efacec NORMAFIX User manual

NORMAFIX

1

NORMAFIX

Modular Distribution Switchgear

INSTRUCTIONS

Nº453030007

NORMAFIX

1

SECURITY INSTRUCTIONS

Read this manual carefully before proceeding with any handling, operation and

maintenance action. Failure to follow safety recommendations, could lead to serious

physical and material injury.

This manual should be accessible to all people involved in the installation, operation and

maintenance of the equipment.

The equipments described in this manual were designed and tested to operate within their

nominal values. Use outside this range may result in malfunction, and could cause serious

physical and material injury.

The cells and switches are equipped with safety interlocks making its use simple and

secure. Do not force them.

This equipment can be remotely controlled and contains live and mechanical parts that

move at high speed.

In the cells with circuit breakers, never perform checks on the circuit-breaker while it is

closed or with the closing springs charged. The circuit breaker must be open and the

closing springs discharged. (See the DIVAC Instruction Manual)

NORMAFIX

2

TABLE OF CONTENTS

1. GENERAL TECHNICAL CHARACTERISTICS...................................................................................................... 3

2. MODULAR UNITS............................................................................................................................................... 4

2.1 IS Cubicle ................................................................................................................................................... 4

2.2 CIS Cubicle ................................................................................................................................................. 4

2.3 DC Cubicle.................................................................................................................................................. 5

2.4 M Cubicle.................................................................................................................................................... 5

2.5 SBM Cubicle ............................................................................................................................................... 5

2.6 CD Cubicle.................................................................................................................................................. 6

2.7 TT Cubicle.................................................................................................................................................. 6

2.8 DB Cubicle.................................................................................................................................................. 6

3. OVERVIEW OF MODULAR UNITS ..................................................................................................................... 7

4. OPERATING MECHANISMS.............................................................................................................................. 10

5. SF6 SYSTEM ..................................................................................................................................................... 12

6. DISPATCH ........................................................................................................................................................ 13

7. RECEPTION...................................................................................................................................................... 13

8. INSTALLATION ................................................................................................................................................ 14

8.1 Preparing the floor ................................................................................................................................. 14

8.2 Unpacking................................................................................................................................................. 14

8.3 Installation on site.................................................................................................................................. 14

8.4 Panels assembly ...................................................................................................................................... 15

8.5 Fastening the panels to the floor......................................................................................................... 15

8.6 Connection of the earthing circuit ...................................................................................................... 16

8.7 Busbar connection .................................................................................................................................. 16

8.8 Cables connection .................................................................................................................................. 17

8.9 Toroidal transformers Cable Connections .......................................................................................... 19

8.10 Assembling of fuses .............................................................................................................................. 19

8.11 Definition of fuses ................................................................................................................................ 20

9. START-UP ........................................................................................................................................................ 20

9.1 Essential checking .................................................................................................................................. 20

9.2 Switchgear operations ........................................................................................................................... 20

9.3 Voltage feeding....................................................................................................................................... 20

9.4 Live cables control ................................................................................................................................. 21

9.5 Phase agreement control in “Incoming” panels ................................................................................ 21

9.6 Busbar feeding and fuses protection................................................................................................... 21

10. EXPLOITATION .............................................................................................................................................. 22

10.1. Operating mechanism operation ...................................................................................................... 22

10.2. Earth Switch opening operation (CI1 and CI2) ............................................................................... 22

10.3. Earth Switch closing operation (CI1 and CI2) ................................................................................. 23

10.4. Switch closing operation (CI1 or CS1).............................................................................................. 23

10.5. Switch opening operation (CI1 or CS1) ............................................................................................ 24

10.6. Switch closing operation and recharge for opening (CI2 - transformer protection function) 24

10.7. Switch opening operation (CI2 - transformer protection function)............................................ 25

10.8. Closing and opening operations (Vacuum Circuit Breaker, CDV mechanism) ........................... 25

10.9. Closing and opening operations (SF6 Circuit Breaker, CLR mechanism) ................................... 26

12. REPLACEMENT .............................................................................................................................................. 27

12.1 Replacing the Voltage Signalization lamps ...................................................................................... 27

12.2 Fuse replacement ................................................................................................................................. 27

12.3 Removing the automatic switch disconnector of the cubicle ....................................................... 28

12.4 Removing cover mechanism................................................................................................................ 29

13. SPARE PARTS ................................................................................................................................................ 29

NORMAFIX

3

1. GENERAL TECHNICAL CHARACTERISTICS

Rated voltage

12 kV

17,5 kV

24 kV

36 kV

Insulation level

- Power frequency (Hz - 1min)

28 kV

38 kV

50 kV

70 kV

-Lightning impulse (1,2 / 50s)

75 kV

95 kV

125 kV

170 kV

Rated current

Busbar

630 A

630 A

630 A

630 A

Incoming/Outgoing

400 A

630 A

400 A

630 A

400 A

630 A

400 A

630 A

Fuses Protection

200 A

200 A

200 A

200 A

Circuit-Breaker Protection

630 A

630 A

630 A

630 A

Rated short-time current

16 (3s) kA

20 (1s) kA

16 (3s) kA

20 (1s) kA

16 (3s) kA

20 (1s) kA

16 (3s) kA

Making capacity

40 kA

50 kA

40 kA

50 kA

40 kA

50 kA

40 kA

Frequency

50 Hz

50 Hz

50 Hz

50 Hz

Internal Arc (IAC A-FL)

16 kA (1s)

16 kA (1s)

16 kA (1s)

16 kA (1s)

Ambient temperature

-5 a 40 ºC

-5 a 40 ºC

-5 a 40 ºC

-5 a 40 ºC

Rated filling pressure (20ºC)

0,3 bar rel

0,3 bar rel

0,3 bar rel

0,3 bar rel

Category of loss of service continuity

LSC 2A (according to CEI 62271-200)

Class partition

PI (according to CEI 62271-200)

Degrees of protection (CEI 60529 e EN 50102)

IP65 (medium voltage compartment)

IP3XC (mechanism compartment)

IP 3XC (cable compartment)

IK09 (medium voltage compartment)

IK08

Standard colour

RAL 7035

Panels dimensions up to 24 kV

Panel type

Width (mm)

Height** (mm)

Depth*(mm)

Weight (kg)

IS

375

1575 (+400)

860 (+110)

100

CIS

375

1575 (+400)

860 (+110)

110

DC

750***

1575 (+400)

860 (+110)

355

CD

375

1575 (+400)

860 (+110)

80

M

750

1575 (+400)

860 (+30)

175

SBM

750

1575 (+400)

860 (+110)

200

TT

500

1575 (+400)

860 (+110)

150

DB

750

1575 (+400)

860 (+110)

460

* Depth of 860 mm for the standard cubicle, adding 110 mm for the operating mechanism.

** Height of 1575 mm for the standard cubicle, adding 400 mm for the top compartment.

*** Width of 750 mm for the standard cubicle, adding 250mm if cubicle is equipped with voltage

transformers.

NORMAFIX

4

Panels dimensions of 36 kV

Panel type

Width (mm)

Height** (mm)

Depth*(mm)

Weight (kg)

IS

600

2010 (+400)

1155 (+110)

275

CIS

600

2010 (+400)

1155 (+110)

300

DC

1200

2010 (+400)

1155 (+110)

900

CD

600

2010 (+400)

1155 (+110)

245

M

1200

2010 (+400)

1155 (+30)

470

SBM

1200

2010 (+400)

1155 (+110)

560

TT

600

2010 (+400)

1155 (+110)

420

DB

1200

2010 (+400)

1155 (+110)

1000

* Depth of 1155 mm for the standard cubicle, adding 110 mm for the operating mechanism.

