EG&G ORTEC 402A Service manual

J

fgAj

n

^Ik}

o%

Models

402A

and

402D

Power

Supplies

Operating

and

Service

Manual

Models

402A

and

402D

Power

Supplies

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

402A

"Rev

47"

on

rear

panel

402D

"Rev

29"

on

rear

panel

3235

5.0C

0482

Printed

in

U.S.A.

STANDARD

WARRANTY

FOR

EG&G

ORTEC

INSTRUMENTS

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

one

year

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

or

use

of

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

purchase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obligation

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

EG&G

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing

or

by

telephone

[(615)

482-4411),

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

sihce

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

(^"^s^sji^^'^i^Ke*

''■ww

.

,'V'*4'j*

,'T-^yF«''*

,'

iti'f'-'^

sr.s^.

?'.'sE»'W^S^*a«^

'^V!T'tiicSSt!i'9^-fii!if'^^*'\'i>^^'*X''i

4:v4*nf

\4*'V•.•■•■

»,-/i*

»iV-iii^^-txS*.

«*-».

I«*V

j*i'-9<t'%iSr'>

/i*

•.i'"%"9-!4

^'*'7.

^■0,-

:

V,

iliPS^-:-:

-

i;^LS

EG&G

ORTEC

402A

POWER

SUPPLY

1.

DESCRIPTION

The

EG&G

ORTEC

402A

Power

Supply

is

designed

to

be

mounted

In

the

space

provided

on

the

rear

of

the

4001

A(B)

Modular

System

Bin.

The

Supply

was

designed

to

exceed

the

recommended

power

supply

specifications,

Appendix

A

of

TID-20893

(Rev),

Type

1,

Glass

A,

adopted

by

the

AEG

Committee

on

Nuclear

Instrument

Modules

(adopted

by

DOE).

The

402A

was

designed

for

both

foreign

and

domestic

usage.

Input

voltage

mains

of

117

V

ac

or

230

V

ac,

50-65

Hz,

may

be

used.

A

simple

circuit

modification

permits

operation

on

100-V

or200-V

input

mains

(see

Section

6).

A

convenience

indicating

switch

located

on

the

rear

of

the

Supply

clearly

identifies

the

intended

main

to

use.

The

primary

circuits

are

fused,

and

a

three-conductor

NEMA-standard

power

cord

is

included.

The

Supply

furnishes

four

standard

dc

voltages;

+12

V

at

2

A,

-12

V

at

2

A,

+24

V

at

1

A,

and

-24

V

at

1

A,

with

a

maximum

power

capability

of

72

W

at

50°G.

A

high-

efficiency

heat

sink

allows

additional

power

dissipation

(see

"Specifications").

The

dc

outputs

are

regulated,

short-circuit

protected,

current

limited,

and

thermal

protected.

The

117

V

ac

is

supplied

to

the

Bin

connector

independent

of

input

mains.

The

117-V

ac

power

available

is

limited

only

by

the

Power

Supply

fuse

when

operating

from

117-

V

ac

mains.

When

operating

from

230-V

ac

mains,

the

117-V

ac

is

derived

by

autotransformer

action

and

is

limited

to

50

VA

output

with

a

dc

load

on

the

power

supply

of

72

W.

A

control

panel

is

provided

on

the

4001

A(B)

Bin

for

oper

ating

and

monitoring

the

402A

Power

Supply.

An

On-Off

switch,

power

indicating

lamp,

thermal

warning

lamp,

and

convenience

dc

monitor

jacks

are

provided.

The

ther

mal

warning

lamp

Is

lighted

when

the

internal

tempera

ture

rises

to

within

20°G

of

the

maximum

safe

operating

temperature.

The

Power

Supply

Is

automatically

cut

off

by

an

internal

switch

should

the

temperature

exceed

the

maximum

safe

operating

temperature.

The

Power

Supply

regulator

amplifiers

are

located

on

the

two

identical

plug-in

printed

circuit

boards,

which

may

be

interchanged

for

maintenance

purposes.

Spare

regu

lator

boards

are

available.

The

regulating

transistors

and

current

monitoring

resistors

for

the

current

limiting

are

mounted

on

a

specially

designed

high-efficiency

heat

sink.

The

power

transistors

are

virtually

indestructible

due

to

their

power

handling

capability,

current

limiting,

and

short-circuit

protection.

Ail-silicon

semiconductors,

85°

G

capacitors

with

conservative

working

voltage

ratings,

and

high-quality

carbon

and

metal

film

resistors

are

com

bined

to

produce

this

Power

Supply

which

exceeds

the

TID-20893

(Rev)

requirements.

The

dc

output

voltages

are

adjustable

over

a

±1-V

range

from

their

nominal

ratings

through

holes

in

the

top

of

the

Power

Supply

cover

plate.

The

15-turn

adjustment

poten

tiometers

are

precision

cermet

for

superior

adjustment

resolution

and

resettabiiity

of

the

output

voltages.

2.

SPECIFICATIONS

The

specifications

for

the

402A

Power

Supply

meet

or

exceed

those

set

forth

by

the

AEG

Gommittee

on

Nuclear

Instrument

Modules,

TID-20893

(Rev),

Appendix

A,

Type

1,

Glass

A.

INPUT

103-129

V

ac,

50-65

Hz,

or

210-258

V

ac,

50-65

Hz.

Input

current

at

117

V

is

1.8

A

fora

72-W

dc

output.

DC

OUTPUT

Output

at

the

following

ratings

+12

V

at

2

A,

-12

V

at

2

A,

+24

V

at

1

A,

-24

V

at

1

A,

maximum

output

power

to

50°

G

ambient,

72

VA;

operation

to

60°

G

ambient

with

current

derated

not

more

than

3%/°G.

Under

certain

conditions

the

72-VA

power

limitation

may

be

exceeded

to

a

maximum

of

96

VA

(see

Fig.

2.1).

117

VOLT

AC

OUTPUT

117-V

ac

output

limited

only

by

the

supply

fuse

when

operating

from

117-V

ac

mains.

Output

is

limited

to

50

VA

at

72-VA

dc

load

while

operat

ing

from

230-V

ac

mains.

30*

C

60"

C*

130

260

120/240

>

110/220

100/200

20O464

'Ambient

Temp.

30

40

50

60

Total

dc

Load

(VA)

Fig.

2.1.

Maxltnuin

Sale

Operating

Range.

