Eisele GTWS 740 Manual

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG

Pumpen- und Maschinenfabrik

D-72488 Sigmaringen

EISELEproductsarerenownedfortheirgoodqualityandsoundmoderntechnology.

Itisessential,however,thatthecustomershouldpaycloseattentiontothe operating and

maintenanceinstructions,asanydamagecausedtothedeviceduetoincorrecthandling

ornon-compliancewiththeinstructionscannotberemediedbyEISELE.

Casesofindirectconsequentialdamageand natural wear and tear are generally excluded from

liabilityandguarantee claims. If mixers aretobe used in chemically corrosivemedia,please

consultthe factory priortostart-up.

Contents

1. Description and applications

2.Transportationandstorageregulations

3.Electricalconnection

4.Start-up

5.Maintenanceandinspection

6. Repairs

7.Troubleshooting

8.Safety information

1. Description and applications

Max.submersiondepth:40m

Medium:chemicallyneutral

Max.temperature: 65°C

Ensuresufficientlyfree-flowing

consistency- dilute if necessary.

EISELEmixers have anextremely

strongstirringaction which may cause

thewall of the tank to vibrate.

Forthis reason, they may only be installed

intanks which arein good condition!

2. Transportation and storage regulations

Thesubmersibleagitatorshouldbefixedsecurelyinahorizontalpositionfortransportationand

storagepurposes.Itmayonlylifted by the screw provided. Make sure thepropellerisnotexposed

toany unilateral forces. Never lift themixerbythecable.

1/8

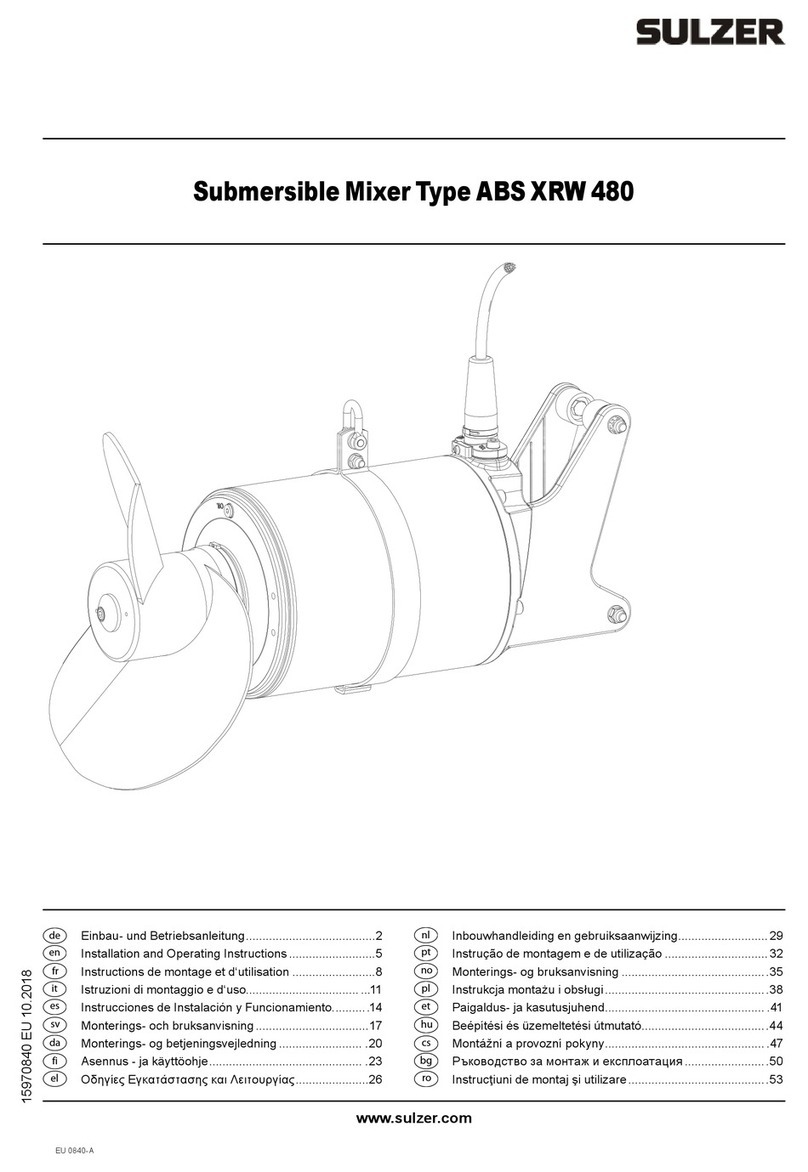

Suspension

screw

Submersible

motor

Oil

chamber

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

3. Electrical connection

Allinstallation work may only becarried out by aqualified electrician in accordancewith the relevant

regulations.Electricalinstallationonsite has to be carried out insuchawaythat overload and

short-circuitprotectionofalllinesandoperatingequipmentis ensured.

