4EWCM 809/NH3/S 5/98 ing

PoPr: Power (with faulty) Probe.

Power level to run the system if the probe

is faulty (CtyP = 0 and CPP = 1).

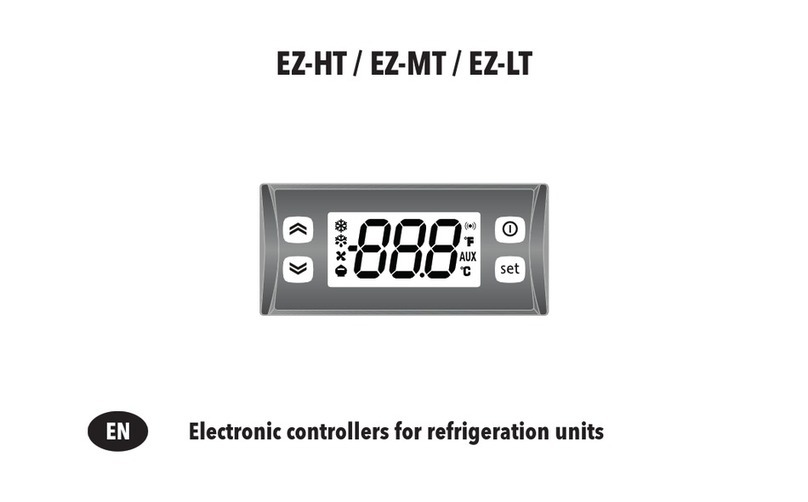

