TELEVAC MP4AR Series User manual

INSTRUCTION MANUAL

MP4AR Remote

Convection Gauge

Range: 1 x 10-3 Torr to 1 x 10+3 Torr

TELEVAC

A DIVISION OF THE FREDERICKS COMPANY

2400 PHILMONT AVE.

HUNTINGDONVALLEY, PA 19006

PARTS LIST

#

QTY

ITEM DESCRIPTION

1

1

4AR Remote Convection Electronics

2

1

Cable (specified at ordering)

3

1

Instruction Manual

4

1

Sensor

1

2

4

3

phone: (215) 947-2500 fax: (215) 947-7464 e-mail: [email protected] web site: www.televac.com

8/15

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

1

TABLE OF CONTENTS

SECTION TITLE PAGE

01. DESCRIPTION and INSTRUMENT OPERATION ……………………………………….2

02. SAFETY ……………………………………………………………………………………….3

03. PRINCIPLES OF SENSOR OPERATION …………………………………………………4

04. SENSOR OPERATION AND INSTALLATION ……………………………………………5

05. RECORDER OUTPUTS ……………………………………………………………………..7

06. MAINTENANCE ………………………………………………………………………………8

07. CALIBRATION ……………………………………………………………………………… .8

08. TROUBLESHOOTING …………………………………………………………………….…8

09. SPECIFICATIONS ……………………………………………………………………………9

10. DIMENSIONS ………………………………………………………………………………..10

11. UNPACKING AND INSPECTION ………………………………………………………….11

12. WARRANTY INFORMATION ………………………………………………………………11

PLEASE READ THIS MANUAL THOROUGHLY BEFORE USING GAUGE. REPORT ANY

PROBLEMS IMMEDIATELY.

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

2

Description and Instrument Operation

The MP4AR series Remote Module provides a compact stand-alone measurement solution for

applications that do not require traditional panel-mounted instrument readouts. These modules

can provide local readout and control or can be interfaced directly with a PLC, chart recorder, or

data acquisition system. The MP4AR series of instruments use the time proven reliable and

rugged TELEVAC 4A Sensor, which can be changed in seconds. These instruments operate from

low voltage DC and are easily integrated into the largest process system with a minimal effort.

Likewise, the MP4AR Remote Gauge can be used as a small stand-alone vacuum measurement

solution.

Features

Wide range 1 x 10-3 Torr to 1 x 10 -3 Torr

Sensors can easily and quickly be replaced

if required

Compact & rugged self-contained package

Fast system control with one setpoint

CHAPTER 1 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

3

Safety Instructions

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS AND NOTES collected here

for your convenience and repeated with additional information at appropriate points in these instructions

In these instructions the word “product” refers to the MP4AR and all of its approved parts and

accessories.

NOTE: These instructions do not and cannot provide for every contingency that may arise in

connection with the installation, operation, or maintenance of this product. Should you require

further assistance, please contact Televac at the address on the title page of this manual.

This product has been designed and tested to offer reasonably safe service provided in it’s

installed, operated and serviced in strict accordance with these safety instructions.

These safety precautions must be observed during all phases of operation, installation, and service of this

product. Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended use of the instrument. Televac disclaims

all liability for the customer’s failure to comply with these requirements.

√ READ Instructions – Read all safety and operating instructions before operating the product.

√ RETAIN instructions – Retain the Safety and Operating Instructions for future reference.

√ HEED warnings – Adhere to all warnings on the product and in the operating instructions.

√ FOLLOW instructions – Follow all operating and maintenance instructions.

√ ACCESORIES – Do not use accessories not recommended in this manual as they may require

a technician to restore the product to its normal operation.

These safety alert symbols in this manual or on the Product rear panel mean

cautions - personal safety, property damage or danger from electrical shock.

Read these instructions carefully.

Failure to comply with these instructions may result in serious personal injury, including

death, or property damage.

The service and repair information in this manual is for the use of Qualified Service

Personnel. To avoid shock, do not perform any procedures in this manual or perform any

Servicing on this product unless you are qualified to do so.

To reduce risk of fire or electric shock, do not expose this product to rain or moisture.

CHAPTER 2 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

4

CHAPTER 2 (cont.) TELEVAC

Safety Instructions (cont.)

`

Principles of Sensor Operation

The convection gauge measures absolute pressures by determining the heat loss from a thermocouple

heated to a constant temperature by a current source. A second thermocouple compensates for ambient

temperature changes and extends the vacuum measurement range above 2 Torr by measuring the

convection effects.

The convection sensor must be mounted vertically for accurate measurements. Sensors are available in

stainless steel or nickel-plated brass and can withstand 150-psi overpressure.

Objects and Liquid Entry – Never push objects of any kind into this product through

openings as they may touch dangerous voltage points or short out parts that could result in

a fire or electric shock. Be careful not to spill liquid of any kind onto the products.

Do not substitute parts or modify instrument.

Because of the danger on introducing additional hazards, do not install substitute parts or

perform any unauthorized modifications to the product. Return the product to Televac for

service and repair to ensure that safety features are maintained. Do not use this product

if it has unauthorized modifications.