3-pole line circuit breakers of characteristic Karerecommended.

Allelectricalinstallations must comply with the VDE regulations.

Mainequipotentialbondingandadditionallocalequipotential bonding between all conductive

parts(guiderail,mixer, immersed vessel, actuating device, catch,

Wirecable,installationframe,cover, service cover etc.) and the earthed conductor of the

operatingequipmentaretobecarriedoutonsite.Effectivenessistoberecordedandregularlychecked.

Whenusing remotecontrols/ switches,thefollowingpoints mustalsobeobserved. Thecontrol/switch

isto be made weather-proofin the operating and visible area ofthe mixer.

Ifthisisnotthe case, an EMERGENCY-STOPswitchmust be provided by the customer in thisarea.

Theregulationsof VDE 0113 or other existing regulationsare to be observed.

3.1 Neutral wire

Theneutralwiremustberoutedtotheswitchorcontrolsystem. 5-core wires must be used for

extensions.

3.2 Residual current device

Aresidual current device(RCD)withamaximum rated residualcurrentof30mA is also tobeinstalled

bythecustomerinadditiontothespecified fuse protection for each individual mixer. In the eventof

afault,thisRCDshould disconnect all power circuits,includingthesealcontrolandthermalsensor.

3.3 Nameplate

Beforeconnectingthemixer, make sure the ratings on thenameplatecoincidewiththeavailable

mainsvoltageandfrequency.

3.4 Thermal monitoring

Thermalcontactsare installed in the submersible motor for temperature monitoring. This ensures

thatthemotorisreliablyswitchedoffintheeventof inadequate cooling.

Inaddition,amotorprotectionswitchmustbe used.

Themotorprotectionswitch/motorprotectionrelaymustbetemperature-compensatedand

phasefailuresensitive.

Themotorcannotbeswitchedon again until it has cooled down.

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

3.5 Electronic leakage control

Anelectrode isinstalledinthe gearboxoilcompartmentwhich indicates theingressoffluid viaasignal

lampof the electronic evaluation system (on theswitchorinthecontrolbox).

Whenafaultis indicated, change the oil and checkthemotorcompartment (see 5. Maintenance and

inspection).Ifthelamplightsupagain,themechanicalsealmustbe replaced.

Attention:thisleakagecontrolisaveryimportantcomponenttoensurethatthemixerfunctionscorrectly.

Atthesame time it is anitem of operating equipment whichensures protection.

Itisnotpermittedtooperatetheunitwithouttheleakagecontrol.

Correctfunctioning is tobecheckedandensured on start-upandmonitored at regular, short intervals.

The electronic evaluation system required for this is available as an accessory (not included in the

scopeofsupplyofthemixersGTWSBandGTWSI).

3.6 Motor protection

Whenmotorprotectionswitchesareusedwithonlyabi-metalactuator,noreliableshut-downisensured

inthe eventofoverheating,i.e. thethermalcontactsinstalled inthesubmersiblemotor mustbelooped

withthe control power circuit.

Thethermalcontactsare designed as normallyclosed (standard:230VAC,1.6Amax.)

3.7 Unit cable

Tomountacontrol/switch,the mixershouldbe loweredcompletelydue tothelength ofcableavailable.

Onlyoriginalcableorlineterminalsmaybeused.

Thedistancebetweenthe cable clampsmust notexceed50cm (GTWSB:70cm).Allscrewsareto be

protectedagainstworking loose.

Inareasinwhichscrapingagainststructuralpartsis to be expected, the connection cable should

beadditionallyprotectedand/ or fixed. The connection cable, protectivetubeandlineterminals are

tobechecked at regular,short intervalsfordamage and replaced after2 years atthelatest.

3.8 Recommended protective equipment

Topreventapotentiallydangeroussituation and prevent operation of the mixer when not submerged

asquicklyaspossible,westronglyrecommendinstallation

ofanautomaticloadgauge which switches the mixer offwhenitrunsempty.

4. Start-up

4.1 Free movement

Before start-up and after long periods of standstill, free movement is to be checked by turning the

propellertoandfro (first disconnect unit from power supply).

4.2 Checking oil level (see5. Maintenance and inspection)

Beforestart-up,the specified oil levelis to be checked byunscrewing the oil fillerplug marked in red

(01 19 mm af).

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

4.3 Direction of rotation

Selectthe“thrust“direction. The propeller should rotate anti-clockwise (GTWS740/1040) as you

lookatit from the frontsideof thepropeller,clockwise at GTWS 1540/204/254/304.

TheoriginalEISELEswitchhasa phase inverter. If the propeller rotates in the wrong direction, press

thescrewdriverintotheslotintheplugandrotatethecontactsby180°untilthephase

inverterisre-engaged.

