Edge EDGE-1830 User manual

Original Service Manual CD-941-500-3

EDGE-1830, EDGE-2440, EDGE-3240, EDGE-2460, EDGE-3260,

EDGE-3860, EDGE-4460, EDGE-3270, EDGE-3870

GENERATION 2

-IHEAT SYSTEM-

ORIGINAL SERVICE MANUAL

NORTH AMERICA

RETAIN THIS MANUAL FOR FUTURE REFERENCE

TO BE SERVICED BY AUTHORIZED PERSONS ONLY

MF&B RESTAURANT SYSTEMS, INC.

119 ICMI ROAD, DUNBAR, PA 15431, USA

TF: 1 (888) 480-EDGE

P: 1 (724) 628-3050 F: 1 (724) 626-0247

Email: SUPPORT@EDGEOVENS.COM

WWW.EDGEOVENS.COM

REVISION 1.6, Jan 2021

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual ii Rev 1.6, January 2021

LEGAL INFORMATION

Copyright 2021 MF&B Restaurant System, Inc. All rights are reserved. To support the intended

use of the product described in this publication, the purchaser of the product is permitted to

copy this publication, for internal distribution only, from the media provided by MF&B

Restaurant Systems, Inc. No other use, reproduction, or distribution of the publication, or any

part of it, is permitted without written permission from MF&B Restaurant Systems, Inc. All rights

are reserved.

Caution MF&B Restaurant Systems, Inc. assumes no responsibility for any injury, or for any

illegal or incorrect use of the product, that may result from failure to use this product in

accordance with the instructions, cautions, warnings, or indications for use published in this

manual.

Software incorporated in this product is copyright protected by MF&B Restaurant Systems or

its vendors. All rights are reserved. The software is protected by United States of America

copyright laws and international treaty provisions applicable worldwide. Under such laws, the

licensee is entitled to use the copy of the software incorporated within this instrument as

intended in the operation of the product in which it is embedded. The software may not be

copied, decompiled, reverse-engineered, disassembled or otherwise reduced to human-

perceivable form. This is not a sale of the software or any copy of the software; all right, title

and ownership of the software remains with MF&B Restaurant Systems, Inc., or its vendors.

Modifications to the EDGE Oven, not expressly approved by MF&B Restaurant Systems, Inc.

may void the purchaser’s authority to operate the equipment.

For information about any EDGE Ovens product, contact MF&B Restaurant Systems, Inc.,

Technical Support or visit www.edgeovens.com.

ALL WARRANTY SERVICE MUST BE PRE-AUTHORIZED BY MF&B OR AN APPROVED

REPRESENTATIVE WITHIN THE DESTINATION REGION. ANY UNAUTHORIZED SYSTEM

DIAGNOSTIC, SERVICE FEES, TRAVEL FEES, PART AND LABOR WILL BE THE

RESPONSIBILITY OF THE APPLIANCE OWNER/OPERATOR. ADDITIONALLY, UNAUTHORIZED

SERVICE WILL VOID ALL EXPRESSED WARRANTIES ON THE PRODUCT. PLEASE CALL FOR

ASSISTANCE AND CONSULT THE WARRANTY POLICY WITHIN THE INSTALLATION AND

OPERATION INSTRUCTIONS FOR COMPLETE DETAILS.

MF&B Restaurant Systems, Inc.

119 ICMI Road

Dunbar, PA 15431-2309, USA

Tel: +00 (1) 724.628.3050

Fax: +00 (1) 724.626.0247

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual iii Rev 1.6, January 2021

Table of Contents

1. SAFETY INFORMATION ________________________________________________________________ 1

❖Purpose of this manual _____________________________________________________________________ 1

❖Service policy _____________________________________________________________________________ 1

❖Symbols _________________________________________________________________________________ 2

❖General Warnings _________________________________________________________________________ 2

❖Warnings related to the operating environment_________________________________________________ 2

❖Warnings related to electric shock ____________________________________________________________ 2

❖Warnings related to hot surfaces _____________________________________________________________ 2

❖General Cautions __________________________________________________________________________ 2

❖Electrostatic discharge (ESD)_________________________________________________________________ 3

2. General Operation (Firmware MC:33, UI:33) _______________________________________________ 4

❖Menu System Overview ____________________________________________________________________ 4

❖Basic Operation ___________________________________________________________________________ 4

❖Advanced Operation _______________________________________________________________________ 5

❖Service Operation _________________________________________________________________________ 9

3. Tools Required for Service _____________________________________________________________ 10

❖Instruments _____________________________________________________________________________ 10

❖Tools___________________________________________________________________________________ 10

❖Supplies ________________________________________________________________________________ 10

4. Sequence of operations (Modulating) ___________________________________________________ 11

❖Electrical supply__________________________________________________________________________ 11

❖MAIN POWER switch______________________________________________________________________ 11

❖Touch POWER Icon _______________________________________________________________________ 11

❖Main Fan is Powered______________________________________________________________________ 11

❖iHeat is Active, begins system test ___________________________________________________________ 12

❖iHeat control ignition/run cycle (1)___________________________________________________________ 12

❖Ignition Module Operation _________________________________________________________________ 12

❖iHeat control ignition/run cycle (2), “Recovery ON/OFF” _________________________________________ 12

❖High limit prevention **STAGE 2 OTP ________________________________________________________ 12

❖Cool down ______________________________________________________________________________ 12

5. System setup (Modulating) ____________________________________________________________ 13

❖Orifice__________________________________________________________________________________ 13

❖Air shutter ______________________________________________________________________________ 13

❖Modulated Induction blower calibration (blower replacement only) _______________________________ 13

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual iv Rev 1.6, January 2021

❖Modulating gas valve ______________________________________________________________________ 14

➢Valve Specifications ________________________________________________________________________________ 14

➢Pressure Taps_____________________________________________________________________________________ 14

