EG&G ORTEC 403A User manual

I

I

100

MIDLAND

ROAD,

OAK

RIDGE,

TENNESSEE,

37830

Lj

area

code

(615)

483-8451

TWX

810-572-1078

INSTRUCTION

MANUAL

403A

TIME

PICKOFF

CONTROL

AN

EGHGCOMPANY

INSTRUCTION

MANUAL

403A

TIME

PICKOFF

CGNTRGL

Serial

No..

Purchaser.

Date

issued.

INCORPORATED

P.O.

BOX

C

OAK

RIDGE,

TENNESSEE

37830

Telephone

(615)

483-8451

TWX

810-572-1078

©ORTEC

Incorporated

1966

Printed

in

U.S.A.

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

1-1

2.

SPECIFICATIONS

2-1

3.

INSTALLATION

INSTRUCTIONS

3-1

3.1

Linear

Output

Signal

Connections

and

Terminating

Impedance

Considerations

3-1

4.

OPERATING

INSTRUCTIONS

4-1

5.

CIRCUIT

DESCRIPTION

5-1

5.1

Power

and

Control

Bias

5-1

5.2

Fan-out

Circuit

5-1

6.

MAINTENANCE

INSTRUCTIONS

6-1

6.1

General

Maintenance

Instructions

6-1

6.2

Calibration

Adjustments

6-1

6.3

Troubleshooting

Suggestions

6-1

6.4

Tabulated

Test

Point

Voltages

6-1

7.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

7-1

BLOCK

DIAGRAM

AND

SCHEMATIC

403A-0101-B1

ORTEC

403A

Block

Diagram

403A-0101-S1

ORTEC

403A

Schematic

STANDARD

WARRANTY

FOR

ORTEC

ELECTRONIC

INSTRUMENTS

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

con

cealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

damage

claims

and

in

providing

replacement

equipment

when

necessary.

WARRANTY

ORTEC

warrants

its

electronic

products

to

be

free

from

defects

in

workmanship

and

materials,

other

than

vacuum

tubes

and

semiconductors,

for

a

period

of

twelve

months

from

date

of

ship

ment,

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replacement,

at

ORTEC

option,

will

be

made

without

charge

at

the

ORTEC

factory.

Shipping

expense

will

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors,

as

made

by

their

manufacturers,

will

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

l

iabi

l

ity

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibility

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

liabi

l

ities

associated

with

the

methods

of

instal

lation,

or

instal

lation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

ORTEC

instruments

not

in

warranty

may

be

returned

to

the

factory

for

repairs

or

checkout

at

modest

expense

to

the

customer.

Standard

procedure

requires

that

returned

instruments

pass

the

same

quality

control

tests

as

those

used

for

new

production

instruments.

Please

contact

the

factory

for

instructions

before

shipping

equipment.

