Contents

1. Generel information page

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 EC Declaration of Conformity for Machinery . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Instructions for use

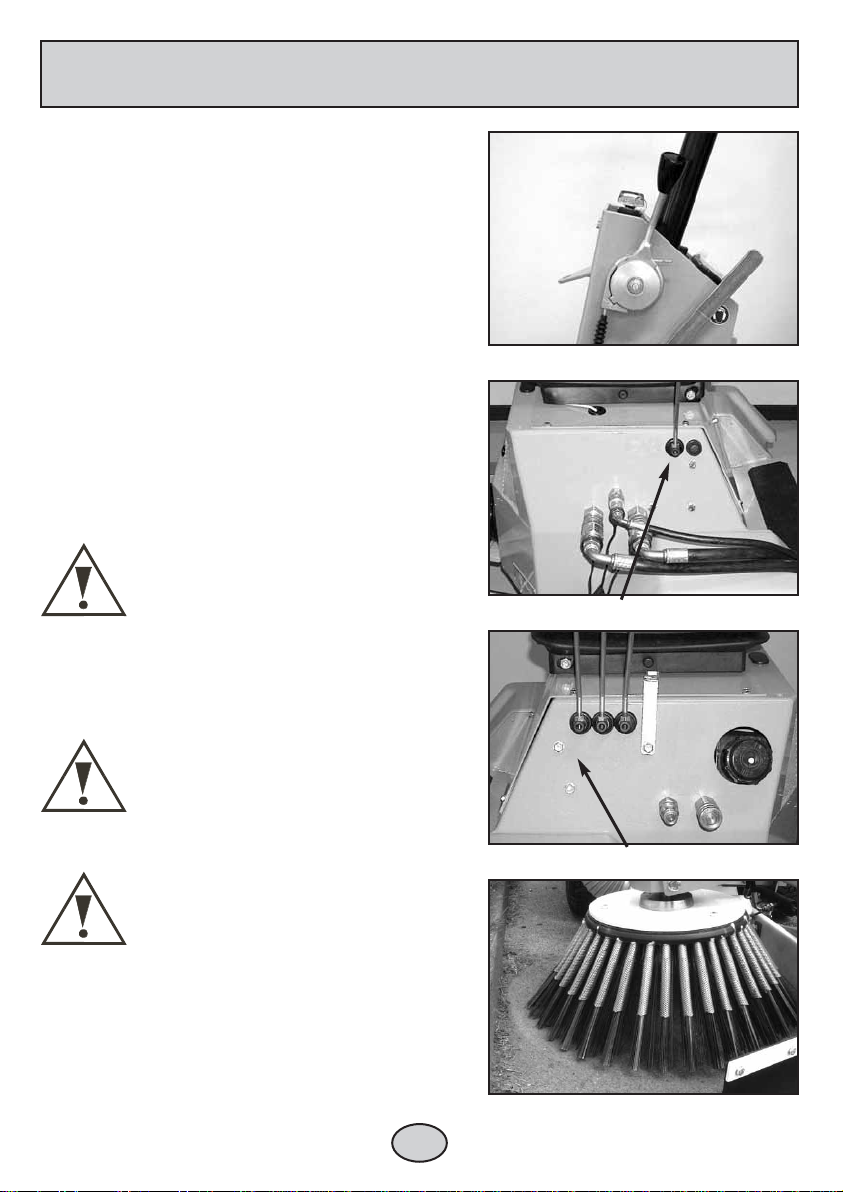

2.1 Assembly / Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 Container discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3. Service and maintenance

3.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4. Conditions

4.1 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Conditions of complaint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

