Ekasand 75 x 100 mm Specifications

DOC 1114 1 04/26/06

EKASAND

75 x 100 mm (3 x 4 in.)

Orbital Sander

Features:

• Free Speed of 10,000 Orbits Per Minute

• Variable Speed Control with Palm Style On/Off Lever

• 3 Sizes of Ergonomic Cushion-Grips for comfort and

stability

•LowProleforOperatorControlandComfort

Please Read and Comply With

1) General Industry Safety & Health Regulations, Part 1910, OSHA 2206,

available from: Superintendent of Documents; Government Printing Of-

ce; Washington DC 20402

2) Safety Code for Portable Air Tools, ANSI B186.1 available from: Ameri-

can National Standards Institute, Inc.; 1430 Broadway; New York, NY

10018

3) State and Local Regulations.

Key parts of the above regulations are excerpted below. They are not in-

tended to be inclusive. Study and comply with all regulations.

1) TOOL INTENT – Tool shall be used only for purposes intended in its

design.

• Rear Exhaust Directs Air away from work

• Suggested Applications:

Sanding and Finishing a Variety of Materials including

Wood, Metal, Plastic, Fiberglass Composites, Solid

Surfaces and other Sandable Surfaces

2) AIR SUPPLY – Test and operate tools at 90 PSIG (6.1 Bar) maximum

unless tool is marked otherwise. Use recommended airline lters -

regulators – lubricators (FRL).

3) UNUSUAL SOUND or VIBRATION – If tool vibrates or produces an

unusual sound, repair immediately for correction.

4) OPERATOR PROTECTIVE EQUIPMENT – Wear goggles or face

shield whenever tool is in operation. Other protective clothing shall be

worn, if necessary.

5) SAFETY MAINTENANCE PROGRAM – Employ a safety program to

provide inspection and maintenance of all phases of tool operation and

air supply equipment in accordance with “Safety Code for Portable Air

Tools.”

Operators Instructions

Includes – Features and Suggested Applications, Please Read and Com-

ply, Assembly Drawing of Machines, Parts List, Proper Use of Tool, Work

Stations, Putting the Tool Into Service, Operating Instructions, EKASAND

Service Tools and Accessories, EKASAND Back-Up Pads™, EKASAND

Service Kit, EKASAND Warranty

Always wear safety

goggles to protect your

eyes.

WARNING

OIL DAILY Important

Read these instructions carefully before installing, operating, servicing or

repairing this tool. Keep these instructions in a safe, accessible location.

EKASAND TOOLS

© EKASAND•0701

Oil daily for superior

performance.

