Ekolot KR-030 TOPAZ Installation instructions

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, maintenanceand periodicinspections

manual

Issue: 1

Rev. No: Date:July2010

Date: Page

1

HANDLING, MAINTENANCE ANDPERIODIC

INSPECTIONS MANUAL

AIRCRAFT

KR-030 TOPAZ

SERIALNUMBER:30 -..…. -…...

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

2

CONTENTS

PAGE

1

SMALL REPAIRS 2

2

PREPARATIONOFTHEAIRCRAFTFORLONG-TERM

SUSPENSIONOFOPERATION 4

3

WORKS TO BE DONEAFTERTHELONG-TERM

SUSPENSIONOFOPERATION 5

4

ROUTINEMAINTENANCELIST 5

5

PERIODICALINSPECTIONSCHEDULE 6

6

LIFECYCLEOFASSEMBLIES 6

7

ASSEMBLYAND DISASSEMBLYOFTHEAIRCRAFT 7

8

ADJUSTMENTPOINTSOFTHECONTROLSYSTEM 12

9.1

FRONTUNDERCARRIAGE 15

9.2

MAINUNDERCARRIAGE 24

9.3

CONTROLSYSTEMS 33

9.3.1

RUDDERCONTROLSYSTEM 33

9.3.2

ELEVATORAND AILERONSCONTROLSYSTEM 47

9.3.3

FLAPS DRIVE SYSTEM 57

9.4

POWERPLANT62

9.4.1

ENGINEMOUNTINGSYSTEM 62

9.4.2

ENGINECONTROLSYSTEM 87

9.4.3

FUELSYSTEM 95

9.4.4

ENGINELUBRICATIONSYSTEM 118

9.4.5

ENGINECOOLING SYSTEM 127

9.5

AIRFRAMESTRUCTURE 145

9.5.1

DOORS 145

9.5.2

REPLACEMENTOFGLAZING 153

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

3

1. SMALLREPAIRS

NOTICE:Incaseofanydamagetothepropeller, please readthe

instructionsplacedintheOperationManualforASType

Propellers.

NOTICE:

All damagestothefuselagecomposite structureandmethodsofrepair

mustbeconsultedwiththeaircraftmanufacturer.

a)Small cracksand paintingimperfectionsaretoberemovedbymeansof

apaintbrush.

b)Cracksinthewindshieldandsidewindowscan be stoppedfrom

spreading bydrillinga ≈∅2holeattheendofcrack.

c)Duringthepainting workson controlsurfaces,suchasflaps,ailerons,

rudderor elevator,thecomponentmustbeweighedwiththeoriginal

factorycoating.Afterremoving the oldcoating and applying anew

coating,thecomponentshouldnot beheavierthanbefore therepair.

After repainting,ailerons' centre ofgravitymustbe verified inthe

following way:

Aileronistobe fixedwithtwohinges(number1and3,counting along

the span)inupside downposition.Thesuspendedaileron mustbe free

toswing.

Ifthe aileronnosehasatendencytogo downor theaileronstaysin

horizontalposition itcanbepresumedthat itiscorrectlybalanced.

Iftheaileron nosehasatendencytogoup,ameasurement mustbe

performedasper thefollowingdrawing.