CHAPTER 3

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

5

SENSOR OPERATION AND INSTALLATION

1.0 Connect the gauge to the vacuum system. It must be mounted vertically with the stem side

down.

NOTE: DO NOT TURN INSTRUMENTATION WHEN MOUNTING ON A THREADED INSTALLATION

TO INSTALL, USE A WRENCH ON THE FLATTED PORTION OF THE SENSOR TUBE

2.0 Assure that there are no leaks.

3.0 Apply 24 DC volt power between pin # 3 (+) and pin # 4 (-) of the connector cable.

4.0 Configure output lines; pin # 5 (for linear 1 T or log 1000T output), pin # 8 (signal gnd) and pin # 7

(for non linear output). The table of voltage versus pressure is shown in chapter # 5. The linear

signal output is 10 volts at 1000 microns and decreases linearly to zero at zero microns. The non-

linear signal output is 10 volts at atmospheric pressure and decreases non-linearly to zero volts at

zero microns. If it is a log 1000T unit, the output decreases logarithmically from 6.0 volts at

1000Torr to zero volts at zero microns.

5.0 Pump down the vacuum system while observing the LED display and the signal voltage reading

on the output. (see chapter # 5 for output values)

6.0 While the pressure is above 1000 Torr the display will show “HI”. Below 1000 Torr the signal

output will correspond to values given in chapter # 5, depending upon chosen output. As the

pressure drops below 1 Torr the red “MICRONS” LED lights and the displayed readings now drop

from 990 down to zero while the linear output voltage drops correspondingly from 9.90 Volts to

zero.

7.0 The trip pressure for the setpoint relay can be displayed by pressing the “setpoint display” button

on the front panel of the instrument or by reading the Set Point voltage at pin # 9 of the cable

connector. The display will blink the reading until the button is pushed again or until it times out

automatically after 60 seconds. If the Set Point adjustment screw is turned to change the setting

the new value displayed will be retained in memory. The setpoint adjustment range is 0 to 1 Torr

for the units with linear recorder output and 0-1000 Torr for units with logarithmic recorder

outputs. The relay contact connections are as follows; to the common # 6, # 1, normally open,

and # 2, normally closed.

8.0 If the display shows “-1” or “LO” then the gauge is out of adjustment. With a known vacuum of at

least 1 X 10-5 Torr, adjust the “Zero” adjustment screw on the front panel.

9.0 With the sensor tube exposed to atmospheric pressure, the display reading should be near 760

Torr (which may vary with geographic location). Adjustment for the correct reading is done with

the front panel “ATM” settings. Make sure that the tube is vertical, with stem down.

SEE NEXT PAGE FOR GAUGE DIAGRAMS

CHAPTER 4 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

6

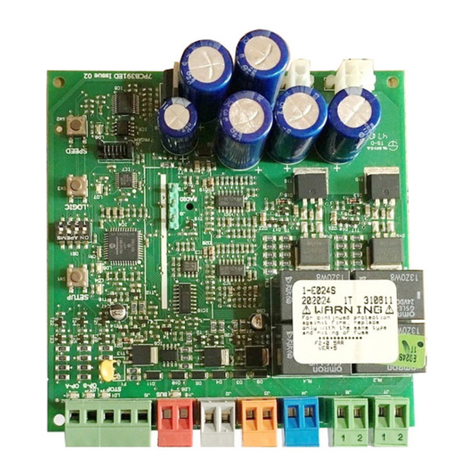

DIGITAL 4AMP4AR REMOTE

SENSOR OPERATION AND INSTALLATION (cont.)

PIN#

PIN OUTS

1

Relay normally open contact

2

Relay normally closed contact

3

+24 volt power

4

Power common

5

Log / Linear signal output

6

Relay common contact

7

Non-linear signal output

8

Signal return

9

Setpoint output

CHAPTER 4 cont. TELEVAC

Setpoint

Display

Potentiometer

Setpoint

Adjust

Potentiometer

LED

display

Zero

Adjustment

Potentiometer

Pin #s

LED lights

for

microns

Phillips

Head

screw

Atmosphere

Adjustment

Potentiometer

SET POINT

RELAY

“ON”

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

7

4A (Logarithmic)

0

2

4

6

8

0.001 0.1 10 1000

PRESSURE (TORR)

VOLTS

4A (Logarithmic)

0

2

4

6

8

0.001 0.1 10 1000

PRESSURE (TORR)

VOLTS

Recorder Outputs

CHAPTER 5 TELEVAC

4AR (linear)

0

2

4

6

8

10

12

0200 400 600 800 1000

PRESSURE (microns)

VOLTS

4AR (linear)

0

2

4

6

8

10

12

0200 400 600 800 1000

PRESSURE (microns)

VOLTS

Non-linear & Logarithmic

Pressure

(TORR)

Voltage (non-

linear)

