NEJE E80 User manual

Packing Contents

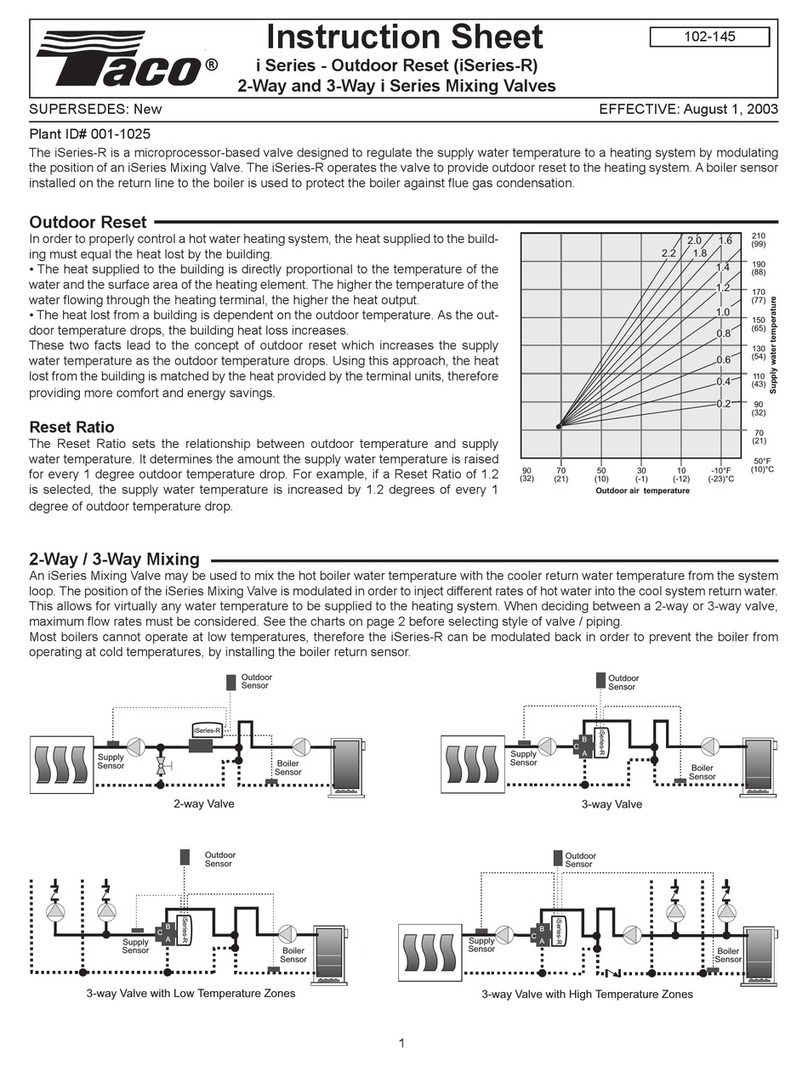

Features

•Hybrid compression technology makes the focal point of NEJE E80 0.1x0.1mm,

and the power density reaches 2400W/mm², Compared with *tool 40W

module,power density:1777W/mm² (0.15x0.15mm,8xLD,Current highest

power) , the performance of E80 is 35% higher than the 40W module. Due to

the extremely strong power density and optical design, NEJE E80 has more

excellent performance when the power is halved. Compared with other 20W

modules, NEJE E80 has great advantages in terms of lifespan and performance.

•The E80 is a 4xLD module designed primarily for large stock removal and

powerful cuts. Yes, it's a cute and rough guy, powerful but attention to detail.

HYBRID Technology (Non-Destructive FAC and Combined Compression Laser

System Technology) makes the performance of E80 is much better than that of

similar 20W and 40W laser modules, with smaller focus, smaller angle, XY

symmetry, and differences in laser systems, which can bring a completely

different experience, not easy to catch fire and cleaner edges , it can even cut

high density materials without air assist, for cutting thick wood, this module

may be revolutionary. E80 has very reliable stable performance and longevity at

the same time, the service life is longer than Ordinary 20W modules are 50%

higher, material process selection, thermal calculation and testing, NEJE has

experienced 3 years of reliable verification testing and 10 years of

manufacturing experience, summed up the design experience of diode lasers

to create a reliable E80.