P

zawieszenie

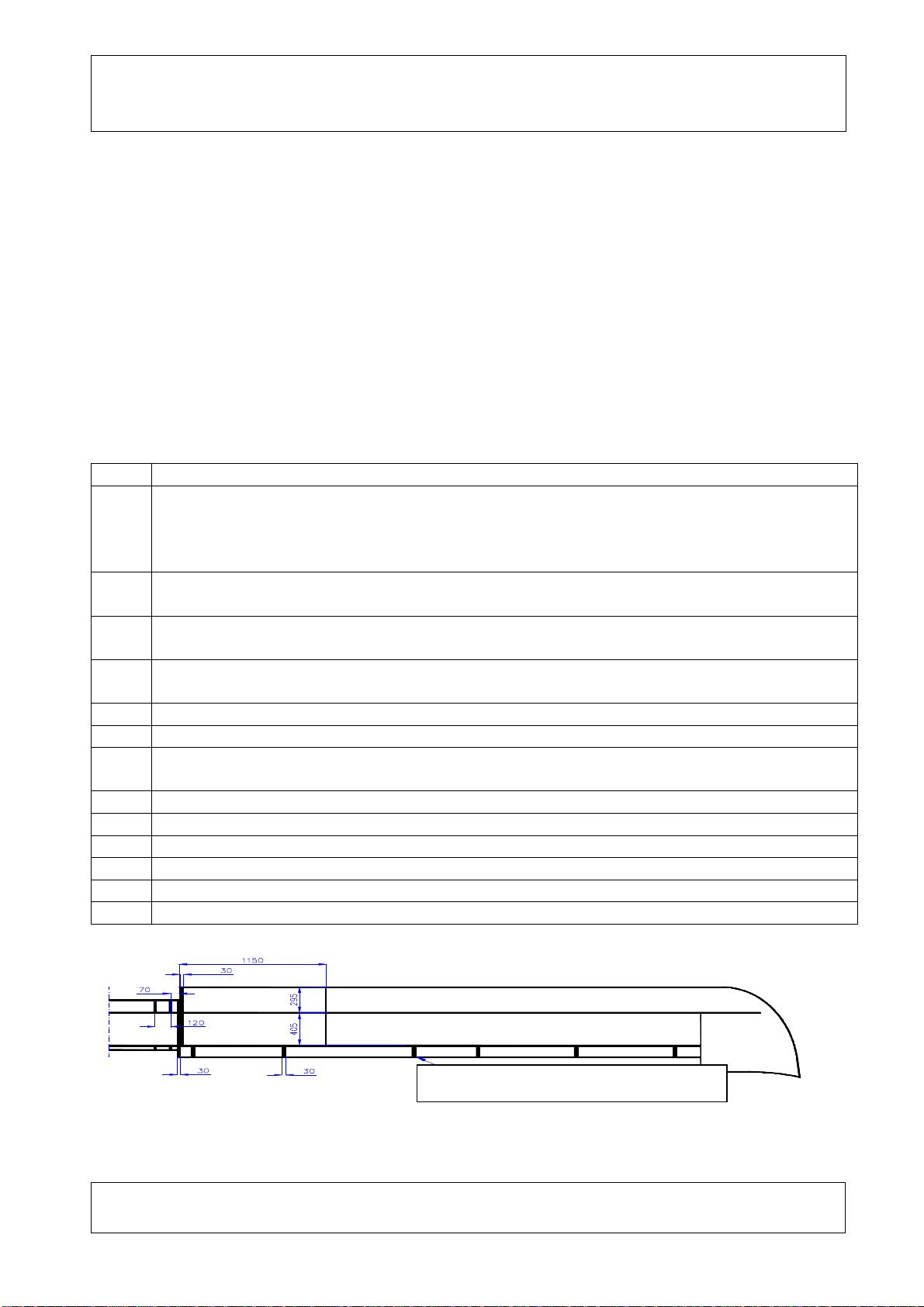

Aileronbalancemeasurement diagram

SUSPENSION POINT

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

4

Value of the P forcerequiredtomaintainhorizontalpositionof the

aileron must notbe greater than0,02kG.

Force Pmust beapplied inthe symmetryplaneofoneof the fastening

point. Toeliminateinfluenceof friction during measurementof Pforce,

the measurement mustbeexecutedbydeflectingthe aileron’send up

anddownandthen arithmeticmean for calculationmustbeapplied.

d)When removingtheoldcoating,specialconsideration must begivento

avoiddestructionof the compositestructure(see: point a)

2.PREPARATIONOFTHEAIRCRAFTFORLONG-TERMSUSPENSION

OFOPERATION

-Disconnect and removethe battery.

-Securetheengine according tothe engine OperationandMaintenance

Manual.

-Emptyfueltanksthrough thefuselage bellydrainvalve.Setthe CUT-

OFFvalvetoOPENposition.

-Dismantlethe aircraft (see:point8.9).Placethe wingsand control

surfaceson specialprops,ideallyinverticalposition,aileron and

controlsurfacestothetop.

-Attachmentpoints,pinsand boltsare tobe cleaned withnaphtha and

coveredwithVaselineorthickgrease.

-Coverthecomponentswithprotectivecovers.

-Fuselageistobeproppedinsuchawaythe tiresdonothavecontact

withthe ground.

-Attachmentpoints,controlsystem,pinsand boltsaretobe covered

withVaselineand wrapped ingreasedclothes.

-Letairoutoftiresto0,5Bar.

-Rearpartof the fuselage (thetail seat)istobe properlycovered.

-Boltsfor mountingwingsare tobecovered withathinlayerof

Vaseline,andthenputintoaplasticbagwithnutsandwashers,which

isinturntobeplacedintheluggage compartment.

-Mountingboltsseatsinwingsand fuselage are tobe cleaned,covered

withathinlayerof Vaselineand pluggedwithpiecesof clothsoaked in

grease.

-Closeandsecurethe door.

-Put aprotectivecover on all elements.

3.WORKSTO BEDONEAFTERTEMPORARYSUSPENSIONOF

OPERATION

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

5

-All partspreserved withgreaseare tobewashedand cleaned.

-Put airintirestothelevelof 1,8-2,0Bar.

-Carryout activities1, 2,3,4,5,6, intheprocedure 8.6.

-Installandconnectthebattery(“+"terminaltothe"+"cableand"-"

terminaltothe"-"cable).

-Removeall preservationfrompowerplant, accordingtothepowerplant

manual.

-Carryout activities7,8,9, intheprocedure8.6.

-Assembletheaircraft (see: point8.9).

-Carryout activities10,11,12, intheprocedure8.6.

4.ROUTINEMAINTENANCELIST

Pos.

Inspection/ check

1

Inspection of airframestructure, givingspecialconsideration toallelementsthat are

heavilyloaded duringtake-off andlanding. Controlof qualityof glue connection of

the wing shellwithinternalwing structurebymeansof tapping, according tothe

schemeattached.

2

Inspection ofallmetaljointspinsand bolts.Check forclearancesinallcriticaljoints

of the airframe.