—

-ym

:fr

ORTEC^

I

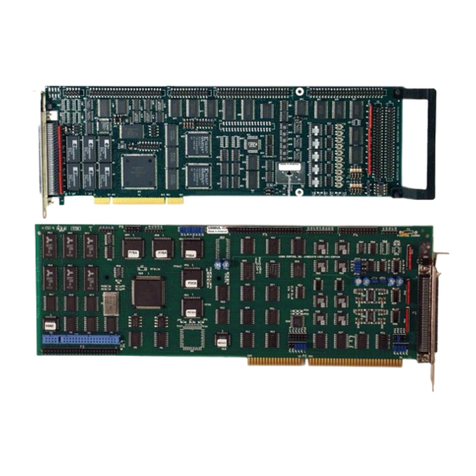

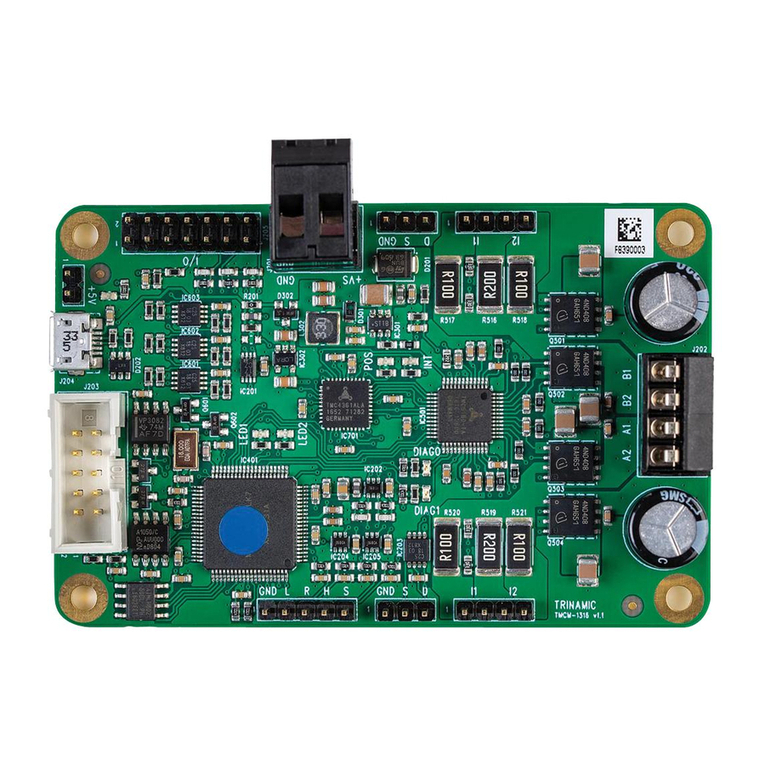

v[5m<"'EL403a3

DISC.

LEVEL

DISC.

INPUT

NEG.

OUTPUT

1

NEG

OUTPUT

2

POS.

OUTPUT

3

L'

1

-1

ORTEC

403A

TIME

PICKOFF

CONTROL

DESCRIPTION

The

403A

Time

Pickoff

Control

provides

control

and

fan-out

buffering

for

time

derivation

units

such

as

the

260, 264,

and

268.

Dc

supply

voltages

and

a

dis

criminator

level

control

current

for

the

time

derivation

unit

are

provided

via

a

multiconductor

shielded

cable.

The

fan-out

buffer

accepts

the

Type

I

(fast

negative)

logic

signal

from

the

time

derivation

and

derives

from

it

three

separate

output

signals.

Two

are

Type

I

logic

and

one

is

Type

I

I

logic

(slower

positive).

The

403A

receives

its

power

from

an

ORTEC

401A/402A

Bin

and

Power

Supply.

2

-

1

2.

SPECIFICATIONS

Input

Signal;

0.3V

minimum

(protected

to

±

1GOV)

(This

signal

conforms

to

the

Preferred

Practices

of

TID-20893

(Rev.)

and

is

normally

the

output

signal

from

the

260

Time

Pickoff,or

264,

or

268

Photomultiplier

Timing

Discriminator

and

Pre

amplifier)

Input

Impedance:

50

ohms

±

1

0%,

dc

Input

-

Output

Count

Rote:

100

MHz

maximum

(fast

negative)

Outputs:

Output

1

:

Fast

logic,

negative,

15

mA

on

50

ohms,

current

drive,

^.5

nsec

for

input

signal

of

2X

threshold,

output

pulse

width

~

width

of

input

signal

at

250

mV

level,

amplitude

limited

at~1.5V

when

unterminated,

dc-coupled

Output

2:

Same

as

1

above

Output 3:

Slow

logic,

positive,

5V,

T^

^10

nsec,

width

~0.5

nsec,

<10

ohms

Connectors:

Signal

:

BNC

Power

and

Bias:

Amphenol

126-198

Power

Connection

Coble:

The

appropriate

connecting

cable

is

furnished

with

the

260

Time

Pickoff

and

264

or

268

Photomultiplier

Discriminator

and

Preamplifier

Power

Required:

+24V

15

mA

+12V

15

mA

-24V

35

mA

-12

V

40

mA

3

-

1

3.

INSTALLATION

INSTRUCTIONS

3.1

General

The

ORTEC

403A,

used

in

conjuncMon

wifh

the

ORTEC

401A/402A

Bin

and

Power

Supply,

is

intended

for

rock

mounting,

ond

therefore

it

is

necessory

to

ensure

thot

vocuum

tube

equipment

operoting

in

the

some

rock

hos

sufficient

cooling

oir

circuloting

to

prevent

ony

locolized

heoting

of

the

oll-tronsistor

circuitry

used

throughout

the

403A.