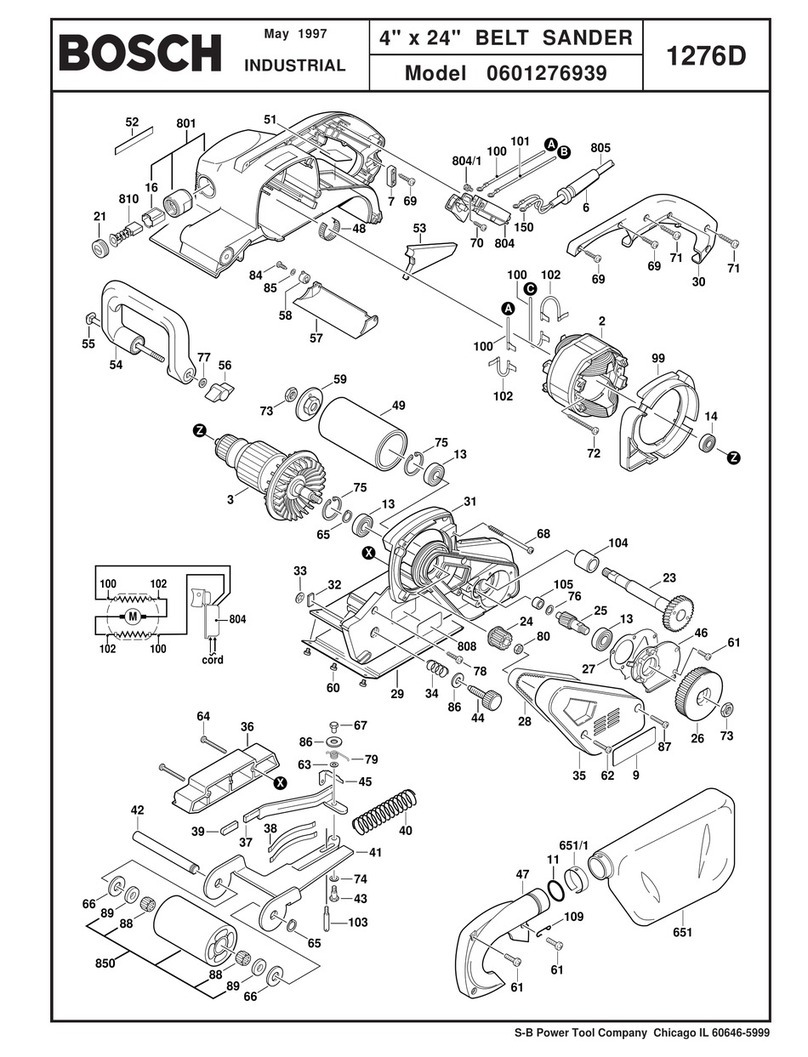

DOC 1114 2 04/26/06

EKASAND 75 x 100 mm (3 x 4 in.)

