EI QVT User manual

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

QVT MULTIVARIABLE TRANSMITTER

QVT

INSTALLATION & OPERATION

MANUAL

REV 8/22

REVISION VERSION 1.0.51

ORIGINAL LANGUAGE

Copyright© 2022 Eastern Instrument Laboratories, Inc.

All Rights Reserved.

2

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

TABLE OF CONTENTS

SAFETY

Safe Operaon................................................................................................................. 3

INTRODUCTION

The QVT Mulvariable Transmier................................................................................ 4

GETTING TO KNOW THE QVT

Exploded View of the QVT Transmier.......................................................................... 5

QVT Transmier Schemac............................................................................................ 6

Close‐Up of the IO Board ‐Wiring Terminals ................................................................. 7

Close‐Up of the Processor Board/LCD Board ................................................................. 7

QUICK START UP GUIDE ........................................................................................................... 8

BOOT SEQUENCE ...................................................................................................................... 9

MECHANICAL INSTALLATION

Mechanical Installaon: Mounng the QVT ................................................................ 10

Tubing the QVT.............................................................................................................. 14

ELECTRICAL INSTALLATION

Accessing the Wiring Connectors of the QVT............................................................... 16

Using the Wiring Connectors ........................................................................................ 17

Wiring the QVT .............................................................................................................. 18

4‐20 mA Loop Power................................................................................................... 19

RTD Temperature Sensor Input .................................................................................. 21

OPTIONS

Purge System (Oponal) ............................................................................................... 23

Using the 3‐Way Valve .................................................................................................. 25

GETTING TO KNOW YOUR LCD SCREEN................................................................................. 26

PROCEDURES

Changing the Ae Number.............................................................................................. 27

Changing the EFS (Electronic Full Scale) ...................................................................... 28

Changing the Units of Measure .................................................................................... 29

Zero DP1 Differenal Pressure Measurement ............................................................. 30

Zero Process Temperature............................................................................................ 32

Revert to Factory Sengs (Factory Restore) ............................................................... 34

QVT SPECIFICATIONS.............................................................................................................. 35