➢Gas Pressures_____________________________________________________________________________________ 14

➢High-Fire Setup ___________________________________________________________________________________ 15

➢Low-Fire Setup ____________________________________________________________________________________ 16

❖Circulation fan speed (VFD Adjustment) _______________________________________________________ 16

6. Gas conversion (Modulating) __________________________________________________________ 17

Gas conversions are not covered under the warranty. However, to satisfy the warranty policy and maintain the

active status of the warranty, the gas conversion must be performed in accordance with this document. ______ 17

❖Removing the Gas Train ____________________________________________________________________ 17

❖Changing the orifice _______________________________________________________________________ 17

❖Replacing the Gas Valve ____________________________________________________________________ 17

❖Installing the Gas Train_____________________________________________________________________ 17

❖Final adjustments _________________________________________________________________________ 18

7. Troubleshooting_____________________________________________________________________ 19

❖Basics First_______________________________________________________________________________ 19

❖iHeat System_____________________________________________________________________________ 20

➢Model configuration _______________________________________________________________________________ 21

➢Service DIP switch settings __________________________________________________________________________ 21

❖G2 Control System Messages________________________________________________________________ 22

❖Troubleshooting flowcharts_________________________________________________________________ 26

➢Ignition Module, Diagnostic LEDs _____________________________________________________________________ 26

➢iHeat Diagnostic LEDs ______________________________________________________________________________ 27

➢Control System, Diagnostic Messages (1 of 2) ___________________________________________________________ 28

➢Control System, Diagnostic Messages (2 of 2) ___________________________________________________________ 29

8. Part failure verification _______________________________________________________________ 30

❖Controls and assemblies____________________________________________________________________ 30

➢Switches _________________________________________________________________________________________ 30

➢Fuses / Fuse holder ________________________________________________________________________________ 30

➢iHeat Burner Controller _____________________________________________________________________________ 30

➢Cooling Fan_______________________________________________________________________________________ 31

➢Main Valve _______________________________________________________________________________________ 31

➢Modulating valve __________________________________________________________________________________ 32

➢Main Valve Rectifying Cable _________________________________________________________________________ 33

➢Optical Flame Detector _____________________________________________________________________________ 33

➢Ignition Electrodes / Flame Rod ______________________________________________________________________ 34

➢Burner Blower Motor (Induction) _____________________________________________________________________ 34

❖Modulated Induction blower calibration (blower replacement only) ________________________________ 34

➢Transformer ______________________________________________________________________________________ 35

➢Conveyor Motor___________________________________________________________________________________ 35

➢Air Switch (3PH, 3/4HP Main Motor) __________________________________________________________________ 35

➢Thermocouple ____________________________________________________________________________________ 35

➢Variable Frequency Drive ___________________________________________________________________________ 35

➢Main Fan, Motor (3PH, 3/4HP) _______________________________________________________________________ 36

➢Main Fan, Motor (1PH, 1/3HP, 30” model)______________________________________________________________ 36

➢Main Fan, Centrifugal Switch (1PH, 1/3HP, 30” model) ____________________________________________________ 36

➢Main Fan, Capacitor (1PH, 1/3HP, 30” model) ___________________________________________________________ 36

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual v Rev 1.6, January 2021

9. Wiring Diagram _____________________________________________________________________ 37

10. Type-J thermocouple chart __________________________________________________________ 39

❖Thermocouple Worksheet__________________________________________________________________ 40

11. Part List__________________________________________________________________________ 41

12. Revision history ___________________________________________________________________ 42

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 1 Rev 1.6, January 2021

1. SAFETY INFORMATION

All service technicians of the EDGE Oven must read this summary and all warnings and cautions in the

manual.

Any internal part(s) replacement or assembly and reassembly must be performed by qualified service

personnel with a good understanding of mechanical, gas and electrical components. If difficulties arise

in locating a qualified service person, please contact your EDGE oven distributor or MF&B for

assistance in locating qualified personnel to assist you.

❖Purpose of this manual

The purpose of this manual is to assist with common troubleshooting scenarios and provide a quick

reference guide for service providers. The information within this document is not intended for

customers or the inexperienced.

❖Service policy

All repairs on products within the warrantyperiod must be PRE-AUTHORIZED by MF&B Restaurant

Systems, Inc., or an approved representative within the destinated region. Unauthorized repairs

will not be reimbursed. Modifications will void the warranty. Consult the WARRANTY POLICY

within the Installation and Operation Instructions for complete details.

If the product fails to function correctly—or if you need assistance, service, or spare parts—contact

MF&B Restaurant Systems, Inc.

Before contacting MF&B Restaurant Systems,Inc., try to duplicate the problem,and check electrical

outlets and gas supply lines to ensure that they are not causing the problem. When calling, please

be prepared to provide:

• Supplier, model number, and serial number of your product.

• Complete description of the problem.

• Complete name, address, and phone number of your facility.

• For out-of-warranty repairs or spare parts orders, a purchase order (or credit card) number.

• For parts orders, the required spare or replacement part numbers.

If your product requires warranty, or non-warranty repair service, please call MF&B Restaurant

Systems, Inc. first. A representative will assist you troubleshooting the problem and will make every

effort to solve it over the phone, avoiding potential unnecessary expenses and downtime.

In case a service call cannot be avoided, the representative will record all necessary

information and may attempt to coordinate the delivery of repair parts with a servicer in your area.

Repair parts which are not used and/or replaced parts should be returned to MF&B Restaurant

Systems, Inc.

To aid in quick service and to accommodate the servicers needs, ensure the product is accessible

and that there is ample clearance for the product to be disconnected and rotated as needed.

Due to the size of the product and the size of the product parts, a servicer may require assistance

with some handling or maneuvering or this product or product parts. Please use care and correct

lifting techniques.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 2 Rev 1.6, January 2021

❖Symbols

WARNING Indicates conditions that could lead to injury or death.