** Height of 2010 mm for the standard cubicle, adding 400 mm for the top compartment.

2. MODULAR UNITS

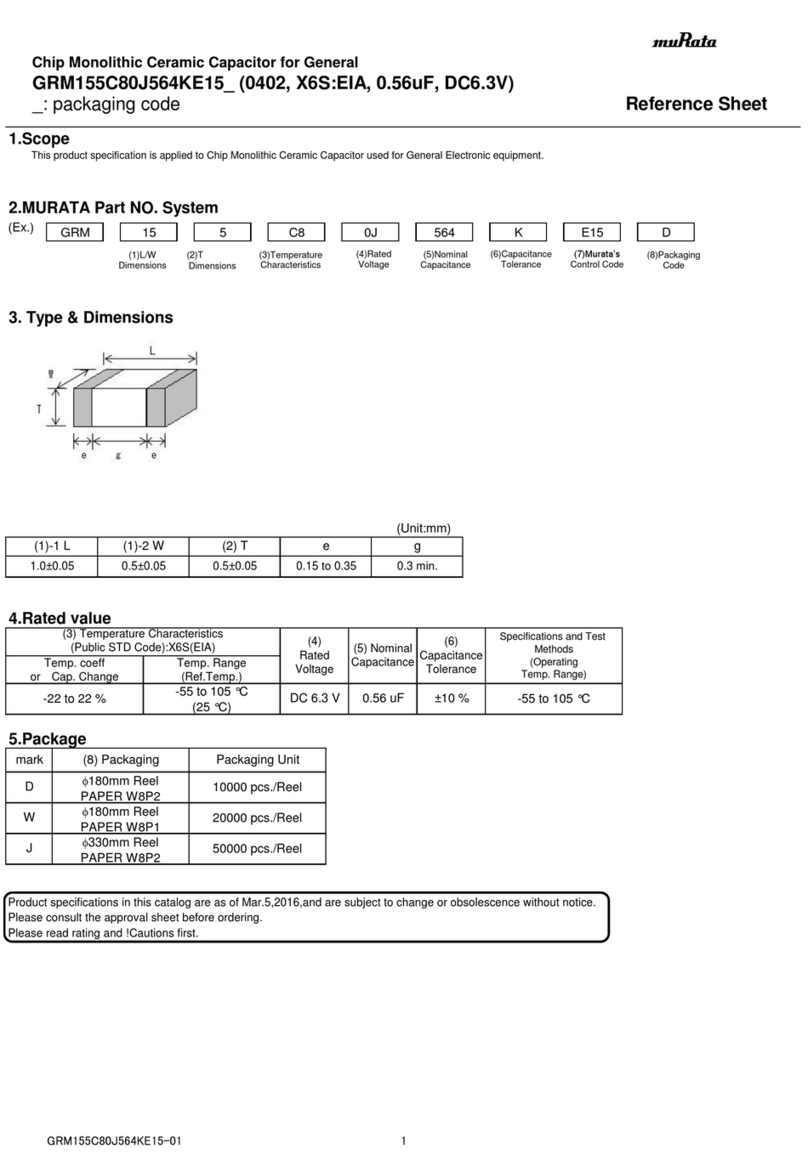

2.1 IS Cubicle

Switch Disconnector

Cubicle (IS)

Cubicle for incoming/outgoing

cable equipped with switch

disconnector ISF (with

operation mechanism CI1).

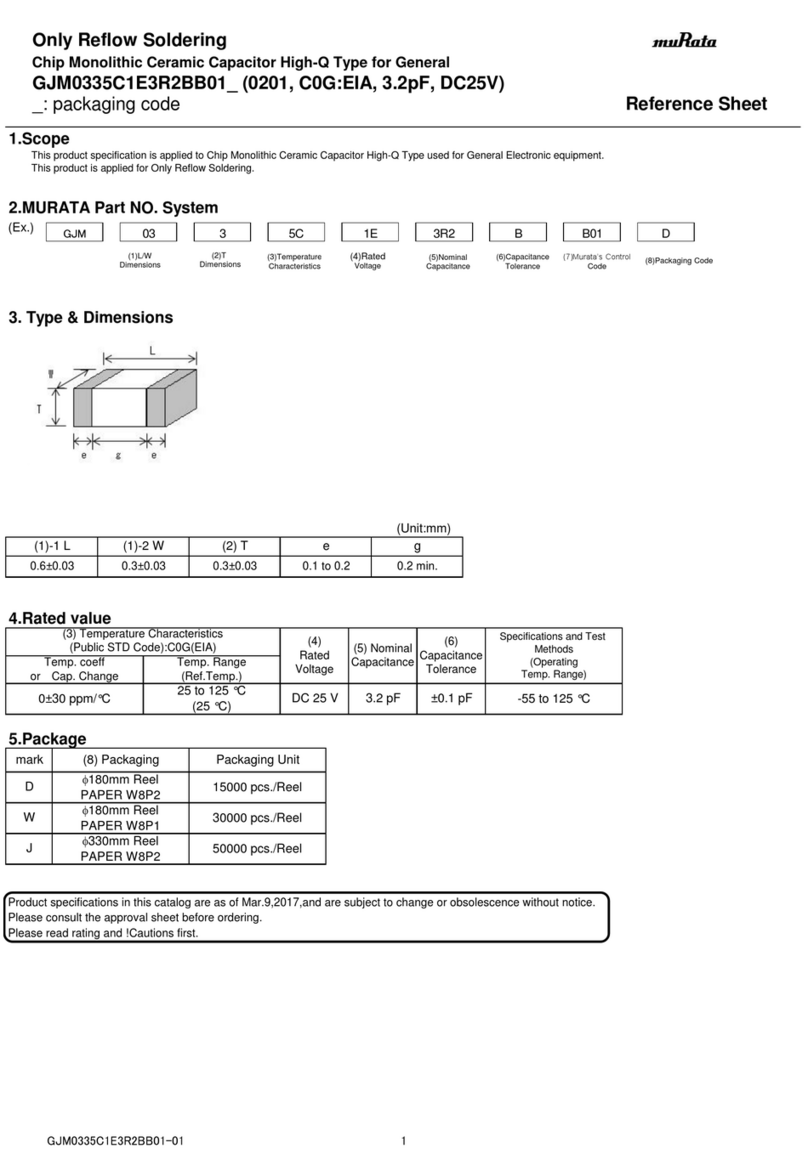

2.2 CIS Cubicle

Transformer Protection

Cubicle (CIS)

Cubicle for transformer

protection by fuses, equipped

with switch disconnector ISF

(with operation mechanism

CI2).

NORMAFIX

5

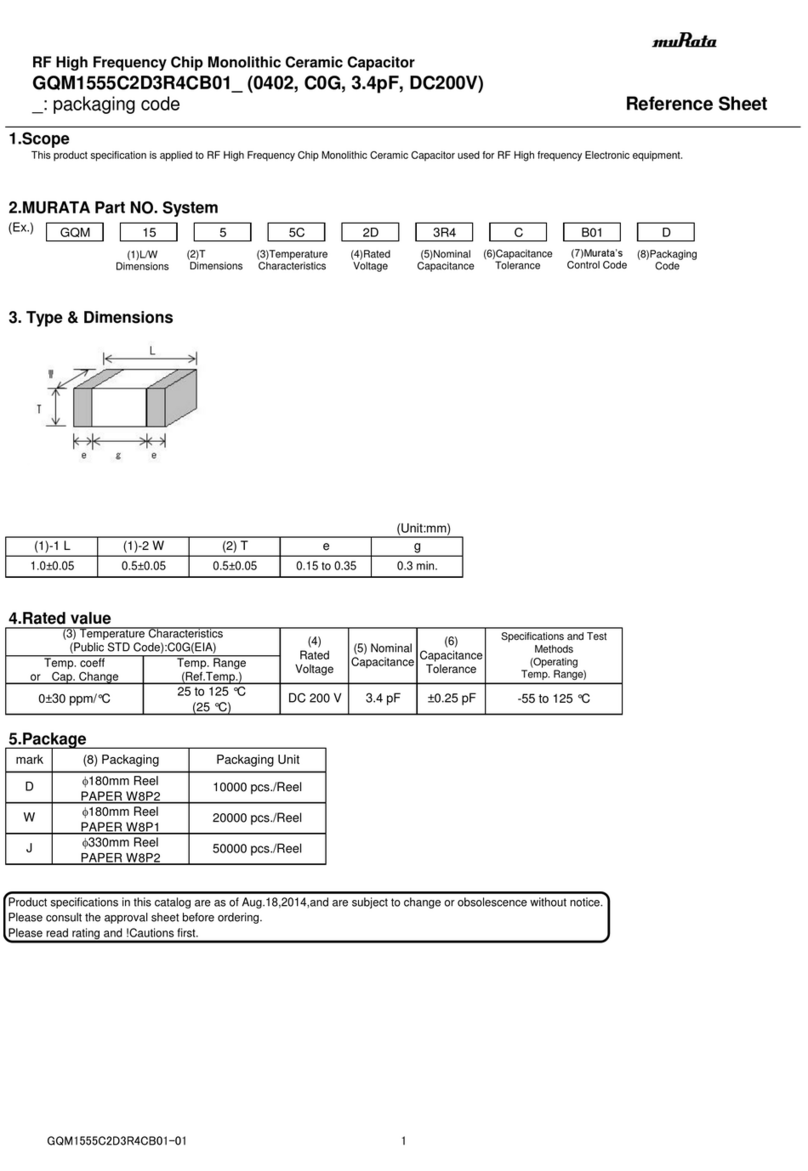

2.3 DC Cubicle

Cables Protection Cubicle

(DC) with circuit breaker.

The circuit breaker

interrupting technology can

be vacuum (DIVAC type) or

SF6 (DIFLU type).

2.4 M Cubicle

Measure Cubicle (M)

Cubicle for measuring current

and/or voltage.

Different versions are

available:

- Lateral incoming and

outgoing;

- Incoming and outgoing by

cable;

- Incoming by cable and

lateral outgoing.

2.5 SBM Cubicle

Sectioning and Measure (SBM)

Cubicle for sectioning and

measuring the current and/or

voltage.

Versions are available with

the right or left rise.

NORMAFIX

6

2.6 CD Cubicle

Direct Incoming Cubicle (CD)

Cubicle incoming or outgoing

cables direct.

2.7 TT Cubicle

Voltage Transformer

Cubicle (TT)

Cubicle for measure voltage

with protection of VT’s by

fuses.

2.8 DB Cubicle

Bars Protection Cubicle (DB)

Cubicle for protection bars

and measuring the current

and/or voltage.