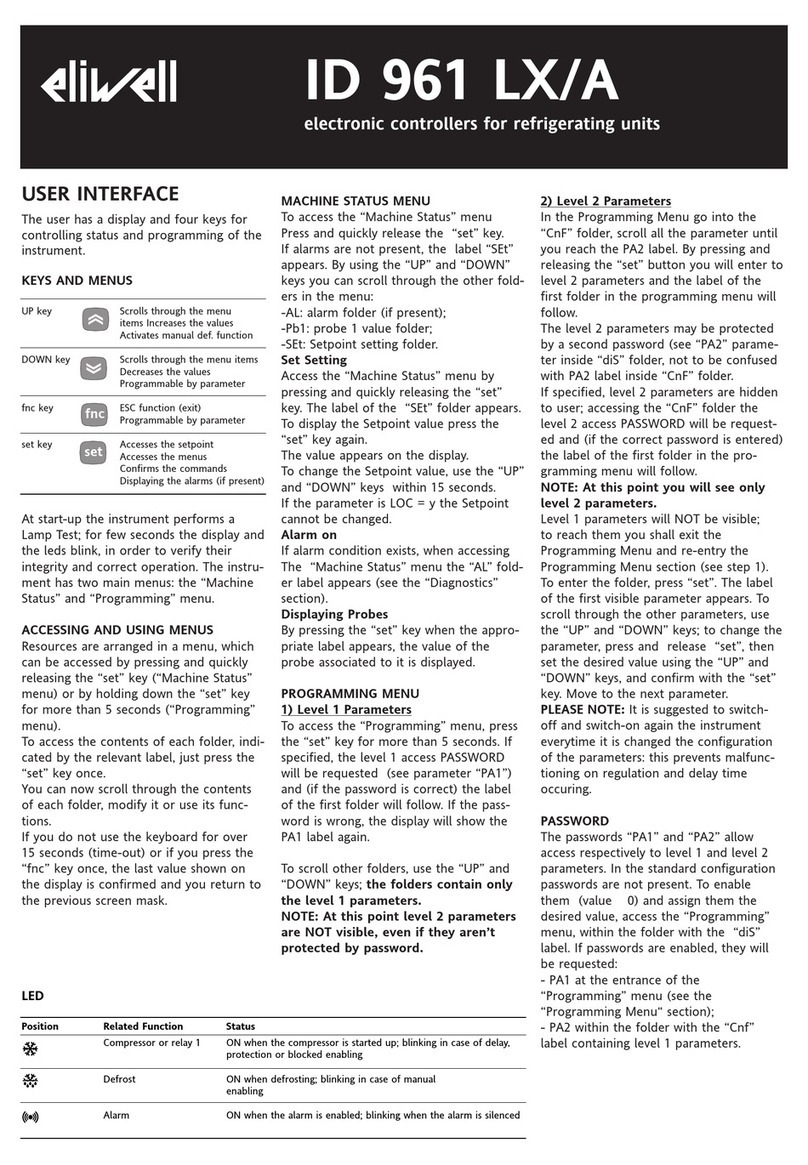

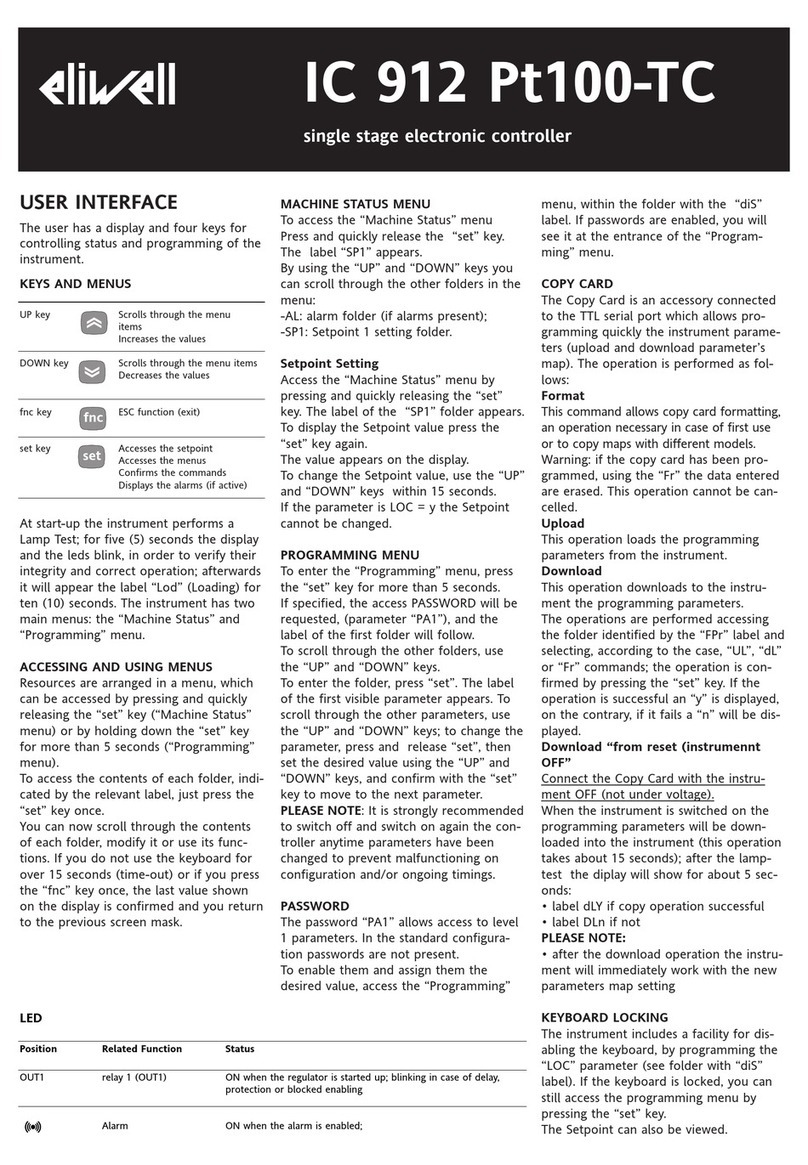

User interface

rELP: rELative Pressure.

Relative or absolute pressure read-out.

0 = absolute;

1 = relative.

