EG&G ORTEC 4002A Service manual

n

Model

4002A

Power

Supply

Operating

and

Service

Manual

Model

4002A

Power

Supply

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

18"

on

rear

panel

Printed

in

U.S.A.

^3''''

standard

Warranty

for

EG&G

ORTEC

Nuclear

Electronic

instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

two

years

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shail

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

[(615)

482-4411]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper,

instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materiais,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

iii

CONTENTS

Page

WARRANTY

.

jj

PHOTOGRAPHS

iv

1.

DESCRIPTION

1

2.

SPECIFICATIONS

1

3.

INSTALLATION

2

3.1.

Packing

2

3.2.

Selecting

the

Mains

Voltage

2

4.

OPERATING

INSTRUCTIONS

3

5.

CIRCUIT

DESCRIPTION

3

6.

MAINTENANCE

4

6.1.

Disassembly

and

Troubleshooting

4

6.2.

Factory

Repair

4

Schematic

tk

S$;lk

?SSi

m.

%s&

giyft

M

1

1

1

hhjjhih'i'

'"♦'"VV.iii

tifhMMtjMi

MMMMi

m»iM

t0:>

Hi

•".'iV'fev

1

ix'b'ki'

--Vf/,'.

/

/

tf

f

»f

ryf

p*

EG&G

ORTEC

4002A

POWER

SUPPLY

1.

DESCRIPTION

The

EG&G

ORTEC

4002A

Power

Supply

is

designed

to

be

mounted

in

the

space

provided

on

the

rear

of

the

4001

Series

Modular

System

Bin.

The

power

supply

meets

or

is

superior

to

the

recommended

power

supply

specifica

tions

in

Appendix

A

of

TID-20893

(Rev).

Type

1,

Class

A,

adopted

by

the

AEC

Committee

on

Nuclear

Instrument

Modules.

Designed

for

international

use.

the

4002A

can

accept

input

mains

voltages

of

100. 120.

220.

or

240

V

ac

at

47-63

Hz.

A

connector

block

at

the

rear

of

the

4002A

is

used

to

select

the

intended

mains

voltage

range

(Section

3).

The

connector

block

also

functions

as

a

fuse

holder

and

power

cord

connector.

By

using

this

CEE-22"

standard

con

nector

on

the

chassis,

virtually

any

type

of

mains

plug

may

be

conveniently

mated

to

the

4002A.

The

power

supply

furnishes

four

standard

dc

voltages:

+12

V

at

2

A;

-12

V

at

2

A;

+24

V

at

1

A;

and

-24

V

at

1

A.

No

power

derating

is

necessary

for

operation

between

0

and

+50°'C

ambient

temperature.

The

dc

outputs

are

regu

lated.

short-circuit

protected,

current

limited,

and

ther

mally

protected.

A

nominal

117

V

ac

is

supplied

to

the

bin

connector

independent

of

input

mains.

The

117

V

ac

power

available

is

limited

only

by

the

power

supply

fuse

when

operating

from

100

or

120

V

ac

mains.

When

operating

from

220

or

240

V

ac

mains,

the

117

V

ac

is

derived

by

autotransformer

action

and

is

limited

to

50

VA

output

with

a

dc

load

on

the

power

supply

of

96

W.

A

control

panel

is

provided

on

the

4001

or

401

Series

Bins

for

operating

and

monitoring

the

4002A

powersupply.

An

On-Off

switch.

power-Indicating

lamp,

thermal

warning

lamp,

and

convenient

dc

monitor

jacks

are

provided.

The

thermal

warning

lamp

is

lighted

when

the

internal

temperature

rises

to

within

20°

C

of

the

maximum

safe

operating

temperature.

The

power

supply

is

automat

ically

cut

off

by

an

internal

switch

should

the

temperature

exceed

the

maximum

safe

operating

temperature.

Fast

disassembly

for

maintenance

purposes

is

made

possible

by

the

use

of

quick-disconnect

connectors.