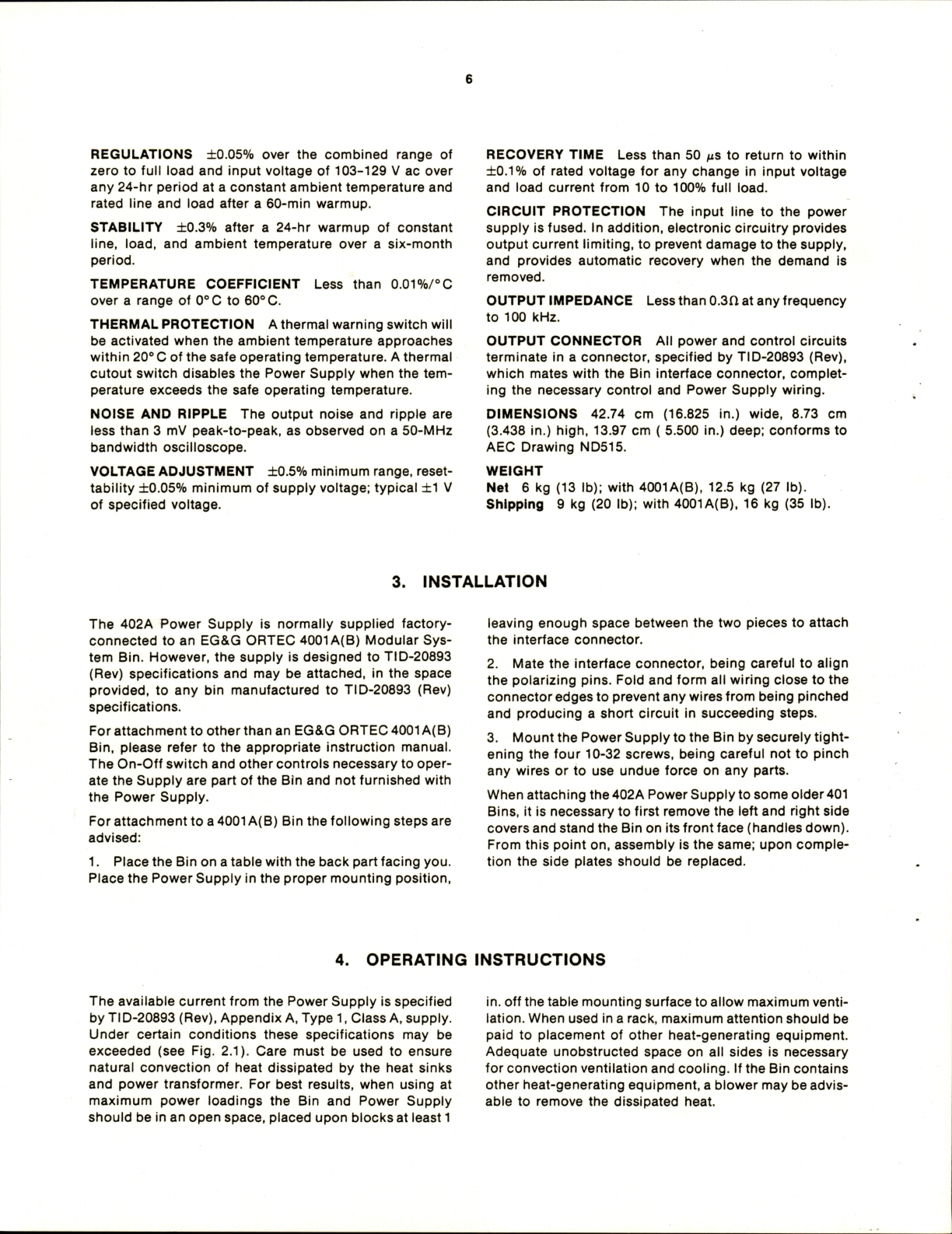

REGULATIONS

±0.05%

over

the

combined

range

of

zero

to

full

load

and

Input

voltage

of

103-129

V

ac

over

any

24-hr

period

at

a

constant

ambient

temperature

and

rated

line

and

load

after

a

60-mln

warmup.

STABILITY

±0.3%

after

a

24-hr

warmup

of

constant

line,

load,

and

ambient

temperature

over

a

six-month

period.

TEMPERATURE

COEFFICIENT

Less

than

0.01

%/°C

over

a

range

of

O^C

to

60°

C.

THERMAL

PROTECTION

A

thermal

warning

switch

will

be

activated

when

the

ambient

temperature

approaches

within

20°

C

of

the

safe

operating

temperature.

A

thermal

cutout

switch

disables

the

Power

Supply

when

the

tem

perature

exceeds

the

safe

operating

temperature.

NOISE

AND

RIPPLE

The

output

noise

and

ripple

are

less

than

3

mV

peak-to-peak,

as

observed

on

a

50-MHz

bandwidth

oscilloscope.

VOLTAGE

ADJUSTMENT

±0.5%

minimum

range,

reset-

tablllty

±0.05%

minimum

of

supply

voltage:

typical

±1

V

of

specified

voltage.

RECOVERY

TIME

Less

than

50

ns

to

return

to

within

±0.1%

of

rated

voltage

for

any

change

In

Input

voltage

and

load

current

from

10

to

100%

full

load.

CIRCUIT

PROTECTION

The

Input

line

to

the

power

supply

Is

fused.

In

addition,

electronic

circuitry

provides

output

current

limiting,

to

prevent

damage

to

the

supply,

and

provides

automatic

recovery

when

the

demand

Is

removed.

OUTPUT

IMPEDANCE

to

100

kHz.

Less

than

0.30

at

any

frequency

OUTPUT

CONNECTOR

All

power

and

control

circuits

terminate

In

a

connector,

specified

by

TID-20893

(Rev),

which

mates

with

the

Bin

Interface

connector,

complet

ing

the

necessary

control

and

Power

Supply

wiring.

DIMENSIONS

42.74

cm

(16.825

In.)

wide,

8.73

cm

(3.438

In.)

high,

13.97

cm

(

5.500

In.)

deep;

conforms

to

AEG

Drawing

ND515.

WEIGHT

Net

6

kg

(13

lb);

with

4001A(B),

12.5

kg

(27

lb).

Shipping

9

kg

(20

lb);

with

4001A(B),

16

kg

(35

lb).

3.

INSTALLATION

The

402A

Power

Supply

Is

normally

supplied

factory-

connected

to

an

EG&G

ORTEG

4001

A(B)

Modular

Sys

tem

Bin.

However,

the

supply

Is

designed

to

TID-20893

(Rev)

specifications

and

may

be

attached.

In

the

space

provided,

to

any

bin

manufactured

to

TID-20893

(Rev)

specifications.

For

attachment

to

other

than

an

EG&G

ORTEG

4001

A(B)

Bin,

please

refer

to

the

appropriate

Instruction

manual.

The

On-Off

switch

and

other

controls

necessary

to

oper

ate

the

Supply

are

part

of

the

Bin

and

not

furnished

with

the

Power

Supply.

For

attachment

to

a

4001

A(B)

Bin

the

following

steps

are

advised;

1.

Place

the

Bin

on

a

table

with

the

back

part

facing

you.

Place

the

Power

Supply

In

the

proper

mounting

position.

leaving

enough

space

between

the

two

pieces

to

attach

the

Interface

connector.

2.

Mate

the

Interface

connector,

being

careful

to

align

the

polarizing

pins.

Fold

and

form

all

wiring

close

to

the

connector

edges

to

prevent

any

wires

from

being

pinched

and

producing

a

short

circuit

In

succeeding

steps.

3.

Mount

the

Power

Supply

to

the

Bin

by

securely

tight

ening

the

four

10-32

screws,

being

careful

not

to

pinch

any

wires

or

to

use

undue

force

on

any

parts.