CAUTION Indicates conditions that could damage equipment or property.

CAUTION Indicates conditions that may result in a burn injury.

❖General Warnings

Warnings indicate conditions or practices that could lead to injury or death.

❖Warnings related to the operating environment

WARNING To avoid a possible explosion, do not service the product in an atmosphere where

explosive gases or fuel vapors are present. Verify all gas valves are in the OFF position and

that enough ventilation is present to evacuate any unburnt gases.

❖Warnings related to electric shock

WARNING Electricity can seriously injure or kill. Disconnect the power cord for the electrical

outlet or lock out the service disconnect before servicing this equipment. Always ensure an

earth ground is correctly connected to the equipment. When troubleshooting live electrical

circuits, use care and best practices to ensure an electrical pathway is not completed through

the body.

❖Warnings related to hot surfaces

WARNING Seriously injures may occur from contact to hot surfaces. Allow adequate cooling

time of the appliance prior to service or maintenance. In situations where handling of the

appliance or its parts in unavoidable, use thermal protective gloves to protect the hands, wear

long shirts and pants to protect arms and legs. Do not attempt to “test” the temperature of

surfaces by touch.

❖General Cautions

Cautions indicate conditions or practices that could damage the equipment or other correctly.

CAUTION To prevent possible damage, do not use sharp or hard objects on interface screen,

use only fingertips.

CAUTION Mobile RF communications equipment and high frequency LED lighting may affect

the performance of this equipment as dictated by FCC regulations.

CAUTION The power cord must be disconnected from the AC power before cleaning,

maintaining, servicing, or transporting.

CAUTION The gas supply line must be disconnected from the oven before cleaning,

maintaining, servicing, or transporting.

CAUTION There are NO parts of the oven that are designed to withstand impacts. Damage

will result.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 3 Rev 1.6, January 2021

❖Electrostatic discharge (ESD)

CAUTION Electrostatic discharge (ESD) can damage or destroy electronic components.

Handle static-sensitive components using safe practices.

CAUTION Assume that all electrical and electronic components of the appliance are

static sensitive.

Electrostatic discharge is a sudden current flowing from a charged object to another objector to ground.

Electrostatic charges can accumulate on common items such as foam drinking cups, cellophane tape,

synthetic clothing, untreated foam packaging material, and untreated plastic bags and work folders, to

name only a few.

Electronic components and assemblies, if not correctly protected against ESD, can be permanently

damaged or destroyed when near or in contact with electrostatic charged objects. When you handle

components or assemblies that are not in protective bags and you are not sure whether they are static-

sensitive, assume that they are static-sensitive and handle them accordingly.

• Always use techniques to protect personnel and equipment from electrostatic discharge.

➢ESD Wrist or Heal strap (recommended for appliance and personal safety)

• Remove static-sensitive components and assemblies from their static-shielding bags only when you

are stationary and prepared to immediately install the component.

• Remove / install static-sensitive components andassemblies only with appliance power disconnected.

• Insert and seal static-sensitive components and assemblies into their original static-shielding bags.

• Always test your ESD strap before beginning any disassembly or assembly procedures.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 4 Rev 1.6, January 2021

2. General Operation (Firmware MC:33, UI:33)

❖Menu System Overview

Additional operation features are found in the Menu System. To access this menu, touch and swipe

the display screen, Left or Right.

The menu icons are: Information, Settings, Power

- Information: The information menu is useful for viewing Alarm history, Software version, Serial

number, Build date, System voltage, Belt demand, iHeat information and for Exporting Logged data

files.

- Settings: The CUSTOMER level Settings Menu provides access to Units of Measurement, Customer

PIN setup, Belt Direction, Software Updating, and Recipe Download/Upload. This menu is protected

by the Customer PIN.

- Power: Touching the Power icon will simply place the oven into Cool Down mode, following a few

seconds of delay. The oven fans will continue to run until the oven temperature falls below 223F /

106C. Normal operation can be resumed by touching and holding the Power icon on the cooldown

screen.