Orbital Sander

DOC 1114 3 04/26/06

Parts List

ITEM P/N DESCRIPTION QTY

1 ESA0400 RETAINING RING 1

2 ESA1200 BEARING 1

3 ESA5600 REAR ENDPLATE 1

4 ESA4000 PIN (included with item 5, Assembly) 1

5 ESA7600 CYLINDER ASSEMBLY (includes item 4, Pin) 1

6 ESA2400 O-RING 1

7 ESA0100 VANE (5 are included with item 8, Set) 5

8 ESA3600 ROTOR, VANES (Qty. 5) AND KEY KIT 1

9 ESA1400 KEY (included in item 8, Set) 1

10 ESA4600 FRONT ENDPLATE 1

11 ESA9100 BEARING 1

12 ESA5400 O-RING 1

13 ESA1000 LOCK RING 1

14 ESB2720 3 in. X 4 in. 1/8 in. ORBIT SHAFT OS BALANCER (for screw type pad) 1

15 ESA7010 RETAINING RING 1

16 ESA2610 BEARING 1

17 ESA6910 SHIM 1

18 ESA1610 BEARING 1

19 ESA8010 SHIM 1

20 ESA6210 WASHER 1

21 ESA7710 RETAINING RING 1

22 ESA3610 SPINDLE (includes item 23 pin) 1

23 ESA2110 PIN (included with item 22, Spindle) 1

24 ESA1800 SPACER KIT (includes ESA9700 AND ESA0800 spacers) 1

25 ESA4110 LEVER 1

26 ESA1300 PIN 1

27 ESA3490 65 mm (2 ½ in.) GRIP OPT

ESA4490 70 mm (2 ¾ in.) GRIP (Standard) 1

ESA5490 75 mm (3 in.) GRIP OPT

28 ESA2490 HOUSING 1

29 ESA8670 SCREW 4

30 ESA6700 WASHER 4

31 ESA8000 VALVE STEM ASSEMBLY (includes item 32 O-ring) 1

32 ESA8900 O-RING (included with item 31 Valve Stem Assembly) 1

33 ESA3400 O-RING 1

34 ESB4100 SPEED CONTROL 1

35 ESA9300 RETAINING RING 1

36 ESC2610 SEAL 1

37 ESC8100 PAD SUPPORT 2

38 ESA6670 SCREW 4

39 ESB1010 PAD BACKING 1

40 ESA7670 SCREW 4

41 ESA8700 SCREW 1

DOC 1114 4 04/26/06

42 2572700 75 x 100 mm (3 x 4 in.) screw-on, non-vac, vinyl face pad 1

2572701 75 x 100 mm (3 x 4 in.) screw-on, non-vac, hook face pad 1

2572710 75 x 100 mm (3 x 4 in.) screw-on, standard vac, vinyl face pad 1

2572711 75 x 100 mm (3 x 4 in.) screw-on, standard vac, hook face pad 1

43 ESA2300 MUFFLER 2

44 ESA8300 PLATE 1

45 ESA6610 MUFFLER HOUSING 1

46 ESA3100 INLET BUSHING (1/4-18 NPT) 1

47 ESA4100 VALVE SPRING 1

48 ESA7000 VALVE 1

49 ESA9000 SEAT 1

50 ESC7100 SNAP-IN EXHAUST ADAPTOR 1

51 ESB9600 SNAP-IN VACUUM COVER PLATE 1

52 ESA2270 10,000 RPM SGV RETAINER ASSY 1

53 ESA4400 O-RING 2

54 ESA8770 Ø 28 mm (1 in.) SuperVAC SGV SEAL (included in item 55) 1

55 ESA2411 Ø 28 mm (1 in.) SuperVAC SGV SWIVEL EXHAUST ASSY (Standard on SGV) 1

56 ESA4580 Ø 19 mm (3/4 in.) SuperVAC SGV SEAL (included in item 57) OPT

57 ESA0411 Ø 19 mm (3/4 in.) SuperVAC SGV SWIVEL EXHAUST ASSY (Optional on SGV) OPT

58 ESA2140 Ø 28 mm (1 in.) VAC HOSE TO DOUBLE BAG FITTING AND AIRLINE ASSY (Standard

on SGV) INCLUDES: ESA3400 Ø 28 mm (1 in.) x 1.8 m (6 ft.) Vacuum Hose, ESB3210 Ø

28 mm (1 in.) Hose to Double Bag Vacuum Fitting, ESA3300 Ø 6.3 mm (1/4 in.) x 1.8 m (6

ft.) Airline with Fittings, ESA2700 Bungee for Ø 6.3 mm (1/4 in.) Airline & Ø 28 mm (1 in.)

Vacuum Hose (5)

1

ESA1140 Ø 19 mm (3/4 in.) VAC HOSE TO DOUBLE BAG FITTING AND AIRLINE ASSY (Optional

on SGV) INCLUDES: ESA0020 Ø 19 mm x 1.5 m (5 ft.) Vacuum Hose, ESB3310 Ø 19

mm (3/4 in.) Hose to Double Bag Vacuum Fitting, ESA2030 Ø 6.3 mm (1/4 in.) x 1.5 m (5

ft.) Airline with Fittings, ESA1030 Bungee for Ø 6.3 mm (1/4 in.) Airline & Ø 19 mm (3/4

in.) Vacuum Hose (5)

OPT

ESA0030 Ø 19 mm (3/4 in.)VAC HOSE TO Ø 19 mm (3/4 in.) x Ø 28 mm (1 in.) HOSE ADAPTER

COUPLING & AIRLINE ASSY INCLUDES: ESA0020 Ø 19 mm (3/4 in.) x 1.5 m (5 ft.)

Vacuum Hose, ESB8800 Ø 19 mm (3/4 in.) Hose to Ø 28 mm (1 in.) Hose Adapter,

ESA2030 Ø 6.3 mm (1/4 in.) x 1.5 m (5 ft.) Airline with Fittings, ESA1030 Bungee for Ø 6.3

mm (1/4 in.) Airline & Ø 19 mm (3/4 in.) Vacuum Hose (5)

OPT

ESA2930 Ø 28 mm (1 in.) VAC HOSE TO Ø 28 mm (1 in.) x Ø 38 mm (1 1/2 in.) FRICTION FIT

ADAPTER & AIRLINE ASSY INCLUDES: ESA4300 Ø 28 mm (1 in.) x 1.8 m (6 ft,)

Vacuum Hose, ESB2900 Ø 28 mm (1 in.) Hose Thread x Ø 38 mm (1 1/2 in.) Friction Fit

Adapter, ESA3300 Ø 6.3 mm (1/4 in.) x 1.8 m (6 ft.) Airline with Fittings, ESA7200 Bungee

for Ø 6.3 mm (1/4 in.) Airline & Ø 28 mm (1 in.) Vacuum Hose (5)

OPT

59 ESA2900 SuperVAC 1 in. CV SWIVEL EXHAUST ASSEMBLY (Standard on CV) 1

60 ESA8400 NUT 1

61 ESA8920 SuperVAC ¾ in. CV SWIVEL EXHAUST ASSEMBLY (Optional on CV) OPT

62 ESA7400 WASHER 1

63 ESA9670 SCREW 1

64 ESC0110 VACUUM BAG (Standard on SGV) 1

65 ESC9010 VACUUM BAG INSERT (Standard on SGV) 1

DOC 1114 5 04/26/06

EKASAND back-up pads are perfectly mated for use on the

EKASAND. Constructed from premium, industrial-quality materi-

als and featuring a riveted berglass and steel hub with molded

urethane, their durability and precise construction are the ideal

complement to the performance of the EKASAND

EKASAND Back-Up Pads EKASAND Overhaul Service Kit

EKASAND Service Tools and Accessories

When an EKASAND OS needs to be serviced, we offer a tool kit to make the disassembly/assembly fast and easy. The Service Tools are highly recom-

mended for use with the Overhaul Service Kit. NOTICE: To receive any expressed or implied warranty, the tool must be repaired by an authorized EKASAND

Service Center.