When

attaching

the

402A

Power

Supply

to

some

older

401

Bins,

It

Is

necessary

to

first

remove

the

left

and

right

side

covers

and

stand

the

Bin

on

Its

front

face

(handles

down).

From

this

point

on,

assembly

Is

the

same;

upon

comple

tion

the

side

plates

should

be

replaced.

4.

OPERATING

INSTRUCTIONS

The

available

current

from

the

Power

Supply

Is

specified

by

TID-20893

(Rev),

Appendix

A,

Type

1,

Glass

A,

supply.

Under

certain

conditions

these

specifications

may

be

exceeded

(see

Fig.

2.1).

Gare

must

be

used

to

ensure

natural

convection

of

heat

dissipated

by

the

heat

sinks

and

power

transformer.

For

best

results,

when

using

at

maximum

power

loadings

the

Bin

and

Power

Supply

should

be

In

an

open

space,

placed

upon

blocks

at

least

1

In.

off

the

table

mounting

surface

to

allow

maximum

venti

lation.

When

used

In

a

rack,

maximum

attention

should

be

paid

to

placement

of

other

heat-generating

equipment.

Adequate

unobstructed

space

on

all

sides

Is

necessary

for

convection

ventilation

and

cooling.

If

the

Bin

contains

other

heat-generating

equipment,

a

blower

may

be

advis

able

to

remove

the

dissipated

heat.

When

it

is

necessary

to

rack

mount

several

Bins

and

Power

Supplies,

especially

when

other

heat-generating

equipment

is

located

within

the

rack,

the

term

"ambient

temperature"

becomes

less

clearly

defined.

A

better

guide

to

maximum

power

loading

capability

is

to

monitor

the

heat

sink

temperature.

In

no

case

allow

the

heat

sink

temperature

to

continuously

run

above

85°

C.

Although

this

is

not

the

maximum

operation

temperature,

any

addi

tional

temperature

rise

due

to

other

conditions

of

the

sys

tem

may

force

the

Supply

out

of

tolerance

and

may

cause

it

to

automatically

shut

down

operation.

Should

your

operation

produce

a

temperature

of

85°

C,

a

blower

to

remove

the

dissipated

heat

is

recommended.

5.

CIRCUIT

DESCRIPTION

The

402A

Power

Supply

produces

four

dc

output

volt

ages.

A

power

transformer

transforms

the

input

ac

line

voltage

into

four

separate

low-voltage

sources.

The

sources

or

windings

are

full-wave-rectified,

capacitor-

filtered,

and

regulated

by

electronic

series

regulator

cir

cuits.

The

regulator

circuits

provide

short

circuit,

current

limiting,

and

reverse

current

protection.

Each

of

the

four

series

regulator

circuits

is

identical

in

operation:

they

are

physically

different

only

in

component

values

for

each

Supply.

The

regulator

essentially

operates

in

two

modes:

First

and

normal

is

the

voltage

regulation

mode:

second

is

the

constant-current

or

current-limiting

protection

mode.

The

regulation

will

operate

in

the

voltage

regulation

mode

at

any

current

output

up

to

and

including

the

full

rated

output

of

a

particular

supply.

When

current

output

beyond

the

rated

output

is

required,

which

includes

a

direct

short

across

the

output

terminals,

the

regulator

automatically

shifts

into

a

constant-current

mode.

This

provides

current

limiting

and

protection

of

the

regulator's

circuitry

and

components.

When

excessive

current

demands

are

re

moved,

the

regulator

resumes

the

voltage

regulation

mode.

For

operation

of

the

regulator,

please

refer

to

Circuit

Drawing

402A-1100-S1.

For

convenience,

only

the

+24-V

regulator

will

be

discussed,

and

the

following

is

an

explanation

of

the

regulation

in

the

normal

voltage

regu

lation

mode.

Transistors

Q6

and

Q7

operate

as

a

differential

amplifier

pair,

comparing

the

reference

voltage

of

04

at

the

base

of

Q6

with

a

portion

of

the

output

voltage

divided

down

through

R16, R17,

and

R18.

Trim

potentiometer

R17

is

used

to

adjust

the

output

voltage

to

the

specified

level.

A

difference

voltage

at

the

collector

of

Q7

is

dc

amplified

by

Q4

and

Q2.

The

collector

of

Q2

drives

emitter-follower

Q1,

which

supplies

the

necessary

current

to

drive

the

remotely

located

series

power

transistor.

This

transistor

is

heat-sink-mounted

to

dissipate

the

power

consumed

in

the

regulation

process.

In

the

constant-current

or

limiting

mode,

remotely

located

resistor

R1,

in

series

with

the

output,

senses

the

output

current

level

and

produces

a

proportional

voltage

rise.

The

sense

voltage

is

compared

to

the

output

voltage

at

the

base

of

Q5.

For

output

current

levels

less

than

or

equal

to

the

rated

output,

Q5

remains

back-biased

and

will

have

no

effect

on

the

regulator

performance.

How

ever,

when

the

output

current

exceeds

the

rated

output,

Q5

becomes

forward-biased

and

conducts,

causing

Q2

to

conduct

harder,

thereby

reducing

the

available

base

drive

current

to

emitter-follower

Q1

and

the

series

pass

regulator

transistor.

As

a

result,

the

output

voltage

is

reduced

until

the

output

current

is

within

the

required

limits.

Upon

removal

of

the

short

circuit

or

excessive

cur

rent

demand,

the

regulator

resumes

the

normal

voltage

regulation

mode.

6.

MODIFICATION

The

transformer

in

this

EG&G

ORTEC

402A

Power

Supply

has

a

tap

in

each

of

the

primary

windings

to

per

mit

operation

with

a

nominal

100/200

V

ac

input.

The

tap

for

one

primary

is

a

yellow

wire

and

for

the

other

primary

is

a

white

wire.

These

leads

are

covered

with

shrinkable

tubing

over

the

ends

and

are

included

in

the

bundle

of

leads

from

the

transformer.

To

operate

the

402A

Power

Supply

from

either

a

100

or

200

V

ac

power

source,

use

the

following

steps

to

change

the

primary

winding

connections;

1.

Remove

the

top

cover

from

the

402A

Power

Supply.

2.

Remove

the

two

piug-in

regulator

boards.

3.

Locate

the

unused

yellow

and

white

wires

and

remove

the

shrinkable

tubing

from

the

wire

ends.

4.

Disconnect

the

black

wire

from

the

117/230

V

ac

switch

and

connect

the

yellow

wire

to

the

switch

terminal

in

place

of

the

black

wire.

5.

Disconnect

the

black/white

and

red

wires

from

the

117/230

V

ac

switch

and

connect

the

white

wire

to

this

switch

terminal.

6.

Use

shrinkable

tubing

or

electrical

insulation

tape

to

cover

the

bare

end

of

the

black

wire.

7.

Connect

the

black/white

and

red

wires

together

and

wrap

the

ends

with

electrical

insulating

tape.

8.

Return

the

two

plug-in

regulator

boards

and

the

top

cover

to

the

402A

Power

Supply.

The

402A

is

now

wired

for

100/200

V

ac

line

operation

instead

of

117/230

V

ac.