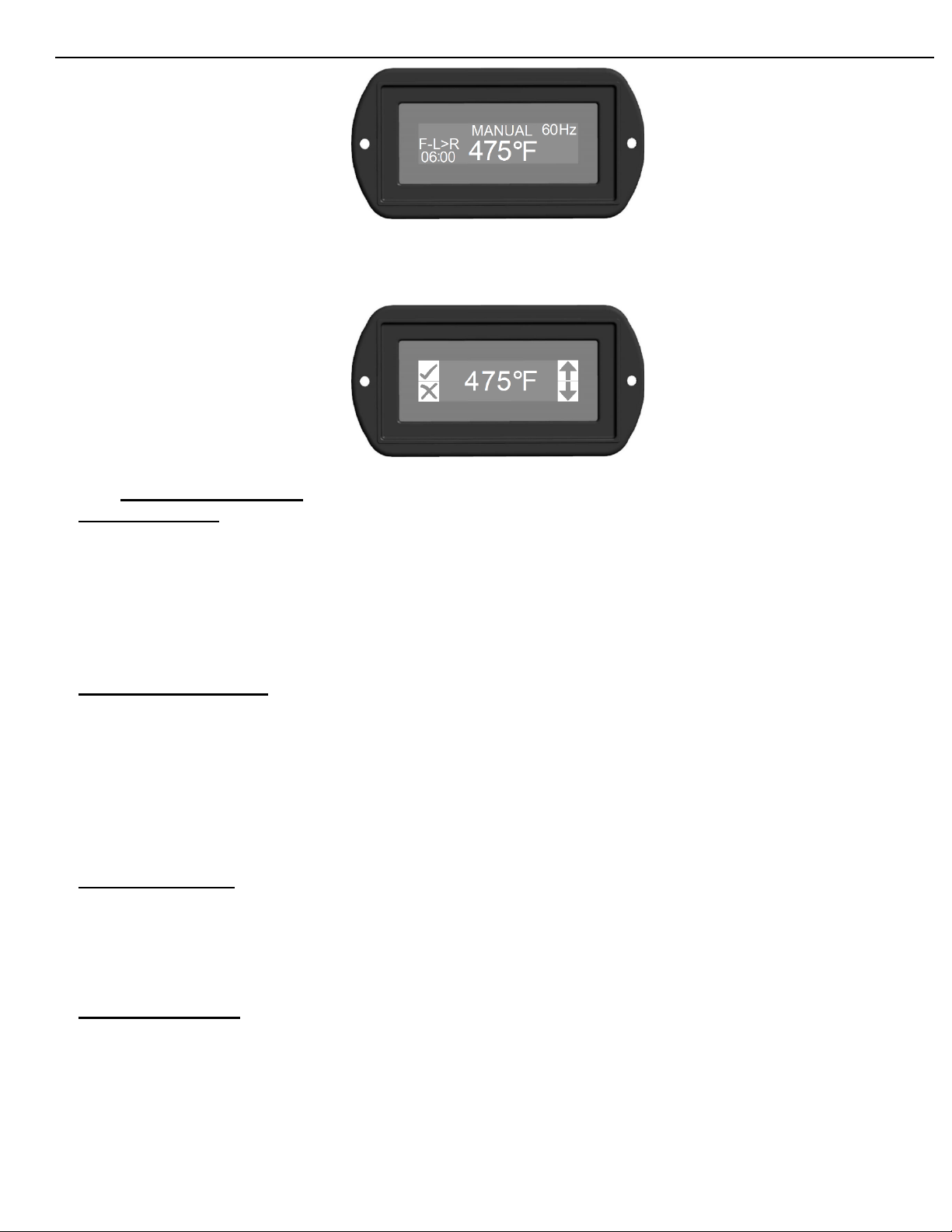

❖Basic Operation

Control Use and Cleaning: The EDGE G2 display is a “touch” screen. Do not strike or impact the

screen with hard objects. Clean with a lightly dampened cloth, do not directly spray the display with

cleaning solutions or water.

Power Up: Power up and starting the oven system is performed by turning the POWER switch to the

ON position. Allow 5 seconds for the system to power up. Touch the power icon on the display.

Operation basics: Basic oven operation is adjustment of bake Temperature adjustment, bake time

adjustment, and main Fan Speed (Hz). While in MANUAL recipe mode (see Advanced Operation for

instructions to Change Recipe), touch the temperature, the adjustment screen will appear.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 5 Rev 1.6, January 2021

Touch the UP/DOWN arrows to adjust the temperature. Touch the CHECK to accept or the X to cancel.

Repeat this method for Time and for the Fan Speed (Hz).

❖Advanced Operation

Change Recipe:

- Touch and hold the recipe namespace on the display for 1-2 seconds.

- Select the desired recipe using the UP/DOWN arrows, touch CHECK to accept.

-*Special items in this menu are:

- ‘<NEW>’ used to define a new recipe based on the current setting of ‘MANUAL’

- ‘MANUAL’ is a “test and tune” mode, allows easy adjustment of the baking parameters

CUSTOMER PIN is required (see CUSTOMER PIN).

Create a New Recipe:

- Define the new recipe in ‘MANUAL’ operation mode.

- Touch and hold the on-screen ‘MANUAL’ namespace for 1-2s.

- Select ‘<NEW>’ from the menu, CUSTOMER PIN is required.

- Define the recipe name (See Recipe NAMESPACE).

- Define/Verify Temp, Time, and Hz (60 is standard).

You may store up to 30 recipes. MANUAL mode is primarily for tuning a recipe, although unsecure,

the oven may be operated in this mode without ever defining a recipe.

Change a Recipe:

- Selecting the recipe (see Change Recipe).

- Touch and hold the recipe namespace on the display until a PIN entry screen appears.

Customer PIN is required.

- Advance through the parameters (Namespace, Temp, Time, Hz), adjustment as needed.

Deleting a Recipe:

- Selecting the recipe (see Change Recipe).

- Touch and hold the recipe namespace on the display until a PIN entry screen appears.

Customer PIN is required.

- In the Namespace adjustment, select ‘<DEL RCP>’.

- The control will default to ‘MANUAL’.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 6 Rev 1.6, January 2021

Customer PIN: (also see CHANGE PIN)

- Touch each digit to adjust from 0-9.

- Adjust the value using the UP/DOWN arrows.

- When the pin is correct, touch the CHECK to accept or X to cancel without storing.

Recipe NAMESPACE:

- UP/DOWN (Orange box) arrows adjust the value of the alpha-numeric character (Red circle)

- To select the alpha-numeric character, touch it (Red Circle). This will advance to the next

character selection.

- Namespaces may be 8 characters long.

- When you complete the Namespace, touch the CHECK (Green box).

The X will cancel without storing any changes.

Temp:

- Use the UP/DOWN arrows to change the temperature value. (350F –600F, 177C –316C)

- When the temperature is correct, touch the CHECK to accept or X to cancel without storing.

Time:

- Use the UP/DOWN arrows to change the time value (03:00 –30:00).

- When the time is correct, touch the CHECK to accept or X to cancel without storing.

Hz: - Use the UP/DOWN arrows to change the VFD Frequency Hz (52 –68).

- When the Hz adjustment is correct, touch the CHECK to accept or X to cancel without storing.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 7 Rev 1.6, January 2021

Belt Direction:

-*Belt direction AND finger pattern are a matched item. Reversing the direction of belt travel

often involves reversing the finger pattern in the oven.

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Customer PIN is required.

- Select ‘CUSTOMER’.

- Use UP/DOWN arrows to navigate to ‘BELT’, select.

- Select ‘FRONT DIR’.

- Select ‘L to R’ or ‘R to L’ to change the belt direction.

- Repeat for ‘REAR DIR’ if equipped with a split-belt system.