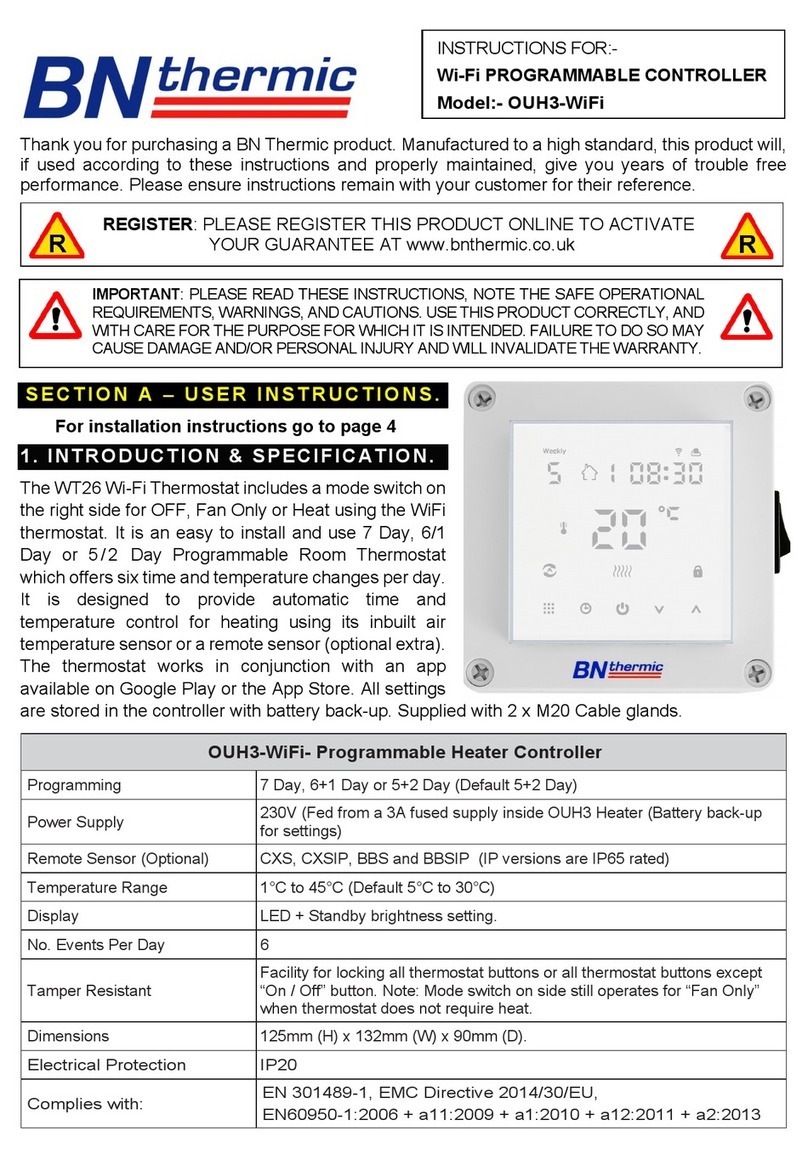

Loc: keyboard Lock function.

It disables the following functions: setpoint

adjustment, compressor running hours re-

set, avilable and in service compressor

status control. The “Loc” parameter can

however be modified.

0 = keyboard unlocked;

1 = keyboard locked.

Pso: Password operating.

Password to access the programming

Operating parameters.

Tele-assistance

FAA: FAmily Address.

It selects the family number when con-

nected to a Televis network.

dEA: dEvice Address.

It selects the device number when con-

nected to a Televis network.

tAb: tAble of parameters.

This parameter can not be modified.

EL1: ELIWELL 1.

This parameter can not be modified.

EL2: ELIWELL 2.

This parameter can not be modified.

