ANI-1F3

2 ANI-1F3_V2.0.0_PI_2021-04_EN

Subject to technical changes

FRIGOLINK

Contents

1 ANI-1F3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

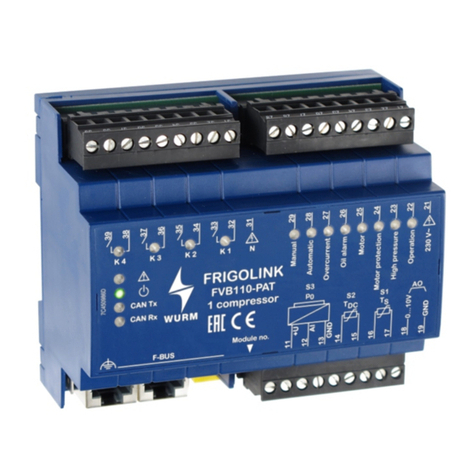

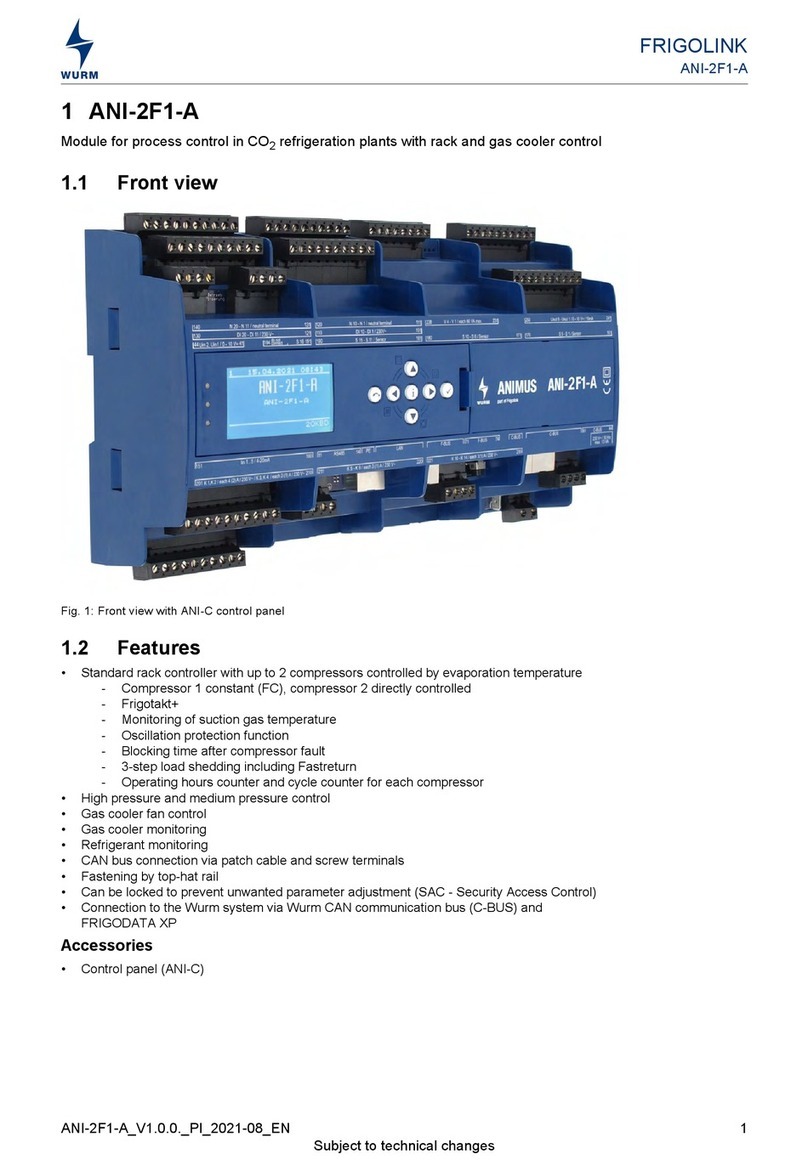

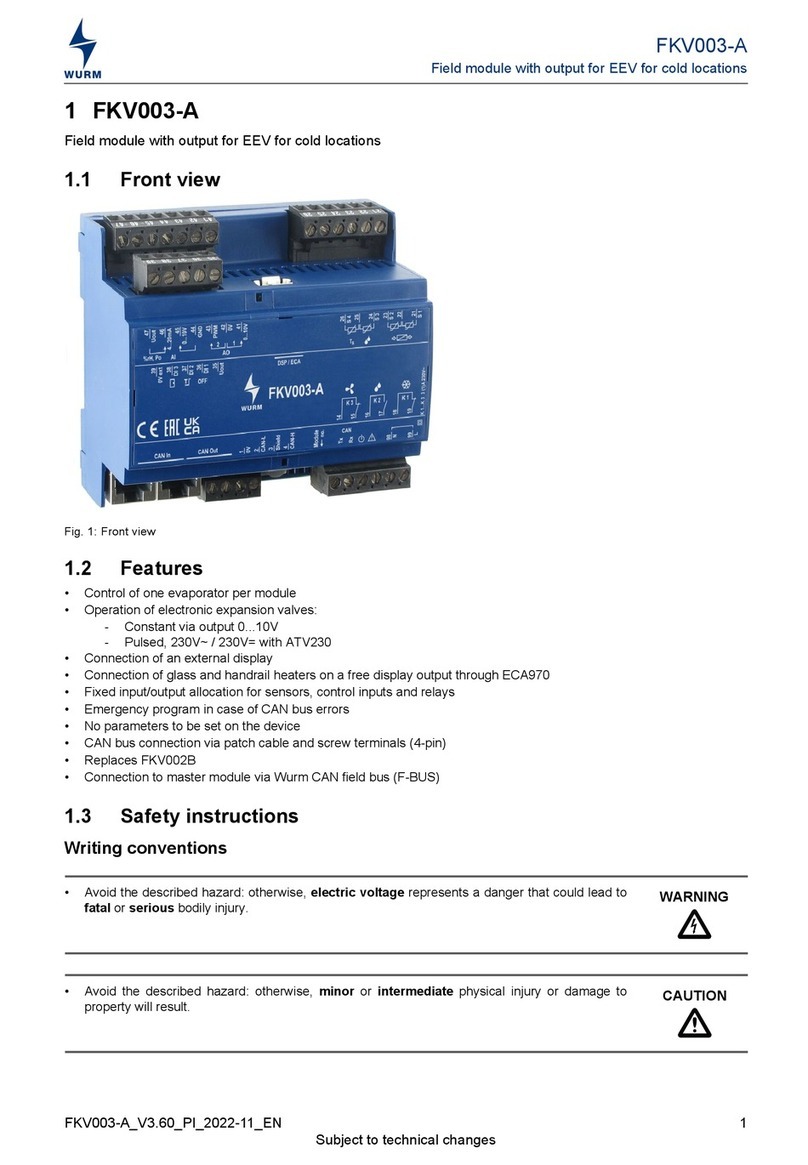

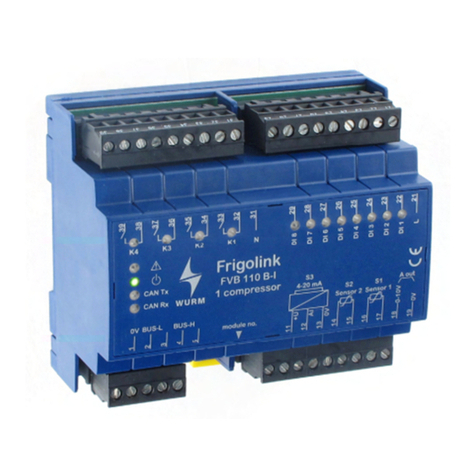

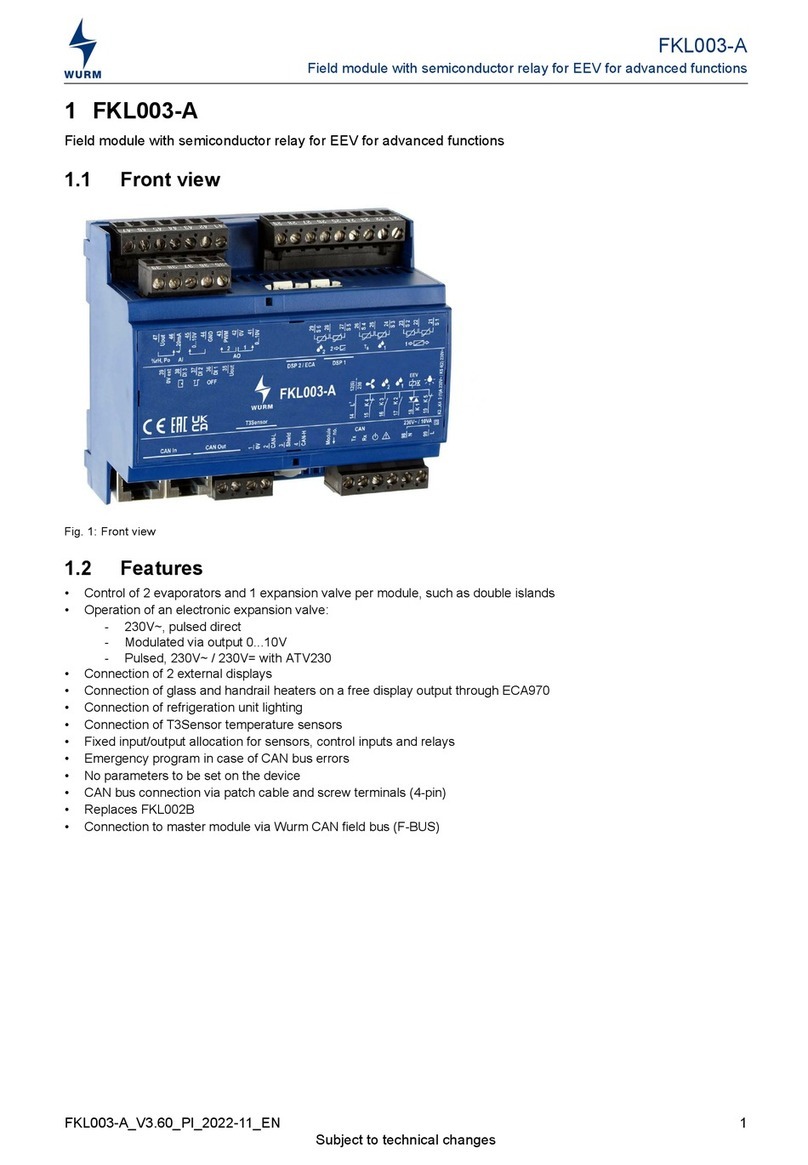

1.1 Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional earth (FE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Input circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Digital inputs DI 1 - DI 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Analogue inputs Uin 1, 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analogue inputs Iin 1 - Iin 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analogue inputs S 1 - S 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.2 Output circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Digital outputs (relays) K 1 - K 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Digital outputs (SSR) V 1 - V 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Analogue outputs Uout 1 - Uout 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.3 Communication circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.4 FIO001B/FIO-PAT circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . 12

Address 0 - extended HR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.5 FKV003 circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Address 1 - heat pump operation, air conditioning. . . . . . . . . . . . . . . . . . . . . . . . . 13

Address 2 - constant gas cooler bypass, constant IHE bypass . . . . . . . . . . . . . . . 14

Address 3 - constant hot gas bypass, constant post-injection MT . . . . . . . . . . . . . 14

1.5 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Top-hat rail installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dismantling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16