Units:

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Customer PIN is required.

- Select ‘CUSTOMER’.

- Select ‘DISPLAY’.

- Use UP/DOWN arrows to navigate to ‘UNITS’, select.

- Select ‘C’ or ‘F’ to change the units of measurements.

Change Pin:

-*This action will change the default Customer PIN. Default is 0000. Please remember this pin

for future use. If lost or forgotten, please contact MF&B for assistance.

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Customer PIN is required.

- Select ‘CUSTOMER’.

- Use UP/DOWN arrows to navigate to ‘PIN SET’, select.

- Touch each digit to adjust from 0-9.

- Adjust the value using the UP/DOWN arrows.

- When the pin complete, touch the CHECK to accept or X to cancel without storing.

Software Update:

-*Updates are available from https://edgeovens.com/support

- Follow the ‘Firmware Update Instructions’ which are also available for download.

Verify the software has installed correctly, see “Software Version Identification”.

Software Version Identification:

To view the current software installed in the oven:

- Swipe the control screen Left or Right to access the Menu System.

- Touch the INFORMATION icon to enter the Information Menu.

- Use UP/DOWN arrows to navigate to ‘UI VERSION’, select.

The UI version will be displayed. *If updated, this number will match the number in the “ui##”

portion of the filename you installed.

To view the MC version, return to the Information menu.

- Use UP/DOWN arrows to navigate to ‘MC VERSION’, select.

The MC version(s) will be displayed. * If updated, this number will match the number in the

“mc##” portion of the filename you installed.

If equipped with a split-belt system, MC1 and MC2 will be shown. If these numbers do not match,

please perform the software update process again.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 8 Rev 1.6, January 2021

Recipe Download:

-*This feature will save the recipes stored within the control system on a USB Thumb drive.

- Remove the USB dust cover, located near the control cabinet, cooling fan.

- Insert a USB thumb-drive in the USB connector.

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Customer PIN is required.

- Select ‘CUSTOMER’.

- Use UP/DOWN arrows to navigate to ‘SYSTEM’, select.

- Use UP/DOWN arrows to navigate to ‘RECIPE DOWNLOAD’, select.

-*The file will be transferred very quickly (< 1s). When the control screen returns to the

DOWNLOAD screen, the process is complete.

- Remove the thumb-drive and install the dust cover over the USB port.

Recipe Upload:

-*This feature will load the recipes stored on a USB Thumb drive to the control system.

- Remove the USB dust cover, located near the control cabinet, cooling fan.

- Insert a USB thumb-drive in the USB connector.

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Customer PIN is required.

- Select ‘CUSTOMER’.

- Use UP/DOWN arrows to navigate to ‘SYSTEM’, select.

- Use UP/DOWN arrows to navigate to ‘RECIPE UPLOAD’, select.

-*The file will be transferred very quickly (<1s). When the control screen returns to the UPLOAD

screen, the process is complete.

- Remove the thumb-drive and install the dust cover over the USB port.

Export:

-*This feature will export system Logfile(s) stored in the control system to a USB Thumb drive.

- Remove the USB dust cover, located near the control cabinet, cooling fan.

- Insert a USB thumb-drive in the USB connector.

- Swipe the control screen Left or Right to access the Menu System.

- Touch the INFORMATION icon to enter the Information Menu.

- Use UP/DOWN arrows to navigate to ‘EXPORT’, select.

-*The EXPORT process may take a few minutes, during this time the oven systems will stop or

be interrupted. It is important that the process complete successfully. If it does not, unplug the

oven for 30 seconds, reconnect and attempt again.

- When complete, remove the thumb-drive and install the dust cover over the USB port.

- Unplug the oven for 30 seconds before reconnecting and returning the oven to service.

file(s) mc1.eec, if the oven is a split-belt, also include mc2.eec. Please include contact

information and store location in the message body. Files can be reviewed M-F, 8AM-

5PM, EST.

*Every stack of ovens installed is supplied with an OTG, 4GB, USB drive. This device works

well with Android devices which have a USB-Micro or USB-C connection. As expected, this

device also works with PCs. iOS mobile devices do not have broad OTG support, therefore

these devices will not work with the iPhone.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 9 Rev 1.6, January 2021

❖Service Operation

Service Menu:

- Swipe the control screen Left or Right to access the Menu System.

- Touch the GEAR icon to enter the Settings Menu, Service PIN is required (6453).

- Use UP/DOWN arrows to navigate to ‘SERVICE’, select.

*Note: The service PIN supersedes the customer PIN, making both the SERVICE and the

CUSTOMER menu trees accessible.

Belt MIN/MAX Time:

-*Minimum and Maximum adjustment must be authorized by MF&B. Although the parameter IS

adjustable, this does not ensure the system is capable of achieving the set value. There are

physical limitations of the conveyor system and the motors. This must not be comprimised.

- Enter Service Menu.

- Use UP/DOWN arrows to navigate to ‘BELT’, select.

- Use UP/DOWN arrows to navigate to ‘TIME MIN’ or ‘TIME MAX’, select.

- Adjust the value using the UP/DOWN arrows,

- Touch the CHECK to accept or X to cancel without storing.

Temp MIN/MAX Time:

-*Minimum and Maximum adjustment must be authorized by MF&B. Although the parameter IS

adjustable, this does not ensure the modulating combustion system is capable of achieving the

set value. 350°F is the minimum assured set-point. 600°F is the maximum allowable operating

temperature, this must NEVER be adjusted higher.

- Enter Service Menu.

- Use UP/DOWN arrows to navigate to ‘TEMP’, select.

- Use UP/DOWN arrows to navigate to ‘TIME MIN’ or ‘TIME MAX’, select.

- Adjust the value using the UP/DOWN arrows,

- Touch the CHECK to accept or X to cancel without storing.