•NEJE summarizes the advantages and disadvantages of various optical system

design methods. After 3 years of research, a perfect 20W laser system with

complex and unique technology is finally adopted. The new laser system adopts

external FAC and lens compression composite technology. The complexity is

more than 3 times higher than that of ordinary 20W modules, so it has better

optical characteristics than ordinary 20W lasers. X and Y have good symmetry

in each focal length, and the focal energy density is 400% higher than ordinary

20W modules. , the divergence angle is reduced by 50%; and these can bring

about cleaner cutting edges, faster cutting efficiency, not easy to catch fire,

smaller smoke, more durable and reliable service life, and more comfortable

experience. NEJE pursues perfect products and insists on 2 years of free

warranty and establishment of a complete after-sales process. In order to

maintain the goal of user value, we postponed the release of 20W-level new

products for 2 years, but for the goal pursued by NEJE, we should insist on

making a perfect module. You can start booking now, NEJE fans.

•NEJE will release more videos to beginners. In fact, we only released a short

test video, which can explain many things. The symmetry of XY, the focus

power density, and the divergence angle. This is to complete the cutting of

medium density plates without the assistance of home air. If the 20W modules

of other families are tested, most of them are directly on fire, which is the

difference.

Specification

Optical Power: Pulse 24W, CW 21W

Focus Size: 0.1×0.1mm

Input: 24V 5A

Interface: 4pin PH2.0 + ( 2pin DC 24V extra power)

Weight: 600g

Number of Diodes: 4

PWM Input: VPP(3.3-24V), Recomend 1KHz,

Quiet Design: Drive the built-in control ic, judge the working state and adjust the fan

work

Adapter Pluga: 5.5 2.1 port

Working Voltage: DC 24V

TTL&PWM Modulation: YES. Compatible with Both TTL & PWM Modulation

Input Interface: PH2.0-4Pin (+,-, PWM/TTL, Temperature), 3Pin (+,-, PWM/TTL) , 2Pin+2Pin

(+,-) + (PWM/TTL,-)

Warranty: 2 Years

FAQs

Q: Will I have to do anything for it to fix to the NEJE 3 max?

NEJE 3 Max V1.1 and above can support this module, 24V5A power supply (please pay

attention to the motherboard version).

Q: Any power test will happen? It is saying 24w?

Optical power 24W, electrical power 80W.

Q: Would this fit straight into the existing frame for a40640 master 2 max?

NEJE 2S Max is not supported, if you have NEJE 2S Max, then you need to upgrade to

NEJE 3 Max. NEJE 3 Max is supported, but you need a 24V power supply for the E80 laser

module.

Q: Is the Atomstack 130w laser module the same?

- The NEJE E80 is different from other 20W (130W is the power adapter) modules. Usage

details vary greatly. If only the power was required, the NEJE could have been sold three

years ago. Those who have used Xtool or At can see four beams of light with a large focus.

These optical systems are simply stacked. The NEJE uses more complex optical systems

inside. The reliability and performance are different. Hopefully time will vindicate

everything. NEJE has established a 2-year warranty after-sales process, and we don't want

to have any loopholes in our products. I suggest you refer to the actual work effect. NEJE

will update more actual carving and cutting videos of different materials later, which you

can watch. Fortunately, NEJE has the support of many professional users.

Q: What exactly is HYBRID TECHNOLOGY?

In fact, this problem is more complicated. The ordinary module only uses FAC lenses to

conjoin 4 beams, which will cause a problem. The included angle is relatively large and

the focus is relatively large. Of course, if compared with CO2 laser, this is still acceptable,

but there is a fundamental problem with this solution, that is, the life of the LD will be

curtailed, which is the reason why NEJE has not launched new products. The NEJE E80

adopts a more extreme solution, and NEJE adopts a more advanced external FAC, first

combine the two beams, and then combine them again through the lens system. This

way the angle of light is smaller, and the focus is smaller. Two lens technologies are

applied here, and the manufacturing process is much more complicated. However, the

effect is very different. In fact, the manufacturing cost of E80 will be higher than other

20W lasers (optical power), but NEJE is the manufacturer, and other merchants are third-

party modules purchased by marketing companies, which is also the advantage of NEJE

as a full-stack design and manufacturer, and why NEJE can provide after-sales service as

standard. I really want to tell users, don't just look at the parameter of power, do users

only need the laser to burn?

