© 2017 Glenair, Inc. CAGE Code 06324 Printed in U.S.A.

GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497

818-247-6000 • FAX 818-500-9912 www.glenair.com

8

601-118

Operating Instructions

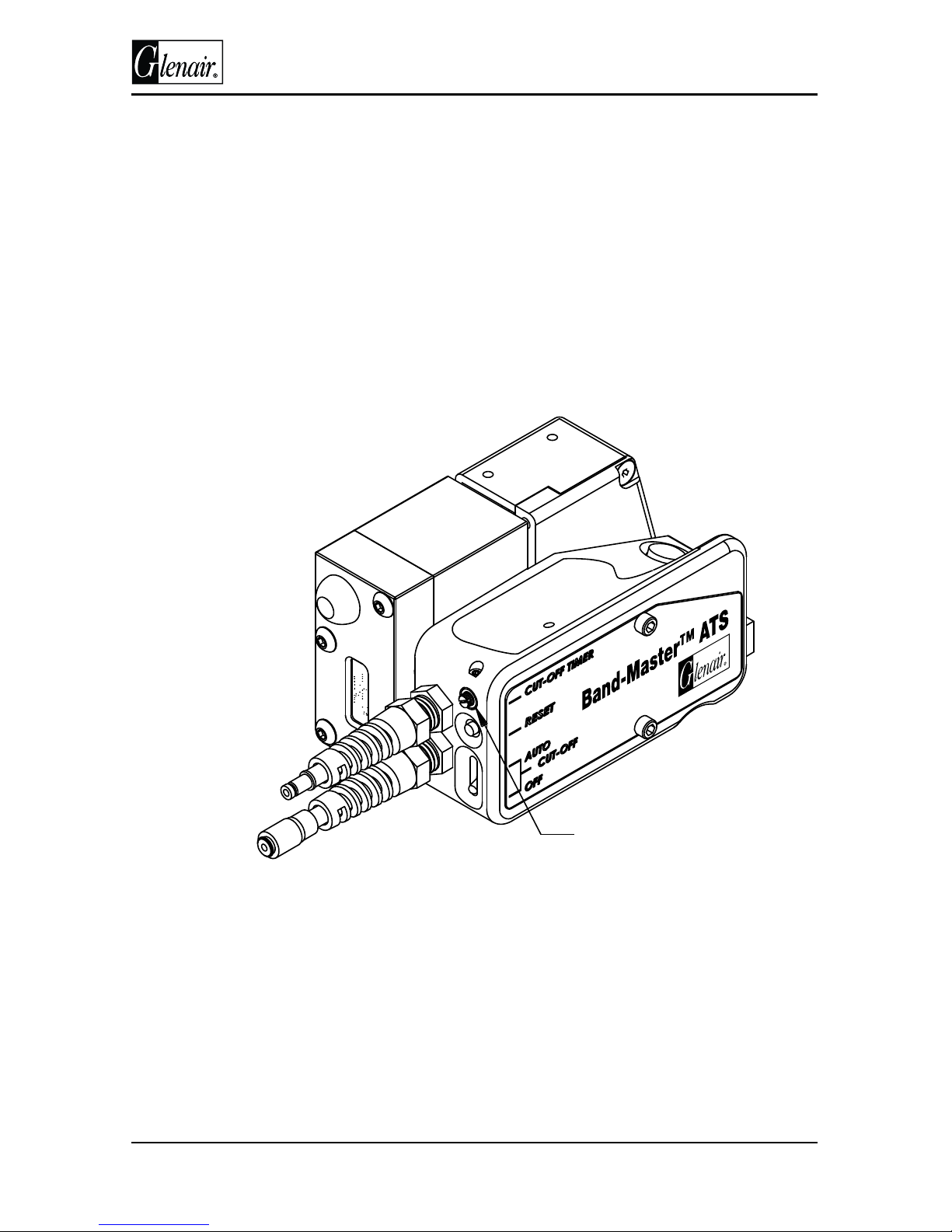

Counter features

(see gure 4)

1. Resettable Mileage counts

(top display)(see page 13)

2. Permanent life accumulate

counts (bottom display)

3. Counter display on switch

4. Power switch

Important notes:

Air supply line pressure is critical. 100-110 psi is required at the inlet port

of the regulator assembly to allow the tool to operate properly. For line

pressures less than 100 psi the tool must be tested for proper operation.

DO NOT ADJUST THE REGULATOR ON THE REGULATOR ASSEMBLY OVER

100 PSI

Do not over tighten the 5/16 inch hex locking collar for the regulator shaft,

damage may occur.

Improperly installed clamps may result in faulty shield termination and

insucient ground bonding.

Do not twist or force tool or cable assembly in any direction while installing

clamps.

Always install clamps perpendicular to the axis of the cable being terminated.

When clamping irregular shaped band platforms, choose a location of the

buckle where it is well supported on the bottom. A properly designed

backshell with a lip are essential when tensile loads may be expected.

To verify tension setting after the tool has been at rest for some time, actuate

the tool momentarily and conrm pressure setting on the digital pressure

gauge.

Glenair recommends that banding occur on an unxtured cable assembly.

Trying to band on a rmly xed surface may aect the applied forces and

interfere with the cut-o operation. The cut-o operation causes a rotation

of the band termination in order to aect a lock. Therefore, when performing

the banding operation on a xtured cable or device the operator MUST allow

the band tool to rotate slightly as the cut-o operation is performed.

012

123

Power Switch

Resettable

Count

Permanent

Count

Battery

Life

Figure 4