Versions are available with

arrival to the right or left.

NORMAFIX

7

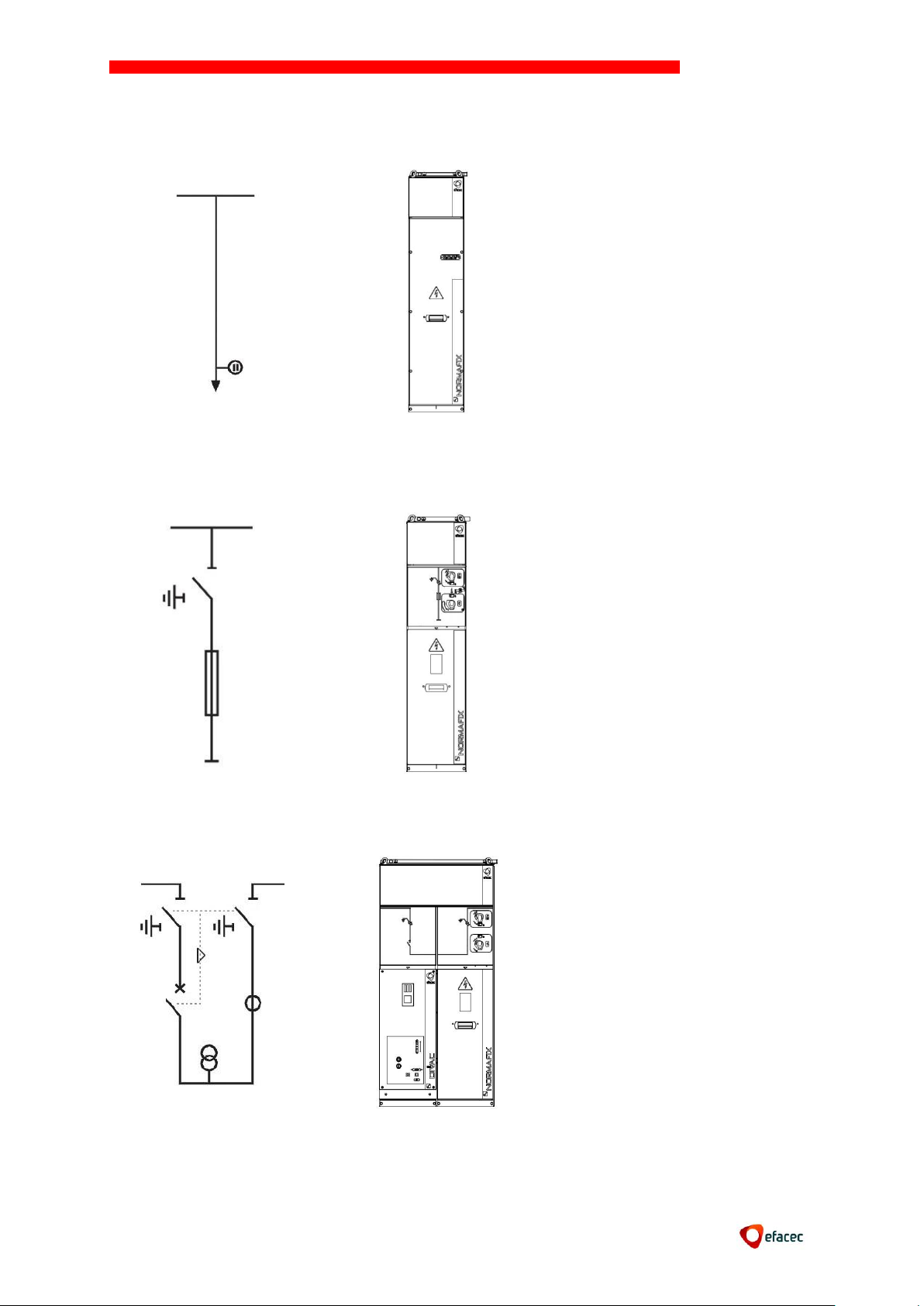

3. OVERVIEW OF MODULAR UNITS

Cubicle IS

1- Accessories for lifting the cubicle

2- Low voltage compartment

3- Earth switch operating mechanism

4- Mechanical synoptic state of the switch disconnector

5- Switch disconnector operating mechanism

6- Live cables signalling neon lamps

7- Cable compartment access door

8- Earth main bar

9- Busbar access panel

10- Busbar deflector Cover

11- Busbar

12- ISF Switch Disconnector

13- Die for cable connection MT

14- Capacitive insulator of support

15- MV Cables

16- Tightening of cables

9

10

15

11

16

7

4

2

1

12

13

14

5

6

3

8

NORMAFIX

8

Cubicle CIS

1- Accessories for lifting the cubicle

2- Low voltage compartment

3- Mechanical synoptic state of the switch disconnector

4- Earth switch operating mechanism

5- Switch disconnector operating mechanism

6- Live cables signalling neon lamps

7- MV Cables acess painel

8- Earth circuit

9- Busbar access panel

10-Busbar deflector

11- ISF Switch Disconnector

12- Fire system protection fuse

13- Upper fuse support

14- MV Fuses

15- Bottom fuse support

16- Capacitive insulator of support

17- Additional Earth switch

18- MV Cables

19- Tightening of cables

9

18

10

19

7

4

2

1

11

12

14

5

6

3

8

15

13

16

17

NORMAFIX

9

Cubicle DC

1- Accessories for lifting the cubicle

2- Low voltage compartment

3- Mechanical synoptic state of switch disconnector

4- Self-powered protection relay

5- Hole insert lever (charging the springs of circuit breaker)

6- Button to open and close the circuit breaker

7- Mechanical synoptic state of circuit-breaker

8- Earth main bar

9- Busbar access panel

10- Disconnector SF

11- Earth switch operating mechanism

12- Disconnector operating mechanism

13- Live cables signaling neon lamps

14- MV Cables access panel

2

1

8

9

10

3

4

6

7

5

11

12

13

14

NORMAFIX

10

4. OPERATING MECHANISMS

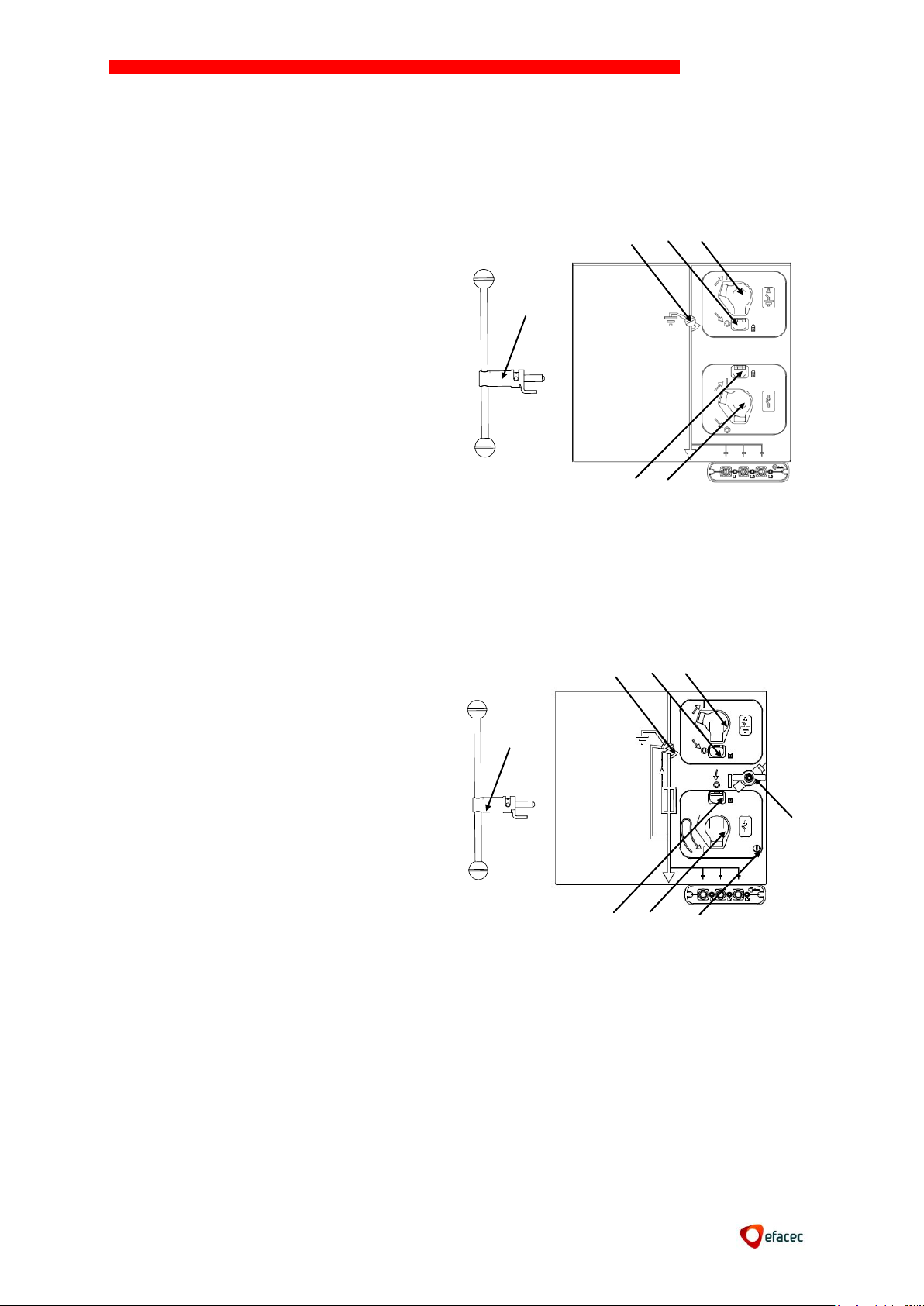

Operating Mechanism CI1, CS1 e CST (Switch Disconnector and Earth Switch)