Q: If I connect the E80 with the 24v power supply in my NEJE 3 max, can you confirm the

NEJE air valve AF3 and the relay will continue to work fine?

I see 3 options:

1. Power on M7 and M8 NEJE modules connectors are still 12v even if the main NEJE 3

MAX board is powered at 24v

2. NEJE AF3 and relay modules can work in 12v or 24v.

3. NEJE AF3 and relay modules cannot work in 24v.

The relay can normally use 24V power supply. If you need to use the air valve, it is

recommended to replace the 24V power supply. The gas valve can also be powered by

12V for short periods of time. Over time, increased temperatures may affect the life of the

air valve.

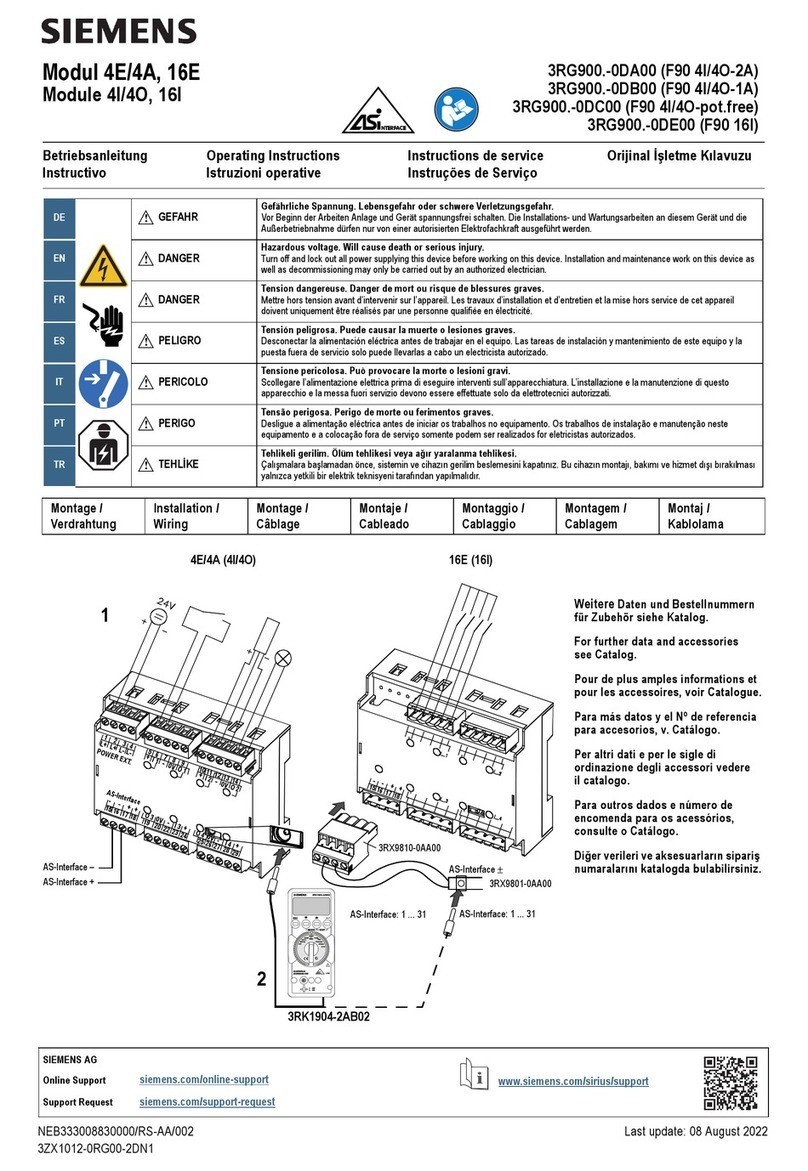

Installation

Install the module height adjuster on the z-axis and adjust the module height and focus by

adjusting the M5 Allen key to slide the module up and down.