3

Inspection ofallsafetyelementsinparticularelementsofairframe,powerplantand

controlsystem.

4

Check offrictionincontrolsystem,controlsystemfair-leadscheck.Flapsand

aileronscheck: externalsurfaces, hinges, drivesystemelements. .

5

Inspection and check of undercarriage.

6

Inspection and check ofinstruments. Checkingairtightness of pneumaticsystems.

7

Inspection and checkoffueland oilsystems(band clipson pipes).Allcracked or

scratched fuelpipesmust be replaced.

8

Inspection of wiring system, check securityofcableconnections.

9

Inspection of externalmetalsurfacesandprotectivecoatings.

10

Inspection and check of brakesystem.

11

Inspection of controlsurfacesdisplacement.

12

Inspection and check of propelleraccordingtothe manualforAS propellers.

13

Lubricationaccording toprocedure8.5.3

Laminationschemeof the KR-030 wing

Flapsand aileronssuspension position

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

6

5. PERIODICALINSPECTIONSCHEDULE

The following scheduleshowsinspectionsthatmustbe carriedoutafterspecifiedperiods

of timeorafterincidentsmentioned:

Period oftime

Perform inspec

tion/check position:

Afterfirst 2hoursof flight 1, 2, 3, 4, 5, 6,7, 8,12

Afterfirst 5hoursof flight 1, 2, 3, 4, 5, 6,7, 8,12

After100 hoursof flight orannually 1, 2, 3, 4, 5, 6,7, 8,9, 10,11, 12,13

Afterhardlanding 1, 2, 3, 5, 6

Safeand correctoperation oftheplane maybe assuredbysystematicmaintenanceand

inspectionsof the airframeand powerplant. The activitiesmustbe performed afterperiods

specifiedinFlightandMaintenanceManualofthe Plane,and powerplantand propeller

manuals.

6.LIFECYCLEOFASSEMBLIES

Item Assembly Lifecycle

1 Airframe

-compositestructure

-metalcomponentsof the

structure

-controlsystemcomponents

Depending on technicalcondition

2 EngineROTAX912 UL Accordingtoupdated technicalbull

etins

issuedbythemanufacturer.

3 PropellerAS 1700/1950 Depending on technicalcondition;see

manualfortheAS typepropellers

4 Cockpit instruments(pneumatic

andelectric) Depending on technicalcondition

5 Radioandother electronic

equipment Accordingtotheupdatedmanualsand

instructionsof respective

manufacturers.

6 Rubber pipesfor fueland oil

Depending on technicalcondition but

no longer than6yearscounted from

the yearof production

7 Rubber shockabsorbersofthe

frontwheel

8 Tiresand inner tubes

9 Rubber dampersinthe engine

frame

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

7

7.ASSEMBLYAND DISASSEMBLYOFTHEAIRCRAFT

At least twopersonsarenecessarytoperformthe assemblydescribed below:

a)Allpartsandelementsthataretobeassembled mustbe checked forany

visibledamages.

b)Beforecommencing assembly,examine generalcondition ofthe wingsand

fuselage structure.If necessary,clean allbolts,pinsandholesand cover

themwiththinlayerofVaseline.Check fueltankbreatherforanyobstruction

(aholeclosetotheflap drivelever, on the left side of fuselage).

c)Putthe wing on the fuselage insuchawaythatitscentralpartslipsintothe

gap overthe cockpit.

Flapsmustbe displacedupinsuchawaythattheyareabovetheflapsdrive

lever(picture8-1).