1 –Lever for the manual operation of the switch

or the earthing switch

2 –Switch Disconnector status indicator

Operating mechanism Earth switch:

3 –Hole to insert Earth Switch interlocking pin

4 –Hole for operating lever of the earth switch

Operating mechanism Switch Disconnector (or

Disconnector):

5 –Hole to insert Switch Disconnector

interlocking pin

6 –Hole for operating lever of the Switch

Disconnector

Operating mechanism CI2 (Switch Disconnector and Earth Switch)

1 –Operating lever tol Switch Disconnector and

Earth Switch

2 –Synoptic to indicate mechanical state of the

Switch Disconnector and earth switch

Operating mechanism Earth Switch:

3 –Hole to insert Earth Switch interlocking pin

4 –Hole for operating lever of the earth switch

CI2 Operating mechanism Switch Disconnector

(Only CIS cubicles):

7 –Hole to insert Switch Disconnector

interlocking pin

8 –Hole for operating lever of the Switch

Disconnector

9 –Fuse fusion signaling

10 –Button for manual opening of Switch

Disconnector

Operating mechanism functional principle CI1(M), CI2(M), CS1, CST

The maneuver of a lever drags a spring away from a balanced position. In this position,

releases the spring stretching up abruptly and independently of the operator.

1

5

6

2

4

3

1

7

8

2

4

3

9

10

NORMAFIX

11

FUNCTIONAL PRINCIPLE

APPLICATION EXAMPLES

CI1(M)

“Tumbler” type operating mechanism.

Opening and closing operations are manually

or electrically performed with a speed

independent from the operator's action.

(Recharging time <= 10s at Un)

Feeder function equipment (set a net to

service or remove it from service) and

transformer fuse protection (load

protection through ISF fuses without

tripping). CI1M enables the ISF remote

switch operation.

CI2(M)

“Tumbler” type operating mechanism.

Equipped with stored-energy spring system

exclusively for opening. The closing

operation is followed by a recharge

operation that enables an eventual opening

operation in less than 100 ms through a

release magnet, a fuse or a push-button

Switch tripping by means of one or

more Fuses.

Switch tripping due to transformers

protection relays.

Switch opening.

CS1

Double function operating mechanism with

dependent operations for the SF switch and

independent operations for the cable

earthing switch (DC panels).

Enables the simultaneous control of two

SF switches (DB panels)

CST

Earthing switch operating mechanism.

Closing and opening speed are independent

from the operator’s action.

Enables the CD panel earthing

switchcontrol

CDV Mechanism (Vacuum Circuit-Breaker)

1 –Lever (charging system the springs of circuit

breaker)

2 –Button to open and close the circuit breaker

3 –Mechanical synoptic state of circuit breaker

4 –Hole to insert lever (charging system the

springs)

5 –Maneuvers counter

6 –Mechanical synoptic state of springs

1

4

3

5

6

2

NORMAFIX

12

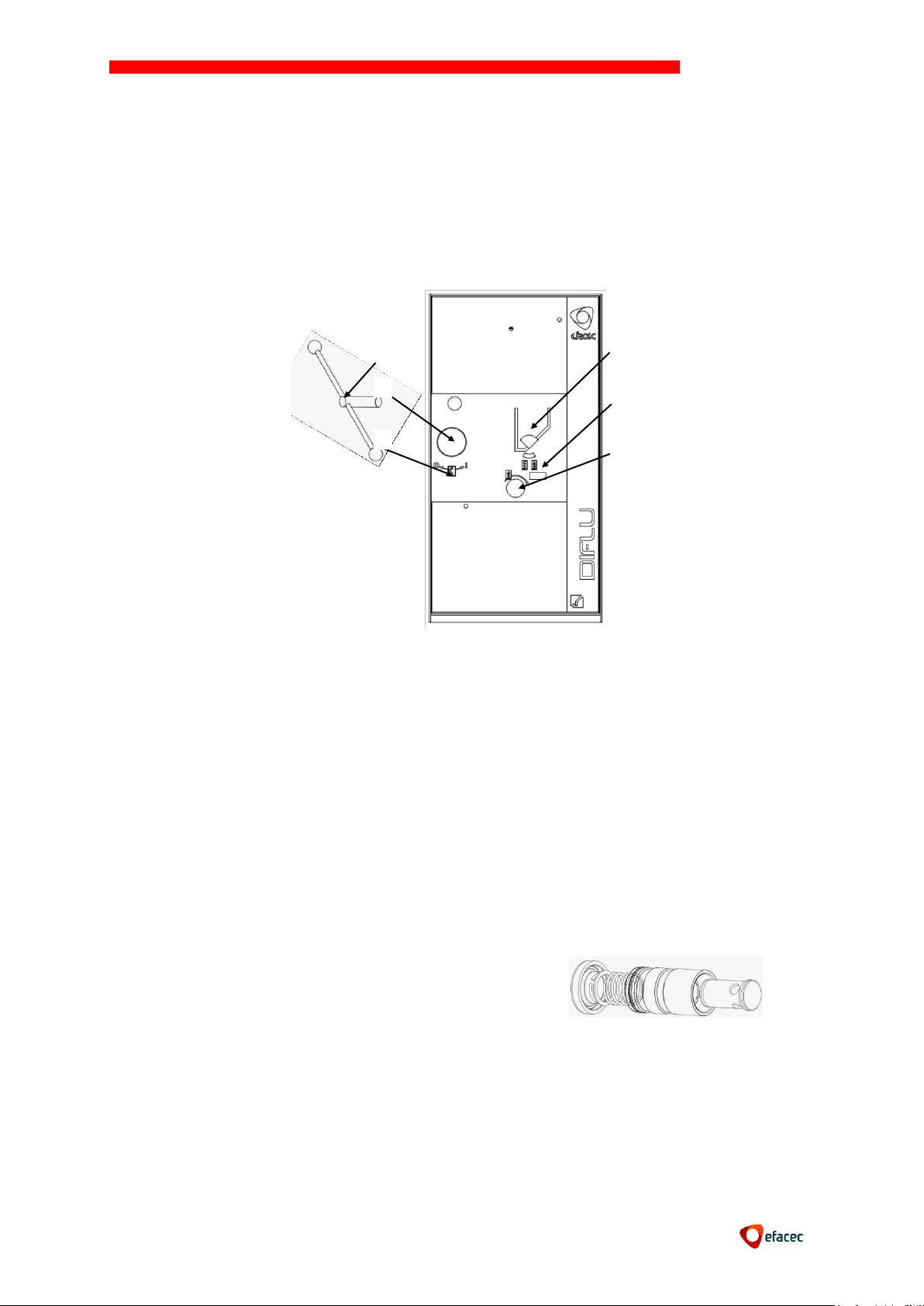

CLR mechanism (SF6 circuit breaker)

1 –Lever (charging system the springs of circuit

breaker

2 –Maniple for open and close the circuit

breaker

3 –Mechanical synoptic state of circuit breaker

4 –Mechanical synoptic state of springs

5 –Maneuvers counter

6 –Hole to insert lever (charging system the

springs)

5. SF6 SYSTEM

The ISF switches and SF isolators, of insulation in SF6, used in the NORMAFIX cells are

devices that are watertight and sealed for life (according to IEC 62271).

The tightness of this equipment is guaranteed by routine tests performed. The expected

life of this equipment is 30 years.

To access the valve it is necessary to remove the hood of the engine command (see

instructions in this manual.)

Features of the valve used:

Supplier: EFACEC

Model: 37409072

Dimensions: DN14,5

The valve is resistant to decomposing SF6.

Operations to remove the SF6 Switches shall be conducted by EFACEC technicians.

1

4

3

5

6

2

NORMAFIX

13

6. DISPATCH

The NORMAFIX cells are shipped with the switch open and the earthing switch closed.

The NORMAFIX cells are shipped individually on a wooden pallet (fixed by four screws and

covered with transparent plastic film).

Accessories for mounting and wiring of the cells are supplied separately.

7. RECEPTION

Identify and confirm in the panels received:

The function through the synoptic

The rating plate

The good condition of the material

Confirm the existence of the separated material package.

Any irregularities found, should be mentioned in the delivery note.

120º Max

Panels must remain fixed to the transportation wooden pallet until assembled. Panels are

displaced with the help of the following tools:

Travelling crane

Pallet-carrier

For the safety of the operator and the equipment itself, the units must be transported

laterally.