Ensure

that

the

switch

selects

the

proper

range

before

applying

power

to

the

unit.

cz

Cl

+

1

:^tj-V

I''

ie

*

mm^m-^wm--

01.

11

EG&G

ORTEC

402D

POWER

SUPPLY

1.

DESCRIPTION

The

EG&G

ORTEC

402D

Power

Supply

Is

designed

to

be

mounted

in

the

space

provided

on

the

rear

of

the

4001

A(B)

Modular

System

Bin.

The

Supply

was

designed

to

exceed

the

recommended

power

supply

specifica

tions,

Appendix

A

of

TID-20893

(Rev

3),

Type

V-H,

adopted

by

the

AEG

Committee

on

Nuclear

Instrument

Modules

(adopted

by

DOE).

The

402D

was

designed

for

worldwide

usage.

Input

volt

age

mains

of

117

V

ac

or

230

V

ac.

47-63

Hz,

may

be

used.

A

convenience

Indicating

switch

clearly

identifies

the

intended

main

to

use.

The

Supply

furnishes

six

standard

dc

voltages,

+24

V

at

1

A,

-24

V

at

1

A,

+12

V

at

2

A,

-12

V

at

2

A,

+6

V

at

8

A

and

—6

V

at

8

A,

with

a

maximum

power

capability

of

132

W

at

50°C.

The

dc

outputs

are

regulated,

short-circuit

pro

tected,

current

limited,

and

thermal

protected.

The

117

V

ac

is

supplied

to

the

Bin

connector

independ

ent

of

input

mains.

The

117-7

ac

power

available

Is

limited

only

by

the

Power

Supply

fuse

when

operating

from

117-V

ac

mains.

When

operating

from

230-V

ac

mains,

the

117-V

ac

Is

derived

by

autotransformer

action

and

is

limited

to

60

VA

output

with

a

dc

load

on

the

Power

Supply

of

132

W.

A

control

panel

is

provided

on

the

EG&G

ORTEC

4001

A(B)

Bin

for

operating

and

monitoring

the

402D

Power

Supply.

An

On-Off

switch,

a

power

indicating

lamp,

a

thermal

warning

lamp,

and

convenience

dc

moni

tor

jacks

are

provided.

The

thermal

warning

lamp

Is

lighted

when

the

internal

temperature

rises

to

within

20°

C

of

the

maximum

safe

operating

temperature.

The

Power

Supply

Is

automatically

cut

off

by

an

internal

switch

should

the

temperature

exceed

the

maximum

safe

operating

temperature.

The

power

transistors

are

virtually

indestructible

due

to

their

power

handling

capability,

current

limiting,

and

short-circuit

protection.

Silicon

semiconductors,

85°

C

capacitors

with

conservative

working

voltage

ratings,

high-quality-carbon

resistors,

and

metal

film

resistors

are

combined

to

produce

the

402D

Power

Supply,

which

exceeds

the

TID-20893

(Rev)

requirements.

The

dc

output

voltages

are

adjustable

through

holes

in

the

top

of

the

Power

Supply

cover

plate,

over

a

±2%

range

from

their

nominal

ratings.

The

adjustment

poten

tiometers

are

20-turn

cermet

potentiometers

for

superior

adjustment

resolution

and

resettability

of

the

output

volt

ages.

2.

SPECIFICATIONS

INPUT

100

to

129

V

ac,

57-63

Hz,

or

200

to

258

V

ac,

47-53

Hz.

Input

current

at

117

V

is

3.5

A

for

a

132-W

dc

output.

i

DC

OUTPUTS

The

Supply

provides

six

simultaneous

dc

outputs

with

the

following

current

ratings:

VOLTAGE

(V)

+24.00

-24.00

+12.00

-12.00

+

6.00

-

6.00

CURRENT

(A)

0

to

1

0

to

1

0

to

2

0

to

2

0

to

8

0

to

8

Maximum

output

power

from

0

to

50°

C

ambient

is

132

W.

Operation

to

60°

C

ambient,

with

current

derated

not

more

than

3%/°C

for

temperatures

above

50°

C.

117-V

AC

OUTPUT

117-V

ac

output

is

limited

only

by

the

Supply

fuses

when

operating

from

117-V

ac

mains.

Output

is

limited

to

60

VA

at

132-W

dc

load

while

operat

ing

from

230-V

ac

mains.

REGULATION

±0.1

%

(typically

±0.05%)

for

±12

V

and

±24

V,

and

±0.2%

(typically

±0.1%)

for

±6

V

over

the

combined

range

of

zero

to

full

load

and

input

voltage

of

100

to

129

V

ac

or

200

to

258

V

ac,

when

measurements

are

made

within

a

period

of

1

min.

±0.3%

(±12

V

and

±24

V)

and

±0.6%

(±6

V)

over

any

24-hr

period

at

constant

ambient

temperature

over

the

combined

range

of

no

load

to

full

load

and

input

voltage

of

100

to

129

V

ac

or

200

to

258

V

ac,

after

a

60-min

warmup.

STABILITY

Long-term

stability

over

a

6-month

period

is

better

than

±0.5%

after

a

1

-hr

warmup

at

constant

load,

line,

and

ambient

temperature.

12

OUTPUT

IMPEDANCE

<0.15n

for

the

±6-V

outputs

and

<0.3n

for

all

other

outputs

at

any

frequency

to

100

kHz.

TEMPERATURE

COEFFICIENT

range

of

0

to

60°

C.

<0.02%/°C

over

a

TEMPERATURE

PROTECTION

A

thermal

warning

switch

will

close

when

the

supply

temperature

ap

proaches

within

20°

C

of

the

safe

operating

value.

A

thermal

cutout

switch

disables

the

Power

Supply

when

the

temperature

exceeds

the

safe

operating

value.

NOISE

AND

RIPPLE

<3

mV

peak-to-peak

for

all

six

outputs,

as

observed

on

a

50-MHz

bandwidth

oscillo

scope.

VOLTAGE

ADJUSTMENTS

±2%

minimum

range,

reset-

tablllty

±0.05%

of

Supply

voltage.

CIRCUIT

PROTECTION

Both

sides

of

the

Input

line

to

the

power

supply

are

fused.

In

addition,

output

current

foldback

limiting

to

prevent

damage

to

the

Supply

and

automatic

recovery

when

the

demand

Is

removed

are

provided

by

electronic

circuitry.

All

six

supplies

are

protected

so

that

any

one

can

be

shorted

to

any

other

one

without

resulting

In

permanent

damage.

Overvoltage

protection

Is

provided

on

±6

V

so

that

these

outputs

will

not

exceed

7.5

V

maximum.

OUTPUT

CONNECTOR

All

power

and

control

circuits

terminate

In

a

connector,

specified

by

TID-20893

(Rev

3),

which

mates

the

Bin

Interface

connector,

completing

the

necessary

control

and

Power

Supply

wiring.

DIMENSIONS

Conform

to

AEG

drawing

ND-515

and

paragraph

L,

page

A-10,

of

TID-20893

(Rev

3).