Voltage

Logarithmic

1 x 10-3

.01

0

5 x 10-3

.06

.70

2 x 10-2

.24

1.3

4 x 10-2

.45

1.6

6 x 10-2

.64

1.78

8 x 10-2

.82

1.9

.1

.98

2

.2

1.67

2.3

.5

2.99

2.7

.8

3.84

2.9

2

5.45

3.3

10

7.32

4

30

7.84

4.48

50

7.93

4.7

80

8.01

4.9

120

8.08

5.08

160

8.19

5.2

180

8.24

5.26

300

8.76

5.48

500

9.57

5.7

760

10

5.88

1000

10.22

6

LINEAR

Pressure

(microns)

Voltage

1

.01

5

.05

10

.1

20

.2

30

.3

40

.4

50

.5

60

.6

70

.7

80

.8

90

.9

100

1

150

1.5

200

2

300

3

400

4

500

5

800

8

1000

10

2000

13.5

4A (non-linear)

0

1

2

3

4

5

6

7

8

9

10

11

12

0.001 0.01 0.1 1 10 100 1000

PRESSURE (TORR)

VOLTS

4A (non-linear)

0

1

2

3

4

5

6

7

8

9

10

11

12

0.001 0.01 0.1 1 10 100 1000

PRESSURE (TORR)

VOLTS

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

8

CHAPTER 7

CHAPTER 8

Maintenance

No maintenance is required beyond periodic replacement of a contaminated sensor. To replace the

sensor, remove the Philips head screw in the center of the instrument, then gently rock and pull off the

electronic assembly. Replace the old sensor with a new one, remount the electronics and replace the

Phillips head screw. DO NOT OVER TIGHTEN THE SCREW! Adjust the “ATM” screw for the proper

reading when the vacuum system is vented.

Calibration

All instrumentation is calibrated at the factory. No further calibration at the customer’s facility should be

required, unless the gauge tube is replaced. In this instance the “ATM” adjustment should be done. No re-

adjustment of the zero should be required unless it has been changed.

For a reliable recalibration at a later date, it is necessary to have a reference standard vacuum system

whose pressure is known to be accurate. For such a calibration, the instrument, sensor tube and cable

should be returned to the factory for re-certification. However, if the vacuum calibration verification must

be done at the customer’s facility, a knowledgeable electronics technician trained in vacuum calibration

should operate equipment of certifiable accuracy.

Troubleshooting

1. If display consistently displays “HI”, the atmosphere adjustment may be incorrect or there may be a

broken filament in the sensor. If a broken filament is suspected, check for continuity between pins # 4 &

# 8 and # 2 & # 6 on the sensor.

2. If the display constantly reads “LO”, the sensor may have become inoperative. Check for correct

reassembly after bake out.

NOTE: If, after doing some or all of the above, the units are still inoperative, return to the factory for

repair.

CHAPTER 6 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

9

Specifications

Measurement range Temperature

1 x 10-3 to 1 x 10+3 Torr Operating +15° to + 50°C

Bake out at 200°C (with electronics

removed)

Calibration Medium

Dry air or nitrogen Power

24VDC @ 100mA (customer supplied)

Materials

Stainless steel or nickel-plated brass Set point Relay

Form C contact

Overpressure 24 v.5 a rating

Indicator lamp provided

150-psi

Accuracy

Adjustment Potentiometers

+/- 1 micron 0 to 10 microns

Zero, Atmosphere, Setpoint

+/-10% of reading 10 microns to 10 Torr

Response Time for a Pressure +/- 20% of reading 10 Torr to 100 Torr

Change from 10-5 Torr to

Atmosphere +/- 10% of reading 100 Torr to 1000 Torr

< 500 milliseconds

CHAPTER 9 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

10

Dimensions

CHAPTER 10 TELEVAC

phone: (215) 947-2500 fax: (215) 947-7464 e-mail:sales@televac.com web site: www.televac.com

8/15

11

Unpacking and Inspection

Before each unit is installed or operated, a quick inspection should be performed and the

following noted:

a. damage to the unit (scratches, nicks, dents, cracks, etc.)

b. missing: screws, switches or switch hardware

c. broken barrier strips, etc.

d. broken or loose components within instrument

Should any of the above problems be encountered, contact the factory immediately. Any

unauthorized repairs will void the warranty.

Warranty information

The Televac division warrants instruments and components to be free of defects in material and

workmanship for a period of one year after the date of shipment unless otherwise specified in

the quotation pr product literature. No salesman, Representative or agent of the Fredericks

Company, or its divisions is authorized to give any guarantee or warranty or make any

representation in addition or contrary to those stated herein.

other than those expressly stated herein, there are no other warranties of any kind, express

or implied and specially excluded but not by way of limitation, are the implied warranties

of fitness for a particular purpose and merchantability. It is understood and agreed the

seller’s liability whether in contract, in tort, under any warranty, in negligence or

otherwise shall not exceed the return of the amount of the purchase price paid by the

purchases and under no circumstances shall seller be liable for special, indirect,

incidental or consequential damages. The price stated for the equipment is a

consideration in limiting seller’s liability. No action regardless of form, arising out of

transactions of this agreement may be brought by purchase more than one year after the

cause of action has accrued, seller’s maximum liability shall not exceed and buyer’s

remedy is limited to either (1) repair or replacement.

CHAPTER 12

CHAPTER 11 TELEVAC

This manual suits for next models

1

Table of contents