NORMAFIX

14

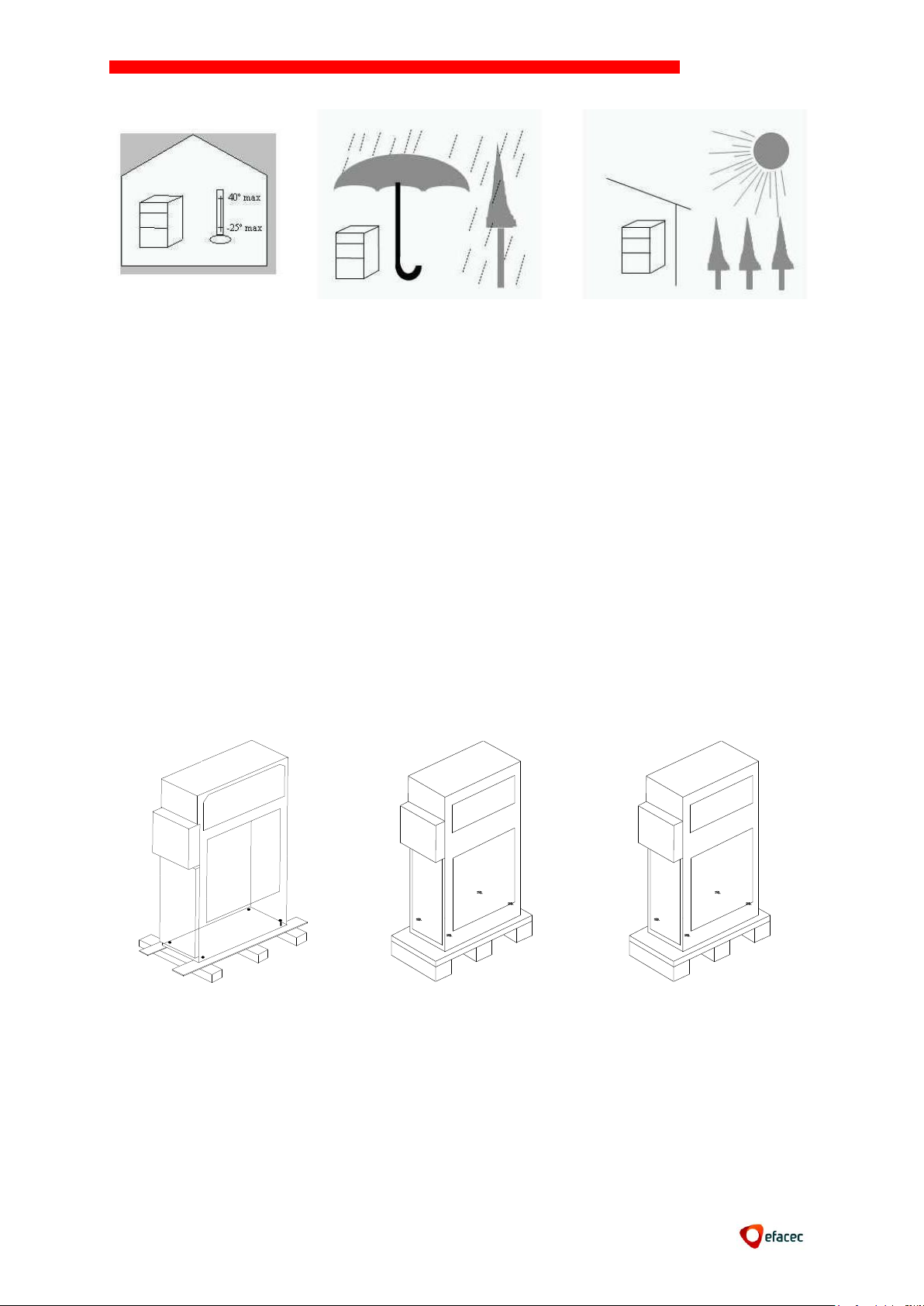

The panels should be stored with its original packaging, to avoid dust, splashing water and

chemicals, in a well ventilated and dry area, at a temperature between -25°C and +40°C.

8. INSTALLATION

8.1 Preparing the floor

The floor maximum admissible unevenness is of 2 mm/m in order to allow an easy

mounting and a good final appearance of the panels set.

8.2 Unpacking

Once the panels are near the assembly place and in the foreseen order:

Remove the plastic film;

Open the cable compartment door (earthing switch must be in the closed position);

Remove the four screws (wrench 17) holding the cubicle to the base;

Rotate the panel in order to release it from the base and place it on the floor

according to movement instructions.

8.3 Installation on site

Removed the access to the cable compartment;

Check the verticality, using pads if necessary;

Fix it to the ground.

NORMAFIX

15

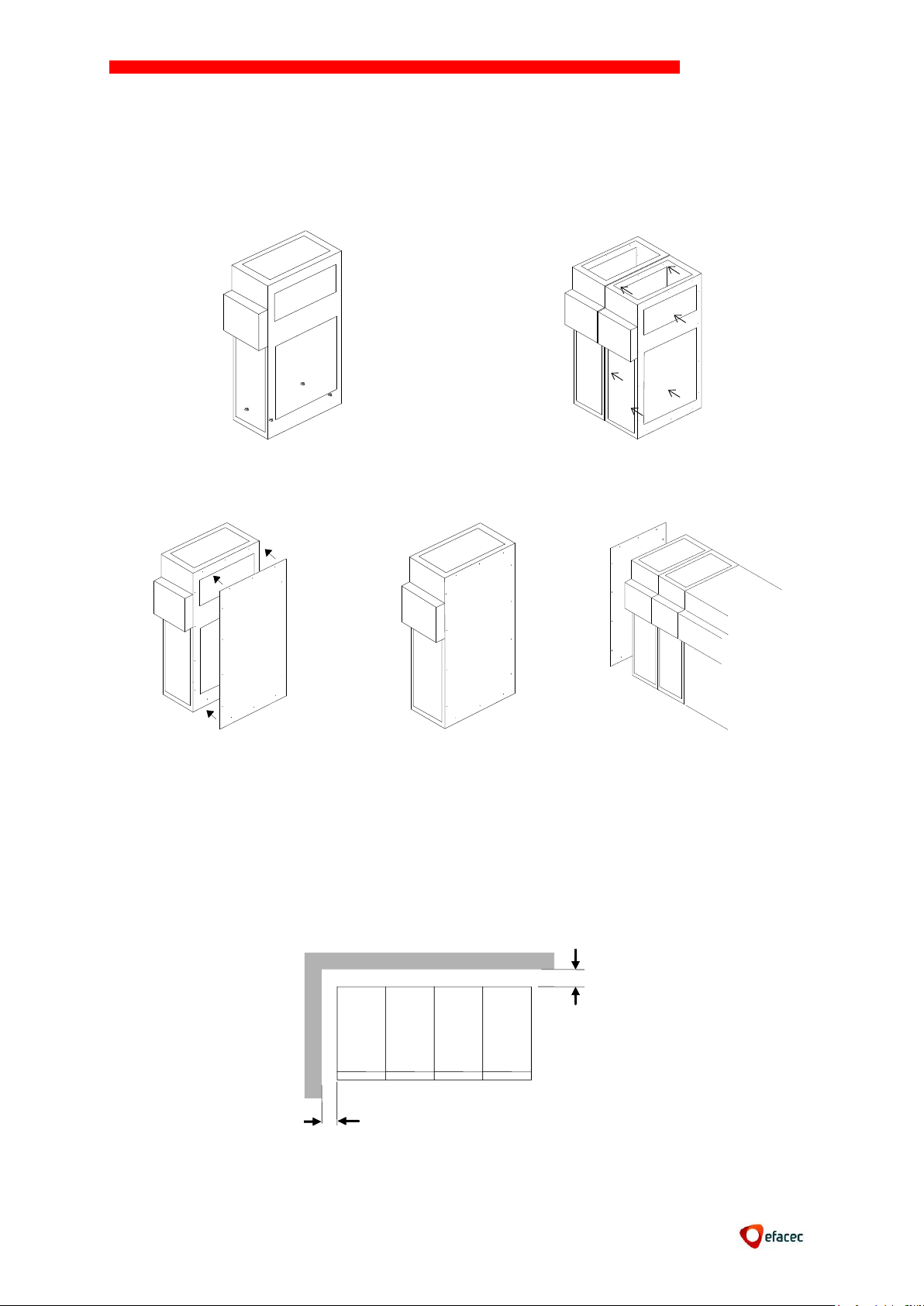

8.4 Panels assembly

Position the first panel and fix it to the floor.

Then, position the second panel and connect it to the first by using M8x16H screws, M8

washers and M8H nuts and fix it to the floor. Do the same for the remaining cubicles.

It is necessary to place the side end panels at the end of the set of cells. They use 14 M6

screws, washers and riveted nuts (supplied as accessories) to attach each panel.

Note: The assembly should be done with the roof panel to access the bus and cable

compartment door removed.

8.5 Fastening the panels to the floor

Refer to the deployment plan of the panels where its configuration is set, the overall

dimensions and recommended points of attachment to the floor.

