Edge Precision Pi-oT 2 User manual

Quickstart Guide

Pi-oT 2 Precision Series

Content Overview

Welcome to the Pi-oT family! Each Module

contains the following-

•1x Pi-oT 2 Base Board & Enclosure

•2x 0.1” Spacers

•2x Hex Standoffs

•4x Nylon Screws

•3x Short Self-tapping Screws

•4x Long Enclosure Lid Screws

•1x 5V fan

•2x 4-40x1/2 Pan Head Screws

•1x Ethernet Jumper Cable

•1x UPS Board (Optional).

Step 1: Attaching Raspberry Pi and UPS

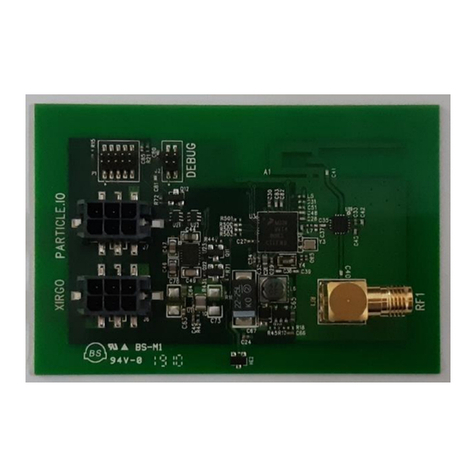

•Start by attaching your Raspberry Pi 4 to the 40

Pin receptacle on the bottom of the base board.

•Once attached, slide the 2 0.1” Spacers between

the Raspberry Pi and the Pi-oT 2 Baseboard as

shown in Figure 1.

•Thirdly, insert 2 Nylon Screws through the Pi and

secure to the Pi-oT Baseboard with 2 Hex

Standoffs.

•If active cooling is needed, install the 5V fan with

the 2 4-40 screws, and plug the fan into the 5V

header in the top right of the board.

•Next, install the UPS Board onto the Pi-oT 2

Baseboard by first aligning 2 mounting holes on

the UPS Board with the 2 Hex Standoffs. This will

ensure the 5 pin connector is properly aligned.

CAUTION: If the UPS board is not properly

connected, damage may occur to either board.

•Once aligned properly and connected, the

remaining 2 Nylon Screws can be used to secure

the UPS Board to the Hex Standoffs.

•If ethernet connection is needed, connect the

Raspberry Pi’s ethernet to the Pi-oT 2 Baseboard

with the supplied Ethernet Jumper cable. Excess

cable can be tucked under the assembly or

above if needed.

Figure 1: Inserting Spacers

Figure 2: Baseboard Installed

Quickstart Guide

Pi-oT 2 Precision Series

Step 2: Final Assembly

•Start by screwing the Pi-oT 2 Baseboard into

the bottom tray with the 3 provided self-

tapping screws shown in Figure 2.

•Finally, the enclosure lid is ready to be

installed with the 4 long machine screws,

once the Module is programmed and

configured, shown in Figure 3.

Step 3: Battery Choice and UPS Configuration

The Pi-oT 2 features an optional UPS powered by 2 LiFePO4

18650 batteries. The preferred cell for this product is the Lithium

Werks APR18650M1B. The UPS charges the cells to 3.4 Volts at

a maximum charge rate of 1 amp. The UPS will prioritize the

system load over battery charging if the maximum current draw is

reached.

CAUTION: To maximize efficiency, no reverse current protection

is present on the UPS. Use care when installing the LiFePO4

cells.

The UPS communicates to the Raspberry Pi via 2 GPIO

channels:

In the event of power failure, GPIO pin 25 (BCM) will be pulled

Low to signal the UPS is supplying power from the LiFePO4 cells.

The UPS is controlled by GPIO pin 24 (BCM), where logic Low

disables the UPS. This signal is held High when Vin is present,

thus allowing the Module to power on when Vin is initially

supplied.

The configuration of these two signals allows for the following

logic to control the Module-

1. The Raspberry Pi and UPS power on when Vin is first

supplied.

2. The GPIO pin 24 is held high via a python script or

similar.

3. GPIO pin 25 is used as an input to monitor for power

failure.

4. Once GPIO pin 25 is pulled low, the Raspberry Pi can set

a time to wait for power to resume before safely shutting

down.

CAUTION: The UPS will stop delivering power once a

dangerously low voltage level in the cells is detected.

This safety measure should not be used as a backstop

and only as an emergency condition. Please calculate a

reasonable time to run off battery power based on your

individual use case, and battery choice.

5. Once the Raspberry Pi shuts down, the GPIO pin 24 will

go Low, thus removing all power to the system.

