M161 REV. B

6

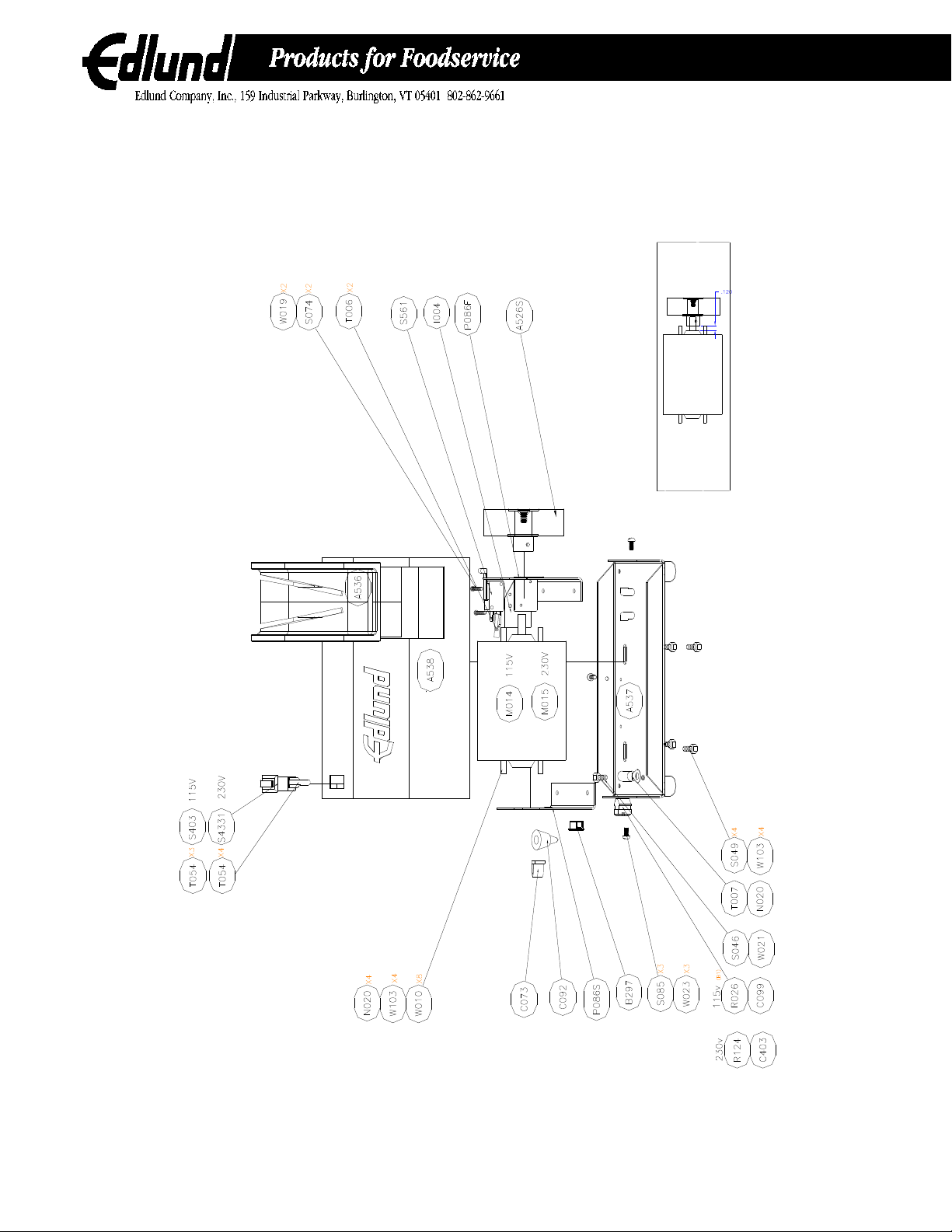

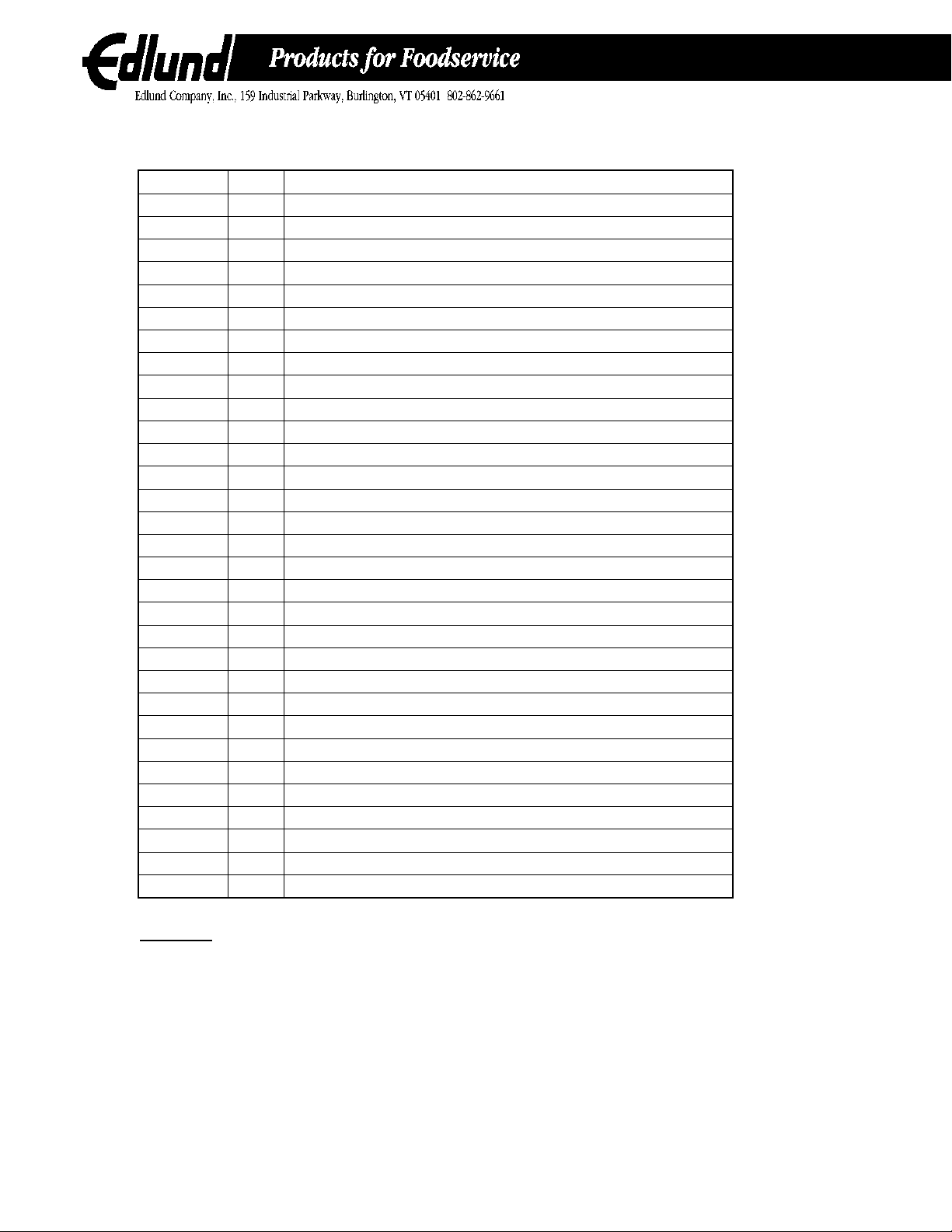

PARTS LIST

PART # QTY DESCRIPTION

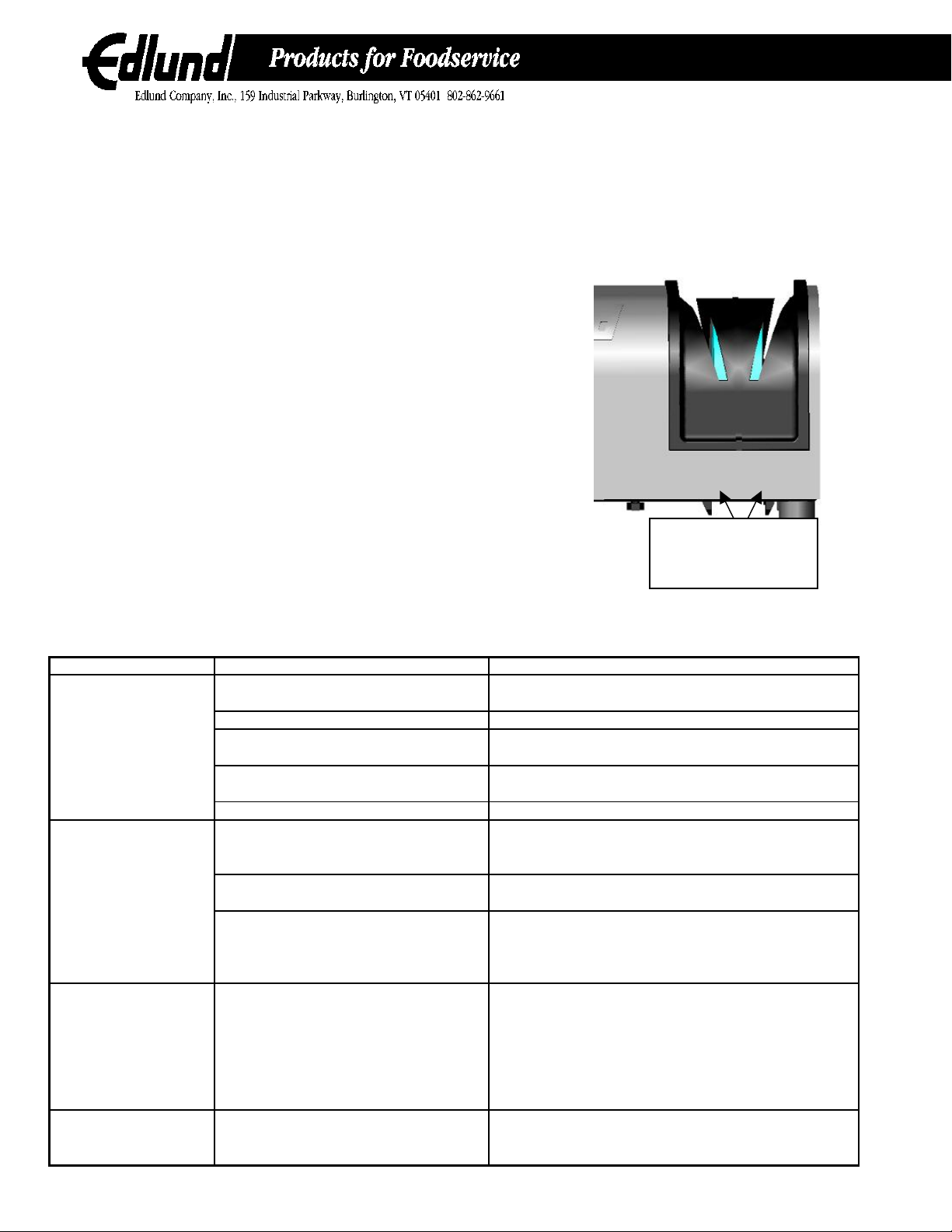

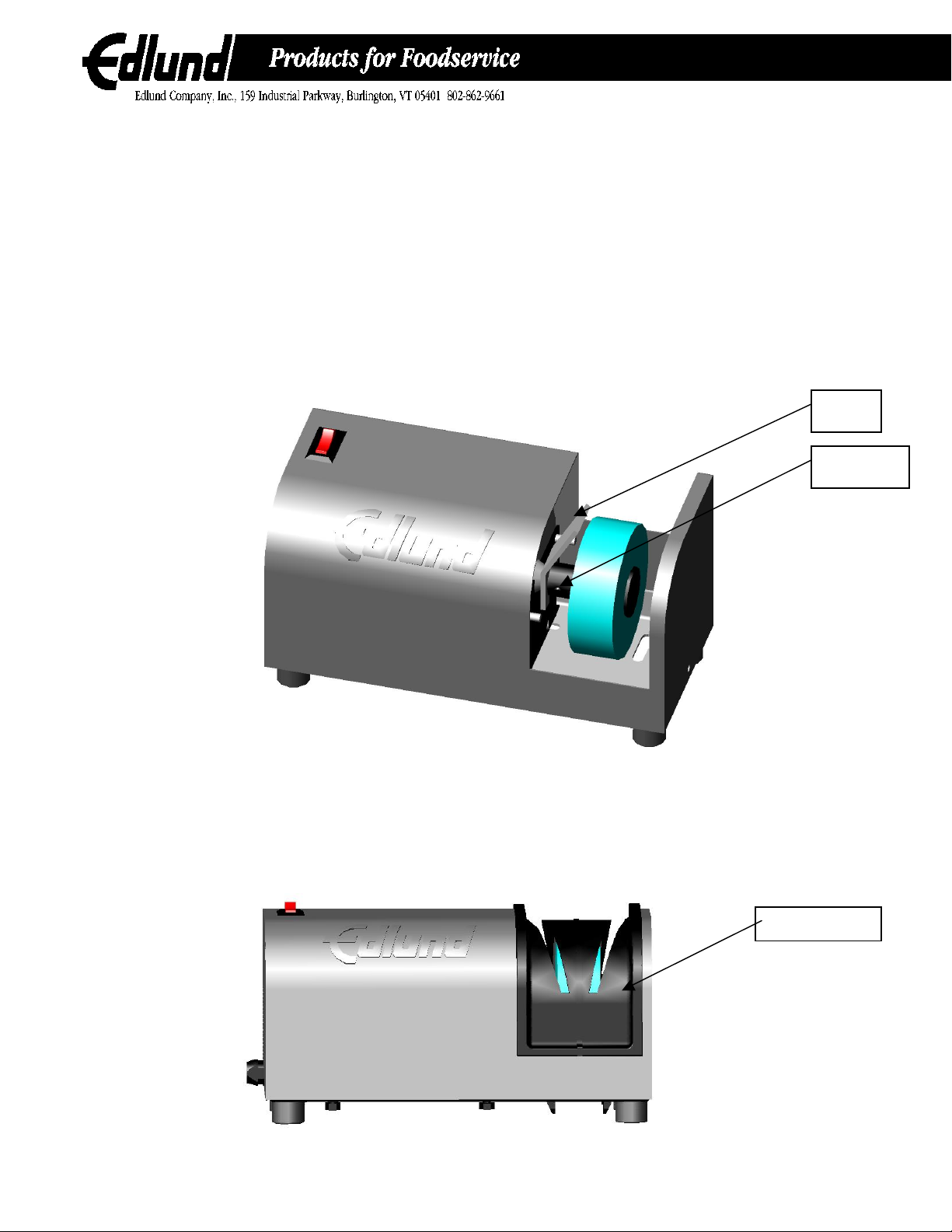

A526 1 ASSEMBLY, #395/401 GRIND WHEEL

A536 1 ASSEMBLY, 401 SNAP IN KNIFE GUIDE

A537 1 ASSEMBLY, #401 SNAP IN BASE

A538 1 WELDMENT, #401 SNAP IN COVER

B297 1 BUSHING,1/2"SNAP,3/8"ID

C073 1 CLAMP, #201 CABLE

C092 1 CONNECTOR, #390/395/CH-5000 LEAD

C099 1 CORD SET, REGULAR 7', 18/3, GRAY