d)Putpinsintothemountingseats(2infrontand 2inback)Frontpinsareto

be inserted afterremoving topwindscreen panel,back pinsaretobe inserted

inthe compartmentarea.Thepinsaretobe securedwithbolts.Boltsareto

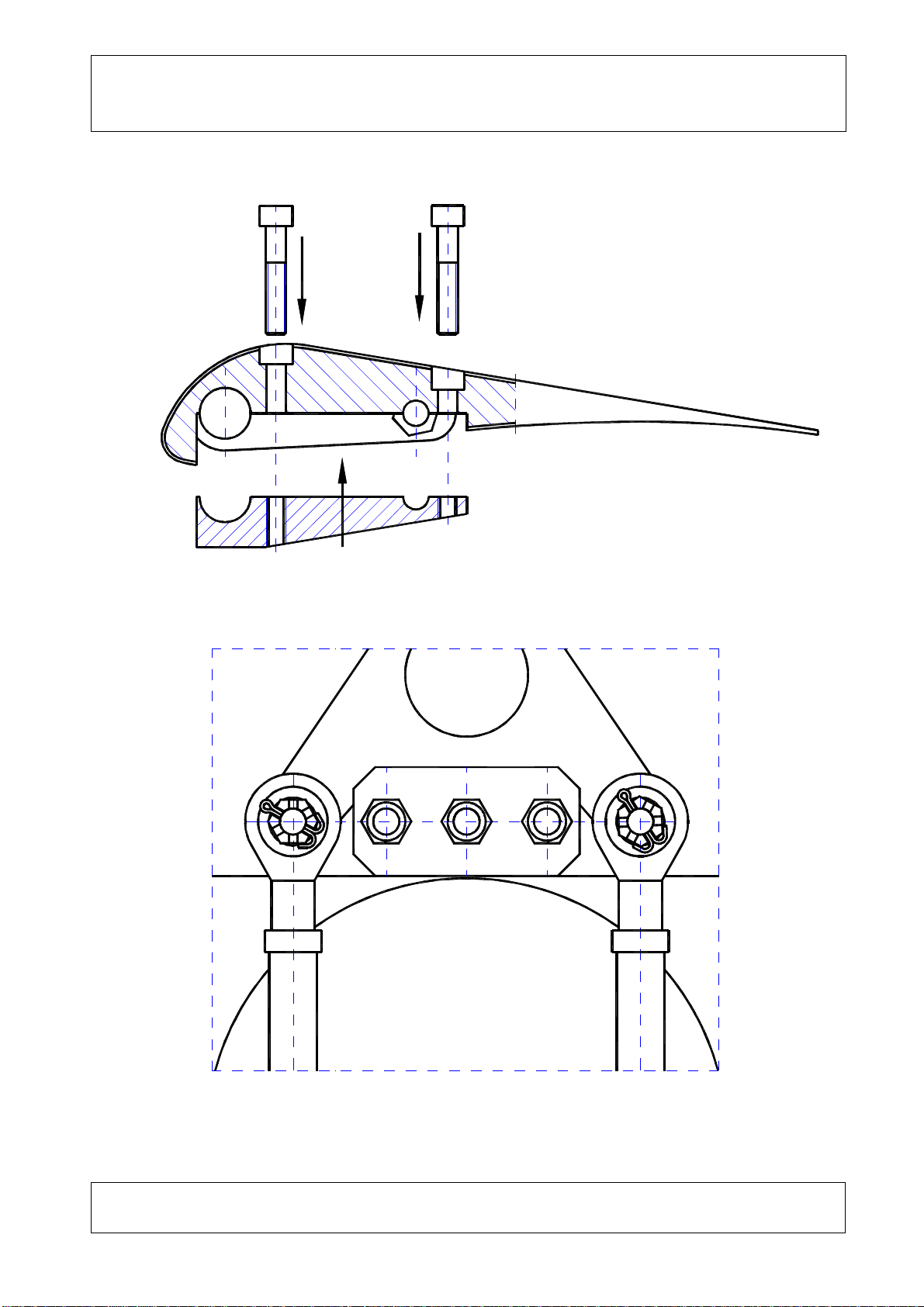

be securedwithcotterpins(picture8-2).

e)Flapsdriveistobe connectedbyaclamping ring,secured withbolts.Bolts

aretobe screwed intousing LOCTITE262 fluid.Theymustbe secured with

cotterpinsfromthe bottom(picture8-3).

f)Aileronsdriveistobe connectedinthecockpitthrough placingrods’eyeson

driveleverpinsinthebottompartofthe wing.Tighten the castellated nuts

and securewithcotterpins(picture8-4).

g)Fixthe controldrivecoverand the panelinfront of the windshield.

