust.

Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distraction can cause you to lose

control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of

electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal injury.

Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid safety

shoe, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in the off-position before plugging in. Carrying power tools

with your finger on the switch or plugging in power tools that have the switch on invites accidents.

Remove any adjusting key such as wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

Page | 8

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power

tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are

connected and properly used. Use of these devices can reduce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will

do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making

any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained

users

Maintain power tools. Checkfor misalignment or binding of movingparts, breakage of parts and any other

condition that may affect the power toolsoperation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions and in the manner

intended for the particular type of power tool, taking into account the working conditions and the work

to be performed. Use of the power tool for operations different from those intended could result in a

hazardous situation.

Service

Have your power tool serviced by a qualified repair personusing only identicalreplacement parts.This will ensure

that the safety of the power tools is maintained.

Additional safety rules

This equipment should be operated in compliance with all OSHA regulations.

Rags, cloth, cord, strings and the like should never be left around the work area. Entangled material

increase the risk of accidents.

Handle the blades very carefully. Sharp edges may cause injuries. Use the provided guard and gloves to

handle.

Ensure that the blade retaining bolts are securely tightened before operating the tool. Loose bolts will

generate unusual vibration and may result in injuries.

Hold the tool firmly with both hands. Control of the tool requires a firm hold and holding with both hands

will prevent potential accidents.

Keep hands away from rotating parts. Moving parts may cause injuries and electric shock.

Before using the tool, let it run idle for a while. Watch for unusual vibrations or wobbling that could indicate

poor installation or a poorly installed balanced blade. Unusual vibrations or wobbling indicate poor

installation or poorly balance blades. This may cause accidents or result in injuries.

Do not leave a power tool running unattended. Operate the tool when hand held only.

Page | 9

Never change the bolt length on the rubber shocks and do not use shims or bushings on top or bottom.

Tampering with these parts may result in accidents and injuries. Periodically verify parts #26 and #50 for

proper operation.

Before using the tool

Check for damaged parts before using the tool. A damaged guard or part should be carefully checked to

determine if it will operate properly and perform its intended function. Check the alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any other conditions that may affect the tool operation.

A guard or other part that is damaged should be properly repaired or replaced by an authorized service center

before using the tool.

Voltage verification

Before connecting the tool to a power source, make sure that the voltage supplied is the same as the one

specified on the nameplate of the tool. A power source with a greater voltage may result in serious injury to the

user as well as damage to the tool. If in doubt, do not plug-in the tool. Using voltage lower than specified is

harmful to the motor.

