Edic COUNTER STRIKE 5 Owner's manual

MODEL:

500M

PROFESSIONAL

DISINFECTING SPRAYER

OWNER’S/OPERATOR’S MANUAL

PROUDLY DESIGNED AND MANUFACTURED BY

WWW.EDIC-USA.COM

Revised 6-15-20

5

COUNTER

STRIKE

2

UNPACKING YOUR NEW 500M: When your package is delivered, check the carton carefully for signs of rough

handling. If your 500M is damaged, notify the carrier immediately and request an inspection. Be sure to keep the car-

ton, packing inserts, packing lists and carrier’s receipt until the inspector has veried your claim.

EDIC’s liability ceases when the carrier picks up the shipment. However, our customer service sta will be happy to

furnish any information needed in connection with the claim and will attempt to expedite a resolution.

PLEASE READ BEFORE OPERATING YOUR NEW 500M:

Read the manual carefully and completely before attempting to operate the unit. is manual has important informa-

tion for the use and safe operation of the machine. Keep this manual handy at all times.

is equipment has been engineered and manufactured to provide excellent performance and service. To ensure that

your equipment will continue to perform as intended:

• Maintain equipment regularly- following the suggested maintenance schedule provided.

• Use only original EDIC parts when servicing.

• Operate equipment with care.

If additional information is needed, please contact:

EDIC

800-338-3342

3

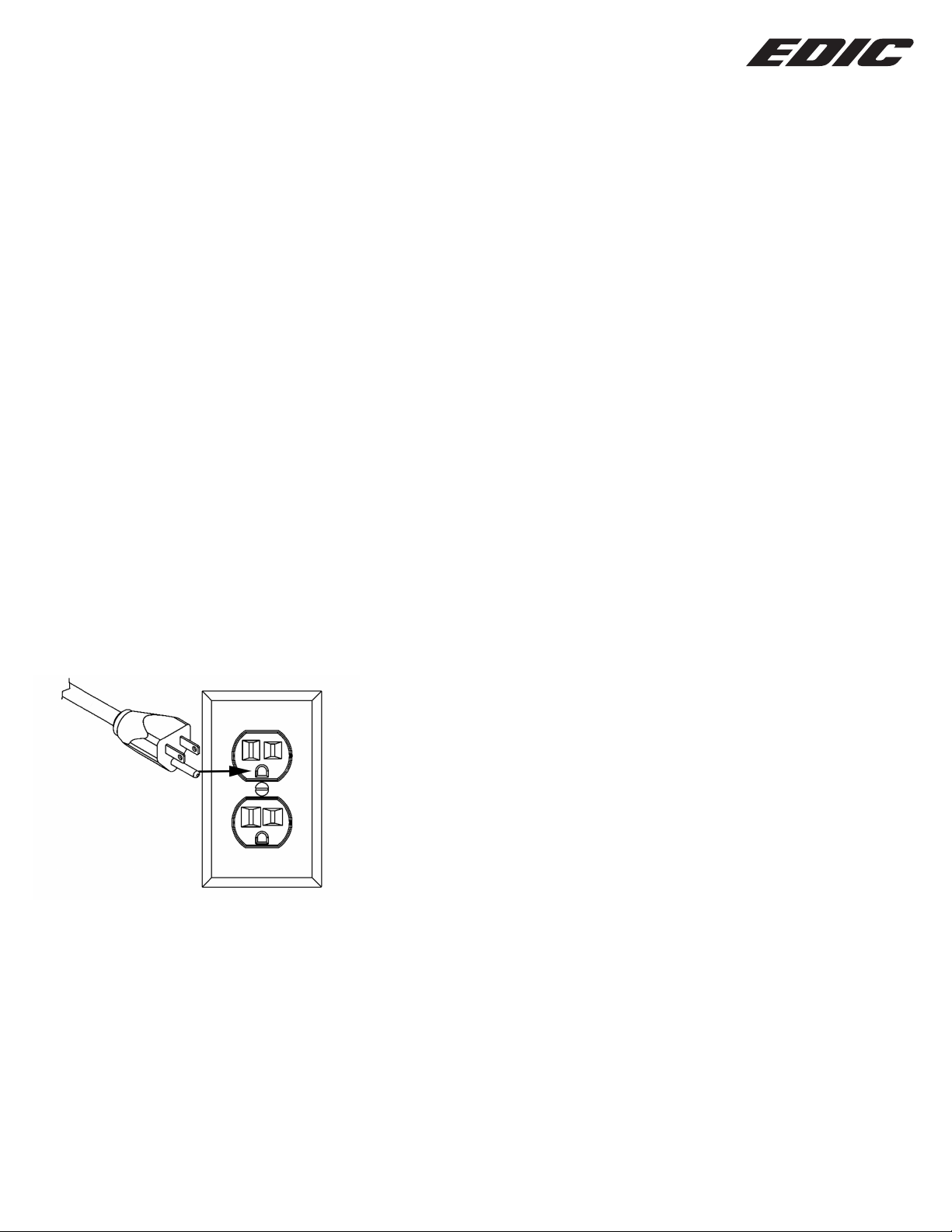

ELECTRICAL - 115 Volt

Model: 500M

is machine is designed to operate on a standard 15 amp, 120 volt, 60 Hz, AC circuit. Voltages below 105 volt AC or

above 125 volts AC could cause serious damage to the motor.