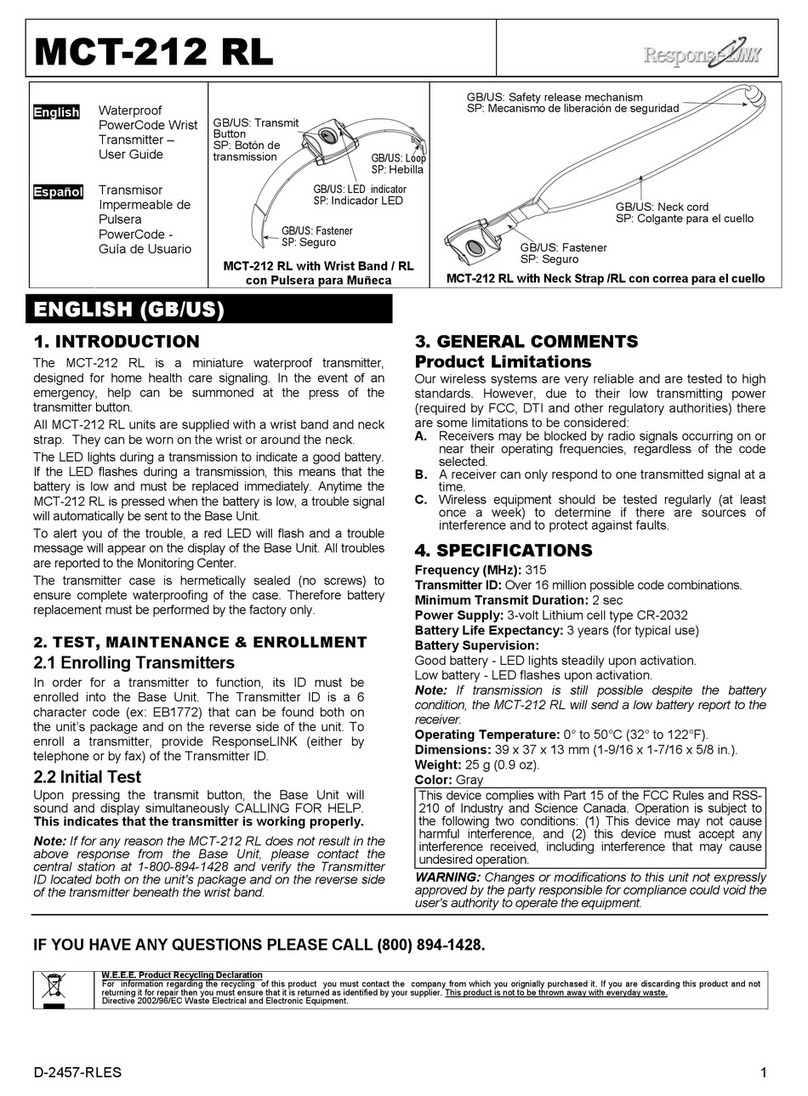

DIMENSIONAL DRAWINGS..................................................................................................... 39

3

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

PLEASE READ BEFORE OPERATING YOUR NEW MULTIVARIABLE TRANSMITTER

For personal/system safety as well as for opmum performance reasons, please read and

understand this manual before working with the transmier.

Check for damaged parts before operang the transmier. Any damaged part should be

properly repaired or replaced by trained personnel. Do not operate the transmier if any

component does not appear to be funconing correctly. Contact Eastern Instruments for

assistance or for repair components.

Ensure that only trained personnel perform installaon of the transmier.

Ensure that assembly of the transmier to a flange or manifold of some kind is done

properly as improper assembly could lead to damage of the sensors of the transmier or

could render the transmier dangerous. Failure to follow the installaon guidelines with‐

in this manual could cause serious injury or death.

If the transmier is installed in a high‐voltage environment, it is possible that a fault or in‐

stallaon error could cause high voltage to be present on the transmier leads and termi‐

nals. Electrical shock could cause serious injury or death.

Use only replacement components or installaon bolts supplied by Eastern Instruments as

non‐approved components or installaon hardware may render the transmier danger‐

ous and could lead to serious injury or death.

For Technical Assistance, please contact us:

Eastern Instruments

416 Landmark Drive

Wilmington, NC 28412

SAFETY

SAFE OPERATION

4

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

THE QVT MULTIVARIABLE TRANSMITTER

The QVTTM Mulvariable Transmier from Eastern Instruments is a Smart Transmier that can

be used for the accurate measurement of up to four separate process variables including

Differenal Pressure, Temperature and Absolute Pressure. When coupled with any DP based

flow measurement element, the QVTTM will calculate the fully compensated mass flow of air/

gas travelling through any process which is at or near atmospheric pressure (5 ‐25 psia). The

QVT will accept a Process Temperature signal from an external RTD and will simultaneously

measure the Differenal Pressure and Absolute Pressure from a coupled flow element. The

QVT will be as accurate whether coupled with an Eastern Instruments flow element or wheth‐

er it is coupled with a flow element from the manufacturer of your choosing. Using these in‐

puts, the QVT will calculate a compensated mass flow rate and will give an output proporonal

to this compensated mass flow rate via a 4‐20 mA signal. Please note that the 4‐20 mA signal

can be fully compensated (live measurement of DP, AP and Temperature), parally compen‐

sated (live measurement of DP only) or the values for the Process Variables (DP, AP or Tem‐

perature) can be output via the 4‐20 mA signal as well.

INTRODUCTION

5

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

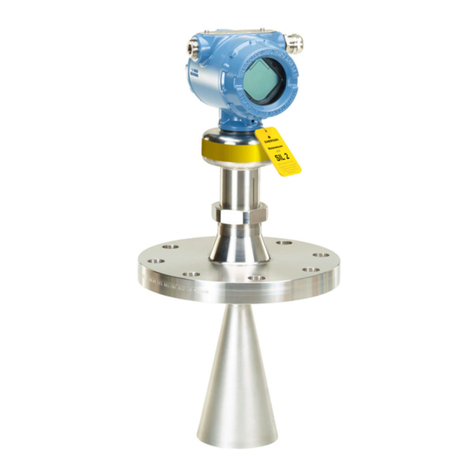

Exploded View of QVT Transmier

GETTING TO KNOW THE QVT

6

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

QVT Transmier Schemac ‐Shown with oponal 3‐Valve Manifold and Purge System

3‐Valve Manifold

(Recommended Accessory)