Page | 10

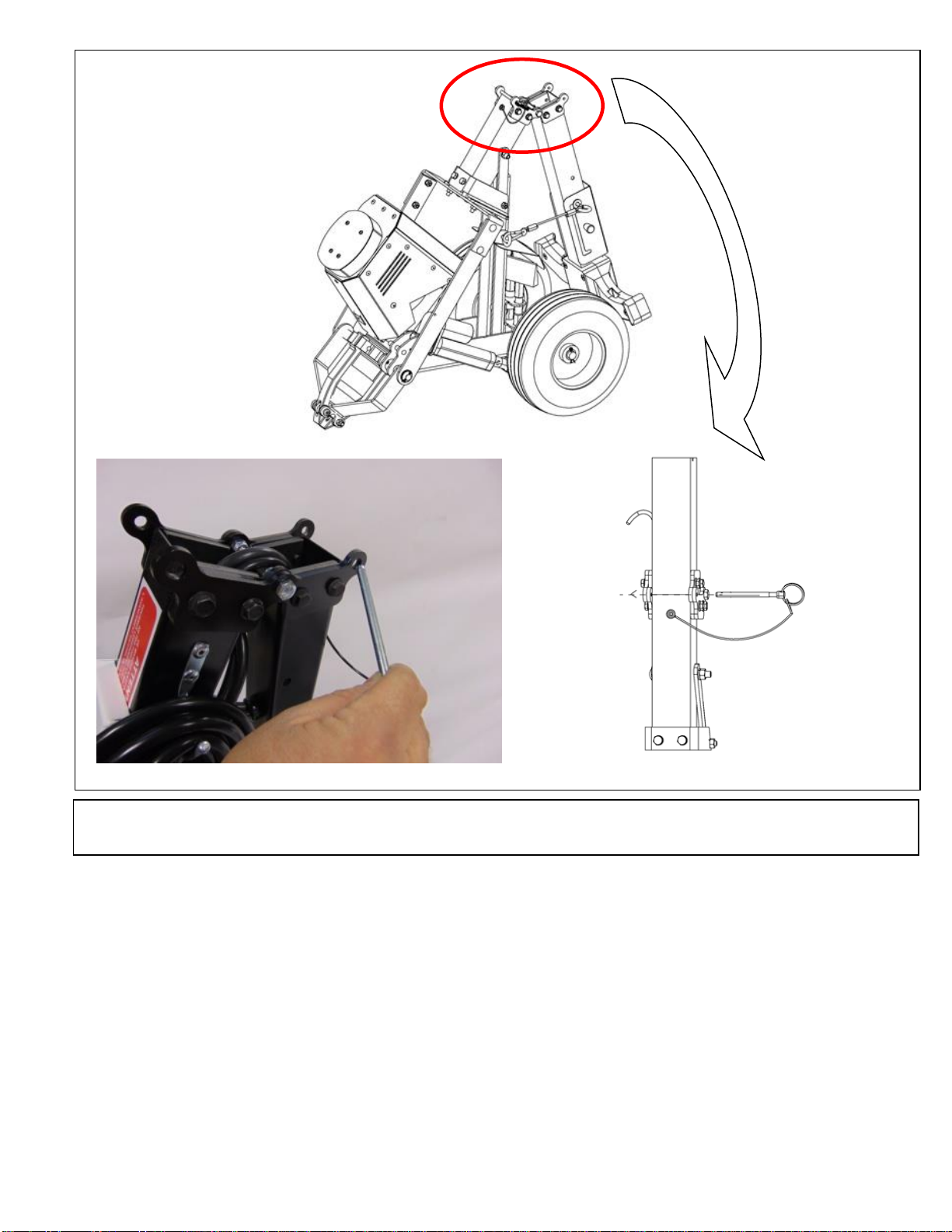

Unpacking

Open the box and retrieve the Tile Breaker from it.

The Tile breaker is in a folded position as shown in the figure below.

Attach the wheels as shown in the third figure.

To prevent injuries, a safety cable is locking the handle in the folded position.

To unfold the handle, open the Cable snap and unfold the handle by lifting it upwards until the hinge

anchors are align. Insert the hinge pin until the spring ball locks in place as shown in the figure.

WARNING When lifting the handle, make sure that nobodies hand or other body part is touching the handle

latching joint.

1) Place the wheel

over the wheel

axle

2) Place the

ring over

the wheel

axle

3) Insert the lock-pin and

bend over the legs

Page | 11

Figure to indicate how to install the handle properly. The hinge pin needs to be inserted in the hinge

anchors. WARNING: Do not pitch fingers when assembling the handle and inserting the pin

Page | 12

Operating instructions

Controls & adjustments

To start removing ceramic tiles, depress the Trigger switch and push the chisel on the tiles. Depressing the

switch will activate the tool motor and the push movement will initiate the striking motion.

Depending on the type of tiles and/or to remove mortar, you may have to change the angle of the tool.

To change the angle, please follow the following steps:

Unlock Lock knob (see the picture on the right below)

Lower the cover using Knob

Press on the Tool angle selector until proper angle is found. (See the picture on the left below)

When finished, move the cover to the upper position using knob and lock with the lock knob.

Picture of how to unlock the angle selector and how to cover it again

Page | 13

Chisel selection

WARNING: Always disconnect the power cord before proceeding to the chisel installation or removal.

The Eddy Tile breaker comes with a complete set of 3 sizes of chisels. You have the option between 1 inch, 2

inch and 3 inch chisels. They are conveniently located at the back of the tool.