Safety

Please do not leave the equipment when the equipment is working, long-term stay may

cause the material to burn!

Please wear protective glasses before operation!

Please do not touch the laser outlet with your hands. It may burn your hands!

Please avoid strongly impact on the machine!

Children under 14 years of age are prohibited from using this product!

Children over 14 years of age need adult supervision when using this product!

Focus

E80 is a fixed focus module, the fixed focus position is 25mm away from the body as shown in the

figure below.

E80 is a quasi-industrial-grade fixed-focus module. Unlike CO2 lasers, the 450nm

semiconductor laser is visible, and the intensity of weak light can be set. Observe the

minimum focus by observing the fluorescence reflected on the surface of the grey

cardboard through protective glasses Location.

NEJE E80 recommends using NEJE Max 4 equipment control, through variable Z-axis multi-

layer sinking settings, cutting from the material surface layer by layer to achieve high

efficiency cutting.

Operation steps controlled by the Z-axis:

1. Reset the motorized Z-axis in the direction of Z0;

2. Find the focus position of the module, and record the distance between the focus and the

module;

3. Install the module on the motorized Z-axis, and set the focus position The distance to the

honeycomb board is set as the electric Z-axis travel distance, (the distance from the module

to the honeycomb platform = the distance from the focus to the module + the distance from

the focus to the honeycomb platform), the LightBurn software sinking setting parameters =

Z-axis travel - material thickness, the first One knife focus is set on the surface of the

material.

If the Z axis of your machine is fixed, it is recommended to adjust the focus to the upper

middle position of the material when cutting the material and repeat the cutting one or

more times.

How to quickly find focus by observing low light?

1. Adjust the suitable low light through the software. The NEJE mode can be adjusted

in the “Settings” column of the NEJE Win software; the GRBL mode can be adjusted in

the “Grbl Configuration” of the laserGRBL software, which has been explained above.

Laser & Material Database

Max Cutting depth < 30mm.

Typical Material Parameters:

17mm Pine Board with NEJE Max 4

Speed (mm/min): 300

Max Power (%): 100

Air Assist: ON

Number of Passes: 3 (2.5)

Z Offset (mm):(The distance between the module and the surface of the board)-Focal

length(25mm) +4mm

Z step per pass (mm): 1.5

10mm BIRCH PLYWOOD With NEJE Max 4

Speed (mm/min): 500

Max Power (%): 100

Air Assist: ON

Number of Passes: 2

Z Offset (mm): (The distance between the module and the surface of the board)-Focal

length(25mm)

Z step per pass (mm): 2

3mm mdf board With NEJE Max 4

Speed (mm/min): 650

Max Power (%): 100

Air Assist: ON

Number of Passes: 1

Z Offset (mm): (The distance between the module and the surface of the board)-Focal

length(25mm)

Note: (Number of Passes - 1) * Z step per pass < 7mm (The standard air nozzle is designed

for cutting less than 17mm. If you want to increase the cutting of materials larger than

17mm, you can increase the cutting thickness by replacing the plane protection head +

metal air pipe.)

The NEJE E80 module adopts NEJE's unique hybrid technology. Compared with similar

products, the NEJE module has a smaller focus angle and relatively uniform XY symmetry. It

is the perfect work of NEJE after summarizing almost all 4xLD solutions. In use It can prevent

the material from igniting. However, too slow a speed setting and unreasonable focus

adjustment may cause the material to catch fire.

When cutting, according to the performance of the controller (synchronous belt equipment),

it is recommended that the cutting speed be greater than 10mm/s to avoid burning the

material. NEJE E80 has very reliable continuous working performance and supports 100%

power continuous working, but please pay attention to prevent the risk of fire. NEJE Max 4

door function can be used to extend the flame sensing and emergency stop, terminating the

job.

About air assist

NEJE E80 is equipped with 2 high-temperature-resistant (1000°C) protective lenses, which

can be replaced. Pay attention to regularly cleaning the surface oil and foreign matter

according to the actual use case. Oil and foreign matter sticking to the surface may cause

high temperature to soften the lens.