The

temperoture

of

equipment

mounted

in

rocks

con

eosily

exceed

the

recommended

moximum

unless

precoutions

ore

token.

The

403A

should

not

be

subjected

to

temperotures

in

excess

of

120°F

(50°C).

3.2

Connection

to

Power

—

AEC

Stondord

Nucleor

Instrument

Module,

ORTEC

401A/402A

The

403A

contoins

no

internol

power

supply,

ond

therefore

must

obtoin

power

from

o

Nucleor

Stondord

Bin

ond

Power

Supply

such

os

the

401A/402A.

It

is

recommended

thot

the

Bin

power

supply

be

turned

off

when

inserting

or

removing

modules.

The

ORTEC

400

Series

is

designed

so

thot

it

is

not

possible

to

over-

lood

the

Bin

power

supply

with

o

full

complement

of

modules

in

the

Bin;

however,

this

moy

not

be

true

when

the

Bin

contoins

modules

other

thon

those

of

ORTEC

design.

In

this

cose,

power

supply

voltoges

should

be

checked

ofter

the

inser

tion

of

modules.

The

401A/402A

hos

test

points

on

the

power

supply

control

pone

I

to

monitor

the

dc

voltoges.

3.3

Connection

to

Time

Derivotion

Unit

Insert

the

403A

into

the

401A/402A.

Connect

the

time

derivotion

unit

(ORTEC

260,

264,

etc.)

to

the

403A

by

the

oppropriote

control

coble,

260-Cl

or

260-C2.

This

coble

is

provided

with

the

time

derivotion

unit.

Connect

o

50-ohm

cooxiol

coble

between

the

output

of

the

time

derivotion

unit

ond

the

input

of

the

403A.

The

outputs

of

the

403A

moy

now

be

connected

to

the

desired

inputs

ond

the

system

should

be

reody

for

operotion.

4-

1

4.

pPERATING

INSTRUCTIONS

The

only

two

controls

associated

with

the

403A

are

the

DISC

ZERO

adjustment

R11,

and

the

DISC

LEVEL

control

R12.

The

DISC

LEVEL

control

varies

the

threshold

in

the

associated

time

deriviation

unit.

The

DISC

ZERO

adjustment

provides

a

means

of

normalizing

the

DISC

LEVEL

at

one

set-point.

Normally

this

set-point

will

be

that

of

maximum

sensitivity,

for

which

the

adjustment

procedure

is:

1.

Monitor

output

#3

of

the

403A

with

an

appropriate

oscilloscope.

2.

Set

the

DISC

LEVEL

control

R12

to

0.0.

3.

Adjust

the

DISC

ZERO

control

R11

clockwise

until

output

signals

appear

(indicating

self

triggering

of

the

time

derivation

unit),

4.

Turn

Rll

counter

clockwise

just

enough

to

cause

the

signals

to

disappear.

The

system

is

now

adjusted

for

maximum

sensitivity.

5-

1

5.

CIRCUIT

DESCRIPTION

(See

Drawings

403A-0101-S1

and

403A-0101-B1)

5.

1

Power

and

Control

Bias

The

403A

furnishes

the

power

and

control

bias

for

a

time

derivation

unit

by

direct

access

via

the

bias

and

power

output

jack

(J2).

5.2

Fan-out

Circuit

The

input

signal

to

the

403A

is

regenerated

in

the

fan-out

circuit

to

produce

three

separate

outputs.

The

input

signal

passes

through

the

current

limiter

circuit

composed

of

IC-1

and

D3

to

the

input

of

the

dc

coupled

amplifier

composed

of

Ql,Q2,

and

Q3.

The

output

current

signal

from

Q3

col

lec

tor

triggers

the

tunnel

diode

D4

from

the

low

state

to

the

high

state.

It

wi

l

l

remain

in

the

high

state

until

the

input

signal

decreases

to

less

than

250

mV.

The

voltage

signal

from

D4

drives

the

two

fast

output

current

switches

Q5-Q6

and

Q8-Q9

via

two

emitter

fol

lowers

Q4

and

QIC.

These

switches

drive

15

mA

of

current

on

Outputs

1

and

2.