7

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Close‐up of the IO Board ‐Wiring Terminals

Close‐up of the Processor Board/LCD Board

The 4‐20 mA Connector The RTD Connector

Board Snap Mounts

Snap Mounng Holes

Snap Mounng Holes

8

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

VERIFY PROPER MECHANICAL INSTALLATION

Verify that the QVT is properly mounted (See “Mechanical Installaon: Mounng

the QVT” secon of the QVT I&O Manual for Addional Info)

Verify that the High and Low Ports of your flow element are properly tubed to the

transmier/manifold/purge system (See “Tubing the QVT” secon of the QVT I&O

Manual for Addional Info)

VERIFY PROPER WIRING OF THE QVT

Verify that the proper power has been supplied to the QVT (See “Wiring the QVT: 4

‐20 mA Loop Power” secon of the QVT I&O Manual for Addional Info)

If using an RTD to measure the process temperature, verify that the RTD is properly

wired (See “Wiring the QVT: RTD Temperature Sensor Input” secon of the QVT

I&O Manual for Addional Info)

PERFORM ZERO OF THE DP1 DIFFERENTIAL PRESSURE

(See “Procedures: Zero DP1 Differenal Pressure Measurement” secon of the

QVT I&O Manual for Addional Info)

VERIFY COMMUNICATION (4‐20 mA OUTPUT)

Compare the readings on your PLC/DCS with the values of the output variable

shown of the QVT screen. (Example: 0 lb/hr on the QVT would equate to 4 mA of

output)

QUICK START UP GUIDE

9

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Aer powering on the QVT, the transmier will proceed through a boot sequence followed by

an automated scrolling of key values and sengs within the QVT.

BOOT SEQUENCE

AUTO SCROLL SEQUENCE

Manual Scrolling of the displays shown in the Auto Scroll Sequence is possible by pressing the

“PRG” Buon repeatedly unl the desired display is shown. The display will be shown for ap‐

proximately 2 hrs before returning to the Auto Scroll Sequence.

BOOT SEQUENCE

Upon Boot/Reboot the so‐

ware version (le) will be

displayed, followed by a

Pass/Fail screen denong

whether the soware has

loaded properly (right). Up‐

on a successful Boot (Pass),

the Auto Scroll Sequence

(below) will begin.

Upon a successful Boot Se‐

quence (Above), the Auto

Scroll Sequence will begin.

Each value will be shown

sequenally for 1.5 seconds

each. Upon compleon, the

sequence will start over

again automacally.

dP Display

Temperature Display 4-20 mA Full ScaleMass Flow Display

AP Display

10

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

MECHANICAL INSTALLATION: MOUNTING THE QVT

The QVT can either be mounted via an oponal mounng bracket which allows the transmier

to be mounted to either a vercal or horizontal 2” pipe, or, if the transmier is purchased with

flow elements from Eastern Instruments, the transmier will be mounted directly to the flow

element (VAP Pitots, DSV Duct Secon or HBP High Beta Flow Condioner). Detailed dimen‐

sional drawings are included within this secon of the manual. The suggested installaon lo‐

caon depends upon the process, but in general, for air and gas flow measurement, the trans‐

mier is suggested to be located above the tap for the air/gas flow measurement so that con‐

densate that may collect in the impulse lines, can drain away from the transmier.

MECHANICAL INSTALLATION

Mount Bracket for QVT: Pipe Mount Mount Bracket for QVT w/ Manifold: Pipe Mount

Mount Bracket for QVT: Panel Mount Mount Bracket for QVT w/ Manifold: Panel Mount

5/16” x 1.75” Bolt For

QVT Mounng

1 1/2” Size U‐Bolt

For Pipe Mounng

1 1/2” Size U‐Bolt

For Pipe Mounng

M8 x 1.25 For Transmier

Manifold Mounng

5/16” x 1.75” Bolt For

QVT Mounng

5/16” x 1.75” Bolt For

Panel Mounng

M8 x 1.25 For Transmier

Manifold Mounng

5/16” x 1.75” Bolt For

Panel Mounng

11

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Vercal Pipe Mount ‐Transmier Only