33

1. General information

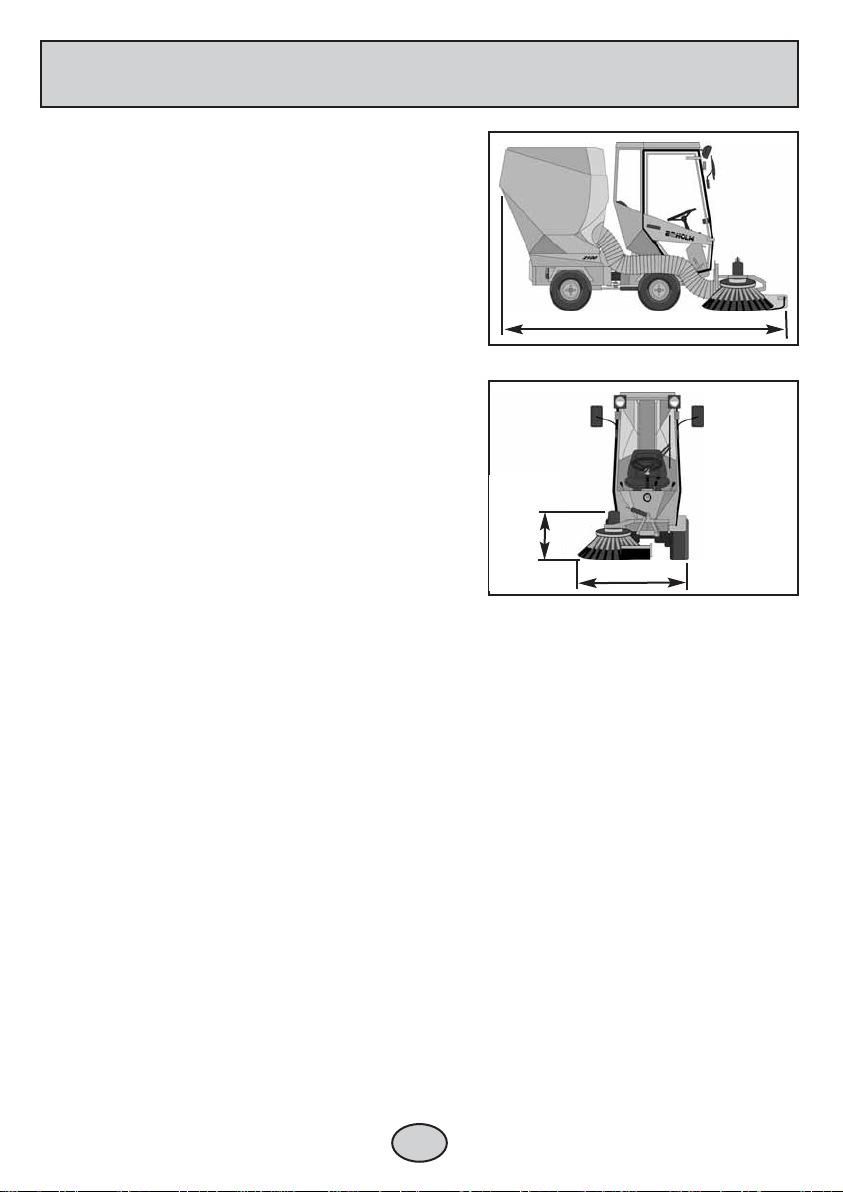

The Weed Brush has been specially developed

for the Egholm utility machine

The Weed Brush is used to remove weeds from

kerbs, pavements and roads.

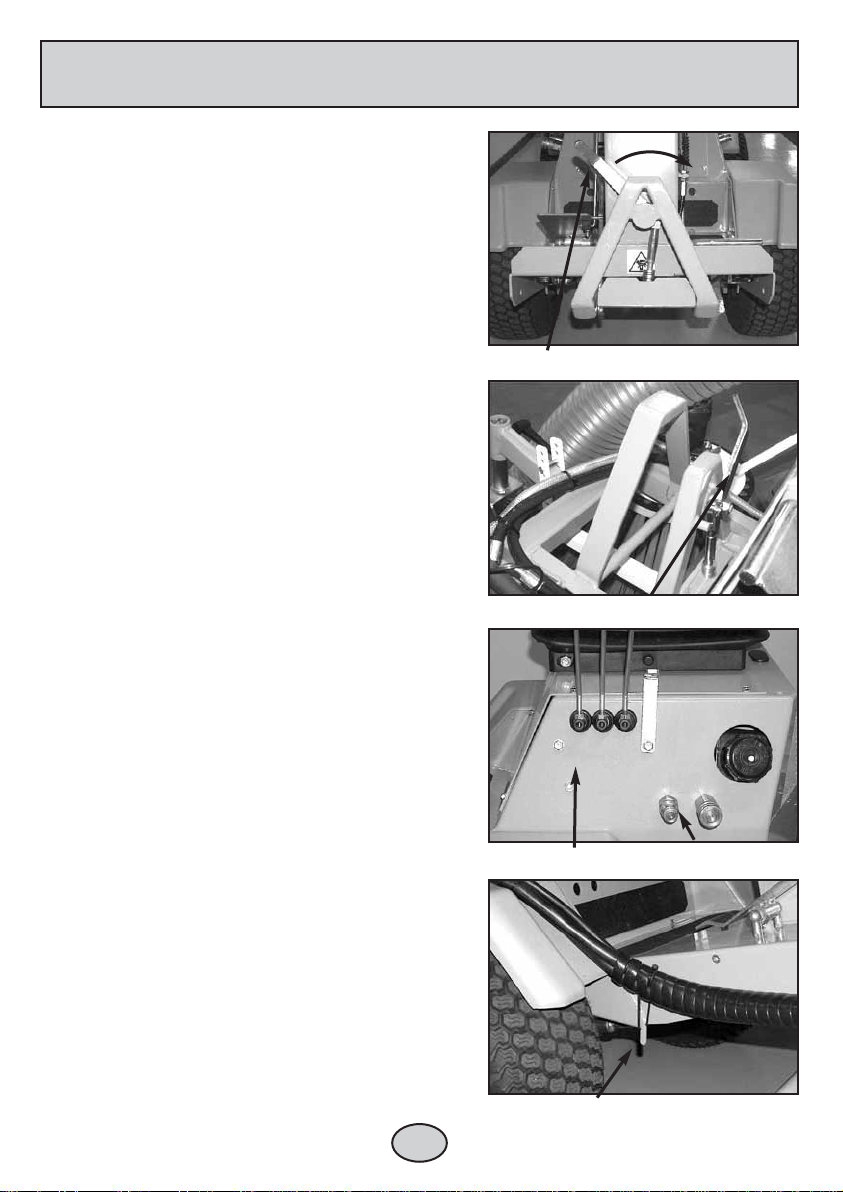

The Weed Brush features a sturdy, front-moun-

ted steel brush that is hydraulically adjustable in

all directions.

The Weed Brush can be fitted together with the

collecting tank from the Suction Sweeper Unit in

order to collect weeds and seeds loosened by

the brush.

The Weed Brush can be assembled and

disassembled without using tools.

Useful tips

Always start your weed control in early spring. A

perfect result requires repeated efforts

throughout the summer.

Grass tufts by the edges of paths and

pavements are easiest to remove when they are

moist. Here, too, you should start weed removal

before the grass starts to grow.

Large, heavy or damp grass tufts can be difficult

for the machine to collect. Therefore, for a

perfect result, leave them to dry for a couple of

days before using the Suction Sweeper Unit to

remove them.