RECOVERY

TIME

<100

fjs

to

return

to

within

±0.1%

of

rated

voltage

for

all

six

outputs

for

any

change

In

Input

voltage

and

load

current

from

10%

to

100%

full

load.

WEIGHT

Net

8.9

kg

(20

lb);

with

4001A(B)

13.6

kg

(30

lb).

Shipping

12.3

kg

(27

lb);

with

4001A(B)

19.6

kg

(43

lb).

3.

INSTALLATION

The

402D

Power

Supply

Is

normally

supplied

factory-

connected

to

an

EG&G

ORTEG

4001A(B)

Modular

Sys

tem

Bin.

However,

the

Supply

Is

designed

to

TID-20893

(Rev)

specifications

and

may

be

attached.

In

the

space

provided,

to

any

bin

manufactured

to

TID-20893

(Rev)

specifications.

For

attachment

to

other

than

an

EG&G

ORTEG

4001

A(B)

Bin,

refer

to

the

appropriate

Instruction

manual.

The

On-

Off

switch

and

other

controls

necessary

to

operate

the

supply

are

part

of

the

Bin

and

are

not

furnished

with

the

Power

Supply.

For

attachment

to

the

EG&G

ORTEG

4001A(B)

Bin

the

following

steps

are

advised:

1.

Place

the

Bin

on

a

table

with

the

back

part

facing

you.

Place

the

Power

Supply

In

the

proper

mounting

position,

leaving

enough

space

between

It

and

the

Bin

to

attach

the

Interface

connector.

2.

Mate

the

Interface

connector,

being

careful

to

align

the

polarizing

pins.

Fold

and

form

all

wiring

close

to

the

connector

edges

to

prevent

any

wires

from

being

pinched

and

producing

a

short

circuit

In

succeeding

steps.

3.

Mount

the

Supply

to

the

Bin

by

securely

tightening

the

four

10-32

screws,

being

careful

not

to

pinch

any

wires

or

to

use

undue

force

on

any

parts.

Unless

otherwise

specified,

the

402D

Is

shipped

with

transformer

connections

appropriate

for

operation

on

nominal

117

or

230

V

mains,

according

to

the

selection

made

with

the

rear

panel

slide

switch.

To

change

the

connections

for

operation

on

100

or

200

V

power

mains,

use

the

following

steps:

1.

Remove

the

top

cover.

2.

Move

the

wires

from

lug

#3

of

T1

to

Its

lug

#2.

3.

Move

the

wires

from

lug

#6

of

T1

to

Its

lug

#5.

4.

Replace

the

top

cover.

5.

Set

the

rear

panel

slide

switch

at

117

for

100

V

opera

tion

or

at

230

for

200

V

operation.

13

4.

OPERATING

INSTRUCTIONS

4.1

POWER

SUPPLY

LIMITATIONS

The

available

current

from

the

Power

Supply

is

given

in

Section

2.

Care

must

be

used

to

ensure

natural

convec

tion

of

heat

dissipated

by

the

heat

sinks

and

power

trans

former.

For

best

resuits,

when

using

at

maximum

power

loadings,

the

Bin

and

Power

Supply

should

be

in

an

open

space,

piaced

upon

blocks

at

least

1

in.

off

the

table

mounting

surface

to

allow

maximum

ventilation.

When

used

in

a

rack,

maximum

attention

should

be

paid

to

placement

of

other

heat-generating

equipment.

Ade

quate

unobstructed

space

on

all

sides

is

necessary

for

convection

ventilation

and

cooling.

If

the

Bin

contains

other

heat-generating

equipment,

a

blower

may

be

advisable

to

remove

the

dissipated

heat.

When

it

is

necessary

to

rack-mount

severai

bins

and

power

supplies,

especially

when

other

heat-generating

equipment

is

located

within

the

rack,

the

term

"ambient

temperature"

becomes

less

clearly

defined.

A

better

guide

to

maximum

power

loading

capability

is

to

monitor

the

heat

sink

temperature.

Never

allow

the

heat

sink

temperature

to

continuously

run

above

lOCC.

Although

this

is

not

the

maximum

operation

temperature,

any

addi

tional

temperature

rise

due

to

other

conditions

of

the

sys

tem

may

force

the

Supply

out

of

tolerance

and

may

cause

it

to

automaticaily

shut

down

operation.

Should

your

operation

produce

a

temperature

of

100°C,

a

blower

to

remove

the

dissipated

heat

is

recommended.

4.2

6-V

POWER

SUPPLIES

CROWBAR

OPERATION

Both

the

-f-e-V

and

the

-S-V

outputs

are

protected

against

overvoltage.

If

for

any

reason

one

of

these

output

voltages

exceeds

7.5

V

maximum

in

absolute

value

an

internal

"crowbar

circuit"

is

triggered,

which

places

a

short-circuit

across

the

output

of

the

corresponding

volt

age.

Since

this

circuit

contains

an

SCR,

normal

opera

tion,

after

suppression

of

the

cause

of

the

overvoitage,

can

be

resumed

only

by

turning

the

power

switch

of

the

4001

Bin

to

Off

for

a

couple

of

seconds,

and

then

turning

it

to

On

again.

If

in

normal

operation

it

is

suddenly

discovered

that

the

+6-\/

or

-6-V

output

is

missing,

first

check

whether

it

can

be

restored

by

following

this

procedure,

after

having

removed

all

the

modules

from

the

Bin.

The

crowbar

pro

tection

circuit

of

the

corresponding

voitage

may

have

been

triggered

by

a

temporary

fault

in

one

module

or

even

by

a

strong

spurious

voltage

transient.

5.

CIRCUIT

DESCRIPTION

5.1.

GENERAL

DESCRIPTION

The

402D

Power

Supply

produces

six

dc

output

voltages;

±12

V,

±24

V,

and

±6

V.

A

power

transformer

reduces

the

input

ac

line

volfage

into

six

separate

low

voltage

sources.

Each

voltage

source

has

a

separate

full-wave

bridge,

a

filter

capacitor,

and

an

electronic series

regula

tor.

Each

regulator

is

composed

of

discrete

solid-state

devices

and

is

completely

independent

from

all

other

output

regulators.

The

six

regulators

are

packaged

on

three

plug-in

printed

circuit

boards.

The

board

closest

to

the

heat

sink

includes

regulators

for

the

±6

V

supplies.

The

board

in

the

middle

includes

regulators

for

the

negative

12

and

24

V

supplies.

The

other

board

includes

regulators

for

the

positive

12

and

24

V

supplies.

The

12

V

and

24

V

regulator

boards

are

identical

and

may

be

interchanged.

The

rectifiers,

series

pass

transistors,

sense

resistors,

and

the

SCRs

for

the

6

V

supplies

are

all

located

on

the

large

heat

sink.

The

filter

capacitors

for

the

12

V

and

24

V

supplies

are

located

on

their

regulator

boards.

The

filter

capacitors

for

the

6

V

supplies

are

mounted

in

the

power

suppiy

chassis.

5.2.

OPERATION

OF

REGULATORS

The

operation

of

the

±12

V

and

±24

V

regulators

are

all

identical.

The

+24

V

regulator

is

discussed

here

as

an

example

that

is

typical

for

all

four

of

these

supplies.