USER INFORMATIONS

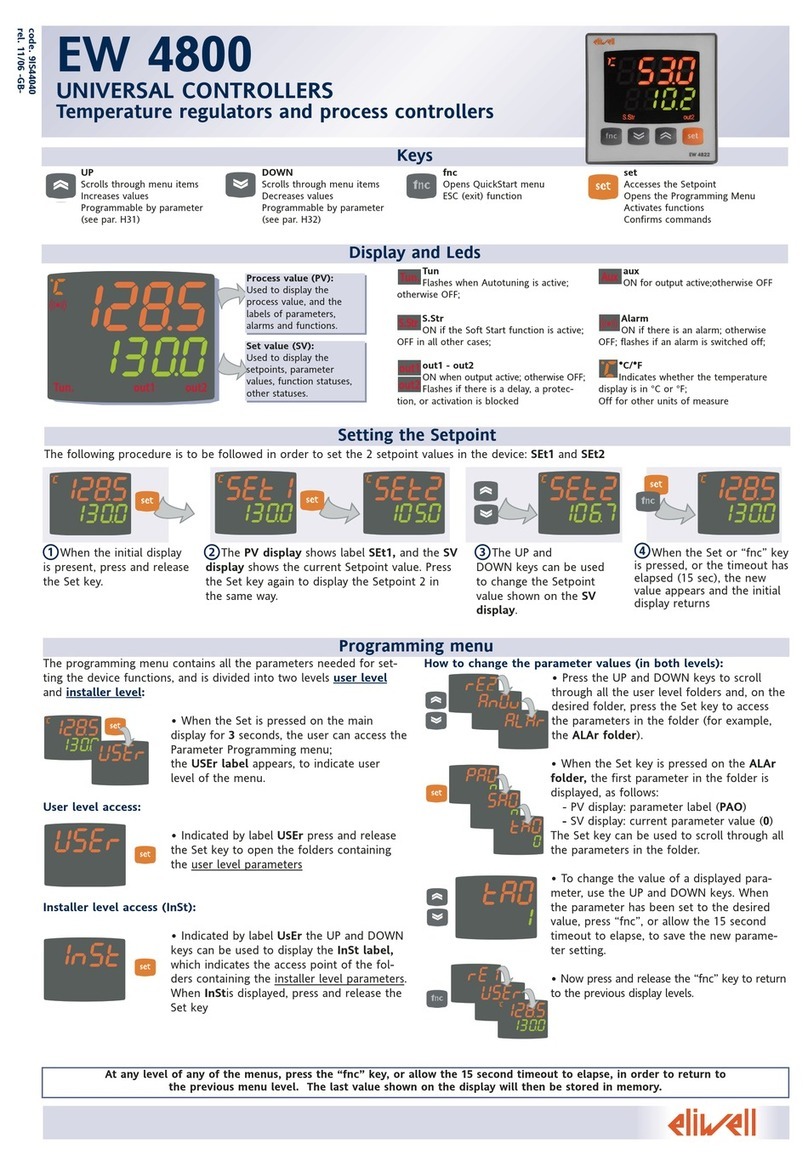

How to display/modify the setpoint

The EWCM is provided with two setpoints:

normal and economy (used during the

night time or holidays).

Push and release the “set” key to display

the normal set, the other unit of measure-

ment and the economy set can be dis-

played by pushing repeatedly the “set” key

whithin 5 seconds.

The corresponding led status lights on the

right side of the display shows the unit of

measurement selected, the active setpoint

displayed is identified by the “N” or “R”

green led, the other setpoint by the “N” or

“R” blinking light. By pushing “UP” or

“DOWN” arrow keys the selected setpoint

can be modified.

Compressors leds status

Before switching on an output the corre-

sponding green led blinks, this blinking pe-

riod depends on the delay parameters.

When the relay output has been swiched

on the corresponding red led will light.

Note: after turning on the power supply the

pressure may result out of range, therefore

to start up the system the EWCM controls

the compressors simply as the probe val-

ue were higher than the alarm limits.

After the time delay set to the parameter

“PAO”, if the probe value is still out of

range, the EWCM will start working follow-

ing the “CPP”, “SPPr” and “PoPr” parame-

ters setting.

How to display/reset the compressors

running hours

Push and release the “hrs” key to display

the first compressor running hours, the

“hrs” led will light; push the “UP” arrow

within 5 seconds to display the successive

compressors, the corresponding red led

will blink; the compressor running hours

can be reset by keeping pressed the

“mute” key for 5 five seconds; to exit this

procedure push and release the “hrs” key

once again.