The

control

circuitry

uses

high-quality

integrated

circuits

and

power

semiconductors

for

simple

and

reliable

operation.

2.

SPECIFICATIONS

The

specifications

for

the

4002A

power

supply

meet

or

are

superior

to

those

set

forth

by

the

AEC

Committee

on

Nuclear

Instrument

Modules

in

TID-20893

(Rev).

Appen

dix

A.

Type

1.

Class

A.

INPUT

Nominal

Voltage

(ac)

100

120

220

240

Regulation

Range

(V

ac)

f

88-110

103-129

191-239

206-258

FREQUENCY

RANGE

47-63

Hz.

Input

current

at

120

V

ac

is

typically

1.8

A

rms

with

a

96

W

load

(43%

efficiency).

DC

OUTPUT

Output

at

the

following

ratings:

+12

V

at

2

A.

-12

Vat

2

A.

+24

Vat

1

A.

-24

V

at

1

A;

maximum

out

put

power

to

50°C

ambient.

96

W;

operation

to

60°

C

ambient

with

current

derated

2.5%/°

C.

117

VOLT

AC

OUTPUT

117

V

ac

output

limited

only

by

the

supply

fuse

when

operating

from

100

or

120

V

ac

mains.

Output

is

limited

to

50

VA

at

96

W

dc

load

while

operating

from

220

or

240

V

ac

mains.

REGULATION

<±0.05%

over

the

combined

range

of

zero

to

full

load

and

input

voltage

of

103-129

Vac

over

any

24-h

period

at

a

constant

ambient

temperature

and

rated

line

and

load

after

a

60-mln

warm-up.

INSTABILITY

<±0.3%

after

a

24-h

warm-up

of

constant

line.

load,

and

ambient

temperature

over

a

six-month

period.

TEMPERATURE

COEFFICIENT

range

of

0°C

to

60°

C.

<0.01

%/°C

over

a

THERMAL

PROTECTION

A

thermal

warning

switch

will

be

activated

when

the

ambient

temperature

approaches

within

20°

C

of

the

safe

operating

temperature.

A

thermal

cutout

switch

disables

the

power

supply

when

the

temper

ature

exceeds

the

safe

operating

temperature.

NOISE

AND

RIPPLE

The

output

noise

and

ripple

are

<3

mV

peak-to-peak,

as

observed

on

a

50-MHz

bandwidth

oscilloscope.

VOLTAGE

ADJUSTMENT

±0.5%

minimum

range,

re-

settability

±0.05%

minimum

of

supply

voltage.

RECOVERY

TIME

<50

jjs

to

return

to

within

±0.1%

of

rated

voltage

for

any

change

in

input

voltage

within

the

specified

range

and

load

current

from

10

to

100%

full

load.

CIRCUIT

PROTECTION

The

input

line

to

the

power

supply

is

fused.

In

addition

electronic

circuitry

provides

output

current

limiting

to

prevent

damage

to

the

supply

and

provides

automatic

recovery

when

the

demand

is

re

moved.

■International

Commission

on

Rules

tor

ttie

Approval

of

Electrical

Equipment,

standard

number

22.

tThe

regulation

range

is

determined

by

changing

thenominal

voltage

+10%to-12%,

where

the

nominal

voltages

are

defined

as

100,

117,217,234.

(TID-20893

defines

the

U.S.

standard

nominal

voltage

as

117.)

To

avoid

confusion

when

reading

the

mains

voltage

selector

of

the

4002A,

nominal

voltages

are

desig

nated

as

100,

120,

220,

and

240.

OUTPUT

IMPEDANCE

kHz.

<0.3

O

at

any

frequency

to

100

OUTPUT

CONNECTOR

All

power

and

control

circuits

terminate

in

a

connector,

specified

by

TID-20893

(Rev),

wfiich

mates

with

the

bin

interface

connector,

completing

the

necessary

control

and

power

supply

wiring.

DIMENSIONS

16.825

in.

wide,

3.438

in.

high,

5.500

in.

deep;

conforms

to

AEG

Drawing

ND515.