System events which have generated an error message ARE logged events. Diagnosis of systems

errors is to be performed by means of Logfile review. Please use the EXPORT function of the oven

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 10 Rev 1.6, January 2021

3. Tools Required for Service

These are the basic tools requirements to handle most of the repairs in this manual.

❖Instruments

> Water Manometer. Best choice: Dwyer Series 1213-15

> Digital Multimeter(s). Choices vary: (low; mid; high) Craftsman 82008;

Amprobe AM-570, Fluke 87-5

- V (AC and DC)

- A, mA, μA (AC and DC)

- Ohm / Ω

- CAP / /

❖Tools

> #2 Phillips screwdrivers, 1.5” and 4” shaft

> Right angle, offset Phillips screwdriver

> 1/8” Standard screwdriver

> 2x Needle nose pliers

> Wire snips, strippers, crimpers

> Socket Set: 1/4”, 5/16”, 3/8”, 7/16”, 1/2”, 9/16”, and 12” of extension

> Wrench Set: 1/4”, 5/16”, 3/8”, 7/16”, 1/2”, 9/16”, 11/16”

> 2x 12” Pipe wrenches

> 1x 12” Adjustable wrench

> SAE Allen wrench set

> Heavy duty rivet gun for structural repairs. Best economical choice: Pittsburgh 66422

> Dead Blow hammer

> Wheel Puller for fan blade removal

❖Supplies

> TFE Pipe sealant

> 220/320 sandpaper or emery cloth

> Leak detector solution (soap water solution)

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 11 Rev 1.6, January 2021

4. Sequence of operations (Modulating)

❖Electrical supply

EDGE, North America, gas fired ovens operate on 120VAC/60Hz, single phase power.

The standard power configuration is a 3-wire supply:

•1 supply line, 1 neutral and 1 ground.

For all wiring configurations, the voltage, when measured from Line to Neutral, should never exceed

132V. Ground to Neutral should not exceed 2VAC.

*1PH, 1/3HP Main Fan systems utilize a Centrifugal Switch for Safety / Proof of Air. (E1830)

*3PH, 3/4HP Main Fan systems utilize a VFD and an Air Switch for Safety / Proof of Air.

These Proof or Air switches will be referred to as the “Safety Switch” within this chapter.

❖MAIN POWER switch

Closing the MAIN POWER switch energizes:

✓The 24VDC SMPS

✓The 24VDC supplies power to the G2 Control System

✓24VDC is supplied to the “Sense” (P10.5) of the G2 Control System

❖Touch POWER Icon

Touching the POWER Icon energizes:

✓K2 is energized (P10.2), as well as the iHeat

✓Control System quickly evaluates the state of the Air Switch; If Air Switch is closed, a system alarm

is triggered

✓K1 Relay is energized (P10.1), powering the Cooling Fan, VFD or 1PH Main Motor and the Cool

Down circuit

✓Communication is established with the VFD

✓Control system evaluates state of the Air Switch; If Air Switch is open, a system alarm is triggered

✓Air Switch (or Centrifugal in 1PH motor systems) feed Line voltage to Over-Temp Protective

Thermostat which supplies 24VAC transformer

✓24VAC is supplied to P9.6. Control system powers combustion system through P9.3 -> iHeat

RELAY COM

✓The conveyor system is energized

❖Main Fan is Powered

✓Cavity pressure reaches 0.15” WC or 1PH Main Motor spins to 1250RPM or greater, safety switch

closes

✓Safety Switch powers 24VAC transformer and iHeat 120V (L)

✓24VAC Transformer powers G2 Control, Burner Voltage (P9.6)

✓iHeat RELAY COM is powered by G2 Control, Burner Voltage output (P9.3)

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 12 Rev 1.6, January 2021

❖iHeat is Active, begins system test

✓iHeat spins up the induction blower and verifies TACH feedback (absence of TACH results in brief

Blower full ON state and a failed verification (not within ±10% of expected TACH feedback)

✓iHeat verifies 4-20mA control signal from the control system (must be > 2mA)

✓iHeat performs self-check on the VALVE output (square wave detection)

✓iHeat begins 30s pre-purge timer, following which, iHeat begins Run Cycle

❖iHeat control ignition/run cycle (1)

✓Pre-purge period expires, iHeat RELAY N.O./COM contacts are closed, passing 24VAC

✓24VAC from RELAY N.O. supplies Ignition Module (FS/SI) and Optical Detector (FS)

✓iHeat valve output (0-10VDC) and MOTOR L/N output to induction blower are modulated according

to control signal

❖Ignition Module Operation

✓FS/SI performs verification of “No Flame” prior to ignition trial

✓FS/SI sends 24VAC from valve output to Honeywell valve cable (output of cable is 24VDC)

✓FS/SI excites electrodes for a period of 4s

✓If flame is detected, valve output remains powered, system is now in normal operation mode

✓If flame is not detected, 30s inter-purge delay followed by 2nd trial, lock-out after 3rd trial (112s)

❖iHeat control ignition/run cycle (2), “Recovery ON/OFF”

✓iHeat modulates induction motor and valve according to control signal

✓If control signal reaches and maintains 4mA for 45 seconds, an over-temperature situation is

presumed: RELAY N.O. will open, deenergizing the ignition system until control loop signal is above

10.2mA *(gas pressure out of adjustment) **STAGE 1 OTP

✓If control signal falls below 2mA, RELAY N.O. willopen until power cycle occurs *(lost controlsignal)

✓If Blower Motor TACH signal falls ±10% of expected, RELAY N.O. will open until power cycle occurs

❖High limit prevention **STAGE 2 OTP

The high limit prevention circuit will shut down the combustion system (P9.3) if the bake chamber

temperature exceeds 650°F / 343°C. This will also occur if the thermocouple is disconnected or has a

break. **STAGE 3 OTP, a 700°F / 371°C Manual Reset Thermostatic switch is installed in the back of

the oven. This thermostatic switch, when opened, will remove power from the combustion system.