The panels are fixed to the ground by means of M12 screws (4 attachment points in the end

cells, and two diagonal fixing points in the others).

20 mm

200 mm

NORMAFIX

16

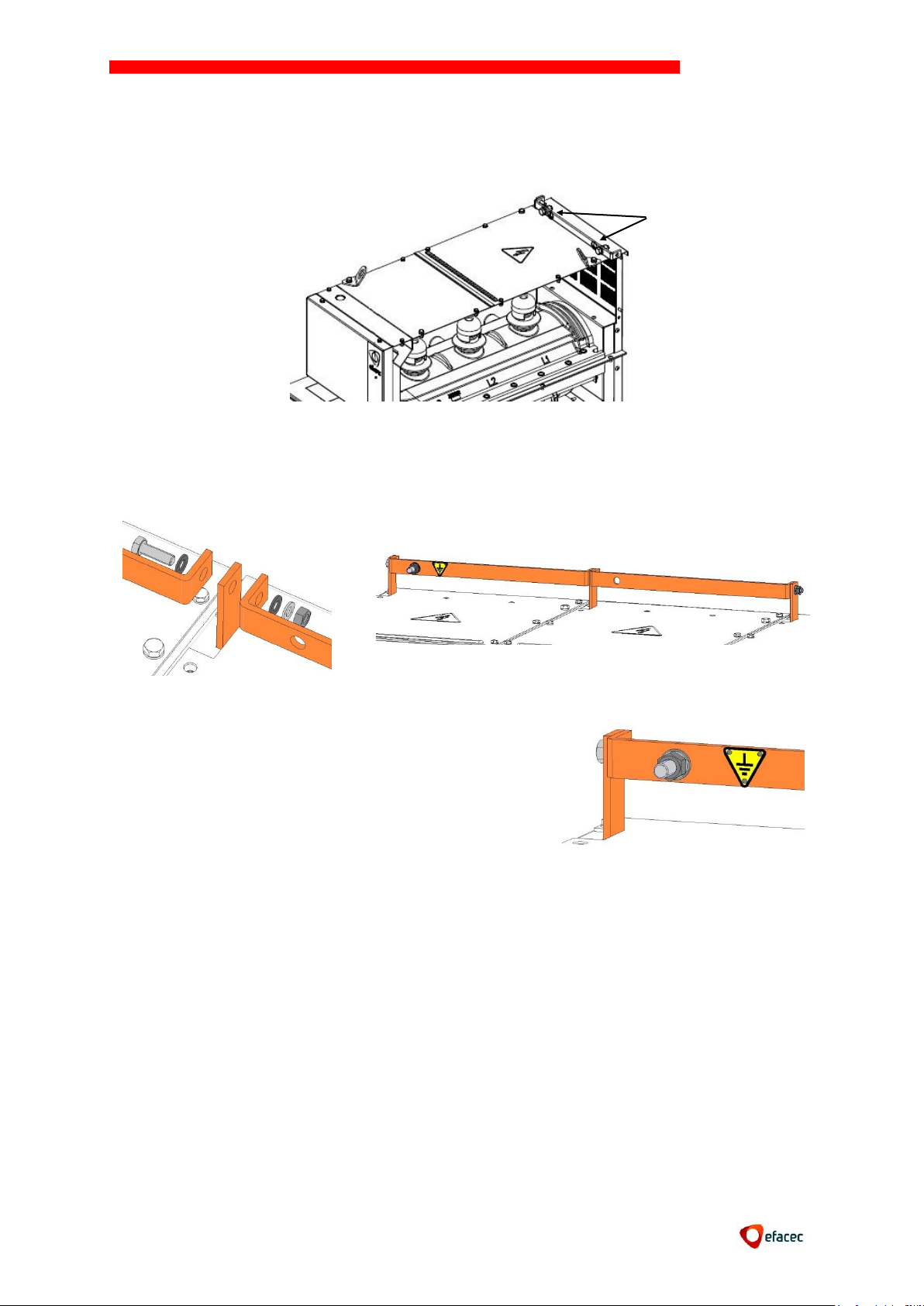

8.6 Connection of the earthing circuit

All NORMAFIX components (bars, cables connections, fuses, etc.) are interconnected and

connected to the earth by the same copper circuit.

(*) –Points of connection of the busbar circuit common ground

Tighten the copper bars of the circuit ground to ensure continuity.

Tighten the M8H nuts with 0.9 daNm binary.

In the cell at the edge of the frame, turn the general

collector to the protective earth of the installation

through a copper conductor of 50 mm², M8H bolt,

washer and nut (binary 1.9 daNm)

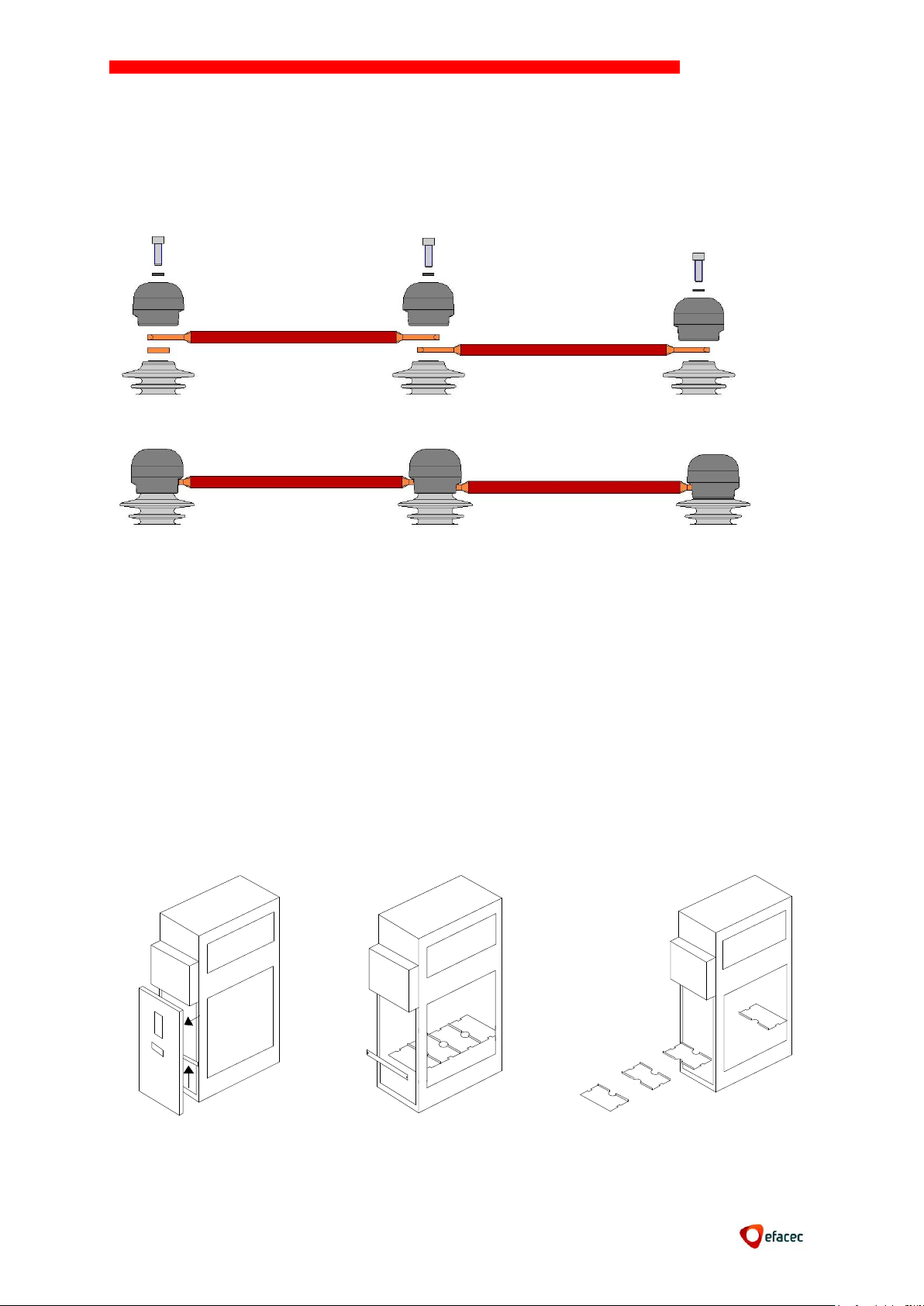

8.7 Busbar connection

It is not necessary to prepare the contact surfaces (eventually, a simple dust cleaning).

However, if the panels have been stored for a long time, check the contacts for oxidation.

Starting at a switchboard end and always at the rear phase L1.

To access the bus it is necessary to remove the access panels (top of the panel).

(*)

NORMAFIX

17

Starting at a switchboard end and at the rear phase L1:

Arrange the bars over the upper sockets;

Place the deflectors, screws and washers in position (orient the deflectors on the

correct position);

Immobilize the fixing screws with a fastening binary of 2,4 daNm, wrench 17.