The ESA3311 EKASAND Overhaul Service Kit contains all the re-

placement parts that naturally wear over time and a straightforward

manual to make servicing an EKASAND sander simple.

Overhauling the Orbital Sander can be made even easier with the

use of the above Service Tools. The Service Tools also reduce the

chance of improper assembly.

ESA3311 Overhaul Service Kit Contents

EKASAND Warranty

All EKASAND Orbital Sanders are warranted for defects in ma-

terials or workmanship for 1 year following the date of delivery to

the user. Combined with the EKASAND name, this Warranty ex-

presses our total condence in the superior quality, durability, and

performance of the EKASAND.

ESA3311 Overhaul Service Kit Contents

Item Part No. Description Qty.

2 ESA1200 Bearing 1

6 ESA2400 O-ring 1

7 ESA0100 Vane 5

8 ESB5000 Rotor 1

9 ESA1400 Key 1

11 ESA9100 Bearing 1

16 ESA2610 Bearing 1

17 ESA6910 Spacer 1

18 ESA1610 Bearing 1

31 ESA8000 Valve Stem Assembly 1

33 ESA3400 O-ring 1

35 ESA9300 Internal Retaining Ring 1

37 ESC8100 Mini Pad Support 2

43 ESA2300 Mufer Insert 2

45 ESA6610 Mufer Housing 1

47 ESA4100 Valve Spring 1

48 ESA7000 Valve 1

49 ESA9000 Valve Seat 1

N/A ESA0620 Service Instructions 1

Description Part#

EKASAND 3 x 4 in. screw-on, non-vac,

vinyl face pad

2572700

EKASAND 3 x 4 in. screw-on, non-vac,

hook face pad

2572701

EKASAND 3 x 4 in. screw-on, standard

vac, vinyl face pad

2572710

EKASAND 3 x 4 in. screw-on, standard

vac, hook face pad

2572711

T-6 Motor Lock Ring

Wrench/Spindle Puller

T-7 Soft Collar

ESA9740 Universal Service Tool Kit

T-8 Motor Face Plate

Bearing Removal Tool

T-13 Bearing

Press Tool

T-9 Bearing

Puller

T-1 Bearing

Press Tool

T-12 5/16-24 to M6 x 1P

Adapter Assembly

T-2 OS Spindle Bearing

Press Tool

ESA9740 Universal Service Tool Kit ESA4840 3 x 4 in. Service Tool Kit

DOC 1114 6 04/26/06

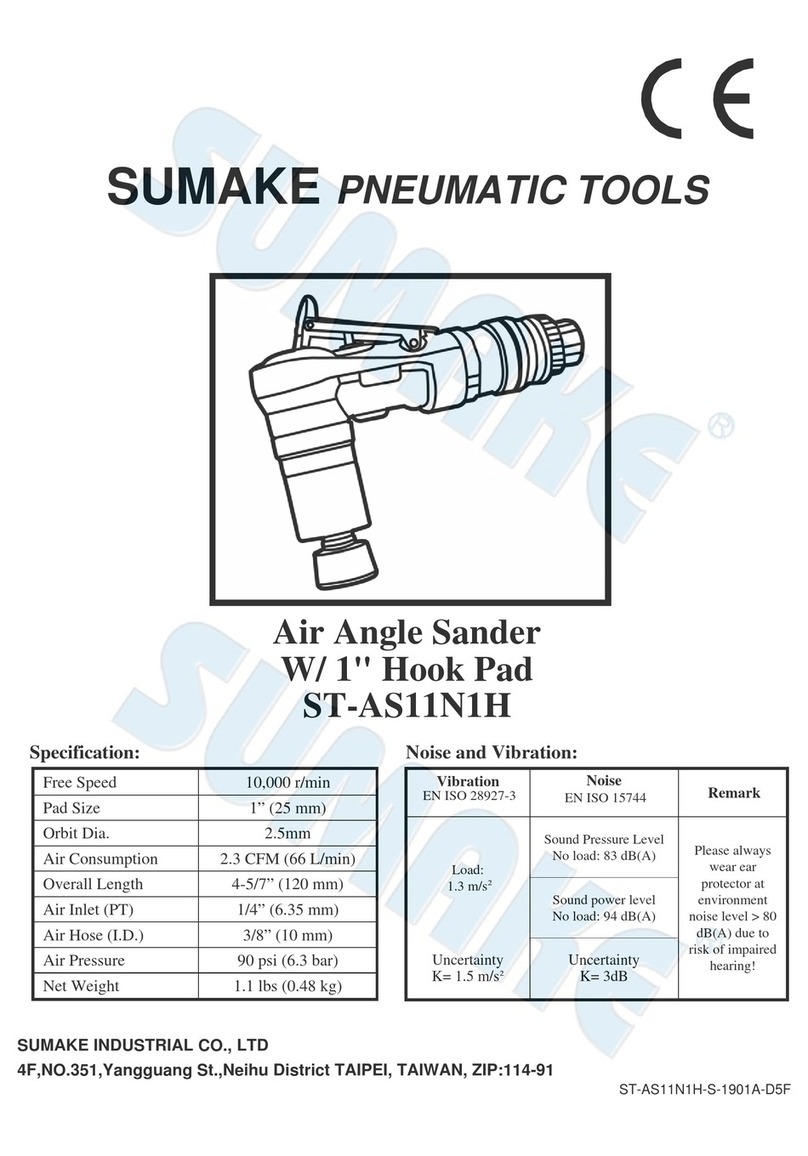

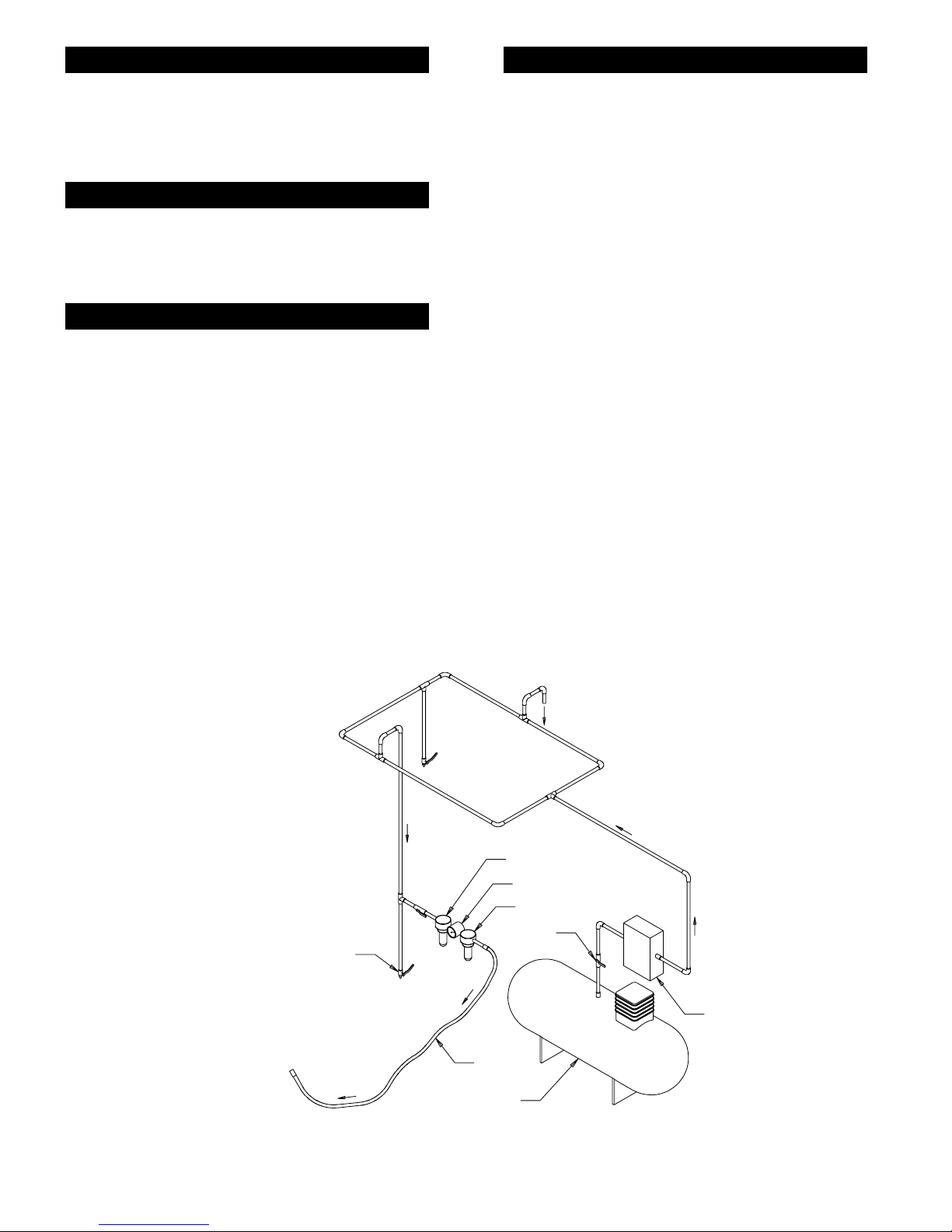

Use a clean lubricated air supply that will give a measured air pres-

sure at the tool of 90 PSI/6.1 Bar when the tool is running with the

lever fully depressed. It is recommended to use an approved 3/8

in./10 mm x 25 ft./8 meter maximum length airline. It is recom-