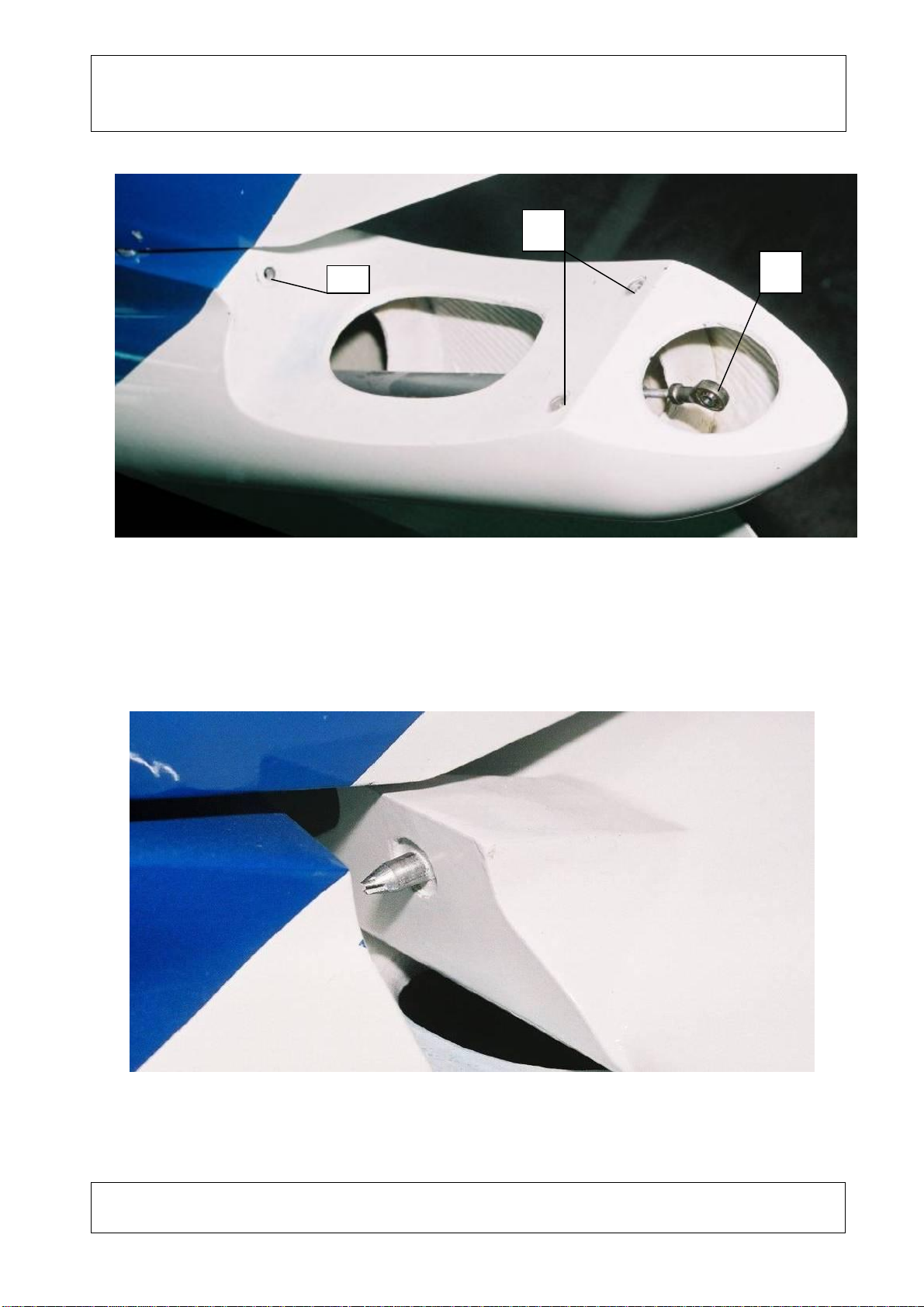

h)Insert the pinlocated inthefront partofhorizontalstabilizer,totheholeinthe

fuselage and tightentwoboltstofixthe stabilizertothe fuselage(pictures8-6

and 8-7)

i)Putelevatorrod eyeontheforkinelevatorcontrollever.Secureitwiththe

pin,screwthe boltinand put the cotterpin(picture8-8)

j)Check performanceof allcontrolsystems, includingflapscontrolsystem.

k)Connect pneumaticpipeswiththePitot pipe.

Disassemblyoftheplaneistobedoneinreverse order.

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

8

Pic. 8-1Placingthe wingon thefuselage

Pic. 8-2Installationof mountingpinstothe fuselage

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

9

Pic. 8-3Flapsdriveconnection

Pic. 8-4Aileronsdriveconnection tothe fuselage

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

10

Pic. 8-5Tailwithout elevatorunit

1

-frontseat formounting the elevatorunit

2

-rearseat formountingthe elevatorunit

3

-elevatorrodeye

Pic8-6

Insertion of elevatorunitpintothe seatinthe fuselage

1

2

3

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

11

Pic. 8-7

Boltsforfixing elevatorunit tothe fuselage

Pic. 8-8

Connecting of elevatorrodtotheelevatorlever

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

12

8ADJUSTMENTPOINTSOFTHECONTROLSYSTEM

8.1Adjustmentofelevator can be donethrough screwinginor outthe

elevator rodeye.See:8-5,pos.3.Locknutmustbe loosenedprior to

thisactivity.When theadjustmentisfinished,thepush-pullrod eye

must besecured withalocknut and Loctite262.

8.2Aileronscontrolsystem isadjustablebychanginglengthofpushrods

(recommended tobe carriedout inEkolotworkshop)

8.3Ruddercontrolsystem isequipped withneutralpositionadjustment

systemwithpedalsinneutralposition,(see Pic.8–10),aswell as

adjustmentofdeflection,bymeansofchanging positionsoflimiters

mounted on thepush-pull rod.