❖Cool down

When the bake chamber temperature exceeds 225°F / 107°C, the cool down circuit will be triggered.

Relay K1 (P10.1) will be held ON until the temperature falls to 223°F / 106°C. During this time, the

Oven Control will display the temperature, Cool Down Icon, and a Power Icon. The cooling fan and

Main Motor fan will remain ON during the cool down process.

Before performing any service tasks on the oven, be sure the power and gas supply have been

disconnected. Always make good notes and take photos to ensure correct re-assembly.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 13 Rev 1.6, January 2021

5. System setup (Modulating)

❖Orifice

The orifice meters the gas flow to the burner. The oven will be shipped from the factory with the correct

orifice size for the specific oven model and gas type. When converting between gas types, see Chapter

6, Gas conversion, in this manual.

❖Air shutter

The air shutter allows the correct amount of combustion air to be drawn into the blower and delivered

to the burner. The shutter is factory set to the correct opening for the oven model and type of gas. A

¼" wrench or socket is required to loosen and adjust the Air Shuttler.

Model Air Shutter Settings

EDGE1830/2440/2460/3240/3260 G20/NAT - 1.25, G30/G31/LPG - 1.5

EDGE3860/3270/4460 G20/G30/G31(ALL TYPES) - 2.5

❖Modulated Induction blower calibration (blower replacement only)

The oven is delivered with the induction blower pre-calibrated to the iHeat. Calibration is only performed

IF the Induction blower motor has been replaced. The calibration process is as follows:

•Turn the oven off.

•Adjust the air shutter to the correct setting per gas type and model.

•Note which iHeat DIP is currently ON. Turn the DIP OFF and the turn iHeat DIP 8 ON: i.e. 1-

7 OFF; 8 ON.

•With the gas supply valve remaining in the closed position, power on the oven.

•The iHeat control module will begin to “learn” the combustion blower. During this calibration

process, the lights on the control board will illuminate in the following manner: FLASH –flash, T-

INPUT –off, VALVE –off, BLOWER –on, 24V/CAL –flash. The calibration process may take

approximately 8 minutes but can be longer. If the iHeat is trying to calibrate, allow it to finish.

EDGE-1830 EDGE-2440 / EDGE-3240 / EDGE-2460 / EDGE-3260 / EDGE-3860 / EDGE-4460 / EDGE-3270

Original Service Manual 14 Rev 1.6, January 2021

A calibration failure will result in the BLOWER LED flashing. A successful calibration is indicated

by continuous illumination of the 24V/CAL light. When the blower is calibrated, the following steps

must be done to place the oven in the normal usage mode:

•Turn the oven off.

•Move the iHeat DIP 8 OFF, return the previously noted iHeat DIP to ON. If you failed to make a

note: (See Chapter 6, Final adjustments for DIP settings.)

•Return oven to service.

❖Modulating gas valve

➢Valve Specifications

Maximum inlet pressure: 37 mbar / 14.8 inW.C.

Maximum BTU rating: 200,000

Pressure drop across valve: as much as 1.5 inW.C.