mended that the tool be connected to the air supply as shown in

Figure 1. Do not connect the tool to the airline system without in-

corporating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that an air

lter, regulator and lubricator (FRL) be used as shown in Figure 1

as this will supply clean, lubricated air at the correct pressure to the

tool. Details of such equipment can be obtained from your supplier.

If such equipment is not used then the tool should be lubricated

by shutting off the air supply to the tool, depressurizing the line by

pressing the lever on the tool. Disconnect the airline and put 2 to

3 drops of a suitable pneumatic motor lubricating oil, preferably in-

corporating a rust inhibitor into the hose end (inlet) of the machine.

Reconnect tool to air supply and run tool slowly for a few seconds

to allow air to circulate the oil. If tool is used frequently lubricate on

daily basis and if tool starts to slow or lose power.

It is recommended that the air pressure at the tool be 90 PSI/6.1

Bar while the tool is running so the maximum RPM is not exceed-

ed. The tool can be run at lower pressures but should never be run

higher than 90 PSI/6.1 Bars. If run at lower pressure the perfor-

mance of the tool is reduced.

Proper Use of Tool

1) Read all instructions before using this tool. All operators

must be fully trained in its use and aware of these safety

rules. All service and repair must be carried out by trained

personnel.

2) Make sure the tool is disconnected from the air supply. Se-

lect a suitable abrasive and secure it to the back-up pad.

Be careful and center the abrasive on the back-up pad.

3) When sanding always place the tool on the work then start

the tool. Always remove the tool from the work before stop-

ping. This will prevent gouging of the work due to excess

speed of the abrasive.

4) Always remove the air supply to the sander before tting,

adjusting or removing the abrasive or back-up pad.

5) Always adopt a rm footing and/or position and be aware of

torque reaction developed by the sander.

6) Use only correct spare parts.

7) Always ensure that the material to be sanded is rmly xed

to prevent its movement.

8) Check hose and ttings regularly for wear. Do not carry the