6. If power is returned to Vin, the UPS will power on and the

process repeats.

Figure 3: Fully Assembled Module

GPIO 24 pulls

LOW, disables

UPS, entire system

is powered down.

Vin Supplied

UPS and Pi

Powered

Pi holds pin 24

HIGH

Vin Fails

GPIO 25 input

reads LOW

Pi waits maximum

time, safely shuts

down

Power is

returned,

GPIO returns

HIGH

Pi waits

predetermined

time, safely shuts

down

Quickstart Guide

Pi-oT 2 Precision Series

Power Supply

Rated Voltage

5 or 12-24V

Power Consumption

3 W Typical

15 W Max.

Reverse Polarity

Protection

None

Digital Inputs

The 24V digital inputs are tied to the GPIO

pins 12, 17, 22, 27 (BCM).

No. of Inputs

4

Voltage Range

0-24 V

Threshold

EN 61131-2 Type III

Common

FGND

Galvanic isolation

Yes

Digital Outputs

The ULN2003a powered open collector

digital outputs are triggered by the GPIO

pins 13, 16, 19, 20, 21, 26 (BCM).

No. of outputs

6

Maximum Voltage

50 V

Maximum Current

per Channel

500 mA

Common

GND

Galvanic isolation

None

Flyback Suppression

Yes, VSUP pin

Step 4: Configuring Power

The Pi-oT 2 Precision Series features an on-board

DC-DC converter to allow the Module to be

powered by either a 5V or 12-24V input. To

configure which power level, adjust the switch on

the right side of the board.

CAUTION: Applying 12-24V while configured to 5V

will damage the boards and cause extreme

damage to any batteries installed. Please use

extreme care when configuring this device.

Once configured, attach the Positive and GND

leads to the screw terminals, using a 3 Watt

capable power supply.

Step 5: Interfacing the Raspberry Pi with the

Pi-oT 2 Baseboard

The Pi-oT 2 has 4 main IO groups:

1. Digital Inputs

2. Digital Outputs

3. Analog Inputs

4. RS485

Digital Inputs:

The 4x 24 volt inputs are connected the

GPIO pins 12, 17, 22, and 27. When interfacing

these DI with switches or sensors in the field,

the FGND terminal should be used as the

ground. This ensures proper galvanic isolation

between the sensor inputs and the rest of the

circuit board. For more information on the input

thresholds, refer to EN 61131-2.

Digital Outputs:

The 6x Open Collector outputs are

controlled by GPIO pins 12, 16, 19, 20, 21, and

26. The open collectors have a maximum

voltage of 50V and a maximum current

capability of 500 mA for a single channel.

Note: When driving inductive loads, to avoid

kick-back voltages, tie the coil supply voltage to

VSUP.

When driving a resistive load, a pullup resistor

is needed in order for the device to sink current

and for there to be a logic high level. VSUP can

be left disconnected in these instances.

Quickstart Guide

Pi-oT 2 Precision Series

Analog Inputs

The MCP3208 powered inputs communicate

with the Raspberry Pi via the SPI 0 channel.

No. of Inputs

8

Resolution

12 Bit

Voltage Range

0-5 V

Common

AGND

Sampling Rate

100 ksps

Galvanic isolation

None

RS485

The SN65HVD72 powered port converts

RS485 signals directly to serial logic, allowing

the Raspberry Pi to communicate with

standard RS485 devices via pins 14 and 15

(BCM).

Surge Protection

≥500-V surge

transients

Termination R.

0 Ohm

Bias R.

0 Ohm

Galvanic Isolation

None

Analog Inputs:

The 8x 0-5V analog inputs interface to

the Raspberry Pi via the SPI 0 channel. With a

resolution of 12 Bits, the MCP3208 chip be

best used with the gpiozero Python library.

The MCP3208 IC is also capable of operating

in differential mode. In this mode one channel

is read relative to the value of a second

channel. For more information, refer to the

gpiozero documentation or the MCP3208

datasheet.

Note: The AGND pin and GND are connected

via a 40 Ohm resistor internal to the MCP3208

IC. The best practice is to operate the Module

and sensor on the same ground plane.

RS485 Terminal:

The single RS485 terminal is

connected to the Raspberry Pi TX and RX

pins. The circuitry converts the RS485 level

signals to standard serial level in order for the

Raspberry Pi to read it. Open-source Python

Libraries such as pyserial or minimalmodbus

work best for interpreting the signals.

In order for the Module to be used as a

Master on an RS485 bus, termination or bias

resistors are not included in the on-board

circuit, and thus may need to be implemented

elsewhere on the bus.