WARNING: only use the 1”, 2” or 3” Eddy chisels. These chisels are 8” long and longer chisels are not suitable

and will damage the tool.

To prevent potential injuries, a cover is placed over the chisels. To reach or store chisels, lift the cover. When

finished, lower the cover back to its original position

Picture showing the chisel cover

Page | 14

Choose the chisel for the job to execute. There are 3 sizes of chisels; 1”, 2” and 3”.

NOTE: Most tiles can be removed using chisel sizes 1” and 2”. The 3”chisel is mostly used to remove mortar.

See Fig. 8.

Insert the chisel as shown in the following Fig. 12 to 14.

Tilt the tool backwards.

Insert chisel while holding back the chuck.

Turn the chisel until the chisel groove is engaged before releasing the chuck..

Release the chuck.

If necessary, grease the chisel with the grease that comes with the tool so that the chisel can

be inserted more easily

Principle of how to install a chisel in the Tile Breaker:

Insert chisel while pushing back the chuck (this is the black part of the hammer)

Put the chisel in the hamer until the chisel groove is engaged

Release the chuck.

If necessary, grease the chisel with the grease that comes with the tool so that the chisel

can be inserted more easily

Page | 15

Maintenance

Tool use and care

Do not force the tool. Use the correct chisel for your application. The correct tool will do the job better and safer

at the rate for which it is designed.

Disconnect the plug from the power source before making any maintenance of the tool.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect

the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly

maintained tools. Develop a periodic maintenance schedule for your tool.

Use only chisels that are supplied with the tool. Accessories that may be suitable for one tool, may become

hazardous when used on another tool.

Cleaning

To avoid accidents always disconnect the tool from the power supply before cleaning or performing any

maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles

when cleaning tools with compressed air.

WARNING: Ventilation openings and controls must be kept clean and free of foreign matter. Do not attempt to

clean by inserting pointed objects through openings.