4.4 Checks

Ifthereare no obstacles in the tank, can the mixer make contact anywhere?

Doesthemixer also turn (two-phase cycle orblockage)?Switch off immediately and do notwaituntil

thermalcontactsaretriggered!

Allscrewsandconnectionsare to be checked for tight fit. Thesechecksaretobe repeated at regular

intervals.

Thewirecable/plasticcablemustnotruborjamanywhere.

The anti-rotation device must be secured with additional limit stops in such a way that the propeller

doesnotmake contact even if the retainingboltswork loose.

4.5Attention

Whenmoving the mixer,payattention totheconnectioncable.

Thewirecable must always be taut. Withaloose wire cable, the mixer couldsuddenlyswing against

the cable and damage it.

Donotoperate the mixer half submerged. Vibrationsonthe mixer and walls aretoogreat.

Operationisonlypermitted when the mixer is covered withatleast0.6 m of fluid.

Ifoscillations and vibrationsbeyond the normalamount occur during operation, the unit is to be shut

downimmediatelyandinspected. This also applies to all fastenings,connectionsandcable clamps.

5. Maintenance and inspection

Allmaintenanceand inspection work etc.may only be carried outwhen the electrical system isto be

disconnectedandprotected against being switchedonagain.

Duringallinspectionand maintenance work, no explosive atmosphere may exist.

Maintenanceandserviceworkmayonlybecarriedoutbyqualified,experiencedpersonnel.

5.1 Cleaning

Themixeristoberegularlycleanedofexternalencrustationandblockages.

Ifcorrosionbecomes visible, it must berectified by suitable means.

5.2 Check connection cable and fastenings

The motor cable is to be checked at regular, short intervals for bends and pinches as well as for

damage.

Thecableprotectionsystem(protectivetube,cableclamps)isalsotobe checkedfordamage,pinches,

movedor loose clamps etc.

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

5.3 Cable winch and fixing cable

WhenEISELEhoisting tackle is used, the cable winch and the wire cablemustbecheckedaccording

toconditionsofuse, but at least once ayear.Thebearingbushesof the drive shaftandthedrum hub

aretobe oiled regularly and thecrown gear greased.

The brake mechanism itself must not be lubricated. It must be possible to turn the hand crank freely

counter-clockwisewithout load.

The wire cable (where applicable plastic cable) is to be checked for fibrous fractures, pinches and

otherdamage along the complete length.

5.4 Checking the gearbox oil

Theoilshouldbechecked every 6 months, or after 500 operating hours atthelatest.Todo this,

unscrewtheredscrewplug (01 19mm af) and insert athinobjectdiagonally downwards in order to

removeasampleofoil from the bottom area. If theoilcontainstoomuch foreign fluid, it will have

astronglyemulsified(creamy)appearanceandshouldbechanged.Thisinspectionshouldbe

repeated14days after changing the oil.

Iftheoilstillcontainstoomuchforeignfluid,thisprobablymeansthattheoutermechanicalsealis

defective.Thisshouldonly be repaired at aspecialistworkshop.

Theoilmustcomeuptotheprescribed level. If necessary,topitupwith normal transmission oil

SAE80-90.Donot overfill, but leave an air cushiontoallowthe oil to expand with heat.

Type 740/1040 :

Air cushion appr.. 3-5 cm

03

01

02

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

Type 1540/204/254/304 :

5.5 Insulation measurement

Every 6 months, but at the latest after every 500 operating hours, an insulation measurement of the

connectioncable is to be carriedout.Thesensorwiremust be disconnected andthethermalcontacts

connectionsshort-circuitedinordernottodamagesensitiveelectroniccomponents.Thetestvoltage

mustbeselectedsothattheinsulationsarenotdestroyed.

5.6 Motor inspection

Themotor compartment is to beinspected when the oilis checked. The screwplug of the inspection

openingistoberemoved(0313mmaf).Iffluidruns out,themixermustno longerbeoperated;slightoil

leakagesofthe axial seal may bepresent. Have the mixer checkedby a specialist company.

Checksmoothrunningofthemixer, itsgear and all bearings by turning.

5.7 Oil change

Anoilchangeistobecarried out at least once a year or ifuseddailyforlongperiodsafter every 1000

operatinghours.Unscrewredscrewplug(0119mmaf),releaseanyoverpressure.Unscrewoildrain

plug(02 24mmaf).Ensurethattheoilisthoroughlydrainedbefore fillingwithnew oil. TheDowtyrings

necessaryforsealing the plugs are tobe replaced.

Theairspace remaining above the oilis essential and enables thermal expansionof the oil.