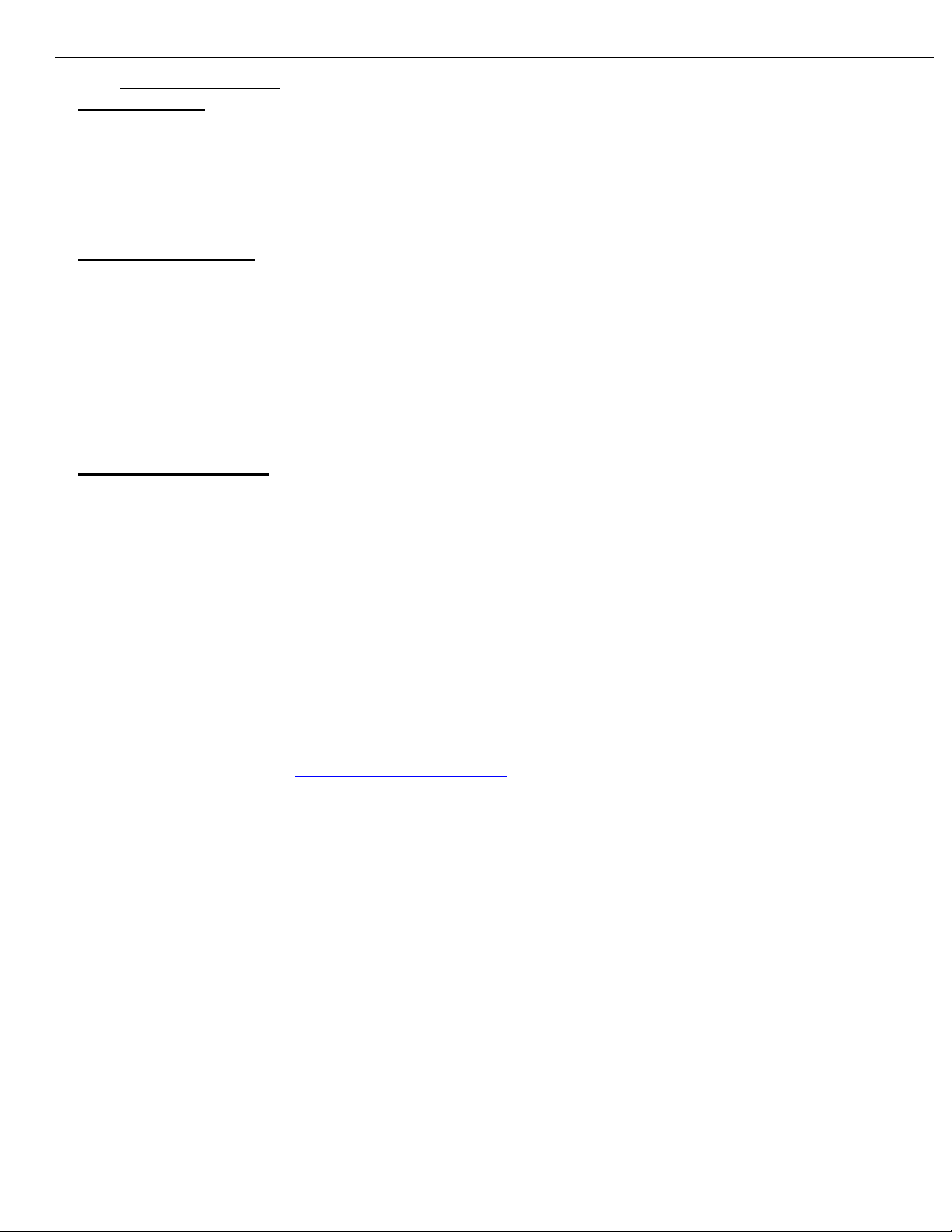

➢Pressure Taps

Located beneath the white regulation solenoid (see illustration above for tap identification). To use,

loosen the center screw within the tap, and make 2 turns CCW with a standard 1/8” screwdriver. Slip

manometer hose directly over the tap. DO NOT remove the screw or attempt to install any fittings.

The INLET PRESSURE TAP is used for measuring supply or “street” pressure to the oven.

The MANIFOLD PRESSURE TAP is used while setting the High-Fire and Low-Fire press adjustments

which follow.

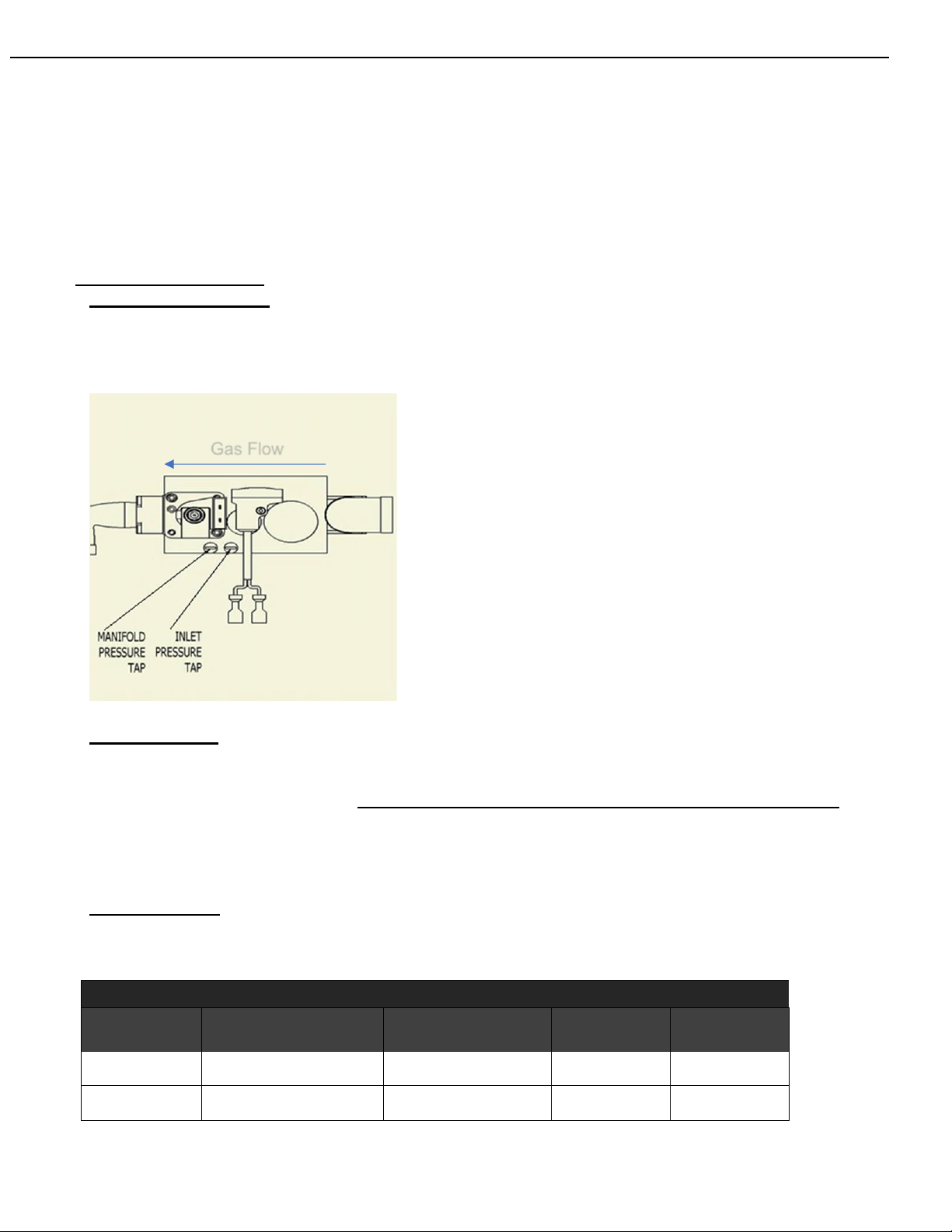

➢Gas Pressures

Do not exceed the valve ratings! Use regulators at each oven as needed. Inlet pressure in to be

measured with ALL gas appliances ON and firing.

GAS TYPE

MAXIMUM INLET

(VALVE RATING)

RECOMMENDED

INLET

HIGH-FIRE

SET-POINT

LOW-FIRE

SET-POINT

NATURAL

14.8 inW.C.

6 –9 inW.C.

4.5 inW.C.

0.2 inW.C.

LPG

14.8 inW.C.

11 –13 inW.C.

10 inW.C.

0.3 inW.C.

Gas Flow

Other manuals for EDGE-1830

4

This manual suits for next models

8

Table of contents

Other Edge Oven manuals