Warning: Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

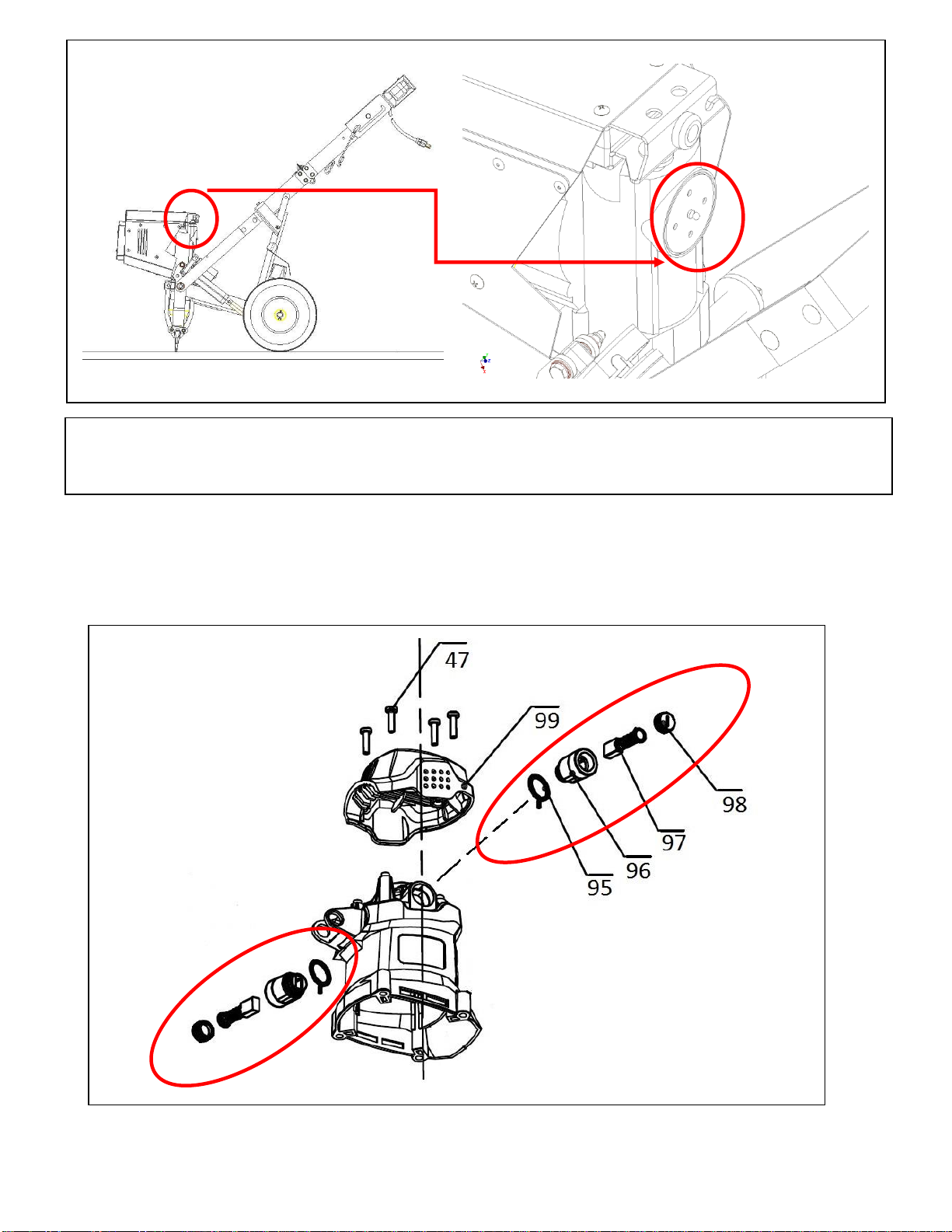

Tool lubrification

WARNING: Prior to greasing, always disconnect the plug from the power supply.

Your Eddy Tile Breaker has been properly lubricated and is ready to use. It is recommended that the tool

be re-greased with a gear lubricant after approximately 40 running hours, i.e.2 hrs. for 20 days.

Adjust the angle of the tool to the maximum upright position. Remove the cap and fill with gear grease. Use a

PAO based grease with a high dropping point and broad application temperature range. We recommend

to use synthetic greases that use a calcium sulfonate complex thickener along with synthetic PAO oil.

An example of such a grease would be Lubex Syn from Irving.

The grease that comes with the tool is used for greasing the chisel so that they can be inserted more easily.

Page | 16

Carbon brushes

The carbon brushes used in your tool have been engineered for many hours of dependable service. To maintain

peak efficiency of the motor, we recommend every two to six months that the brushes must be examined. Only

genuine Eddy 91 replacement brushes specially designed for your tool must be used.

Picture showing where the motor grease needs to be added. The tool need to be re-greased with

a gear lubricant after approximately 40 running hours. Use a PAO base grease with a high

dropping point: e.g.: Lubex Syn grease from Irving

Page | 17

Accessories

If an extension cord is necessary, a cord with adequate size conductors that is capable of carrying the current

necessary for your tool must be used. This will prevent excessive voltage drop, loss of power or overheating.

Grounded tools must use 3-wire extension cords that have 3-prong plugs and receptacles.

Note: The smaller the gauge number, the heavier the cord.

