GE AKD-6 User manual

Other GE Industrial Electrical manuals

GE

GE QuiXtra 630 Quick start guide

GE

GE AKD-8 User manual

GE

GE AF-650 GP Series Operating instructions

GE

GE QuiXtra 4000 Quick start guide

GE

GE DS-19 User manual

GE

GE Entelliguard TU Conversion Kit User manual

GE

GE Spectra Series User manual

GE

GE Entellisys User manual

GE

GE GTP0060U0101 User manual

GE

GE Fuji Electric MICRO-SAVER AF-300 User guide

GE

GE RSTi-EP Instructions for use

GE

GE THQ Series User guide

GE

GE PHI 530.1425.2500 Manual

GE

GE AF-650 GP Series User manual

GE

GE ABB ReliaGear SB User manual

GE

GE PowerMark Plus DEH40228 User manual

GE

GE Spectra Series AMC6EB User manual

GE

GE Entellisys 4.0 User guide

GE

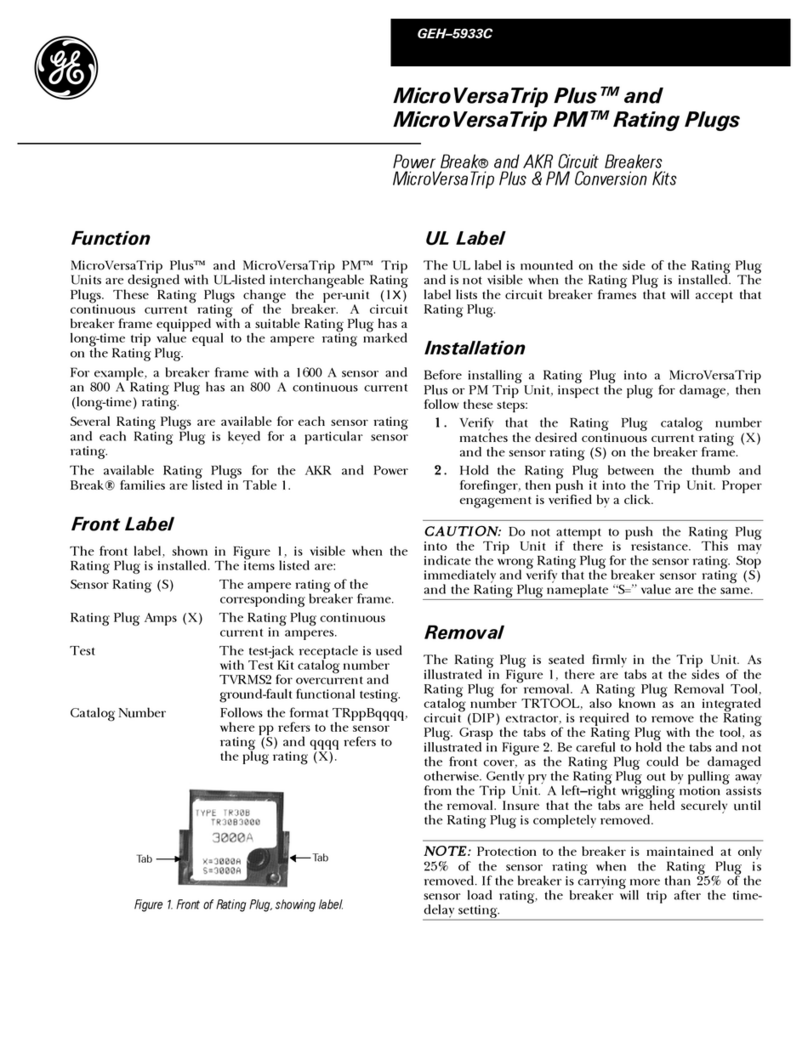

GE MicroVersaTrip Plus User manual

GE

GE A-Series II Panelboard User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

Murata

Murata GRM0335C1H8R1DA01 Series Reference sheet

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

Eaton

Eaton Ulusoy HMH24-04 user manual

Murata

Murata GJM0335C1E4R4BB01 Series Reference sheet

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

Murata

Murata GRM1555C1H2R7CA01 Seies Reference sheet

Murata

Murata GRM0225C1E6R4BA03 Series Reference sheet

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Murata

Murata GRM0335C2A7R3CA01 Series Reference sheet

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Murata

Murata GRM32ER60G227ME05 Series Reference sheet

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions