ELA MIE User manual

MIE Rev. 1.4, © ELA, spol. s r.o. www.elabrno.cz

USER MANUAL

MAGNETIC - INDUCTIVE FLOWMETER

MIE

Please read this manual before first use. The manufacturer reserves the right to make changes without prior notice.

MIE Rev. 1.4, © ELA, spol. s r.o. www.elabrno.cz

Notes

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

MIE Rev. 1.4, © ELA, spol. s r.o. www.elabrno.cz

Contents

Introduction .........................................................................................................................................................4

Technical conditions ............................................................................................................................................5

Measurement conditions .....................................................................................................................................5

Sensor option .......................................................................................................................................................5

Main unit option...................................................................................................................................................6

Connection and assembly.....................................................................................................................................6

Magnetic –induction sensors..............................................................................................................................6

Tolerance of built-in lengths.................................................................................................................................7

Signal cable (connection between sensor and converter of the MIE-S) ..............................................................7

Sensor location and its position in piping.............................................................................................................8

Recommended positions for sensor installation .................................................................................................8

Recommendations for installation .......................................................................................................................9

Sensor grounding..................................................................................................................................................9

Electrodes.......................................................................................................................................................... 10

MIE commissioning........................................................................................................................................... 10

Checking installation and connections.............................................................................................................. 10

Service ............................................................................................................................................................... 10

Additional devices ............................................................................................................................................. 10

Packing and transport........................................................................................................................................ 11

Connection ........................................................................................................................................................ 11

Sensor connection............................................................................................................................................. 11

Control unit communication connection .......................................................................................................... 11

MODBUS protocol............................................................................................................................................. 12

MODBUS register............................................................................................................................................... 13

Declaration of conformity ................................................................................................................................ 14

Specification...................................................................................................................................................... 15

Adjustment protocol

Warranty

4

Introduction

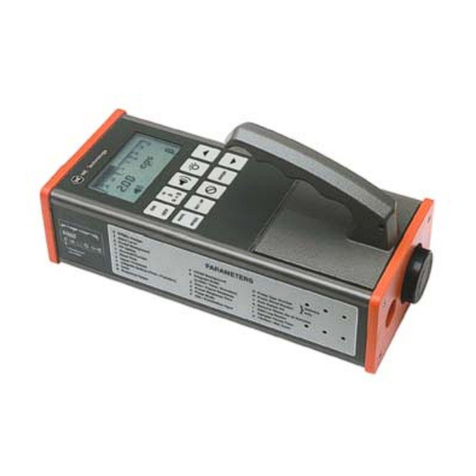

MIE magnetic-inductive flowmeters (compact version: MIE-C, separated version: MIE-S) are precise measuring

devices intended for the measurement of liquid flow of electrically conductive media. The meters may be used

for measurements, registration, dosing, mixing, etc.

Applications

Water management, drinking and waste water measurement

Chemical, textile, paper, mining industry

Food industry

Power engineering and heating plants

Agriculture

Main advantages

Independent of power supply fluctuation and line voltage interference

Independent of pressure, temperature and density, etc of the media

No pressure losses

No disturbances of measured liquid consistency

Installation requirements

Minimum liquid conductivity 5 µS / cm (for demineralised water 20 µS / cm)

Fill the entire sensor profile

Steady flow through the sensor (keeping the calming distances at the inlet and outlet)

When selecting DN, it is necessary to consider the dependence of measurement accuracy on speed

Principle of magnetic –induction sensor

The measurement is based on the principle of Faraday’s law of electromagnetic induction. In compliance with

this law, electric voltage is induced in an electrically conductive body, which moves across a magnetic field.

The following equation is applied for voltage to be induced (generally):

U= B×D×vwhere: U- inductive voltage B- magnetic induction

D- piping diameter v- flow speed vector

If magnetic induction B and piping diameter D are constant, then induction voltage is proportional to the mean

flow speed. Liquid is flowing via a flowmeter

perpendicularly to the direction of the magnetic field.

Electric voltage which is monitored by two electrodes

placed perpendicularly to both magnetic field and flow

is induced by a stream of liquid with minimum electrical

conductivity. Excitation current with a rectangular

waveform is generated in a converter and fed to sensor

coil windings generating the flowmeter magnetic field.

The forced-current system provides constant excitation

under all conditions that can occur during the

operation.

B

v

U

!

5

Technical conditions

Measurement conditions

Measurement is independent up on:

Liquid temperature and pressure

Liquid density and viscosity

Solids contents

Usual level of magnetic field interference

For maintaining the MQI accuracy and reliability, it is necessary to meet the following conditions:

Electrical conductivity of medium ≥5 µS/cm, for demineralized water ≥20 µS/cm

Liquid velocity min. 0.3 m / sec, max. 12 m / sec.

Steady flow section performance no DN change bevel pipe part(s) of maximum 8˚.

Steady flow section length 5 DN upstream / 3 DN downstream (from sensor)

Fully filled sensor profile with liquid measured.

High quality operational contact between the sensor and liquid measured.

Measurement accuracy is interfered by:

Gassing of measured liquid and air bubbles

Strong stray earth currents

Liquid turbulence in the sensor

Solids of magnetic metals in the medium measured

Sensor option

A measuring pipe is made of non-magnetic material with welded flanges and assembly clamps. An

insulating liner with required properties is installed inside the pipe (according to the medium used). A

system of driving coils generating the required magnetic field is directly fixed on the measuring pipe

body.

A pair of electrodes located opposite and passing through the measuring pipe with liner is made of

high-grade steel and/or other material (according to the required chemical resistance against the

medium being measured).

The complete electrical section is assembled in steel housing (welded) with a neck for internal cabling.

Remote version: A signal cable with the standard length of 8 m/ Cu type 2 ×2 ×0.25 mm2is attached

to the neck and the cable passes through a cable seal (also other lengths are available).

Compact version: The instrument box body is attached to the neck.

The housing welding makes it possible to achieve a high-grade protection and surface finish provides

a steady climate resistance.

!

6

Main unit option

Control and evaluation electronics is assembled into robust aluminium housing with IP67 protection,

or in case of remote version, protection of sensor is IP68.

Additional option (customer request):

Multi-point calibration of the measuring range. The flowmeters are usually calibrated in 3 points. On

the customer‘s request, the number of calibration points can be increased.

Higher sensor protection IP 68: the requirement must be precisely defined (i.e. immersion depth and

time, and/or explosive zones).

Higher PN, and/or different sensor built-in lengths, different flange options (DIN, ANSI, etc.), after

consultation of your supply.

Connection and assembly

Converter connection to power supply must be performed in compliance with the standards and rules:

Connection of electrical instruments and appliances.

Protection against electric shock.

Heavy current distribution network in industrial plants.

Safety operational rules for electrical installations operated by low-level experienced personnel.

If requested our Service Division will carry out commissioning. If work is done by any different organisation,

the warranty can be cancelled in the case of such unauthorised work.

Electrical protection allows the use of the instrument in all kinds of active, passive and complex environments,

and after an agreement with us, it is possible to carry out some additional modifications even for severe

climaticconditions.

Signal and output cable routing should not be located near power output distribution network or in common

ducts.

Magnetic –induction sensors

Table for 1 m / s flowrates

Constructional dimensions and weights of inductive sensors

DN

m3/h

l/min.

l/s

DN

PN

Dimensions [mm]

Weight

[kg]