The

circuit

is

shown

on

schematic

402D-0201-S1.

The

circuit

consists

of

two

parts;

these

are

the

voltage

regulator

and

the

current

foldback

circuit.

The

voltage

regulator

includes

Q10,

Q11,

Q3,Q4,

Q2,Q1,

and

Q101.

The

current

foldback

circuit

includes

Q5,Q7,

Q8,06,

and

09.

Transistors

010

and

Oil

operate

as

a

differential

ampli

fier,

comparing

the

voltage

from

the

reference

diode,

D4,

at

the

base

of

010

to

the

output

voltage

divided

down

by

resistors

R21,R22,

and

R23.

Potentiometer

R22

is

used

to

adjust

the

output

voltage

to

the

desired

level.

The

differ

ence

voltage

is

amplified

by

03

and

04

to

reduce

the

current

through

02

and

to

increase

the

output

voltage

or

14

to

increase

the

current

through

Q2

and

to

then

decrease

the

output

voltage.

Q2

drives

emitter

follower

Q1

to

supply

drive

current

for

series

pass

element

Q101.

In

the

current

limiting

mode,

the

voltage

across

sense

resistor

R101

is

applied

between

the

bases

of

Q6

and

Q9.

When

the

current

level

is

less

than

the

rated

current,

Q6

and

Q7

conduct.

If

the

output

current

exceeds

its

rated

value,

the

voltage

at

the

base

of

Q6

goes

higher

than

the

voltage

at

the

base

of

Q9

and

Q9

conducts.

This

turns

Q8

on

to

increase

the

current

through

Q2

and

to

decrease

the

current

drive

to

the

base

of

Q1.

The

amount

of

current

that

the

series

pass

element,

Q101,

can

supply

is

reduced.

When

the

over-current

condition

is

corrected,

normal

regulation

returns

automatically.

The

±6

V

regulators

operate

much

the

same

as

the

+24

V

regulator.

The

circuit

for

the

±6

V

regulators

is

shown

on

schematic

402D-0301

-SI.

The

sense

amplifier

of

the

+6

V

regulator

includes

Q11, Q10,

Q9,

Q26,

Q4,

Q5,

Q2.

Q1,

and

Q3.

The

operation

is

the

same

as

for

the

+24

V

regu

lator.

The

addition

of

Q9

and

Q26

provides

a

constant

current

for

reference

diode

D11.

In

the

current

limiting

mode,

operation

is

the

same

as

for

the

+24

V

regulator.

Resistors

R105

through

R108

are

used

to

balance

the

current

in

the

four

series

pass

tran

sistors,

Q105

through

Q108.

R108

is

also

used

as

a

sense

resistor.

The

four

transistors

are

used

to

keep

the

power

dissipated

in

each

device

below

the

maximum

rated

value.

The

"crowbar"

circuit

is

used

for

over-voltage

protection.

It

includes

Q12,

D12,

and

SCR

D107.

If

the

output

voltage

exceeds

the

zener

voltage

of

D12

(~6.8

V),

Q12

turns

on

and

triggers

the

gate

of

the

SCR.

When

the

SCR

turns

on,

it

appears

as

a

short

across

the

supply

output

and

causes

the

current

to

fold

back.

After

the

cause

of

the

over-

voltage

has

been

removed,

the

supply

must

be

switched

off

for

two

seconds

and

can

then

be

turned

on

again

to

restore

its

normal

operation.

6.

MAINTENANCE

6.1.

ACCESS

The

top

cover

of

the

402D

Power

Supply

is

attached

with

sixteen

4-40

Phillips-head

machine

screws.

When

all

16

screws

are

removed

the

cover

can

be

lifted

for

access

to

the

plug-in

regulator

boards.

Each

regulator

board

has

keying

pins

to

prevent

reversal

of

position

in

the

connec

tor

and

to

prevent

insertion

into

the

incorrect

location.

Be

very

careful

to

prevent

breaking

or

removing

the

keying

pins

from

the

connector

during

either

removal

or

return

of

the

board.

There

are

copper

clips

attached

to

some

of

the

transis

tors

on

the

printed

circuit

boards.

Their

purpose

is

to

ensure

equal

operating

temperatures

for

these

transis

tors.

Do

not

remove

the

copper

clips

from

these

transis

tors.

Most

of

the

components

mounted

on

the

heat

sink

can

be

replaced

easily.

If

access

is

required

to

the

chassis

side

of

the

heat

sink,

remove

the

14

mounting

screws

that

secure

it

to

the

chassis

and

carefully

fold

the

heat

sink

away

from

the

chassis

to

prevent

breaking

any

of

the

wire

leads

or

the

soldered

connections.

6.2.

TROUBLESHOOTING

Any

of

the

three

transistor

boards

may

be

operated

separately

without

requiring

the

other

boards

to

be

installed

in

the

power

supply.

If

an

output

voltage

is

high

and

cannot

be

adjusted

down

to

its

proper

level,

its

series

pass

transistor,

mounted

on

the

heat

sink,

may

be

shorted.

This

condition

will

usually

cause

damage

to

the

regulator

that

is

mounted

on

the

printed

circuit

board.

Check

the

emitter-base

junction

of

the

series

pass

transistor

with

an

ohmmeter

if

a

short

is

suspected.

Do

not

install

another

regulator

board

if

the

transistor

is

shorted,

or the

new

board

will

be

damaged.

Since

the

positive

12/24

V

regulator

board

is

identical

to

the

negative

12/24

V

regulator

board,

the

boards

can

be

interchanged

for

troubleshooting.

Replacement

regula

tor

boards

are

available

from

EG&G

ORTEC.

6.3.