NEJE E80 can use 2 types of air assist. a. Conical air nozzle in the inner cavity, this method

needs to use oil-free and water-free air source, (Note: ordinary oil-water filters can only filter

simply, not completely, and need to be cleaned regularly built-in protective lens) b. Stainless

steel pipe air nozzle, this method can use oily water air source, easy maintenance, and can

quickly clean the lens, the metal pipe needs to be aligned with the focus.

When cutting mdf, leather and high-density materials, it is necessary to add air assistance

with a pressure of not less than 30psi.

The air nozzle must be aligned with the cutting port to blow off the carbonized material,

otherwise it will be ineffective.

When do you need air assist?

Air-assisted engraving or cutting should only be used for engraving or cutting that produces

more carbonized substances. Generally, for depth of engraving less than 1mm, and the

cutting of plywood less than 2mm air assist is not required. A small fan can be used to blow

off the smoke generated by the engraving. Air assist is not recommended when engraving

images, and adding air assist at this time will destroy image details.

What kind of air pump is suitable for cutting?

The main function of air assist is to blow off the carbonized material produced by cutting,

and the general oxygener and electromagnetic inflator have almost no meaning. only the

pressure of the oil pump and air compressor (0.4-1.5mPa) has the effect of blowing away

the carbonized material. but it should be noted that the air of the oil pump contains oil and

cannot be directly used for the air-assisted module of the closed cavity, otherwise the oil will

contaminate the lens, resulting in power drop or damage to the lens. The air pressure of the

air compressor can be used for a short time with the closed cavity, but when used for a long

time, the water-containing gas will contaminate the lens, cause the power to drop, and even

damage the lens.

Specification

Power density: 2400W/mm²

Focus size: 0.1x0.1mm

Radiator Size: 40.5 x 56 x 113 mm

Weight: 600g

Interface: PH2.0 4Pin + 2Pin(EX Power)

Drive Design: Built-in

Input: 24V 3A +

Optical Power: < 24W

Wavelength: 450nm

Laser Class: Class 4

Number of Diodes: 4

PWM Input: VPP(3.3-24V), Recommend 1KHz

Max Speed of the Fan: 10600 RPM (Double ball bearing)

Quiet Design: (Dynamic adjustment) Drive the built-in control IC, judge the working state

and adjust the fan.

ESD Design: Yes

Temperature feedback: Yes

Recommend Cutting & Carving Depth: <16mm (The data is tested by NEJE users, and it needs to

be done under more accurate focusing and adding correct and certain strength of air

assist.)

Stainless Steel Carving: Yes

0.1mm Stainless Steel Cutting: Yes

Interface

24V: Power positive.

GND: Power ground or power negative.

TTL/PWM: TTL = PWM, input 3.3V~24V to turn on laser module, connect to GND to turn off

laser module.

Temperature: do not connect, please ignore.

Connect 24V and GND pin to 24V power, ensure the power adapter is sufficient, 3A-5A is

recommended.

Connect TTL/PWM pin to your control board PWM output pin.

E80 driver has very high conversion efficiency, input 65W can output 24W optical power.

FAQs

Inferior power supply leads to the problem of laser power drop!

How to test my laser module?

About PWM signal specification.

How to distinguish my laser module types?

How to make laser module work with your control board?

How to check my cable connection is properly

Compatibility

Compatible with NEJE 3 Max (the motherboard model is higher than V1.1), only need to

update the 24V power supply, the relay and valve control module are compatible, the

temperature will be higher than in 12V mode, and there is no problem with indirect use. It is

recommended to connect other devices through the control board, and it is recommended

to use the device with Z-axis control, which is conducive to the full performance of the E80.

Maintenance

Although this module adopts internal air-assisted design, long-term use may not prevent

dust or a small amount of smoke from affecting the lens. It is recommended to clean the

lens with a clean cotton swab. Dust or smoke may overheat the lens and cause the lens to

burn out. Re-acquire the lens Will delay your use.

Table of contents