How to display/modify the “MAINTE-

NANCE” and “IN SERVICE” status

Push and release the “maint” key to dis-

play the first compressor status, the corre-

sponding red led blinks and the “maint”

green led is on.

The “onLn” (on line) message means that

the output is “in service”.

To modify it keep the “mute” key pressed

for 5 seconds, the “oFLn” message means

that the output is in “maintenance” and the

corresponding red led will blink.

During the working cycle the “maintence”

status of a compressor is shown by the

blinking of the corresponding red and

green leds, in this case the output com-

pressor is always swiched off.

Digital alarm inputs

High and low pressurestat alarm

Terminal 5 and 6, “SEP” parameter.

Until the condition alarm on these termi-

nals is active, the EWCM keeps all the

compressor outputs switched off. This

kind of alarm does not need a manual re-

set.

If during the “PEI” interval time the number

of pressurestat errors reaches the “PEn”

value, the “Er0L” or the “Er0H” warning

message will be displayed. “Er0L” means

low pressurestat alarm and “Er0H” means

high pressurestat alarm. Press the “mute”

button for 5 seconds to reset this alarm.

This function can be excluded by setting

PEn = 0.

Alarm inputs linked to outputs

Terminals from 22 to 39, “ALIP” parameter.

Each compressor alarm protection must

be connected to the corresponding alarm

input (e.g. low compressor oil level, klixon

etc.). If one of these alarms is active, the

corresponding compressor output will be

switched off, the corresponding red led will

blink, the “alarm” red led will light and the

display will show the “Er02” warning mes-

sage.

This alarm does not need a manual reset.

Alarm silencing

When an alarm condition is active, the

alarm relay will be energized and the termi-

nal 1 and 2 are closed.

To silence an alarm push and release the

“mute” key, the alarm relay will be de-ener-

gized and the “alarm” led will blink if the

alarm condition is still active. The silencing

time depends on the “UAro” and “Aro” pa-

rameters setting.

If during the silencing time another alarm

becomes active, the silencing time will be

reset, and the new alarm condition will be

displayed.

Alarms that need a manual reset: keep

pressed the “mute” key, the display will

show the “CAnC” message and then the

“rES” message.

ALARM WARNING MESSAGES

Er0L…Er0H: Error Low…High.

Low and high pressurestat alarms. It

switches off all the compressor outputs.

Er01: Error 01.

Faulty probe alarm, see “CPP”, “SPr” and

“PoPr” parameters setting.

Er02: Error 02.

Inputs linked to outputs compressor

alarms. It switches off the corresponding

compressor output.

Er03: Error 03.

Low pressure alarm. It appears when the

probe value is lower than the Set – LAL.

Er04: Error 04.

High pressure alarm. It appears when the

probe value is higher than the Set + HAL.

Er11: Error 11.

Wrong clock programming. Check “Pri”,

“HoUr” and “dAY” parameters setting.

Er12: Error 12.

Wrong parameter programming. More

than the 9 available outputs have been

programmed. It needs a manual reset.

Er13: Error 13.

Wrong data memory. It needs a manual re-

set.

Er14: Error 14.

Maintenance alarm.

TECHNICAL DATA

Housing: black ABS plastic, 72x144 mm,

depth 120 mm.

Mounting: flush panel mount

(67x136 mm) with brackets.

Connections: quick-disconnect screw

terminal block.

Data storage: non-volatile EEPROM

memory.

Type of refrigerant: ammonia.

Suction sensor input: NTC or 4…20 mA

(scaleable).

Pressure switch input: one (1).

Global alarm output: relay 6(3)A 250V

AC.

Controller breakdown output: relay

6(3)A 250V AC.

Configurable outputs: 9 relays outputs

6(3)A 250V AC.

Alarm inputs: 9 inputs (250 Vac optoiso-

lated; other voltages on request).

Serial connection: RS-485 port for con-

nection to the TELEVIS system.

Consumption: 6 VA.

Power supply: 12, 24, 110, 220 Vac

±10%, 50/60 Hz.