EIP Limited AF5100 User manual

AF5100 OWNERS MANUAL

1

Drawing No. :- TPC309

Issue :- 1

Date :- 18/04/07

AF5100

AXIAL FAN

OWNER’S MANUAL

EIP Limited

St Helens Trading Estate

Bishop Auckland

Co. Durham

DL14 9AD

Telephone: +44 (0) 1388 664400 Fax: +44 (0) 1388 662590

Website: www.eipl.co.uk

AF5100 OWNERS MANUAL

2

CONTENTS

1. Product Information

Important Safety Advice

Guidelines for the operator

Transporting the machine

2. Preparing for use

Electrical connections

3. Controls

4. Operation

5. Storage

6. Maintenance

7. After sales service

8. Guarantee

9. Technical specification

10. Fault diagnosis

Operating Positions

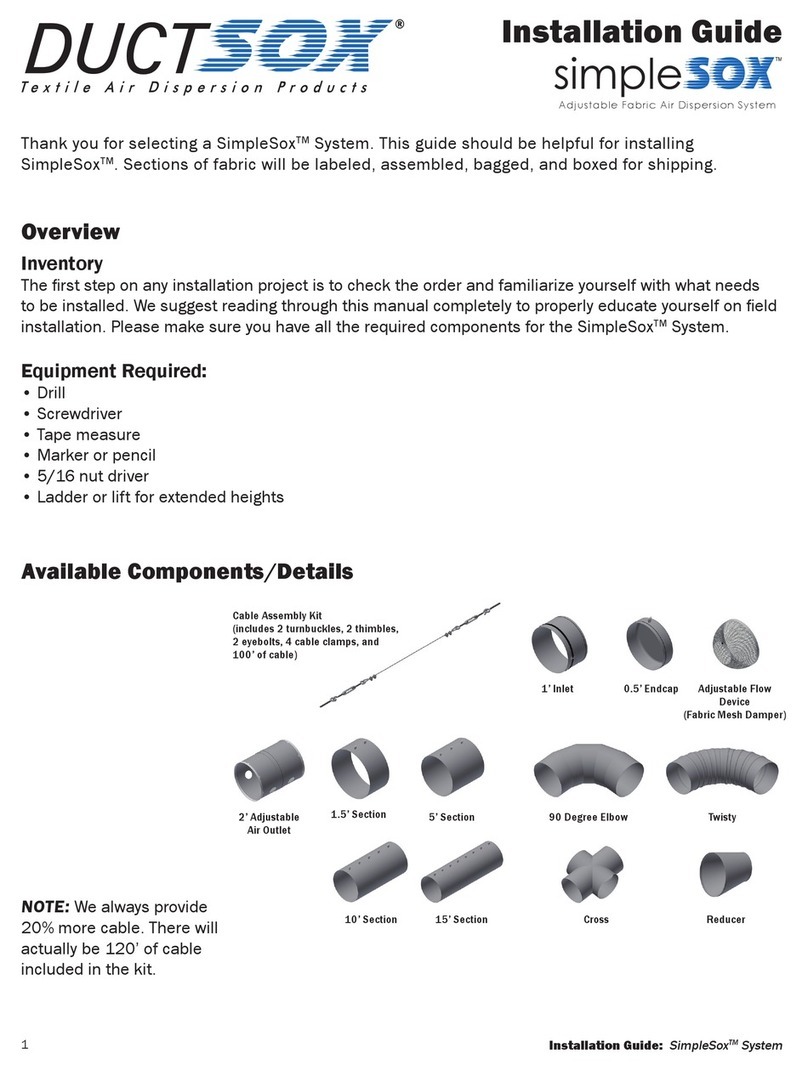

Fig 1 Fig 2 Fig 3

Fig 4 Fig 5

AF5100 OWNERS MANUAL

3

IMPORTANT

READ THESE INSTRUCTIONS C

A

REFULLY AND RETAIN FOR FUTURE USE

1. Product Information

These machines are designed for the drying carpets,

hard floors and other interior areas. They can also be

used to ventilate and cool areas. They should not be

used in outdoor areas.

The following instructions contain important information

about the machines and safety advice for the operator.

Equipment must be operated, serviced and maintained in

accordance with the manufacturer’s instructions.

If in doubt contact the supplier of your machine.

1.1 Important Safety Advice

When using electrical equipment basic safety precautions

should be adhered to including the following:

•Read all instructions carefully before use.

•Use only as described in this manual.

•Only use manufacturer’s recommended components

and attachments.

•Do not handle plug or appliance with wet hands.