GROUNDING INSTRUCTIONS FOR 115VOLT:

is piece of equipment must be grounded. Should an electrical malfunction occur, grounding provides a path of least

resistance for electrical current- reducing the risk of electric shock. is piece of equipment is furnished with a cord that

has a grounding conductor and grounding plug. e grounded plug must only be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

WARNING:

Connecting the equipment to an improperly grounded outlet can result in an increased risk of electric shock. A qualified

electrician should be consulted if you are unsure that the outlet is properly grounded. Do not modify the plug provided

with the equipment. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

is appliance is designed for use on a 120-volt circuit. e grounding plug provided looks like the plug illustrated in

Figure 1. Replace the power cord if the grounding pin is damaged or broken.

Extension cords connected to this machine should be 14 gauge, three-wire cords with three-prong plugs and outlets. DO

NOT use extension cords more than 25 feet (7.6 m) long.

4

NOTICE RE OWNER’S MANUAL

• Prior to use, read and understand the Owner’s Manual completely. It is the owner’s responsibility to ensure

that each operator of the 500M (“equipment”) has read and understands the Owner’s Manual.

• Use this equipment only in accordance with the Owner’s Manual. Familiarize yourself with all components

prior to use. Check and test completed assembly as directed in this Owner’s Manual. Failure to read and follow the

Owner’s Manual is a misuse of the equipment.

WARNINGS

INTENDED USE

• is equipment is intended for use in commercial operations by personnel trained and experienced in the safe

use of commercial cleaning compounds, including those that may be classied as hazardous materials and high

pressure equipment.

• e equipment should never be used in a hazardous environment. It should never be used in an area containing

volatile chemicals, or any area containing volatile or explosive levels of gas, vapor or particulates.

• Do not alter or modify the equipment, including the design of the 500M and sprayer. Alterations or modications

void your equipment’s Limited Warranty and may create safety hazards.

GENERAL PRECAUTIONS

• Read and fully understand the Owner’s Manual prior to use.

• Obtain, read, and fully understand the product labels and warnings of all commercial chemical products, as well

as the Safety Data Sheets (SDS) for those products prior to using them with this equipment.

EQUIPMENT MISUSE HAZARD

• Use the equipment only for its intended use as directed in this Owner’s Manual.

• Only trained and qualied personnel should operate the equipment.

• Do not operate the equipment while fatigued or under the inuence of drugs or alcohol.

• Keep equipment and commercial chemical products away from children and pets.

• Do not turn on power to sprayer until ready to spray in order to avoid unintentional spray release. Turn o all

5

equipment when not in use.

• Do not place body parts or any foreign objects into, or in front of, any opening of the sprayer.

• Never operate the equipment if it has been damaged or if it is not working properly.

• Serious injury could occur from chemical leaks if sprayer is improperly assembled.

• Always hold the sprayer rmly when spraying at higher pressures to prevent sprayer from whipping, acciden-

tal self spraying, or other injury. Keep good footing and balance at all times.

• Check equipment daily and prior to each use. Repair or replace worn or damaged parts immediately with

genuine replacement parts from EDIC only.

• Store equipment in a cool, dry place, away from heat and open ames. Do not expose to extreme tempera-

tures.

• Directly spray only toward appropriate surfaces and never aim the sprayer at yourself or another person.

FIRE, EXPLOSION AND ELECTRIC SHOCK HAZARD AND ELECTRICAL SAFETY

• Use and clean equipment only in well-ventilated area.

• Never spray a ammable chemical.

• Keep spray area free of debris, including solvents, rags, gasoline or any ammable chemicals.

• Keep a working re extinguisher in the work area.

• Turn o and unplug the equipment whenever leaving the equipment unattended.

• Flush the equipment oen, including aer each use, before storing, and when switching chemicals.

PERSONAL PROTECTIVE EQUIPMENT

• Always use appropriate personal protective equipment (PPE) when operating the equipment, or when in the

work area, to help prevent serious injury. Refer to chemical product’s SDS for those products for the proper PPE

required for each cleaning agent utilized.

• Use of fully enclosed eyewear protections, such as goggles, is recommended when using this equipment.

• Refer to commercial chemical product’s SDS for any additional PPE recommended for use with the cleaning

products being utilized.

This manual suits for next models

1

Table of contents