Horizontal Pipe Mount ‐Transmier Only

12

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Vercal Pipe Mount ‐Transmier and 3‐Way Valve Manifold

Horizontal Pipe Mount ‐Transmier and 3‐Way Valve Manifold

13

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Vercal Pipe Mount ‐Transmier, 3‐Way Valve Manifold and Purge System

Horizontal Pipe Mount ‐Transmier, 3‐Way Valve Manifold and Purge System

14

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

TUBING THE QVT

Process Connecons are made to the boom of the QVT via 1/4” NPT female connecons on 2

1/8” Centers. Please note that if the oponal 3‐Way Valve or the Purge System were pur‐

chased, the Process Connecons will vary. These connecons can be modified to accept mani‐

folds on 2”, 2 1/8” and 2 1/4” centers by using an oponal adapter flange.

It is recommended that the tubing used to connect the QVT to your flow element be at least

3/8” hard walled Stainless Steel or Copper Pipe if using the oponal Purge System. Please see

the accompanying table in the “Purge System” secon of this manual for specifics on the rec‐

ommended diameter of tubing versus the run length of the pipe.

Please note that the connecons will differ depending on whether you are connecng directly

to the QVT, via a 3‐way valve or via the TMP transmier purge. The connecons for each of

these three scenarios are illustrated below.

QVT Transmier Process Connecons

15

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

QVT Transmier with 3‐Way Valve Process Connecons

QVT Transmier with 3‐Way Valve and TMP Purge System Process Connecons

16

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

ELECTRICAL INSTALLATION

ACCESSING THE WIRING CONNECTORS OF THE QVT

NOTE: POWER MUST BE OFF BEFORE REMOVING

THE COVER OF THE QVT!

REMOVING THE LCD BOARD

1. Once power has been turned offto the trans‐

mier, remove the cover to expose the Processor

Board or LCD Circuit Board. Once the cover has

been removed, your QVT should look similar to

the picture #1 on the right.

2. Remove the Processor Board or LCD Circuit

Board. To remove the board, press on the

boom and pull out at the top behind the circuit

board as seen in picture #2. DO NOT PULL ON

THE OVERLAY AS IT COULD BE DAMAGED.

3. Carefully remove the board as shown in picture

#3.

REPLACING THE LCD BOARD

1. Align the Board Snap Mounts with the Snap

Mounng Holes on the LCD Board

2. With fingers over the snap mounts press the

board into place as in picture #4. The Board Snap

Mounts should snap into the Snap Mounng

Holes.

3. Please note that the Board has four holes and

there are only two Board Snap Mounts. This ena‐

bles the board to be rotated to any of four posi‐

ons depending on the desired orientaon of the

LCD screen. Please see picture #5 for reference.

4. Check the wiring to ensure that the internal wir‐

ing clears prior to snapping the board into place.

5. Replace the cover of the QVT.

#1

#2

#3

#4

#5

17

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

USING THE WIRING CONNECTORS

Male Locking Latch

Electrolyc Copper (E‐Cu)

Tin‐Plated Contact Bridge

Female Locking Latch

Gripping Plate with

Sliding Connector Release

Straight or Angled, E‐CU, n‐plated

solder pins for both wave and THR soldering

Push‐Buon

Test Port

High‐Alloy Stainless Steel (CrNi)

Clamping Spring

Original Size:

3.5 mm Pin Spacing

Male Header

Female Connector Wire Gauge: 24 – 14 AWG

Strip Length: 8 – 9 mm

Gripping Plate

Sliding Connector

Release

Connecng/Disconnecng Male Header and

Female Connector

To Disconnect: Press down on the Sliding

Connector Release (towards the Male Head‐

er) and pull on the Gripping Plate to release

Female Connector from Male Header.

To Connect: Push the Female Connector into

the Male Header unl you hear a click.

Inserng and Removing Conductors

from Connector

To Insert: Using the supplied screwdriver,

press down on the Push Buon and insert

the wire into the terminal.