TYPICAL

VOLTAGES

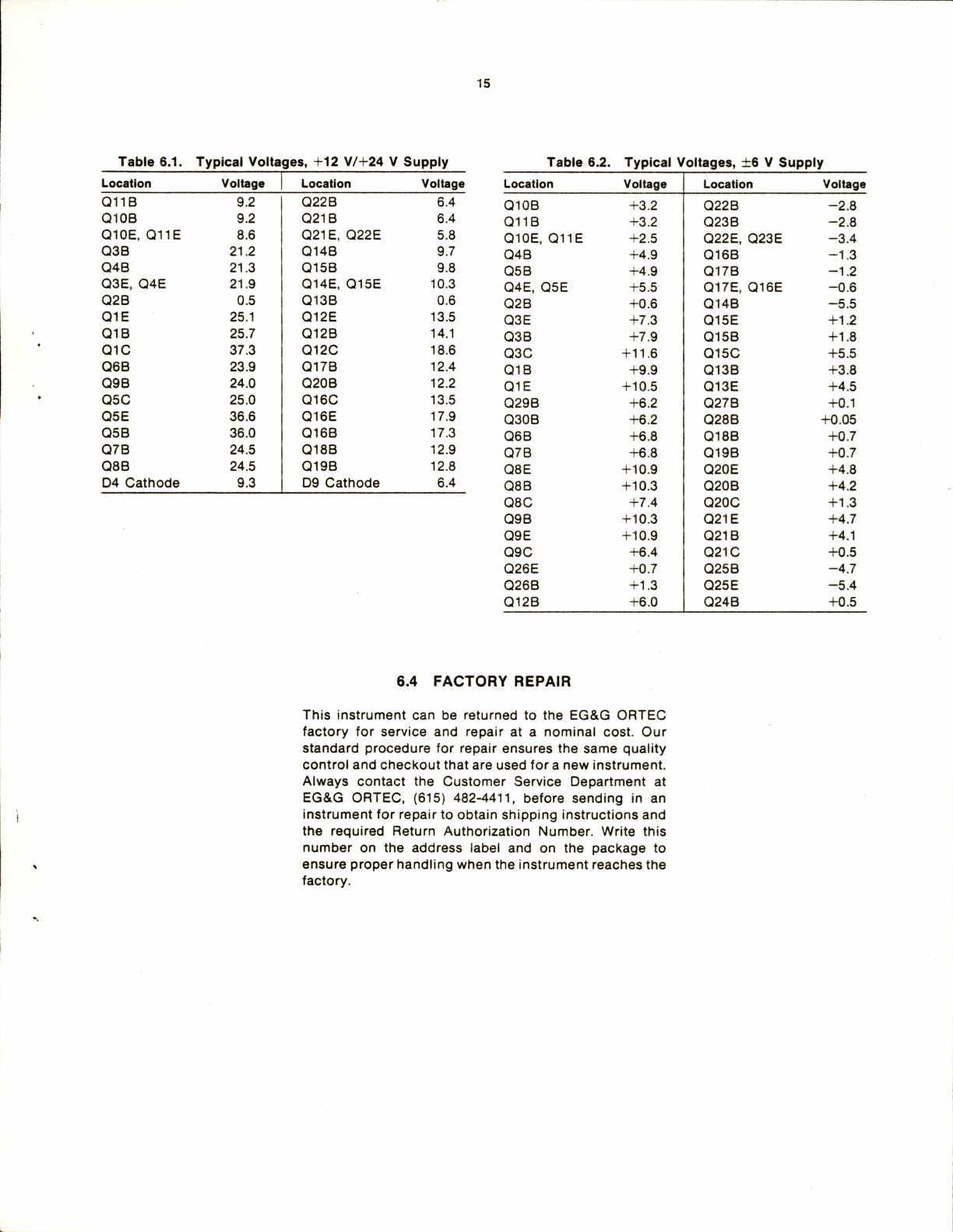

Tables

6.1

and

6.2

list

typical

voltages

that

were

meas

ured

with

respect

to

ground

potential

and

they

are

given

here

as

an

aid

in

troubleshooting.

These

voltage

levels

are

typical

of

a

circuit

that

is

operating

properly,

but

the

precise

values

will

vary

between

individual

circuits.

The

12/24

V

table

indicates

the

voltages

on

the

board

when

it

is

installed

at

the

positive

location,

furthest

from

the

heat

sink.

Line

voltage

is

117

V

ac.

The

24

V

supply

is

loaded

for

1

A

and

the

12

V

supply

is

loaded

for

2

A.

All

measurements

are

referenced

to

chassis

ground

and

are

made

with

a

voltmeter

that

has

a

10

MO

input

impedance.

The

regulator

board

for

the

±6

V

supplies

operates

in

the

location

closest

to

the

heat

sink.

The

following

voltages

assume

a

line

voltage

of

117

V.

Each

supply,

+6

V

and

—6

V,

is

loaded

for

8

A.

All

measurements

are

referenced

to

chassis

ground

and

are

made

with

a

voltmeter

that

has

a

10

Mn

input

impedance.

15

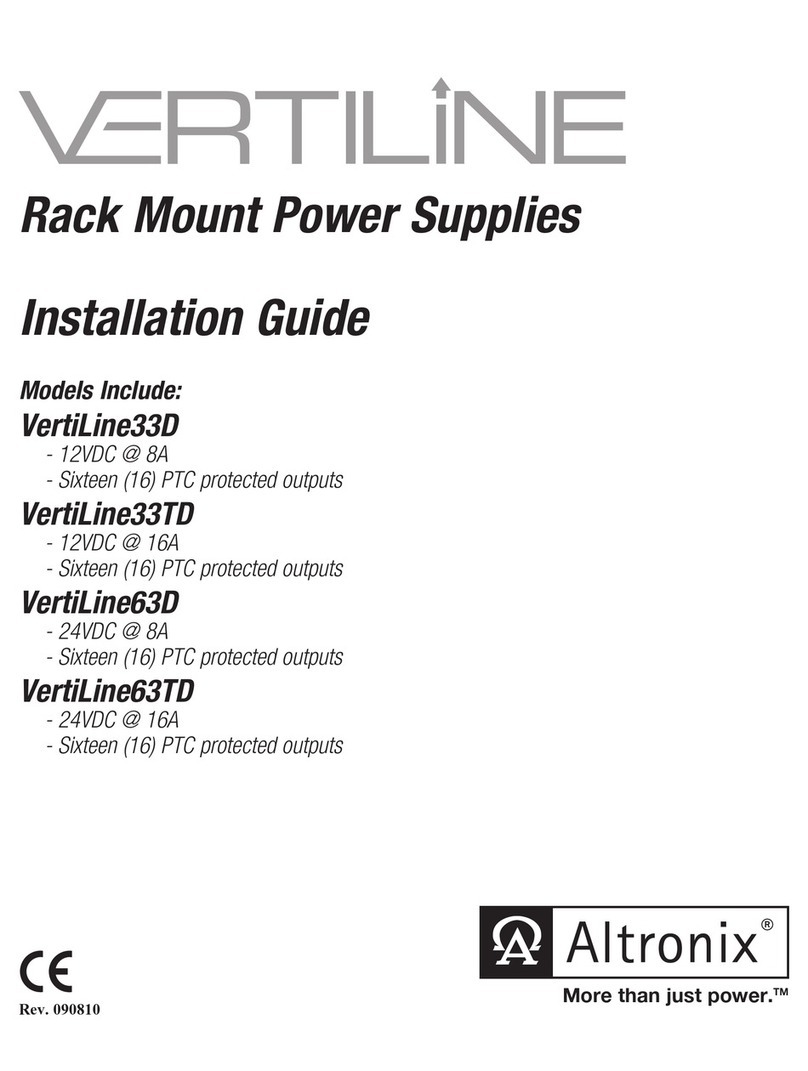

Table

6.1.

Typical

Voltages,

+12

V/+24

V

Supply

Table

6.2.