WEIGHT

13

lb

net;

with

4001C

bin

27

lb

net.

Shipping

weight

for

4001C/4002A

35

lb

gross.

3.

INSTALLATION

3.1.

PACKING

Unpack

the

unit,

being

careful

to

retain

all

packing

materials

until

the

unit

has

been

checked

for

possible

concealed

damage.

The

power

cord

is

packed

with

the

unit

and

attaches

to

a

3-pin

connector

that

is

mounted

on

the

rear

of

the

4002A.

3.2.

SELECTING

THE

MAINS

VOLTAGE

The

4002A

is

designed

so

that

the

transformer

primary

can

be

connected

in

a

configuration

that

is

compatible

with

the

availabie

mains

voltage.

Check

the

voltage

level

to

be

used

and

select

the

appropriate

range

on

the

4002A.

A

small

printed

circuit

card

is

installed

in

a

recessed

portion

of

the

power

connector

that

is

covered

by

a

clear

plastic

window.

The

orientation

of

the

small

printed

circuit

card

determines

the

nominal

voltage

and

the

result

is

visible

through

the

plastic

window.

The

four

alternate

settings

are

100,

120,

220,

and

240

V,

and

each

selects

an

input

range

as

defined

in

Section

2,

"INPUT."

If

the

setting

does

not

match

the

available

ac

voltage

level,

use

the

following

steps

to

change

it;

1.

Remove

the

ac

power

cord.

2.

Slide

the

clear

plastic

window

from

its

operating

position

(over

the

fuse)

to

its

alternate

position

over

the

ac

power

plug

connector.

3.

Remove

the

fuse

by

pulling

outward

on

the

handle

marked

"Fuse

Pull."

4.

Extract

the

small

printed

circuit

card.

5.

Orient

the

printed

circuit

so

that

the

desired

voltage

is

readable;

the

selections

are

100,

120,

220,

and

240.

6.

Insert

the

small

printed

circuit

back

into

the

slot

under

the

fuse

location

and

check

to

see

if

desired

voltage

is

visible.

7.

Return

the

handle

(marked

"Fuse

Pull")

to

its

original

position.

8.

Install

the

fuse

with

the

proper

rating;

use

a

3

A

fuse

for

100

or

120

V;

use

a

1.5

A

fuse

for

220

or

240

V.

9.

Slide

the

plastic

window

back

to

its

position

covering

the

fuse.

10.

Leave

the

power

cord

disconnected

while

mounting

or

dismounting

the

4002A.

The

4002A

power

supply

is

normally

supplied

factory

con

nected

to

an

EG&G

GRIEG

4001G

Modular

System

Bin.

However,

the

supply

is

designed

to

TID-20893

(Rev)

speci

fications

and

may

be

attached,

in

the

space

provided,

to

any

bin

manufactured

to

those

specifications.

For

attachment

to

a

bin

other

than

an

EG&G

GRIEG

401

or

4001

Series

Bin,

please

refer

to

the

appropriate

instruc

tion

manual.

The

Gn-Gff

switch

and

othercontrols

neces

sary

to

operate

the

supply

are

part

of

the

bin

and

not

furnished

with

the

power

supply.

For

attachment

to

the

4001G

bin

the

following

steps

are

advised;

IMPORTANT

NOTICE

Always

disconnect

the

power

cord

at

the

power

supply

chassis

before

connecting

or

disconnecting

the

bin-

power

suppiy

connector

(PG13-PG14).

Faiiure

to

do

so

wiil

result

in

a

shock

hazard

at

PG14

and

can

also

damage

the

power

supply

and/or

bin

contents.

1.

Place

the

bin

on

a

table

with

the

back

part

facing

you.

Place

the

power

supply

in

the

proper

mounting

position,

leaving

enough

space

between

the

two

pieces

to

attach

the

interface

connector.

2.

After

ensuring

that

the

power

cord

is

disconnected,

mate

the

interface

connector,

being

careful

to

align

the

polarizing

pins.