Oiltype:conventional gear oil SAE80-90

Oilquantity, type 740/1040 approx.3.6 l, type 1540/204 approx. 5.6l,type 254/304 approx. 4,6 l

Oillevel

01

02 03

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

5.8 Changing the propeller

Beforedismantlingthepropeller, allow any excess pressure in theoilchamber to escape by

looseningtheredplugscrew(0119mmaf)slightlyandthentighteningitagain.Themechanical

sealremainsontheshaft.Beforeassembly,clean the shaftendandfeatherkey,remove

anybursand treat with fretting rust preventives (anti-seize or possibly grease/oil).

Usenew securing elements.

5.9 Other

Allscrewconnectionsaretobe checked regularly for tight fit.

The customer is to ensure that all protective and monitoring equipment is connected and functional.

Thisisto be permanently ensured with suitable measures.

6. Repairs

Repairsbeyondthose mentioned above may onlybecarried out in the Eiselefactory or in a

specialistworkshopauthorisedbyus.

6.1 Bearings

Thebearingsare to be completely replacedat the latest after11000 operating hours.

6.2 Mechanical seals

Themechanicalseals are to be replaced atthe latest after every 3000 operatinghoursor after

2years.Mechanicalsealsmayonlybereplacedcompletely. Mechanical seals which have been

removed(disassembled)oncemustnotbe reinstalled.

6.3 Cables and cable protections systems

Theconnectioncable,protective cable tube and cable clamps mustbereplacedat least every

2years.Damagedcables must never continue to be used.

7. Troubleshooting

7.1Agitator won't start.

Check: -residual-current-operatedcircuitbreaker,mainswitchandfuses

-Motorpreviously overloaded, thermal switchesactivated

due to-two-phaseoperation

-overload

-inadequatecoolingduetoinsufficientsubmersiondepth

Eliminatethecause of the error andletthe agitator cool down beforeswitching it on again.

7/8

Operating and Maintenance Instructions

Submersible Mixer GTWS/B/I 740/1040/1540/204/254/304

MTe12318a1p.

FRANZ EISELE u.SÖHNE GmbH u.Co.KG Telefon07571/109-0

Pumpen- und Maschinenfabrik Telefax 07571/10988

7.2 Leak test indicator lamp illuminated.

Changeoil as described insection 5.7. If theindicator lamp lights up again after ashort time, this

meansthatforeignfluidhasgotintothe gearbox between the motor and agitator.Continued

operationcan cause seriousdamage to the seals, bearing and motor. Such damageis not covered

bytheguarantee.Inthiscase,the outer mechanical seal is probably defective.

Thedamagemay only be repairedby a specialist workshop.

7.3 RCD device

Iftheresidual-current-operatedcircuitbreakerisactivated,theinstructionsinsection5.6mustbe

observedwithout fail.

8. Safety instructions

Pleasetakeexplosionprotectionveryseriously. Observe all relevant regulations and safety

instructions.Theslightestcarelessnessmaycauseseriousdamagetopropertyandinjuries!

Allmaintenanceworketc.mayonlybecarriedoutwhentheunitisdisconnectedfromthepower

supplyandprotectedagainst being switched on again.

Thewindingsareto be discharged, all wiresdisconnectedand short-circuited.

Electrostaticchargesandmechanical sparks must always be avoided.

8.1 The applicable regulations concerning

-industrialsafety

-plantdesign

-andelectrical connection

e.g.specifications of professional associations,VDE (German EngineeringAssociation),etc.

mustbe strictly observed.

8.2 Toxic gases! Risk of explosion!

Mostofthefluidsprocessedconsist of fermenting biomass (e.g. liquid manure, sludge), which

canformtoxic and explosive gases.The release of these gasesis intensified by pumping and

stirringactions.

Forthisreason, smoking and naked flames areprohibited,adequate ventilation must be

ensured,andthe specifications of the professional associationmust be observed.

8.3 Use in agriculture

Bindingthreads,strings andsimilar matter in liquid manure leadtooperatingfaultsinthe mixer.

Thesethreads will not rot .The long-fibres ofthethreadswrapthemselvesaroundthepropeller,

oftenresulting in a significantly reduced output. Such threadsmayalsogetcaughtbetweenthe

propellerandgearcase and so destroy the seal. Inyourowninterest, please bear in mind the

possibledisadvantagesofdischarging these threads into the liquid manurecycle.

8/8

This manual suits for next models

17

Table of contents

Popular Mixer manuals by other brands

Kenwood

Kenwood Major KM001 series user guide

KitchenAid

KitchenAid 5KSM150PS instructions

KitchenAid

KitchenAid KHM926WH instructions

Engineering Solutions

Engineering Solutions MXB-075 instructions

BakeMark

BakeMark HS10 Installation, Operation and Care Manual

MULTIQUIP

MULTIQUIP Whiteman WM120SH Series Operation manual