Typical

Voltages,

±6

V

Supply

Location

Voltage

Location

Voltage

Location

Voltage

Location

Voltage

Q11B

9.2

022

B

6.4

Q10B

+3.2

Q22B

-2.8

Q10B

9.2

021

B

6.4

Q11B

+3.2

Q23B

-2.8

Q10E,

Q11E

8.6

021E,

Q22E

5.8

Q10E,

Q11E

+2.5

Q22E,

Q23E

-3.4

Q3B

21.2

Q14B

9.7

Q4B

+4.9

Q16B

-1.3

Q4B

21.3

Q15B

9.8

05

B

+4.9

Q17B

-1.2

Q3E,

Q4E

21.9

Q14E,

Q15E

10.3

Q4E,

05E

+5.5

Q17E,

Q16E

-0.6

Q2B

0.5

Q13B

0.6

Q2B

+0.6

Q14B

-5.5

Q1E

25.1

Q12E

13.5

Q3E

+7.3

Q15E

+1.2

01B

25.7

Q12B

14.1

Q3B

+7.9

Q15B

+1.8

QIC

37.3

Q12C

18.6

030

+11.6

0150

+5.5

Q6B

23.9

Q17B

12.4

01B

+9.9

Q13B

+3.8

Q9B

24.0

Q20B

12.2

01E

+10.5

Q13E

+4.5

050

25.0

0160

13.5

Q29B

+6.2

027

B

+0.1

Q5E

36.6

Q16E

17.9

Q30B

+6.2

028

B

+0.05

Q5B

36.0

Q16B

17.3

06

B

+6.8

Q18B

+0.7

Q7B

24.5

Q18B

12.9

07

B

+6.8

Q19B

+0.7

Q8B

24.5

Q19B

12.8

08

E

+10.9

Q20E

+4.8

04

Cathode

9.3

09

Cathode

6.4

Q8B

+10.3

Q20B

+4.2

080

+7.4

Q20C

+1.3

09

B

+10.3

021E

+4.7

09E

+10.9

021B

+4.1

090

+6.4

021G

+0.5

Q26E

+0.7

Q25B

-4.7

Q26B

+1.3

025

E

-5.4

Q12B

+6.0

Q24B

+0.5

6.4

FACTORY

REPAIR

This

instrument

can

be

returned

to

the

EG&G

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

Our

standard

procedure

for

repair

ensures

the

same

quality

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

the

Customer

Service

Department

at

EG&G

ORTEC,

(615)

482-4411,

before

sending

in

an

instrument

for

repair

to

obtain

shipping

instructions

and

the

required

Return

Authorization

Number.

Write

this

number

on

the

address

label

and

on

the

package

to

ensure

proper

handling

when

the

instrument

reaches

the

factory.

i

0

-(BZS-

I

-{SO-

(S)

-SID—

^

|a

-{HB-

(D

I

-iSS

n

—fRSaT—

@

'

—fgzl

N

-cm^K^rizten}-

--0

40.;

U-O20I©

IR

C

CO

UMttM

01WWW

$1

ORTEC

Afi

t*3«0cicav»*js|>'

irvJC30F4H=>CDMArei3

lOO

MIDLAND

ROAD.

OAK

RIDOE,

TENNESSEE

37830

MLV

B-Zt-74

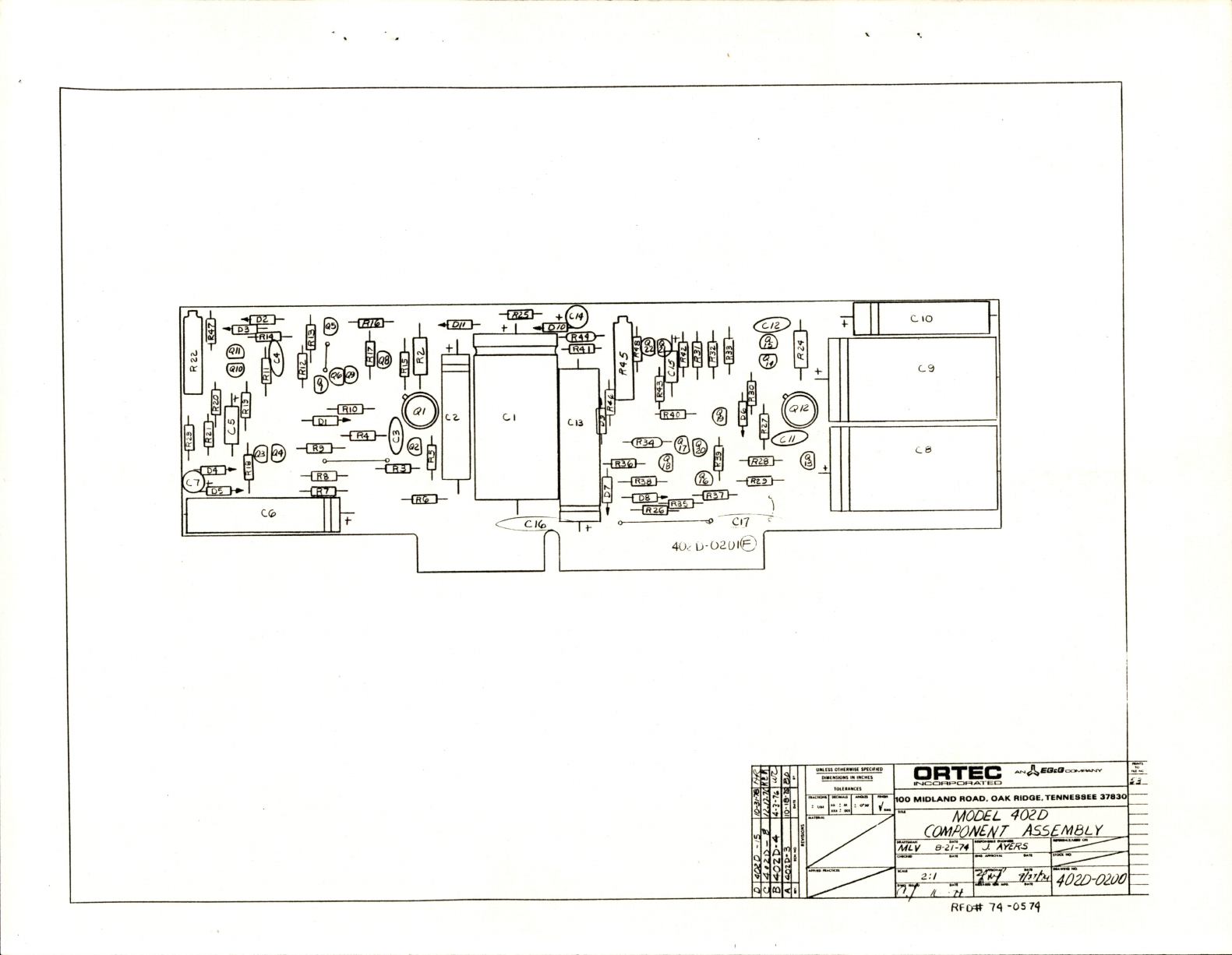

MODEL

402D

rnMPDNEA/T

ASSEMBLY

J.

AYS/rs

402D-0100

RFC#

74

-05

74

This manual suits for next models

1

Table of contents

Other EG&G Power Supply manuals

Popular Power Supply manuals by other brands

Puls

Puls PIC480.241C installation manual

Zennio

Zennio ALLinBOX 1612 v2 manual

Delta Elektronika

Delta Elektronika SM 15-400 product manual

Test Equipment Depot

Test Equipment Depot PS-1303C user manual

Agilent Technologies

Agilent Technologies 6622A Service manual

Philips

Philips dynalite DDNP1501 installation instructions