Fold

and

form

all

wiring

close

to

the

con

nector

edges

to

prevent

any

wires

from

being

pinched

and

producing

a

short

circuit

in

succeeding

steps.

3.

Mount

the

power

supply

to

the

bin

by

securely

tight

ening

the

four

10-32

screws,

being

careful

not

to

pinch

any

wires

or

to

use

undue

force

on

any

parts.

When

attaching

the

40G2A

power

supply

to

very

old

401

bins

it

is

necessary

to

first

remove

the

left

and

right

side

covers

and

stand

the

bin

on

its

front

face

(handles

down).

From

this

point

on,

assembly

is

the

same;

upon

com

pletion

the

side

plates

should

be

replaced.

4.

OPERATING

INSTRUCTIONS

The

available

current

from

the

power

supply

is

specified

in

Section

2,

"DC

OUTPUT."

Care

must

be

used

to

ensure

natural

convection

of

heat

dissipated

by

the

heat

sinks

and

power

transformer.

When

used

at

maximum

power

load

ings

on

a

bench

or

table

top,

the

bin

and

power

supply

should

be

in

an

open

space,

placed

upon

blocks

at

least

1

in.

off

the

table

mounting

surface

to

allow

maximum

ventilation.

When

used

in

a

rack,

attention

should

be

paid

to

placement

of

other

heat-generating

equipment.

Adequate

unobstructed

space

on

all

sides

is

necessary

for

convection

ventilation

and

cooling.

If

the

bin

contains

other

heat-generating

equipment,

a

blower

may

be

ad

visable

to

remove

the

dissipated

heat.

When

it

is

necessary

to

rack

mount

several

bins

and

power

supplies,

especially

when

other

heat-generating

equip

ment

is

located

within

the

rack,

the

term

"ambient

temper

ature"

becomes

less

clearly

defined.

A

better

guide

to

maximum

power

loading

capability

is

to

monitor

the

heat

sink

temperature.

Never

allow

the

heat

sink

tempera

ture

to

continuously

run

above

85°

C.

Although

this

is

not

the

maximum

operating

temperature,

any

additional

temperature

rise

due

to

other

conditions

of

the

system

may

force

the

supply

out

of

tolerance

and

may

cause

it

to

automatically

shut

down

operation.

Should

your

opera

tion

produce

a

temperature

of

85°

C,

a

blower

to

remove

the

heat

is

necessary.

The

EG&G

ORTEG

Model

M127/N

Rack-Mountable

Cooling

Fan

is

recommended

in

this

situation.

5.

CIRCUIT

DESCRIPTION

The

4002A

power

supply

produces

four

dc

output

volt

ages.

A

power

transformer

changes

the

input

ac

line

voltage

into

four

separate

low-voltage

sources.

The

sources

or

windings

are

full-wave-rectified,

capacitor-

filtered,

and

regulated

by

electronic

series

regulator

cir

cuits.

The

regulator

circuits

provide

short

circuit

and

cur

rent

limiting

protection.

Each

of

the

four

series

regulator

circuits

are

identical

in

operation;

they

are

physically

different

only

in

component

vaiues

for

each

supply.

The

regulator

can

operate

in

two

modes:

First

and

normal

is

the

voltage

regulation

mode;

second

is

the

current-foldback

or

current-limiting

protection

mode.

The

regulator

will

operate

in

the

voltage

regulation

mode

at

any

current

output

up

to

and

including

the

full

rated

output

of

a

particular

supply.

When

current

output

beyond

—150%

of

the

rated

output

is

required,

which

includes

a

direct

short

across

the

output

terminals,

the

regulator

automatically

converts

to

a

current-foldback

mode.

This

provides

power

limiting

and

protection

of

the

regulator's

circuitry

and

components.

When

excessive

current

demands

are

removed,

the

regulator

resumes

the

voltage

regulation

mode.

