3

en

BW/H Komfort HE

1 Overview ...............................................................................................4

1.1 Optional functions ........................................................................................................5

2 Installation ............................................................................................5

2.1 Mounting .........................................................................................................................5

2.2 Electrical connection ....................................................................................................6

2.3 Data communication / Bus ...........................................................................................7

2.4 SD memory card slot ...................................................................................................7

3 Step-by-step parameterisation ...........................................................8

4 Operation and function .......................................................................9

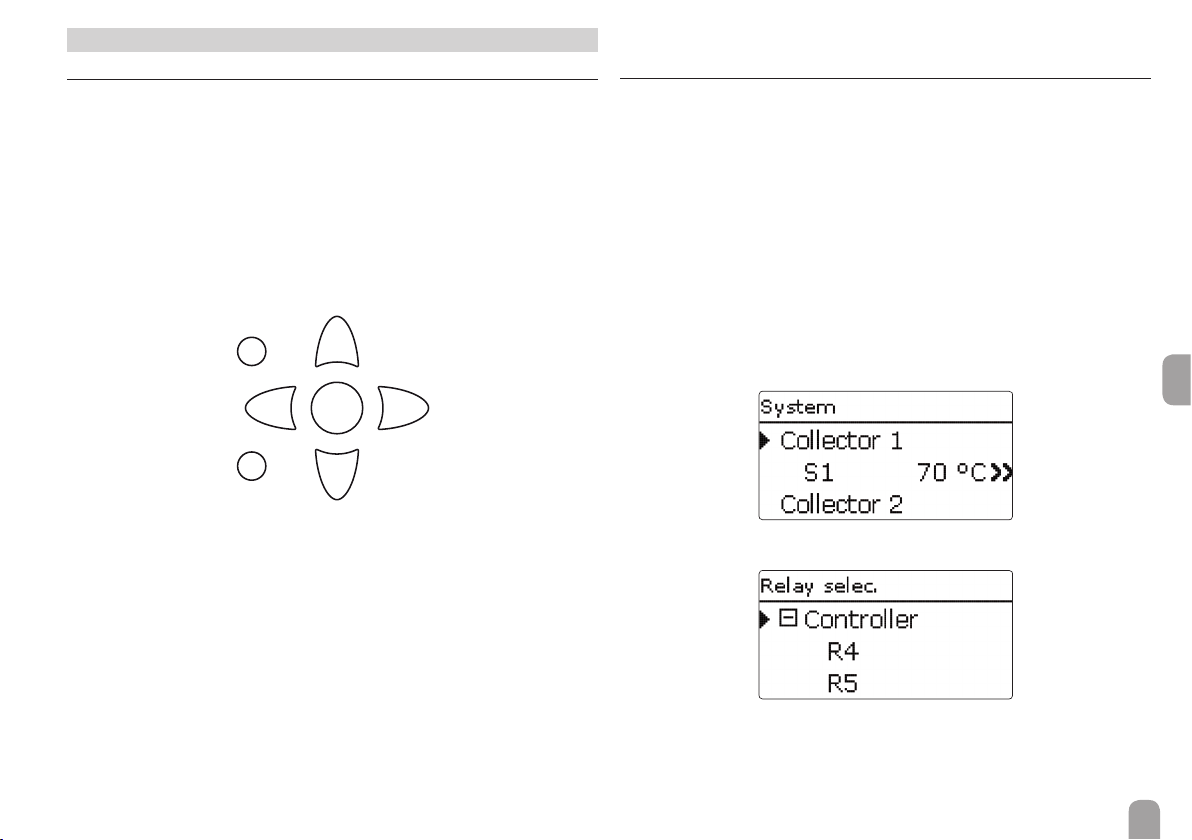

4.1 Buttons ............................................................................................................................9

4.2 Selecting menu points and adjusting values .............................................................9

4.3 Menu structure ........................................................................................................... 13

5 Commissioning...................................................................................14

5.1 Basic systems and hydraulic variants ...................................................................... 16

5.2 Overview of relay and sensor allocation .............................................................. 17

6 Main menu ..........................................................................................27

7 Status...................................................................................................27

7.1 Solar .............................................................................................................................. 27

7.2 Arrangement ............................................................................................................... 27

7.3 Heating .......................................................................................................................... 27

7.4 Messages ....................................................................................................................... 28

7.5 Meas. / Balance values ................................................................................................. 29

7.6 Service .......................................................................................................................... 29