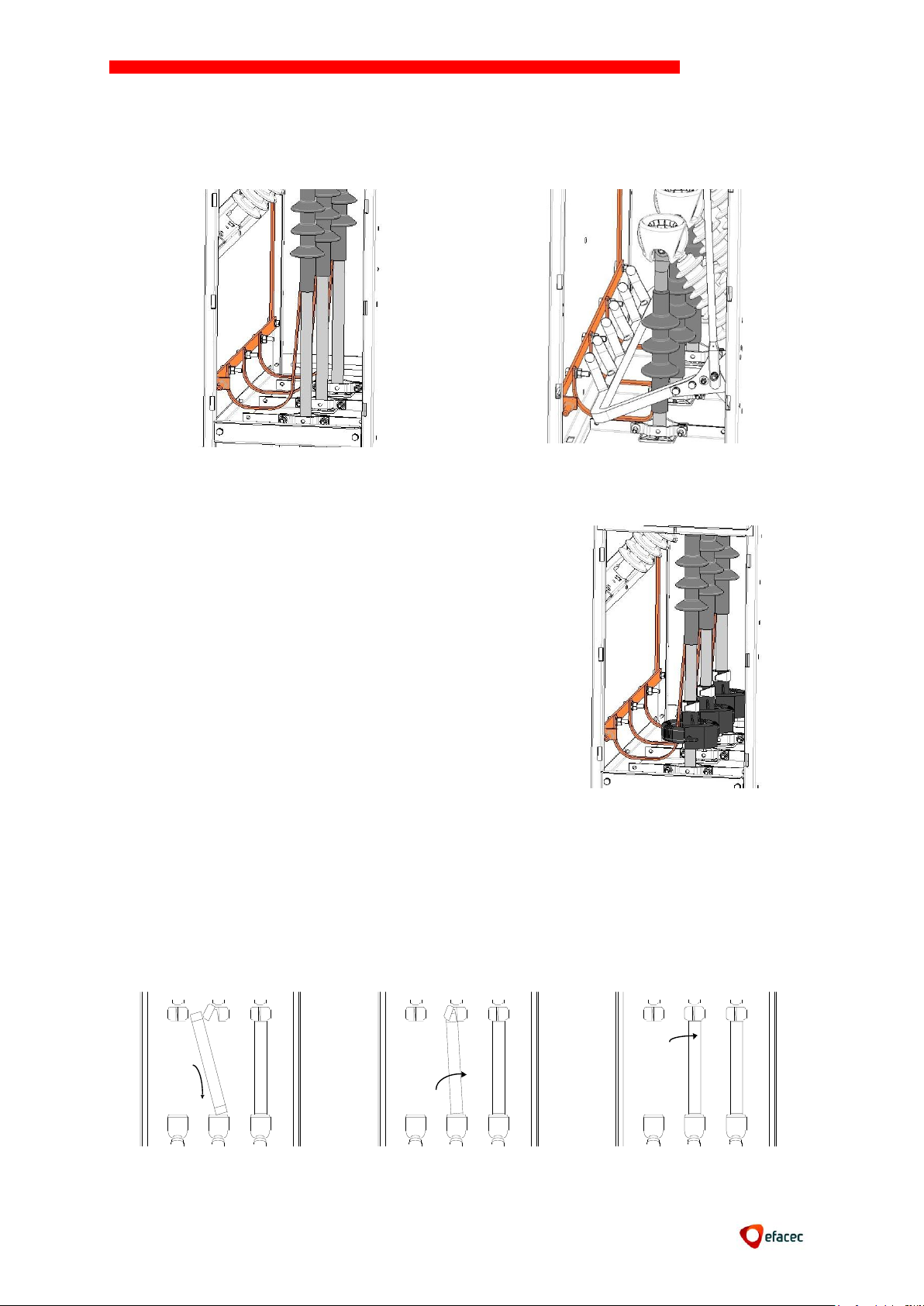

8.8 Cables connection

NORMAFIX was designed for use with cable, shrink or silicon terminals. The selection of the

cables and cable terminals are the responsibility of the customer. The materials should be

compatible with the NORMAFIX equipment.

To access the cable compartment and work safely, you must open the load break

disconnector switch and close the earthing switch.

Remove the cable access panel;

Dismantle the lower front crossbar (2 nuts, wrench 13);

Dismantle the medium front crossbar (2 nuts, wrench 13);

Extract the first three elements of the bottom plate;

2

1

NORMAFIX

18

Access the current switch screw where the terminal is fixed to the cable (on the

panels IS and CD it is necessary to remove the deflector);

Place the cables at terminal height, starting by the furthest phase;

Mark the terminal lower limit on the cables;

Pull the cables outside and execute the ends following the cable manufacturer's

instruction;

Starting from the farther phase, locate the current terminal and fasten the screw

with the nut and washer - tightening torque 4,5 daNm (and,

replacing the deflector in the IS and CIS);

Assemble the second element of the bottom plate, taking care to leave the cable

earth plait above the plate.

Cut the cable bushing according with the cable outside diameter and insert it down

the cable to the bottom plate.

Adapt the tightening clamps and immobilise the nuts (wrench 13), being careful not

to overtorque the cable.

NORMAFIX

19

Connect the three cable earth plaits to the earth main bar with M8x30H screws and

immobilize the nut with a wrench 13, tightening torque 0,9 daNm.

8.9 Toroidal transformers Cable Connections

It is possible to install toroidal current sensors in

fault detector’s cables.

To assure its correct operation, it is necessary to

confirm that the earth cable connection is made

from the interior of the current sensors.

8.10 Assembling of fuses

Proceed as indicated in figures:

Using the fuse itself, rise the fuse holder upper shell cover;

Fit the fuse lower part into the fuses holder lower shell;

Fit the fuse upper part into the fuses holder upper shell making sure that the upper

shell cover is correctly closed;

The fuse should not be held by its central part.