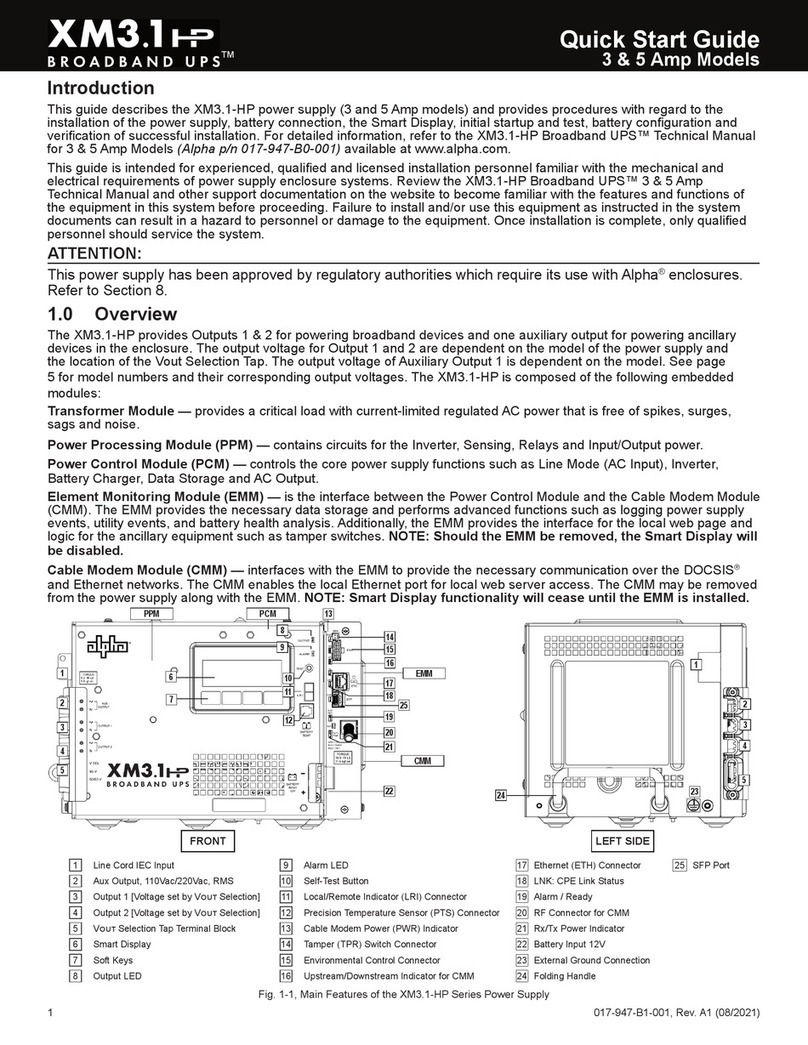

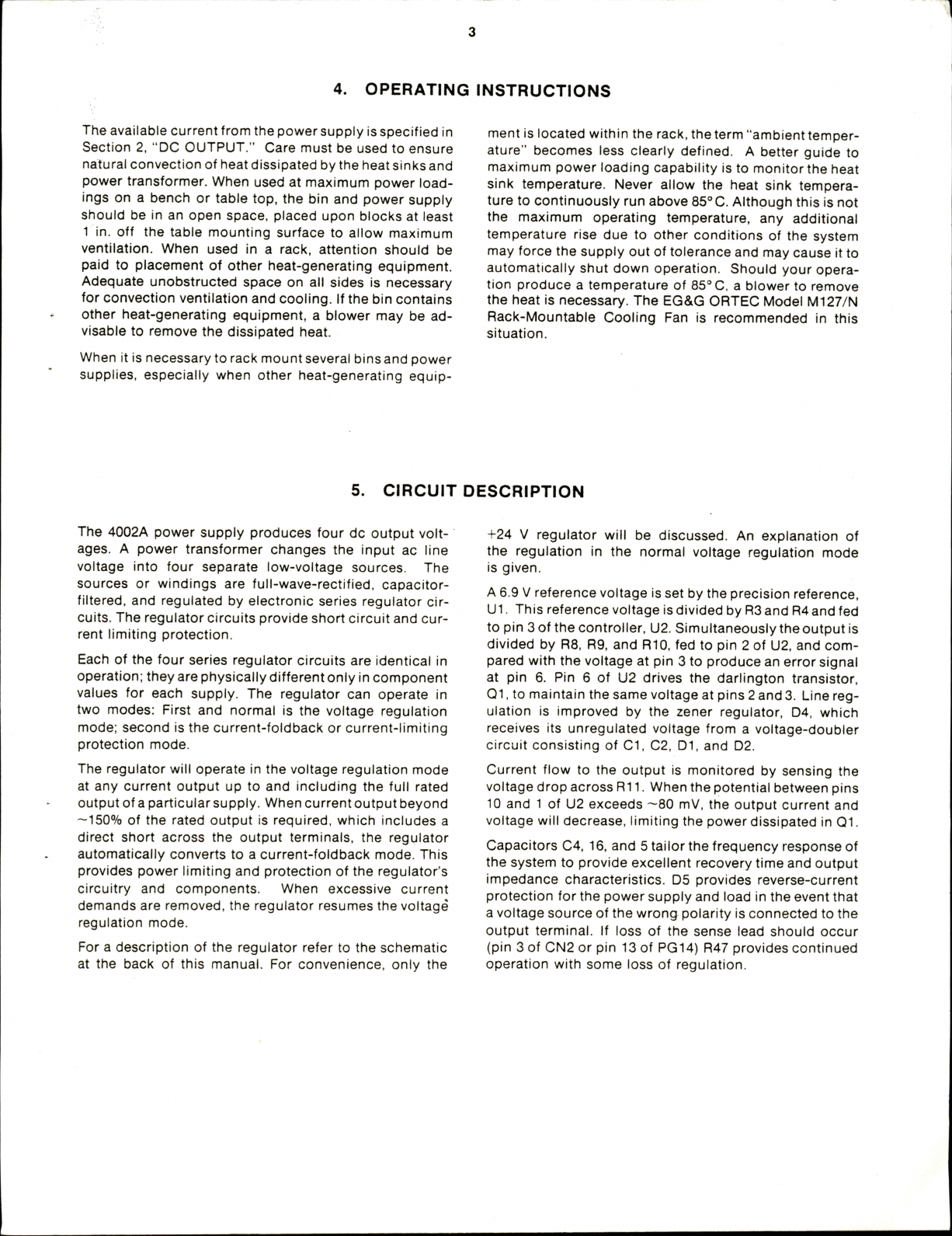

For

a

description

of

the

regulator

refer

to

the

schematic

at

the

back

of

this

manual.

For

convenience,

only

the

+24

V

regulator

will

be

discussed.

An

explanation

of

the

regulation

in

the

normal

voltage

regulation

mode

is

given.

A

6.9

V

reference

voltage

is

set

by

the

precision

reference,

U1.

This

reference

voltage

is

divided

by

R3and

R4and

fed

to

pin

3

of

the

controller,

U2.

Simultaneously

the

output

is

divided

by

R8,

R9,

and

RIO,

fed

to

pin

2

of

U2,

and

com

pared

with

the

voltage

at

pin

3

to

produce

an

error

signal

at

pin

6.

Pin

6

of

U2

drives

the

darlington

transistor,

Q1,

to

maintain

the

same

voltage

at

pins

2

and

3.

Line

reg

ulation

is

improved

by

the

zener

regulator,

04,

which

receives

its

unregulated

voltage

from

a

voltage-doubler

circuit

consisting

of

01,

02,

01,

and

02.

Ourrent

flow

to

the

output

is

monitored

by

sensing

the

voltage

drop

across

R11.

When

the

potential

between

pins

10

and

1

of

U2

exceeds

—80

mV,

the

output

current

and

voltage

will

decrease,

limiting

the

power

dissipated

in

01.

Oapacitors

04,

16,

and

5

tailor

the

frequency

response

of

the

system

to

provide

excellent

recovery

time

and

output

impedance

characteristics.