•Do not put any object into openings. Do not use with

any opening blocked; keep free of dust, debris and

anything that may reduce airflow.

•Do not cover machine when in use.

•Keep children and unauthorized persons away from the

machine when in use.

•Do not leave the machine connected to the electricity

supply when not in use, always remove the plug from

the socket-outlet.

•Switch off the machine before removing the plug.

•When unplugging pull the plug, not the supply cord.

•Do not pull or carry by supply cord. Do not use cord as

handle, close door on cord or pull cord around sharp

edges or corners.

•Keep cord away from heated surfaces.

•Do not operate the machine with a damaged supply

cord or plug, or after the machine malfunctions or is

damaged in any way. Contact an authorized Service

Agent for repair or adjustment.

•The plug of the power supply cord must be removed

from the socket-outlet before commencing cleaning of

the machine or undertaking maintenance operations.

•The power supply cord must be regularly inspected for

signs of damage. If the power supply cord is damaged,

it has to be replaced.

•Do not use where hazardous dust is present.

•Do not use near flammable fluids, dust or vapours.

•Do not use in an explosive atmosphere.

•Take care when using a machine near the top of stairs

to avoid overbalancing.

•Warning: do not stack dryers more than two units high

without tie-downs.

1.2 Guidelines for the operato

r

•Operators must be fully trained in the use of machine in

accordance with these instructions, able to perform

user maintenance and the correct selection of

accessories.

•Operators should be physically capable to manoeuvre,

transport and operate the machines.

•Keep machine clean and in good operating condition.

•Operators should be able to recognize unusual

operation of the machine and report any problems.

•Wear suitable footwear to avoid slipping.

•Wear suitable clothing to keep dry and warm.

•Do not smoke when using the machine.

•CAUTION – For indoor use only. Do not use outdoors

or expose to rain.

1.3 Transporting the machine

Carry the machine by the handle

CAUTION – THIS MACHINE IS HEAVY

Incorrect lifting techniques may result in personal injury.

2. Preparing for use

2.1 Electrical connection

Before connecting the machine to the power supply,

check that your supply voltage corresponds with that

marked on the rating label on the machine.

The power supply cord plus any extension leads should

not exceed 30m in total. The cross-section of any

extension cable wiring must be at least 2.5mm².

The supply cord for 230v models is fitted with a plug

containing a 13 amp fuse. Should the fuse require

replacement it must only be replaced by a 13 amp fuse

conforming to BS1362, and the fuse cover must be

refitted. If the fuse cover is lost, the plug must not be

used until the correct replacement cover is fitted.

MPORTANT – If the supply cord is damaged, it must only

be replaced by a suitable cord available from the

manufacturer or and authorized service agent.

WARNING – THIS APPLIANCE MUST BE EARTHED

3.Controls

The operating switch is located on the side.

Low speed – move switch to position ’I’

High speed – move switch to position ‘II’

WARNING – Only use accessories or spares specifically

designed for use with this appliance. The fitting of other

accessories or spares may affect its performance and

safety.

AF5100 OWNERS MANUAL

4

4. Operation

•Select suitable location for dryer.

•IMPORTANT – Ensure dryer is in a safe position. Do

not sit dryer in a puddle and make sure it is protected

from drips and splashes.

•Fully unwind the supply cord from the cable winder and

plug into a convenient socket outlet

•Place the dryer in a desired operating position. (see fig

1-5 page2)

1. Tilt Back – Tilt the Axial Fan backward on the four

curved molded legs at an angle to direct air for

elevated drying.

2. Upright – Set the axial Fan square with the handle

on the top to direct air across the room.

3. Tilt Forward – Tilt the Axial Fan forward on the

“standing legs at an angle to direct airflow along the

flow in front of the dryer.

4. Face Down – Set the Axial Fan on the four curved

molded legs with the “standing legs” facing up to

direct air straight down.

5. Power Pitch – place on 3º down angle leg.

6. Stack for Storage – Axial fans interlock and stack for

easy storage and transport.

•Set the desired speed low or high.

•Check for proper operation before leaving the unit

unattended. Do not move or carry the dryer when it is

running.

•To stop the machine turn switch to OFF (position ‘O’).

5. Storage

A

lways unplug and wipe down and dry the machine after

use. Wrap supply cord around the cable winder ensuring

that the plug is not trailing on the floor.

Store the machine in a dry indoor area only.

6. Maintenance

WARNING – Before undertaking maintenance

operation or adjustments switch off machine and

unplug from electricity supply.