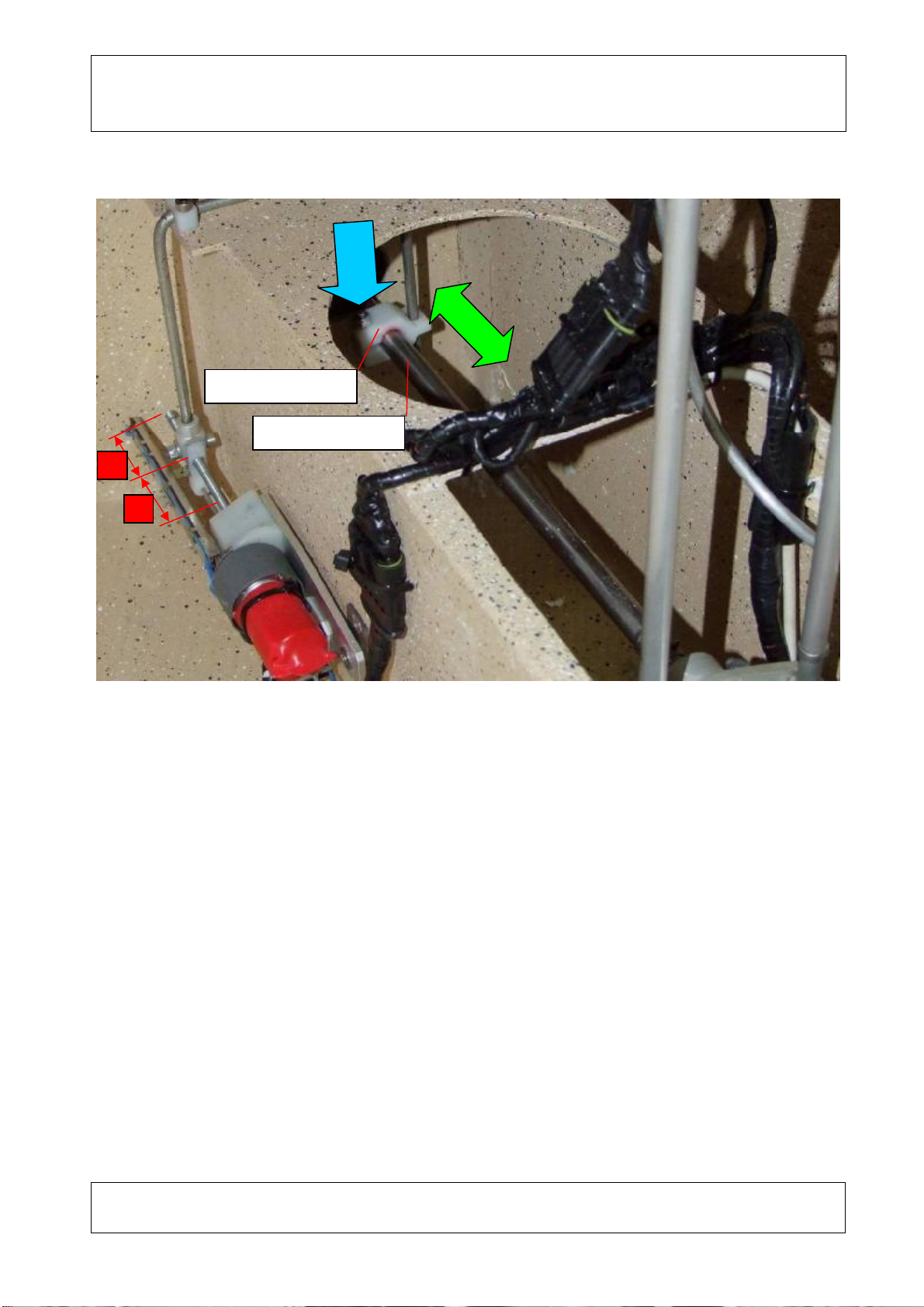

9 Pic. 8-10.Rudderneutralpositionadjustmentpoint

1. Settingtheneutralpositionoftheruder.

2. Removetheadjustment tipof therudderpushrodfromthebolton

the middlelever.

3. Positionpedalinneutralpositionand immobilize.

4. Prior toscrewingtheadjusting tipinorout(see:8-10)neutralposition

of ruddermustbe maintained. Securethe endapplyingthe same

methodasused for rudder assemblycomponents.

Adjustabletipof the

rudderpush-pull rod

Middlelever

Viewof thecentraltunnelfromthen rightsideof

thecockpit

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

13

5. Placealockwasheronthe middlelever, screwinacrownnutand

secure it withapin.

6. Freethe rudder pedal.

Pic. 8-11.Adjustmentpointof rudderpush-pull rodmovement limiters

(armrestremoved fromthechannel)

7. Identification ofrudder deflection (frontwheeldoesnottouchthe

ground).

8. Loosenthelimiterbolts.

9. Deflect theruddertotheleft tothefull possibledeflection.

10. Pushthefrontlimitertotheretainingplateandclampthelimiteron

the pushrod bymeansoftighteningtheclampbolt.

11. Deflectthe rudder tothe rightand setthe positionoftherearlimiter

similarlytopoint3.

Push-pull

rod

movement

limiters

Rudder

push-pull

rod

Bumper

plate

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

14

8.4Elevatortrimmeradjustment

1. Usingpressbuttonson thecontrolstick setthetrimmer motorslider

inthecentralposition (dimensions„a”shouldbeidentical)

2. Loosen the boltintheclampJ.12.310.03.00 (blue arrowintheabove

photograph)

3. Movethe clampalongthe rod T.12.121.00.01tothe pointelevatoris

inneutralposition.

4. Tightenthe bolton the clampJ.12.310.03.00 (blue arrowinthe above

photograph)inorder tofixtheclampJ.12.310.03.00on therod

T.12.121.00.01.