tool by its hose, always be careful to prevent the tool from

being started when carrying the tool with the air supply con-

nected.

9) Do not exceed maximum recommended air pressure.

10) Use safety equipment as recommended.

11) The tool is not electrically insulated. Do not use where

there is a possibility of coming into contact with live electric-

ity, gas pipes, water pipes, etc. Check the area of operation

before operation.

12) Take care to avoid entanglement with the moving parts of

the tool with clothing, ties, hair, cleaning rags, etc. If en-

tangled, it will cause the body to be pulled towards the work

and moving parts of the machine and can be very danger-

ous.

13) Keep hands clear of the spinning pad during use.

14) If the tool appears to malfunction, remove from use imme-

diately and arrange for service and repair.

15) Do not allow the tool to free speed without taking precau-

tions to protect any persons or objects from the loss of the

abrasive or pad.

Operating Instructions

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Figure 1

This sander is designed for sanding all types of materials i.e. met-

als, wood, stone, plastics, etc. using abrasive designed for this

purpose. Do not use this sander for any other purpose than that

specied without consulting the manufacturer or the manufactur-

er’s authorized supplier.

Do not use back-up pads that have a working speed less than

10,000 OPM free speed.

Putting the Tool into Service

Work Station

The tool is intended to be operated as a hand held tool. It is always

recommended that the tool be used when standing on a solid oor.

It can be in any position but before any such use, the operator must

be in a secure position having a rm grip and footing and be aware

that the sander can develop a torque reaction. See the section

“Operating Instructions”.

Table of contents

Popular Sander manuals by other brands

Westfalia

Westfalia 92 86 57 Original instructions

Parkside

Parkside PBS 900 B2 Translation of the original instructions

Einhell Global

Einhell Global EX-G 125 E operating instructions

Berner

Berner BP 40-82 C Original instructions

PEUGEOT

PEUGEOT EnergySand-200ASP using manual

Sealey

Sealey S01046.V2 quick start guide