A

B

D1

D2

d

n

10

0,283

4,712

0,079

10

16

150

or

200

266

90

60

14

4

2,5

15

0,637

10,62

0,177

15

268

95

65

14

4

2,5

20

1,131

18,85

0,314

20

273

105

75

14

4

3

25

1,767

29,452

0,491

25

280

115

85

14

4

3,5

32

2,895

48,255

0,804

32

293

140

100

18

4

5

40

4,524

75,398

1,257

40

298

150

110

18

4

6

50

7,069

117,81

1,964

50

200

304

165

125

18

4

7

65

11,946

199,1

3,318

65

322

185

145

18

4

8

80

18,096

301,59

5,027

80

337

200

160

18

8

9,5

100

28,274

471,23

7,854

100

250

358

220

180

18

8

12

125

44,179

736,31

12,272

125

389

250

210

18

8

15

7

150

63,617

1060,3

17,671

150

300

418

285

240

22

8

20

200

113,1

1885

31,42

200

350

488

340

295

22

12

36

250

176,71

2945,2

49,087

250

400

543

405

355

26

12

58

300

254,47

4241,2

70,686

300

500

600

460

410

26

12

70

350

346,36

5772,7

96,211

350

655

520

470

26

16

85

400

452,39

7539,8

125,66

400

600

728

580

525

30

16

100

450

572,26

9537,5

158,96

450

770

640

585

30

20

120

500

706,86

11781

196,35

500

863

715

650

33

20

160

600

1017,9

16965

282,74

600

983

840

770

36

20

190

700

1384,7

23079

384,65

700

700

1040

910

840

36

24

260

800

1809,6

30159

502,65

800

800

1163

1025

950

39

24

350

900

2289,1

38151

635,85

900

900

1258

1125

1050

39

28

450

1000

2827,4

47124

785,4

1000

1000

1398

1255

1170

42

28

550

Tolerance of built-in lengths:

DN 10 ÷ DN 150 → A ± 5 mm, DN 200 ÷ DN 1000 → A ± 10 mm

Signal cable (connection between sensor and converter of the MIE-S):

Signals which are transmitted from a sensor electrode circuit to the converter will be in a range of

millivolts. They will be very sensitive to magnetic and electrostatic interference from neighboring

high-voltage cables, power supply cables and high power output motors, etc. The interference is

mainly compensated for by the converter connection, nevertheless if possible, it is necessary to

prevent all spurious signals.

The signal cable is of a special construction and length and is a part of the shipment, its length should

not be changed (for certificated meter must not be changed). The proper cable connection to the

converter is important; doing so may cause measurement failures. Special requirements are laid on

shielding, and the measurement precision depends on its quality.

8

The cable must not be extended.

The shielding must be well insulated on the whole route from ground and the other metal subjects. It

is recommended that the cable is located in a separate conduit or trays.

Sensor location and its position in piping

The inductive flowmeter sensor can be installed in any position according to requirements, however

for horizontal assembly, the electrode axis must always be horizontal.

Sensor must remain full of liquid.

It is recommended that the flow direction should follow the arrow on the sensor cover; the converter

is also preset for this direction. On the operating meter, it is possible to adjust the reverse flow

direction by changing the MIE converter parameter.

Bolts and nuts –verify if there is a sufficient space for their installation near flanges.

Vibration and deflection of piping –fix the piping on both sides from the flowmeter to avoid any

deflection and vibrations.

If you install any pipes with higher internal diameters, install a reducer; this will provide an axial shift

without increased mechanical stress of piping and sensor flanges.

To improve flow, use only the recommended straight lengths upstream (5DN) and downstream of the

sensor (3DN). Any change of a diameter with an angle up to 8˚is excluded from the above-mentioned

straight lengths. Suitably assembled flow deflectors and a combination of diffusers are used in more

sophisticated installations.

When you install the sensor in insulated piping (e.g. glass, artificial mass, etc.), use proper sealing

ground rings. A conductive connection between a sensor ground point and the liquid to be measured

is needed for a proper measurement.

Recommended positions for sensor installation

Air bubles inside the

sensoor.

Free discharge -

sensor at zero flow

without water.

Suitable location in the rising pipe

section.

In case of vertical piping downstream of the sensor

longer than 5m, install a venting valve (vacuum).

In a situation of free inlet or outlet, place the

sensor in the siphon.

!

9

Recommendations for installation

To avoid any measurement errors which are caused by air bubbles or failures on the lining, pay attention to

the following recommendations:

During assembling correctly seat the sensor, tighten screws uniformly and move on a diagonal one

after another.

It should be noted that the parallelism of flanges has a greater effect on packing than excessive

tightening forces on curved and seated flanges.

The sensor must be installed inside piping so that the axis of sensor electrode is always horizontal.

A PTFE (teflon) lining calls for extra care during handling and assembly. During installation/operation

avoid excessive under pressure in pipes. Please do not change and damage the outlet extension on

both ends of the sensor. The sensors are shipped from the factory with special covers to avoid any

shape deformations. (PTFE elastic memory should cause a partial compensation in future). Please

remove the covers just before installation, and when you insert it between counter flanges, replace

by a number of smooth metal sheet pieces which are removed just before tightening the bolts.

Packing –The extended part of lining does not operate properly as a seal, hence appropriate packing

must be inserted between sensor and pipeline. If the packing protrudes into a flow profile at any point,

this will cause turbulence and reduce the measurement quality.