05

provides

reverse-current

protection

for

the

power

supply

and

load

in

the

event

that

a

voltage

source

of

the

wrong

polarity

is

connected

to

the

output

terminal.

If

loss

of

the

sense

lead

should

occur

(pin

3

of

0N2

or

pin

13

of

PGM)

R47

provides

continued

operation

with

some

loss

of

regulation.

6.

MAINTENANCE

6.1.

DISASSEMBLY

AND

TROUBLESHOOTING

The

4002A

needs

no

routine

maintenance

or

adjustment.

If

a

problem

develops

and

troubleshooting

becomes

necessary,

the

top

and

bottom

screen

covers

should

be

removed

to

provide

access

to

the

components.

While

probing

inside

the

4002A

chassis

use

extreme

caution.

There

are

two

shock-hazard

locations

to

regard:

the

wiring

side

of

the

input

line

cord

connector

block

and

the

two

thermal

switches

(SI

and

S2)

mounted

against

the

heat

sink.

These

two

locations

have

exposed

primary

circuit

conductors.

A

test

point

(TP1)

is

provided

on

the

circuit

board

to

con

nect

the

reference

lead

of

any

probe.

Table

6.1

shows

typical

dc

voltages

measured

with

respect

to

ground

refer

ence

potential

(TP1).

These

voltage

levels

are

typical

of

a

circuit

that

is

operating

properly;

the

precise

values

will

vary

between

individual

units.

If

the

power

transformer

(Tl)

or

any

component

mounted

on

the

heat

sink

Is

found

to

be

defective,

the

heat

sink/PC

board

assembly

must

be

removed.

First

disconnect

the

free-hanging

connector

(P/J3)

and

the

printed

circuit

board

connectors

(PI

and

P2).

Then

remove

the

ten

screws

that

fasten

the

heat

sink

to

the

chassis

and

slide

the

heat

sink/PC

board

assembly

out

of

the

chassis.

The

heat

sink-mounted

components

will

then

be

accessible

for

replacement.

6.2.

FACTORY

REPAIR

This

instrument

can

be

returned

to

the

EG&G

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

Our

stand

ard

procedure

for

repair

ensures

the

same

quality

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

the

Customer

Service

Department

at

EG&G

ORTEC,

(615)

482-4411,

before

sending

in

an

instrument

for

repair

to

obtain

shipping

instructions

and

the

required

Return

Authorization

Number.

Write

this

number

on

the

address

label

and

on

the

package

to

ensure

proper

han

dling

when

the

Instrument

reaches

the

factory.

Table

6.1.

Typical

DC

Voltages

(measured

with

respect

to

TP1).

Node

U2

pin

8

3

5

7

2

1

10

6

U4

pin

8

3

5

7

2

1

io

6

U6

pin

8

3

5

7

2

1

10

6

U8

pin

8

3

5

7

2

1

10

6

Voltage

+36.5

+

2.5

0

0

+

2.5

+24.0

+23.9

+25.3

+36.5

+

2.5

0

0

+

2.5

+

12.0

+11.8

+13.5

+

9.5

-

9.5

-12.0

-12.0

-

9.5

0

-

0.2

+

1.4

+

9.5

-21.5

-24.0

-24.0

-21.5

0

-

0.2

+

1.3

3

I

"•

<ii

JTiTTU

-HfTTn-

-fjm-

-CSSh

_<E3-

"QHh

-0*3-

-H"y7~|-

~t

HI

?t—

—i

m

h-

0

.M©^®

HODEL

4002«/<.00

1

M

Accp

OUTEC

POWER

SUPPLY

^

P/N

6202100

LfiHK

ci»

C©c»t

^

-CUD-

_-CHD-

-CUD-

C7)^iiy-

-ais-e^

cTHTtV^

-qs)-'^

-C33S-

,

-Tiigii-

®i

CAO

Ft

PflRTIPL

SIDE

VIEW

Table of contents

Other EG&G Power Supply manuals