The machine requires minimum maintenance apart from

the following checks by the operator.

•Supply cord – Regularly inspect sheath, plug and cord

anchorage for damage or loose connection.

•Body of the machine – Clean with a damp cloth.

•Air vents – Check for dust accumulation around the air

inlet and outlet vents and clean if necessary. Blocked

vents will cause the motor to overheat, and may lead to

premature failure. Warranty claims for this type of

damage will not be accepted.

•Motor overload cut-out – All machines are witted with

an automatic reset motor overload cut-out. The cut-out

will operate to protect the motor from overheating by

switching the machine off. Should the cut-out operate it

will reset automatically when the motor has cooled

sufficiently, usually after 15 – 30 minutes.

IMPORTANT – Should the machine fail to operate

contact EIP Customer Service Department for rapid

attention.

7. A

f

ter sales service

EIP machines are high quality machines that have been

tested for safety by authorized technicians. It is always

apparent that after longer working periods, electrical and

mechanical components will show signs of wear and tear

or ageing.

To maintain operational safety and reliability the following

service interval has been defined. Every year or after 250

hours.

Under extreme or specialized conditions and/or

insufficient maintenance intervals are necessary. Use

only original EIP spare parts. Use of other spare parts will

invalidate all warranty and liability claims!

Should you require after sales service please contact the

supplier from whom you purchased the machine, who will

arrange service. Repairs and servicing of EIP products

should only be performed by trained staff. Improper

repairs can cause considerable dangers to the user.

8. Guarantee

Your product is guaranteed for one year from the date of

original purchase, or hire purchase, against defects in

materials or workmanship during manufacture. Within the

guarantee period we undertake at our discretion, to repair

or replace free of charge to the purchaser, any part found

to be defective, subject to the following conditions.

CONDITIONS

1 Claims made under the terms of the guarantee must

be supported by the original invoice/bill of sales

issued at the time of sale, or the machine Serial No.

2 For claims under this guarantee contact the supplier

from whom you purchased the product who will

arrange the appropriate action. Do not initially return

the product as this could result in transit damage.

3 Neither EIP nor its distributor shall be liable for any

incidental or consequential loss.

4 This guarantee is governed by the laws of England.

5 This guarantee does not cover any of the following:

Periodic maintenance, and repair or replacement

of parts due to normal wear and tear.

Damage caused by accident, misuse or neglect,

or the fitting of other than genuine EIP parts.

Defects in other than genuine EIP parts, or

repairs, modifications or adjustments performed

by other than a EIP service engineer or

authorized service agent.

Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

This guarantee does not affect your statuary

rights, or your rights against the supplier arising

from their sales or purchase contract.

EIP Limited’s policy is one of continual product

development and we reserve the right to alter

specifications without prior notice.

AF5100 OWNERS MANUAL

5

9. Technical specification

Model AF5100

Part No. 1095820

Voltage V 230

Frequency Hz 50 / 60

Rated power w 1150

Construction class Earthed

Protection IP IP22

cfm 3000Maximum airflow

m³/h 5100

Noise level (1) Db(A) 78

Speeds 2

Thermal overload Yes

Telescopic handle & wheels No

High visibility mains lead m 6

Size (h x w x l) cm 61x48x56

Weight Kg 17

Warranty 1 year on electrical components,

5 year on housing.

1) Noise levels measures at a distance of 1 metre from machine and 1.6 metres above floor.

Measurements recorded using a hand held meter

This product has been manufactured using the following transposed harmonized European

Standards and technical specifications :-

BS EN 5008-1, BS EN 55014-1 & 2, BS EN 60335-1 and BS EN 60335-2-67, and is conformity with

The Machinery Directive 89/392/EEC and subsequent amendments

The Low Voltage Directive 73/23/EEC and subsequent amendments

The EMC Directive 89/336/EEC and subsequent amendments

Fault diagnosis

Trouble Reason Remedy

Machine not

working

- Lack of voltage/electricity supply

- Axial Fan circuit breaker has

tripped

- Check fuse*, supply cord, plug and

socket outlet.

- Reset circuit breaker

* If the fuse blows several times, the machine should be checked by an authorized Service Agent.

AF5100 OWNERS MANUAL

6

AF5100 OWNERS MANUAL

7

AF5100 OWNERS MANUAL

8

EIP Limited. St Helens Trading Estate, Bishop Auckland, Co. Durham. DL14 9AD England

Telephone: +44 (0) 1388 664400 Fax: +44 (0) 1388 662590

Website: www.eipl.co.uk

Table of contents