During installation, make sure the sensor slides into piping if the pipeline is not flexible enough. It is

recommended that installation inserts (especially for greater internal diameters) should be used.

During installation of the sensor, counter flanges must not be welded (danger of the sensor lining

failure).

Sensor grounding

For reliable and proper operation of the inductive meter, it is necessary to use high-quality protective

grounding. Internal flowmeter cables and power supply PE (PEN) conductors provide protective

grounding. Working grounding is also provided via internal cables and a high-quality connection of the

sensor body with two metal pipe counter flanges. It is recommended that a connection made with M6

welded screws or bored threaded holes is used. The connection under flange fixing screws is not

recommended because of possible corrosion resulting in measurement failures.

When assembled into piping made from non-conductive material (or with non-conductive lining), it is

necessary to provide working grounding with liquid by a different method, e.g. by grounding rings –

valid for DN 10 ÷ DN 40. The rings can be ordered from factory, their material and chemical resistance

must comply with the liquid to be measured –usually produced from the same material as sensor

electrodes. The flowmeters from DN 50 ÷ DN 1000 are equipped of grounding electrode. Function of

grounding electrode is same as grounding ring.

When assembled, it is necessary to insert the packing on both sides of the grounding ring. Make sure

that no parts will protrude into an internal sensor profile (turbulence).

Drawing of sensor working grounding inside pipeline

Use of grounding rings –valid for DN 10 ÷ DN 40

10

Electrodes

The electrode material must be selected according to its chemical resistance of the liquid to be

measured.

The electrode purity can affect the measurement precision, and high impurity concentration can affect

the measurement process (liquid insulation).

Immediately after shipping, it is not necessary to clean the electrodes before installing the sensor

inside piping. Clean with a fine cloth, or use a chemical detergent. Avoid any damage of the lining! If

the electrodes must be cleaned during operation, either mechanical or electrolytic methods may be

used. Mechanical cleaning can only be used for a suitable sensor assembly, otherwise dismantle the

sensor from the pipeline. After cleaning reinstall the sensor.

Any electrolytic method is advantageous for its simplicity, however it can only be applied for the

contamination that can be removed by electrolysis (low contamination and deposit).

All detailed instructions are available from the flowmeter manufacturer on request.

If a flowmeter operates under normal conditions, for most liquids it is not necessary to clean

flowmeters during their life, only self-cleaning by flowing liquid is satisfactory (a recommended

velocity is over 3 m/s).

MIE commissioning

Checking installation and connections

Proper sensor and grounding.

Tightening all cable connection clamps and plug in all connectors.

For MIE-S verify the completeness of the shipped set according to the serial numbers of sensor and

converter.

Verify proper supply voltage; see the label on the converter.

Verify proper electrical protection.

If the installation is fault-free, fill the pipeline with liquid and verify the sensor tightness inside the

pipeline. After short washout, switch the system on-off-on.

Service

The commercial, service and technical assistance for MIE is provided by Ela Brno, Ltd.

The Service Division secures all activities that are related to the commissioning and all parameter

changes at site (with the exception of certificated meters).

Ela Brno, Ltd can authorise another organisation to provide service. The organisation must be able to

submit the appropriate approval/certificate on request. The producer carries out recalibration of all

meters and their repairs.

Additional devices

The additional devices are intended for remote control of the converter output signals (displaying

and processing).

The additional devices are not usually included in MIE shipment, but their type should be approved

by the manufacturer. In such a case, the manufacturer is only responsible for the suitability of input

parameters, and all other parameters are set according to the manufacturer’s specifications of the

additional devices.

If a set is ordered without installation, the sensor is packed in corrugated paper and the converter is

enclosed in a cardboard box or wooden palette.

11

Packing and transport

If the kit is ordered without assembly, the sensor is packed in bubble wrap (per pallet) and the control

unit is paper boxes.

The delivery can be carried out by a public carrier, the transport of the customer or the import by the

production organization. The costs are paid by the customer.