A

signal

is

also

derived

from

the

col

lector

of

QIC

which

triggers

the

trigger

pair

Q11-Q12.

This

trigger

pair

generates

a

positive

signal

of

approximately

5V,

500

nsec

wide.

Q13

is

a

cutoff

emitter

fol

lower

which

is

driven

into

the

conduction

state

by

this

5V

signal

and

thereby

presents

this

signal

to

Output

3.

6-

1

6.

MAINTENANCE

INSTRUCTIONS

6.1

General

Maintenance

Instructions

The

operation

of

the

DISC

LEVEL

control

is

a

simple

shorting

rheostat

in

series

with

a

current

sensitive

device

which

exists

in

the

associated

time

derivation

device,

e.g.,

ORTEC

260.

The

operation

of

the

DISC

ZERO

control

is

the

same

and

is

covered

in

Section

4

of

this

manual

.

The

fan-out

buffer

may

be

tested

with

a

signal

from

a

pulse

generator

or

from

a

time

derivation

unit.

The

input

signal

is

regenerated

in

the

403A

to

a

standard

output

amplitude,

but

having

a

width

approximately

equal

to

the

input

signal

at

a

level

of

-250

mV.

6.2

Calibration

Adjustments

The

operation

of

the

DISC

ZERO

control

is

covered

in

Section

4

and

is

the

only

calibration

associated

with

the

unit.

6.3

Troubleshooting

Suggestions

In

situations

where

the

403A

is

suspected

of

malfunction,

it

is

essential

to

verify

such

malfunction

in

terms

of

simple

pulse

generator

pulses

at

the

input

and

output.

The

403A

should

be

disconnected

from

its

position

in

the

system

and

routine

diagnostic

analysis

performed

with

a

test

pulse

generator

and

oscil

loscope.

The

guide

plate

and

shield

cover

may

be

completely

removed

from

the

module

to

enable

oscil

loscope

and

voltmeter

observation

with

a

minimal

chance

of

accidental

ly

short-

circuiting

portions

of

the

etched

board.

The

403A

may

be

returned

to

ORTEC

for

repair

service

at

nominal

cost;

our

standardized

procedure

re

quires

that

each

repaired

instrument

receive

the

same

extensive

quality

control

tests

that

a

new

instrument

receives.

6.4

Tabulated

Test

Point

Voltages

The

following

voltages

are

intended

to

indicate

typical

dc

voltages

measured

on

the

etched

circuit

board

as

an

aid

in

troubleshooting.

6-2

Table

of

Typical

Voltage

for

ORTEC

403A

+

24V

buss

23.8

-

24V

buss

23.6

+

12V

buss

1 1

.9

-

12V

buss

n.6

Q1b

+

0.014V

Qle

-

0.74V

Q2e

-

0.67V

Q2c

-

1.02V

Q3c

-

0.0015V

Q4e

-

0.71V

Q5e

-

1

.45V

Q6b

-

0.9V

Q7e

-

0.7V

Q8e

-

1

.45V

Q9b

-

0.71V

Q9c

-

0.73V

QlOe

-

0.71V

Qlle

-

11

.9V

Q12b

-

11

.2V

Q12c

-

0.027V

Q13c

f

11

.9V

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

—3

volts

24

Reserved

3

Spare

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

*28

+24

volts

7

Coaxial

*29

—24

volts

8

200

volts

dc

30

Spare

Bus

9

Spare

31

Carry

No.

2

«10

+6

volts

32

Spare

*11

—6

volts

*33

115

volts

ac(H°0

12

Reserved

Bus

*34

Power

Return

Ground,

13

Carry

No.

1

35

Reset

14

Spore

36

Gate

15

Reserved

37

Spare

*16

+12

volts

38

Coaxial

*17

—12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

*41

115

volts

ac

(Neut.)

20

Spare

*42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

*

These

pins

are

installed

and

wired

in

parallel

in

the

ORTEC

401A

Modular

System

Bin.

The

transistor

types

installed

in

your

instrument

may

differ

from

those

shown

in

the

schematic

diagram.

In

such

cases,

necessary

replace

ments

can

be

made

with

either

the

type

shown

in

the

diagram

or

the

type

actually

used

in

the

instrument.

Table of contents