To Remove: Press the Push Buon and

pull upwards on the wire to remove the

wire from the Female Connector.

Push‐Buon

Insert Wire

Here

Included

Screwdriver

18

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

WIRING THE QVT

There are two parts to wiring the QVT. For all versions of the QVT, 4‐20 mA loop power must

be supplied. For mulvariable transmiers in which Process Temperature will be measured,

an RTD must also be wired to the QVT. The wiring connecons for both the 4‐20 mA loop

power and the RTD inputs are located behind the LCD circuit board inside the head of the

transmier. Once the LCD Board has been removed, the connectors for both the 4‐20 mA

loop power and the RTD can be wired. You can wire the connectors by either removing the

female connector from the board, adding the wire externally and replacing the female con‐

nector into the male header already wired, or you can leave the female connector seated in

the male header and wire it in place or internally.

NOTE: ALWAYS REMOVE POWER TO THE QVT BEFORE REMOVING THE LCD BOARD AND ON‐

LY RESTORE POWER AFTER THE LCD BOARD HAS BEEN RETURNED TO ITS PLACE!

Please note the color indicators at the boom of the customer connecon wiring terminals

for both the 4‐20 mA Connector and the RTD Connector. The following pages offer a more

detailed descripon of the proper wiring for each of these connecons.

The 4‐20 mA Connector The RTD Connector

Board Snap Mounts

19

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

4‐20 MA LOOP POWER:

An example of loop wiring is shown below. We have assumed that we used 5000 feet of

Belden 88760 twisted, 18 AWG shielded pair, 7.5 ohm/1000 conductor. The Receiver and A/

D data logger both have a 250 Ωresistor. The power supply is assumed to be a +/‐10%, 24 vDC

source, with the negave terminal grounded, which is shared with other loops. The minimum

voltage expected is the 24 x 0.9 = 21.6 v DC. NOTE: POWER SUPPLY SHOULD BE A GOOD

QUALITY ISOLATED POWER SUPPLY.

+

‐

LOOP POWERED

RECEIVER

The internal connector’s polarity is

color coded as shown

+

‐

SIGNAL COMMON

QVT Transmier

+

‐

24 vDC

POWER

5000

+ ‐

A/D System

The Shield is grounded only

on the power supply end!

QVT Transmier

POWER

SUPPLY

+

‐

RECEIVER

IN SERIES

OR

PARALLEL

Type 2‐2 Wire Circuit

+

‐

SIGNAL

COMMON

The 4‐20 mA loop transmier in the QVT

is a TYPE 2‐2 Wire Circuit as defined in

ANSI/ISA‐50.00.01‐1975 (R2012) as

shown in the sketch (right) and is

assumed to have the negave terminal

of the power supply grounded.

Typical Calculaon Based on 5,000 feet of Cable

Descripon Length () Ω/ΩmA FS Volt Drop

Transmier Minimum Drop 8.8

Posive Cond. 5000 0.0075 37.5 20 0.75

Negave Cond. 5000 0.0075 37.5 20 0.75

Loop Powered Receiver 250 20 5

A/D Data Logger 250 20 5

Total 575 20.3

20

Phone:(910) 392‐2490

Fax: (910) 392‐2123

416 Landmark Drive

Wilmington, NC 28412 www.easterninstruments.com

Be sure to check your load resistance in the output current loop as too high a load resistance

will cause malfuncon or incorrect operaon of the QVT transmier. Below are two methods

of determining whether the load resistance exceeds the allowable operaonal limit.

Voltage Drop: The minimum transmier voltage as seen in the chart below, is 8.8 V. The re‐

sistance values of the conducve elements are mulplied by the current to give the voltage

drop of each element. Sum the voltage drops for all conducve elements along with the mini‐

mum transmier voltage and compare that value with the minimum power supply voltage. If

the total is less than the minimum power supply voltage, the load is OK.

Summing Resistances: Sum the resistances of all circuit elements. Find where the total,

summed resistance total intersects the supply voltage in the below graph. Compare the value

for supply voltage that you found on the graph with your minimum power supply voltage. If

the value from the chart is lower than the minimum power supply voltage, the load is OK.

Load Resistance, OHM

Supply Voltage, vDC

Table of contents