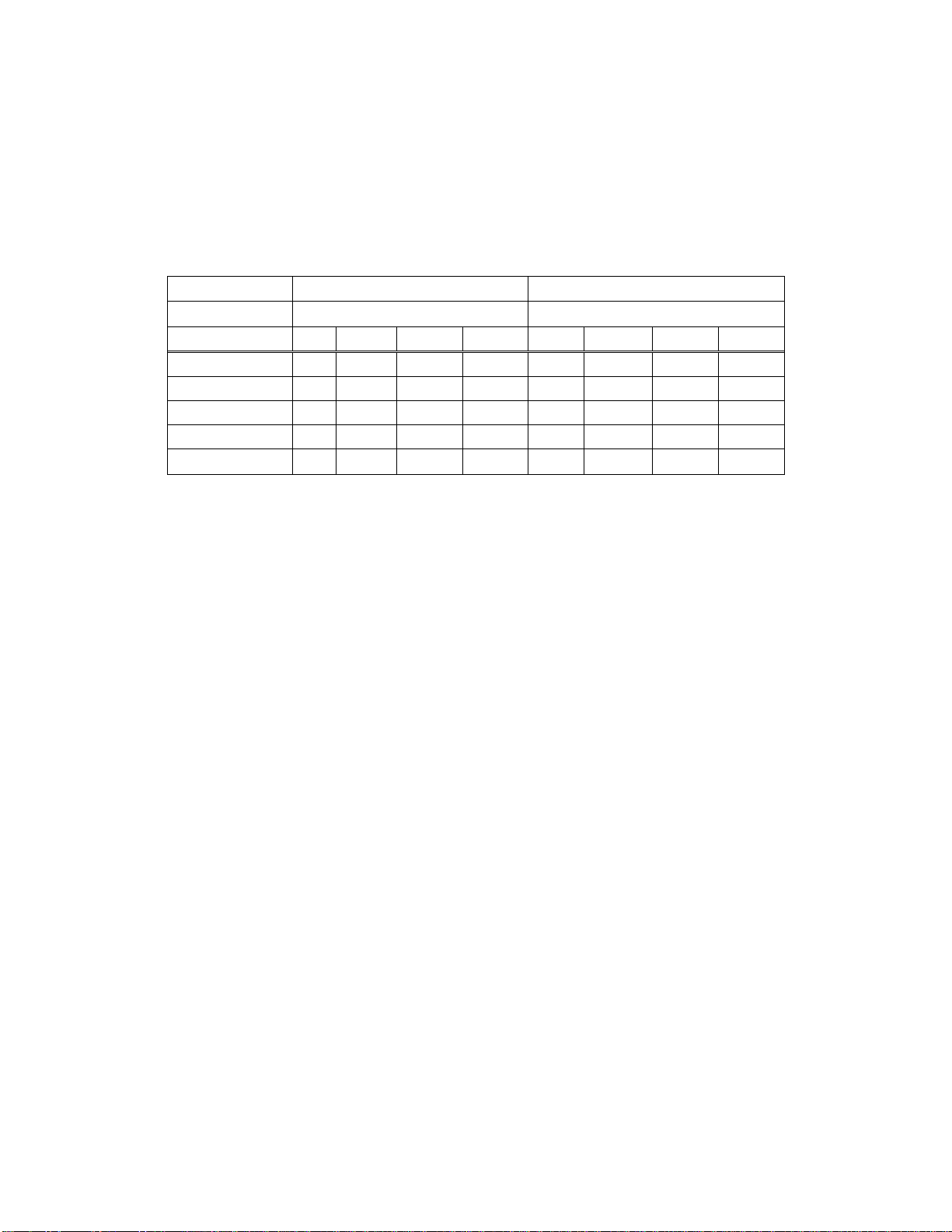

RECOMMENDED SIZES OF EXTENSION CORDS FOR 120 VOLT ALTERNATING CURRENT TOOLS.

Cord size in AWG

Wire size in mm2

Amps Rating

Cord length in feet

Cord length in meters

25

50

100

150

15

30

60

120

3 - 6

18

16

16

14

0.75

0.75

1.5

2.5

6 - 8

18

16

14

12

0.75

1

2.5

4

TBE2 -> 8-10

18

16

14

12

0.75

1

2.5

4

10 - 12

16

16

14

12

1

2.5

4

-----

12 - 16

14

12

-----

-----

-----

-----

-----

-----

Page | 18

Warranty

Eddy 91 Inc.

12 months warranty

Every Eddy 91 Inc. tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free

of defectsfrom workmanship and materialfor theperiodof twelve (12) monthsfrom the date of originalpurchase.

Should any trouble develop during this twelve (12) months period, return the complete tool, freight prepaid, to

one of Eddy 91 Inc. authorized service centers. If the inspection shows the trouble to be caused by defective

workmanship or material, Eddy 91 Inc. will repair or replace it without charge.