8 Solar.....................................................................................................29

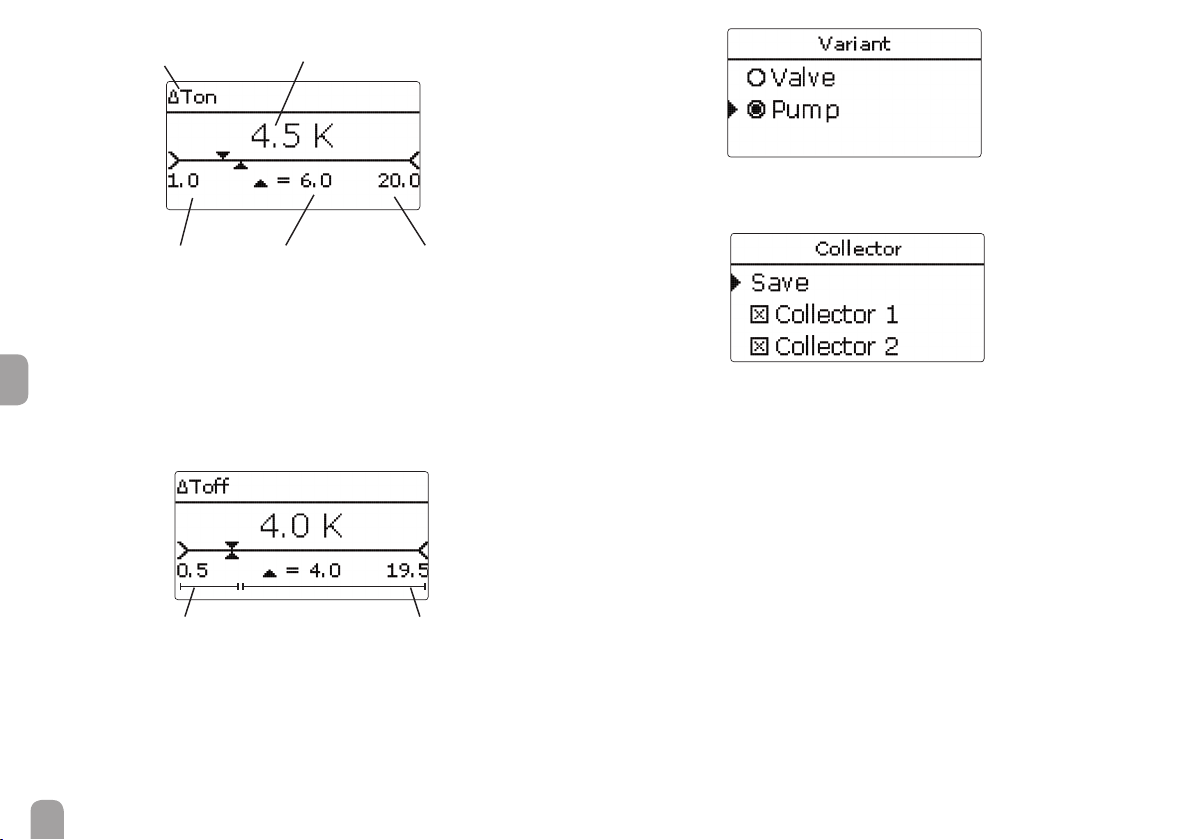

8.1 Basic solar settings ..................................................................................................... 30

8.2 Solar optional functions ............................................................................................ 32

8.3 Function control ......................................................................................................... 43

8.4 Solar expert menu ..................................................................................................... 44

9 Arrangement ......................................................................................45

9.1 Optional functions ..................................................................................................... 45

10 Heating................................................................................................54

10.1 Demands ...................................................................................................................... 54

10.2 Heating circuits (with EM Extension Modules only) .......................................... 56

10.3 Optional functions ..................................................................................................... 59

10.4 Screed drying ............................................................................................................... 62

11 HQM ....................................................................................................63

12 Basic settings ......................................................................................65

13 SD card................................................................................................65

14 Manual mode ......................................................................................66

15 User code ............................................................................................67

16 In- / Outputs.........................................................................................67

16.1 Modules ........................................................................................................................ 67

16.2 Inputs ............................................................................................................................. 68

16.3 Outputs ........................................................................................................................ 69

16.4 VBus .............................................................................................................................. 70

17 Troubleshooting..................................................................................71

18 Accessories .........................................................................................74

18.1 Sensors and measuring instruments ...................................................................... 75

18.2 VBus® accessories ...................................................................................................... 75

18.3 Interface adapters ....................................................................................................... 76

19 Index ....................................................................................................77

The BW/H Komfort HE is a system controller for multi-store solar and heating

systems.

The intuitive commissioning menu leads you through the system conguration by

requiring the most important adjustments directly after connecting the controller.

For an optimum overview, all sensor and relay allocations are listed in the service

menu.

Contents