I004 1 INSULATOR, ECO MICRO SWITCH PAD

M014 1 MOTOR, 395/401 115V #7163-7783

M015 1 MOTOR, 395/401 230V

N019 4 NUT, 10-32 PLATED HEX

N020 1 NUT, 10-32 S/S HEX

P086F 1 PLATE, 401 S/S MOTOR MTG. FRONT

P086S 1 PLATE, 401 S/S MOTOR MTG. BACK

R023 1 WASHER, #8 S/S LOCK

S049 4 SCREW, 10-32 X 3/8 S/S HEX HEAD

S074 2 SCREW, 4-40 X 5/8 BRASS RHM

S085 3 SCREW, 8-32 X 1/4 S/S RHM

S403 1 SWITCH, CH-350 USA LIGHTED ROCKER

S4331 1 SWITCH, 230V

S561 1 SWITCH, 401 INTERLOCK MICRO

T006 2 TERMINAL, #203/266 FEMALE, 3/16

T007 1 TERMINAL, ECO ROUND TONGUE

T054 (3)(4) TERMINAL, 1/4" FEMALE FULLY INS

W010 8 WASHER, #10 S/S FLAT

W017 4 WASHER, #10 EXT. TOOTH LOCK, PTD

W019 2 WASHER, #4 INTRL TOOTH LOCK, S/S

W023 3 WASHER, #8 S/S LOCK

W103 4 WASHER, #10 S/S INTERNAL TOOTH LOCK

W105 1 WASHER, 1/4" S/S FLA

Warranties:The Edlund Company warrants these products to be free from defects in material and

workmanship for a period of one year from date of purchase. The company’s obligation under this

warranty is limited to repairing or replacing without charge any parts or parts found to be defective under

normal use. It is the responsibility of the purchaser to return the entire unit to the factory or a factory

service branch, transportation charges prepaid. This warranty does no cover parts that must be replaced

under normal use, including knives and drive gears on can openers. The company authorizes no other

warranty, written or verbal. Carrier is responsible for merchandise in transit to you.