This warranty does not apply:

Where normal maintenance is required

Repairs have been made or attempted by non-authorized personnel

The tool has been abused, misused or improperly maintained

Alterations have been made to the tool

IN NO EVENT SHALL EDDY 91 INC. BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE PRODUCT, THIS DISCLAIMER APPLIES BOTH DURING

AND AFTER THE TERM OF THIS WARRANTY.

The Eddy 91 Inc. warranty is the only and the entire written warranty given by Eddy 91 Inc. tools. No dealer or

his agent or employee is authorized to extend or enlarge upon this warranty by any verbal or written statement

or advertisement.

Eddy 91 Inc. disclaims liability for any implied warranties, including implied warranties of MERCHANTABILITY

‘’AND FITNESS FOR A SPECIFIC PURPOSE’’, after the twelve (12) months term of this warranty.

This warranty gives you specific rights. The provisions contained in this warranty are not intended to limit, modify,

take away from, disclaim or exclude any warranties set forth in any provincial or state legislation. To the extent

required by law, the provision in any provincial or federal legislation with respect to warranties takes precedence

over the provisions in this warranty.

Service

INSTRUCTIONS IF YOU NEED SERVICE

Explain the problem in a letter. Indicate in it your name, address and phone #.

Enclose the letter with the tool.

Enclose copy of your purchase record (see at the end).

Package carefully the tool and send prepaid to the nearest Eddy 91 authorized service center, listed

below.

Page | 19

Version Francais

Page | 20

Introduction

RÉSUMÉ

En raison de l'effort physique prolongé et exigeant que nécessite la suppression manuelle des carreaux de

céramique, des ciments et des colles, nous avons développé un outil permettant à l'utilisateur d'avoir une

meilleure posture et ce, pour toutes les phases et les matériaux à enlever.

ERGONOMIE

Un outil ergonomique pour enlever revêtement de sol en céramique dont la conception vise à réduire l'effort

physique et la prévention des blessures professionnelles de l'utilisateur. Grâce à sa géométrie qui permet une

grande variation d’angles d’attaque sur les divers revêtements à enlever et à la hauteur minimum de ses

poignées, l’outil briseur de tuile permet une position confortable à l'utilisateur.

DESCRIPTION GÉNÉRALE

Le système se compose d'un outil à percussion, d’un système de positionnement et de réglage des angles,

d’une poignée avec un interrupteur et boutons de contrôles, d’une colonne, d’une fourche, des roues et des

ciseaux 1'', 2'' et 3''.

AJUSTEMENT D’ANGLE

L'actuateur électrique permet le positionnement de l'outil aux différents angles nécessaires pour le travail à

effectuer. Sur le côté opposé de l'actionneur, nous avons ajouté un autocollant gradué et une aiguille indiquant

les degrés de l'outil à l'utilisateur. Par exemple, un angle de plus ou moins 30 degrés est utilisé pour l'enlèvement

de carreaux de céramique et angle de 70 degrés pour l'enlèvement du mortier. Cette règle devient alors un point

de référence pour l'opérateur. L'actuateur électrique est connecté à une commande vers le haut et vers le bas

intégré dans la poignée qui permet le positionnement de l'outil en toute sécurité sans intervention manuelle.

Table of contents

Languages:

Other Eddy Power Tools manuals

Popular Power Tools manuals by other brands

Roby

Roby RMT1801 Original instructions

Euro Shatal

Euro Shatal PC1614-50 Operating instructions/spare parts list

Bosch

Bosch GDS 18 E Professional Original instructions

Makita

Makita RP1800 instruction manual

Greenlee

Greenlee GATOR ESP710 instruction manual

Glenair

Glenair band-master ATS 601-118 operating instructions

stayer

stayer HDB L20 operating instructions

Nakayama

Nakayama ES2001 Translation of the original instructions

Valfor Tools

Valfor Tools Router Bit Vise owner's manual

pela tools

pela tools 50841 manual

DeWalt

DeWalt DW892 instruction manual

Scheppach

Scheppach HP1800S Translation of original instruction manual