Connection

Sensor connection

(compact version MIE –C)

1

Elecctrodes

White

Red

2

Screen

3

Black

Red

4

Screen

5

Coils

excitation

Green-yellow

6

Yellow

7

Blue

Sensor connection

(separated version MIE –S)

1

White

2

Screen

3

Brown

4

Green yellow - grounding

5

Screen

6

Yellow

7

Green

Control unit communication

connection

Connect the main unit to the Ethernet network

with an RJ45 connector. Power is via passive

PoE. The meaning of the RJ45 connector pins

corresponds to the table:

Pin RJ45

Description

1

TX+

2

TX-

3

RX+

4

+24V1)

5

+24V1)

6

RX-

7

0V1)

8

0V1)

1) The device is equipped with overvoltage

protection and protection against polarity

reversal.

!

12

MODBUS protocol

MODBUS protocol implementation conforms MODBUS Application Protocol Specification, version 1.1,

modbus.org 12/06/02.

Device comes with default settings that are:

slave address set to 1,

baud rate 9600 Bps,

8 data bits, even parity, one stop bit.

Each MIE register takes two MODBUS registers, i.e. each MIE register is 32 bits long. These 32 bits are

interpreted as an integer with or without a sign or as a floating point number with single precision. Double

precision floating point numbers are stored in eight bytes, so they are transmitted in four MODBUS registers.

The MODBUS register with lower address is transferred first.

Device implements MODBUS functions 0x03 and 0x10.

Coding of integers:

Coding of floating point numbers:

Floating point numbers compatible with single type defined by IEEE 754.

Floating point numbers compatible with Double type defined by IEEE 754.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

sign for signed integer

MODBUS register with lower address

MODBUS register with higher address

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

significant field

exponent

sign

MODBUS register with lower address

MODBUS register with higher address

MODBUS register MODBUS register

with the highest address of four with the lowest address of four

63

62

52

51

0

significant field

exponent

sign

13

Modbus registers

All registers are read only. For security reasons writing to registers is a bit more complex than reading, so the

manufacturer provides configuration software which is free to charge.

Address

Type

Name

Unit

Description

[dec]

[hex]

100

0064

unsigned int

Slave address

Slave device address in range from 1 to 247.

102

0066

unsigned int

Baud rate

Bps

Transmission rate, one value from 1200, 2400,

4800, 9600, 14400, 19200, 28800, 38400, 57600.

104

0068

unsigned int

Parity

Transmission parity check, one value from 0 = no

parity, 1 = even, 2 = odd, 3 = no parity, two stop

bits.

106

006A

unsigned int

Pause

µs

Additional time in microseconds to extend silent

interval between server request and slave

response.

108

006C

unsigned int

Response

time limit

µs

If slave device is not able to prepare response

until this time expires, response isn't be send.

110

006E

unsigned int

Secondary

flow unit

Unit of register 1024(10). Can be one from: 0 = l/s,

1 = m3/h, 2 = m3/s, 3 = l/min, 4 = UKgal/s, 5 =

USgal/s.

1000

03E8

float

Q

l/s

Current flow, in litres per second.

1002

03EA

unsigned int

Main status

Bit 15: Parameter memory reading error.

Neither measurement nor service

function can be started.

Bits <7, 0>: State of device:

0x00 … idle time,

0x80 … measurement is in progress,

0x80 to 0xFF … service function is in

progress.

1004

03EC

unsigned int

Alarms

Bit 31: excitation circuit failure,

Bit 29: unfilled pipe error.

1008

03F0

float

CM

Main calibration constant (significant field)

1010

03F2

signed int

CE

Main calibration constant (exponent)

1020

03FC

float

Velocity

m/s

Flow velocity in meters per second.

1022

03FE

signed int

Temperature

˚C

Converter temperature.

1024

0400

float

Q in

secondary

unit

Current flow in unit by register 110.

2000

07D0

double

S+

m3

Forward volume counter.

2004

07D4

double

S-

m3

Backward volume counter.

4002

0FA2

unsigned int

Back

Flow direction reversal. QM is measured flow

obtained by reading a register 1000 (or 1024) and

Q is a real flow. If Back = 0 than Q = Qmotherwise

Q = -Qm.

4004

0FA4

float

Cutoff low

%

Lower and upper limits for small flow suppression

(hysteresis algorithm), in percentage of calibration

range (register 8100(10). Usual values are 0.4 and

0.6%.

4006

0FA6

float

Cutoff high

%

8002

1F42

float

DN

mm

Nominal sensor size.