Table of contents

Popular Industrial Electrical manuals by other brands

Milltronics

Milltronics ACCUMASS BW500 instruction manual

BIRD

BIRD TERMALINE 8400 SERIES Operation manual

OBO Bettermann

OBO Bettermann isCon Series System instructions

Eaton

Eaton Crouse-hinds series operating instructions

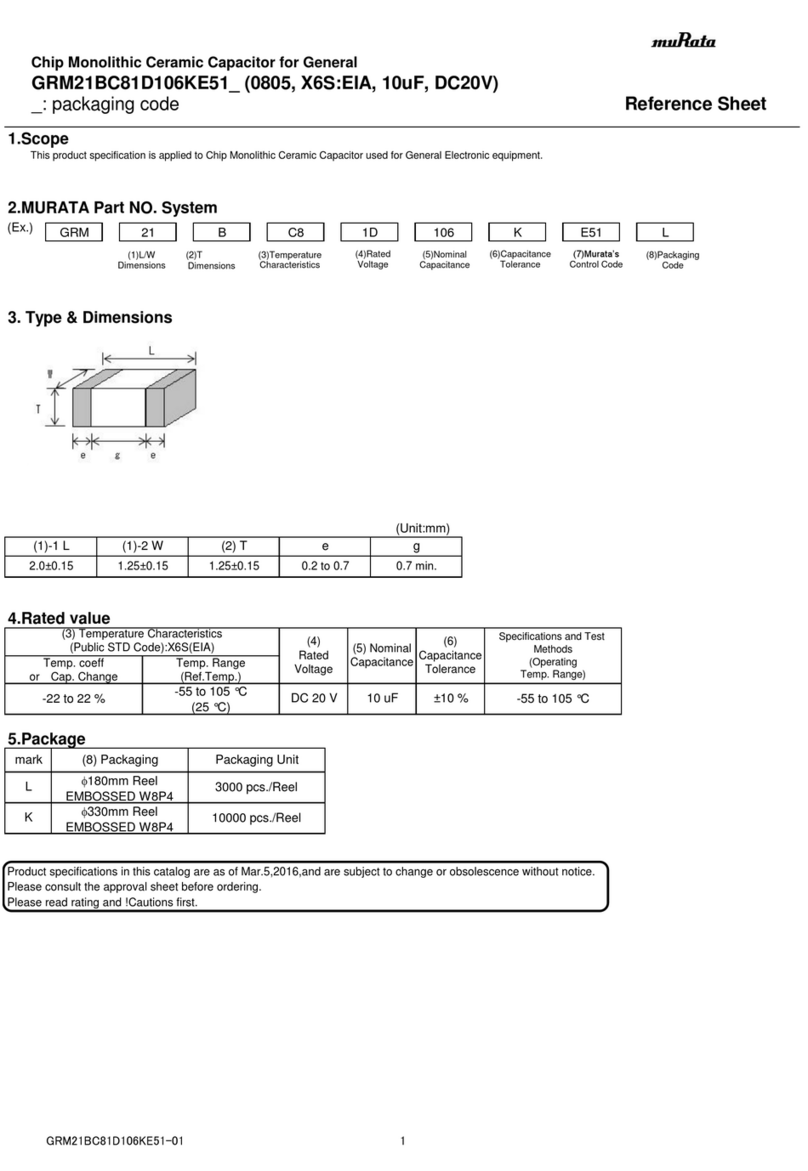

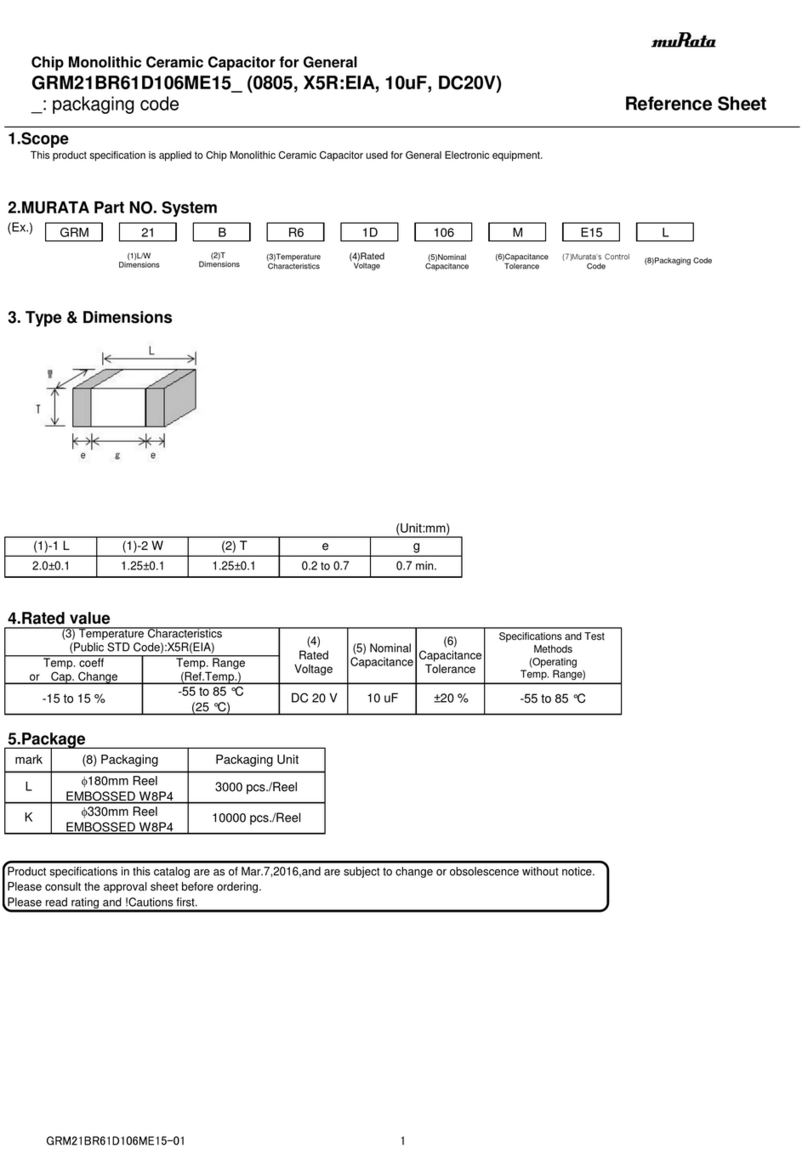

Murata

Murata GRM21BR61D106ME15 Series Reference sheet

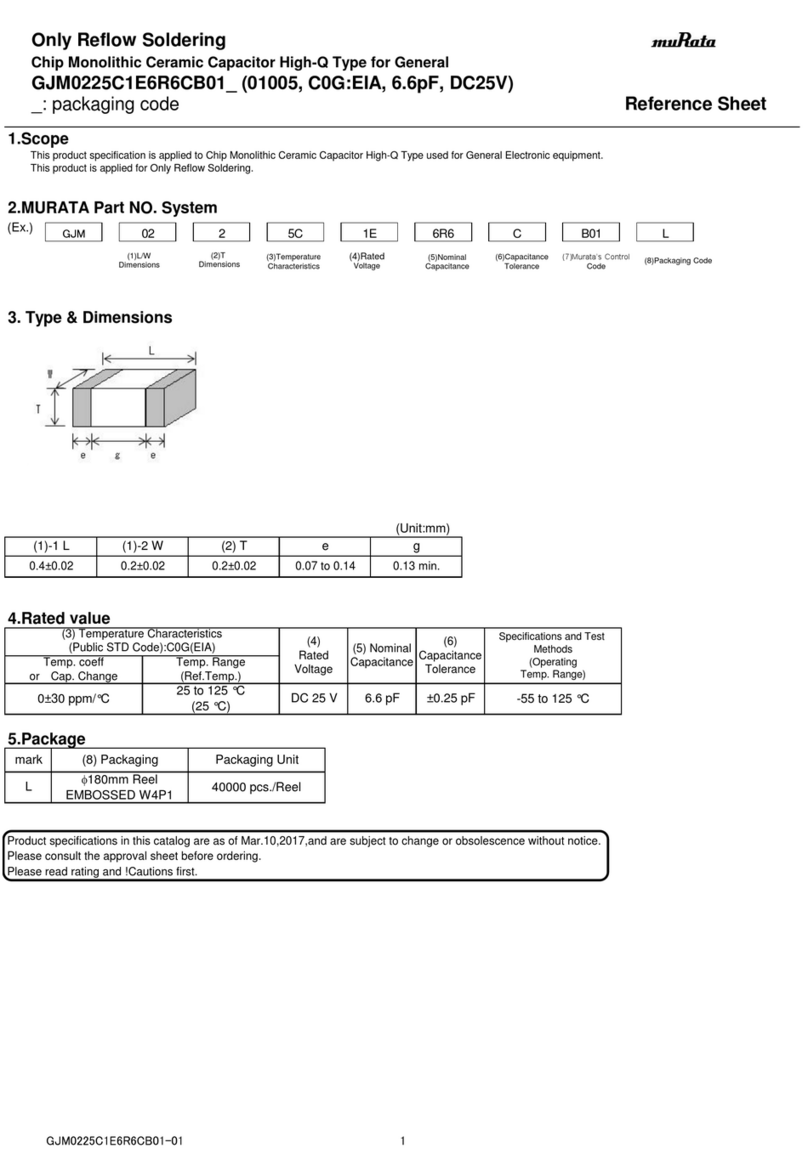

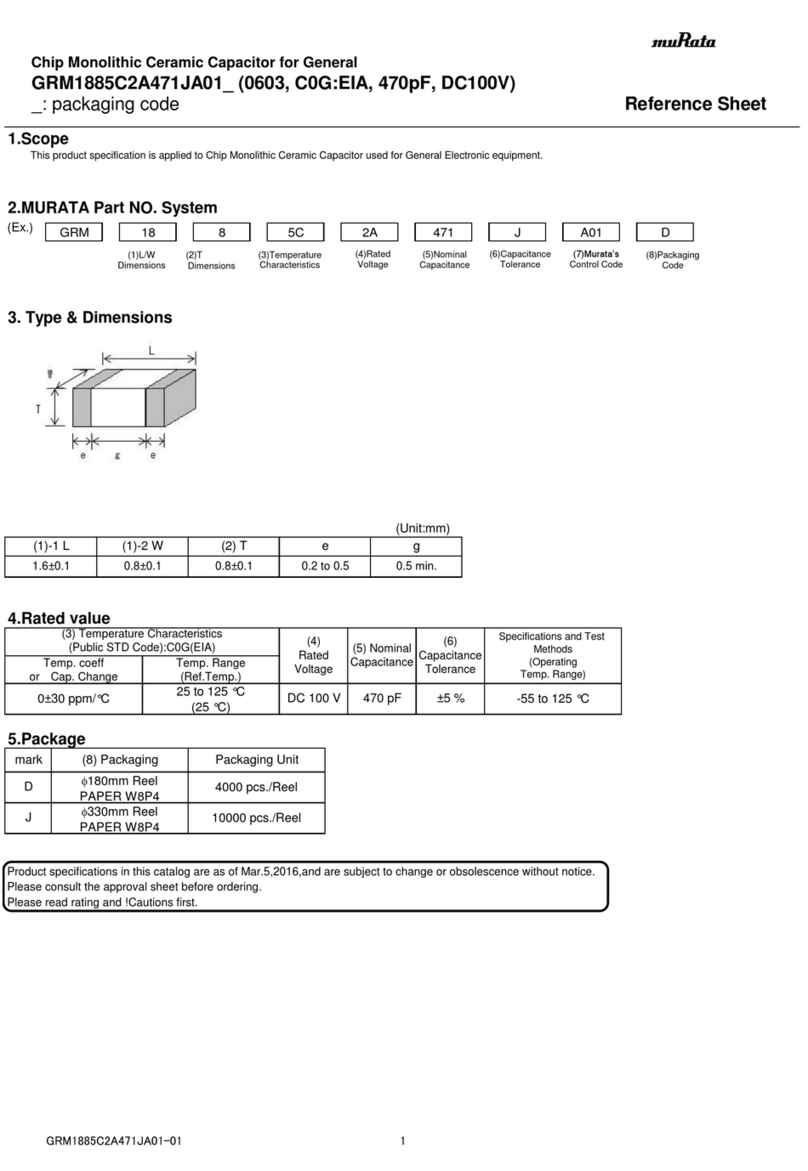

Murata

Murata GRM1885C2A471JA01 Series Reference sheet