a

a

T.12.121.00.01

J.12.310.03.00

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

15

PARTSAND SUBASSEMBLIES TO BEREPLACEDOUTSIDETHE

MANUFACTURER’SFACTORY

9.1FRONTUNDERCARRIAGE

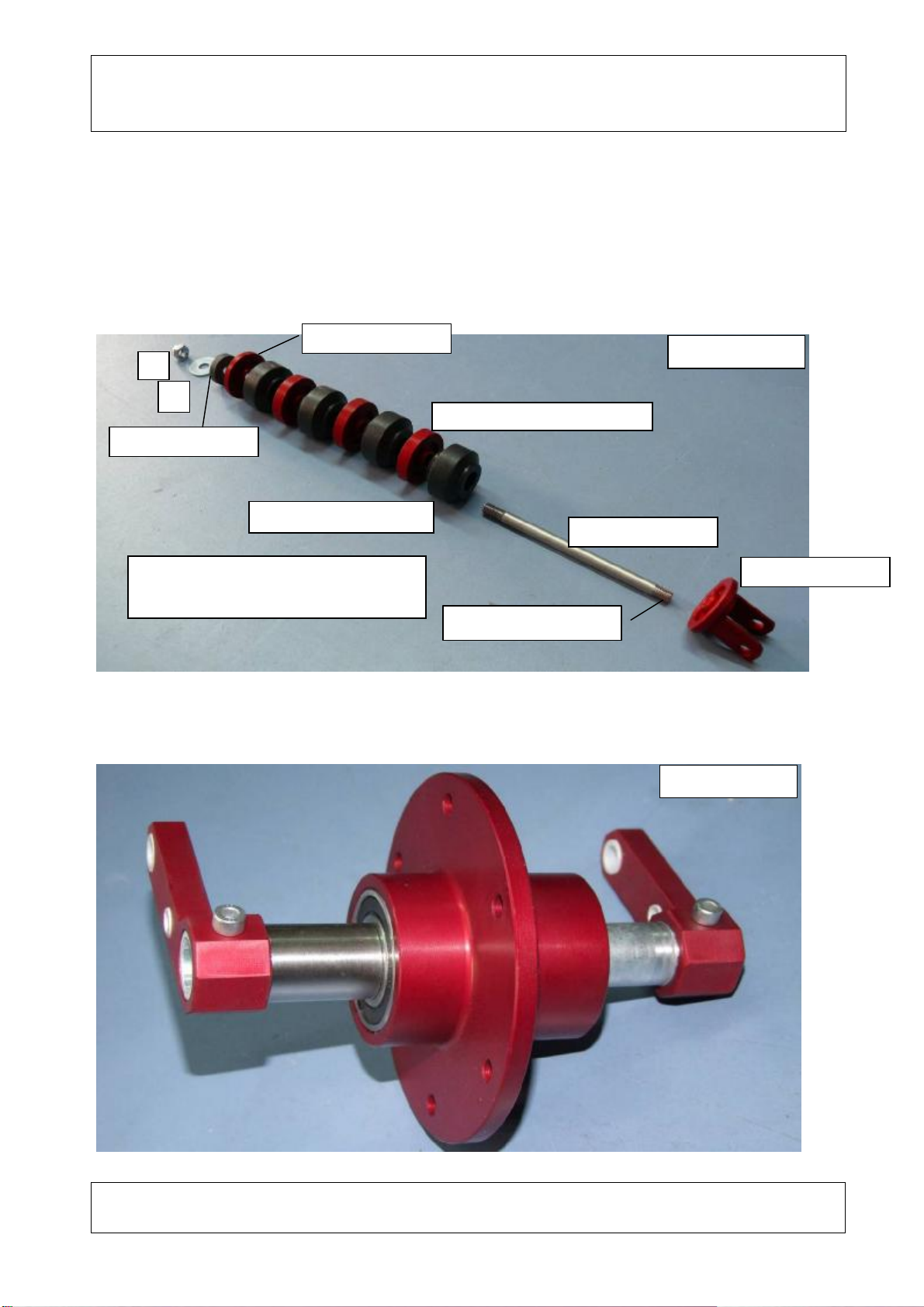

9.1.1Shock absorberassemblyJ.13.201.00.00

9.1.2Axle,rockerandhubassembly

J.13.201.01.00

J.13.201.01.00

3pcs. J.13.201.02.00

J.13.201.03.00

4pcs. AP.PF 126P

J.13.201.01.00

1

2

1.Washer 5–16 –1,5

2.Nut M5DIN982 UseLOCTITE262

Pic.

9.1.1

Pic. 9.1.2

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

16

9.1.3ForkassemblyJ.13.200.00.04withshock absorbersJ.13.200.00.00

J.13.130.01.02

J.13.100.01.02

J.13.200.01.00P

J.13.200.01.00L

J.13.200.02.00

J.13.200.03.00

J.13.100.02.00

Bear

ing 6004 ZZzzZ

J.13.200.02.00

J.13.200.03.00

Bearing 6004 ZZ

1

2

3

1

2

3

J.13.200.00.04

J.13.201.00.00

J.13.201.00.00

1.Bolt M6x50 gat. 8,8DIN912

2.Washer 6DIN1440

3.

Nut

M6DIN982

Pic. 9.1.3

Pic. 9.1.4

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

17

9.1.4Completeassembly:hub,rims,tire,innertube

9.1.5Completewheelassemblywithaxleandrockers

Tyre4.00x66ply

1

Innertube 4.00

x6

J.13.130.01.02

6pcs. BoltM6x50,8,8DIN912

2

J.13.130.02.