8100

1FA4

float

Calibrated

range

l/s

9002

232A

unsigned int

Device type

Device type:

9004

232C

unsigned int

Firmware

version

for example 0x01090C00 = 1.9.12.0

9006

232E

unsigned int

Serial number

14

Declaration of conformity

Product: MQI 99 - C/S - SMART, MQU 99 - C/S - SMART, MHU 99 - C/S -SMART, MI,

MIA, MIE, ESONIC, PU, CU

Manufacturer: ELA, spol. s r.o.

Headquarter: Mikulovská 1, 628 00 Brno

Office, workshop: Sokolova 32, 619 00 Brno

Product description and

designation: flow and level measuring instruments

This Declaration of Conformity is issued under the sole responsibility of the manufacturer.

The product above is in compliance with the following laws:

Act No. 90/2016 Coll., On technical requirements for products

Council Directive 2014/35 / EU (Government Regulation No. 118/2016 Coll. On conformity assessment

of electrical equipment intended for use within certain voltage limits during their delivery to the

market)

Council Directive 2014/30 / EU (Government Regulation No. 117/2016 Coll., On Conformity

Assessment of Products in terms of Electromagnetic Compatibility when Delivering to the Market

The following technical standards and specifications were used in the assessment:

ČSN EN 61010-1 ed. 2

ČSN EN 61326-1 ed. 2

ČSN EN 61000-4-2 ed. 2

ČSN EN 61000-4-3 ed. 3

ČSN EN 61000-4-4 ed. 3

ČSN EN 61000-4-5 ed. 3

ČSN EN 61000-4-6 ed. 4

ČSN EN 61000-4-8 ed. 2

ČSN EN 61000-4-11 ed. 2

The device may only be installed, commissioned and repaired by a person instructed and authorized in

accordance with applicable regulations.

Issued in Brno: 1.9.2020 Ing. Milan Vlček, Director of company

15

Specifications

Option compact version

separated version (sensor instalated under ground or under

liquid level), fixed cable, cable length according to the order

(max. 50 m)

Nominal sizes flange DN 10 ÷ 1000 mm, without flanges DN 10 ÷ 100 mm

Insulation class of excitation coils class E

Connection flanged DIN (ANSI, BS, JIS) / hygienic - food DIN 11 851

Maximum pressure standard 1,6 MPa (0,6 / 1,0 / 2,5 / 4,0 MPa)

Liner material hard + soft rubber DN 10 ÷ DN 1000 / teflon PTFE DN 10 ÷ DN

500

Electrodes stainless steel 316Ti (Hastelloy / Tantal / Titan / Platinum)

Outer casing and flanges carbon steel standard (stainless steel 304, 321)

Flow tube stainless steel 321

External coating acrymetal multi component lacquer / polished stainless steel

Protection IP67-NEMA5 (compact version) / IP68-NEMA6 (separated

version)

Media temperature compact version: 0 ÷ 90 °C

separated version: hard rubber (0 ÷ 90 °C), PTFE (-20 ÷ 130 °C)

Accessories options sensor grounding ring for plastic pipe for DN 10 ÷ DN 40

sensor grounding electrode for DN 50 ÷ DN 1000

Special option food industry stainless steel version –teflon lining, fitting DIN 11

851

flange version with stainless steel cover –teflon / rubber lining

flange all-stainless steel version –teflon / rubber lining

without flange version –teflon / rubber lining

Flow direction both direction

Suppresion of small flows yes

Empty pipe detection yes

Electrical conductivity of medium ≥5 µS/cm, for demineralized water ≥20 µS/cm

Accuracy of measurement 0,5 % of measured value + 2 mm/s (reference conditions)

Communication port ETHERNET, 10Base-T resp. 100Base-TX, protocol MODBUS TCP

(instantneous reading, parameters setting and calibration)

Power supply 9 ÷ 36 V DC / 10 W

Main unit protection IP67 - NEMA5

Ambient temperature -20 ÷ 60 °C

16

Headquarters / Service

ELA, spol. s r. o.

Sokolova 32

619 00 Brno

Czech Republic

Billing address

ELA, spol. s r.o.

Mikulovská 1

628 00 Brno

Czech Republic

IČO:46969063

DIČ:CZ46969063

More on: www.elabrno.cz/contacts

Table of contents

Other ELA Measuring Instrument manuals