INTRODUCTION

Foreword

www.

grizzly.com

Contact Info

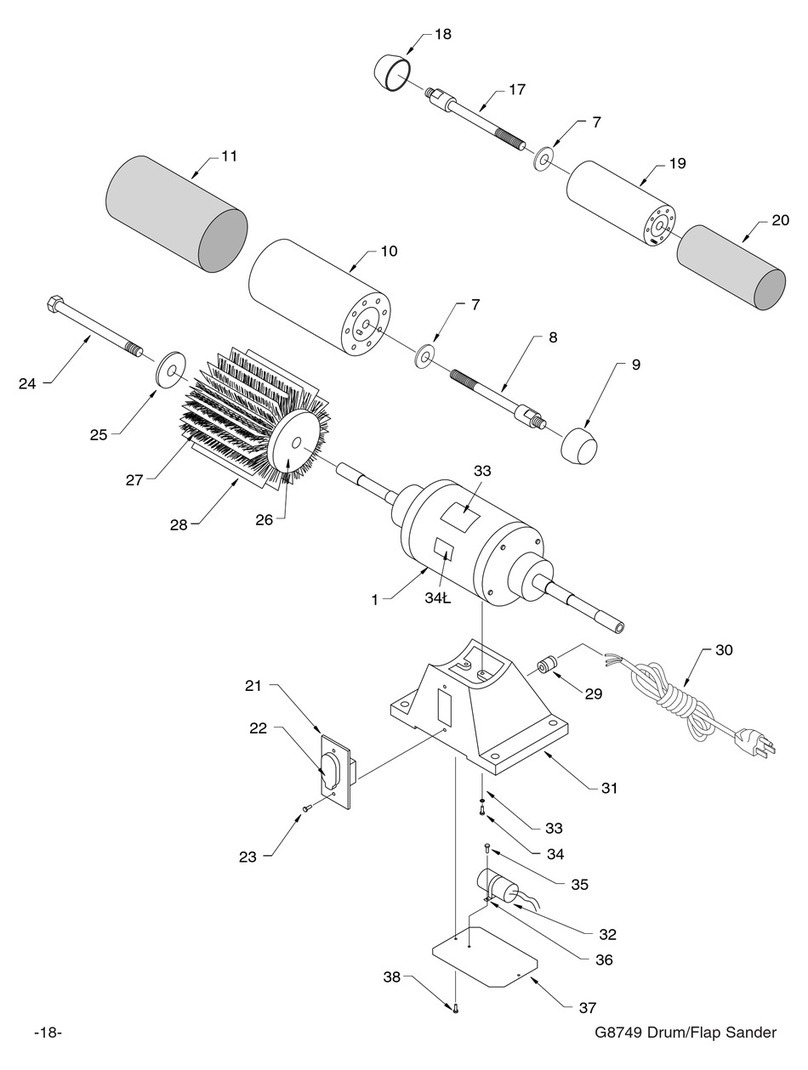

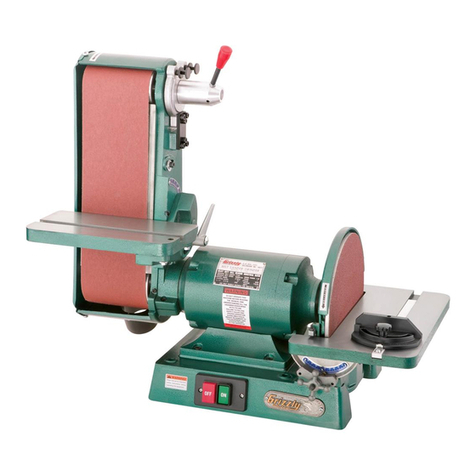

Functional Overview

ON,

OFF

ON,