01

6pcs.Washer 6

6pcs. Nut M6DIN982

1. Part no.42206-0www.ulmtechnologie.com

2. Part no.42206-1www.ulmtechnologie.com

Pic. 9.1.5

Pic. 9.1.6

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

18

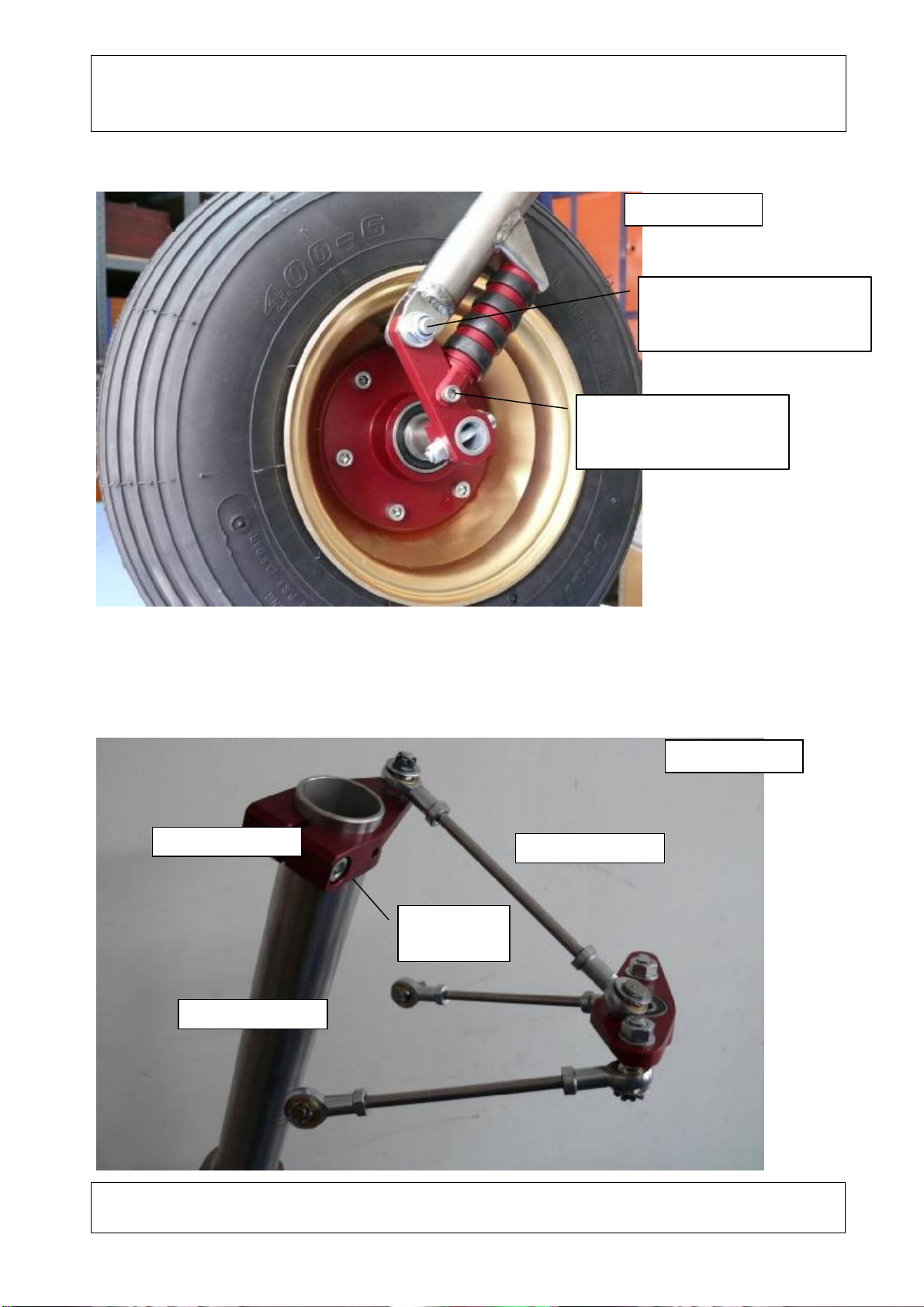

9.1.6Wheel mountedonthefork

The othersideof the wheelisidentical.

9.1.7Frontundercarriagecontrol leverwiththepole

(removed fromthe airplane)

BoltM8

Washer 8

Nut M8DIN982

BoltM5

Washer 5DIN1440

Nut M5DIN982

J.13.200.00.04

J.13.122.00.01

T.12.622.00.00

Clampbolt

Pic. 9.1.7

Pic. 9.1.8

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

19

(installed inthe airplane)

9.1.8Removalofwheel fromfork

1.Removethefairingretainingbolts.

J.13.200.00.04

J.13.122.00.01

T.12.622.00.00

BoltM5x10, 8,8DIN912

BoltM5x10, 8,8DIN912

Washer 5DIN1440

Pic. 9.1.10

Pic. 9.1.9

Manufacturer: PPHU

EKOLOT

Type: KR-030TOPAZ

Handling, Maintenanceand PeriodicInspections

Manual

Issue: 1

Rev. No: Date:July2010

Date: Page

20

2.Movethefairing upward, alongthepole.

3.Unscrewthe shockabsorbersmountingbolts.

Pic. 9.1.11

Pic. 9.1.12

Table of contents