ElcoBrandt 2004 solo User manual

STEAM OVEN

2004 solo model

STEAM OVEN 2004 SOLO MODEL

Technical training CONTENT

- 3 -

CU5-VAP2004-001UK-03/05

1 - GENERALS..............................................................................................................................................................4

1.1. - Overview ...........................................................................................................................................................4

1.2. - Control panel.....................................................................................................................................................4

2 - FITTING....................................................................................................................................................................5

2.1. - Build-in the oven ..............................................................................................................................................5

2.2. - Electrical connection .........................................................................................................................................6

2.3. - Technical features.............................................................................................................................................6

3 - USING.......................................................................................................................................................................7

3.1. - Setting the time .................................................................................................................................................7

3.2. - Possible functions .............................................................................................................................................7

3.3. - Locking the control panel..................................................................................................................................7

3.4. - Cleaning the channel ........................................................................................................................................7

4 - GENERAL PRINCIPLE............................................................................................................................................8

5 - STUDY OF THE COOKING CYCLE........................................................................................................................9

6 - AIR FLOW ..............................................................................................................................................................10

7 - DIFFÉRENT COMPONENTS.................................................................................................................................11

8 - DIAGRAM...............................................................................................................................................................13

9 - TEST PROGRAM...................................................................................................................................................14

9.1. - Important instructions......................................................................................................................................14

9.2. - Preliminary steps ............................................................................................................................................14

9.3. - Run of the test program ..................................................................................................................................14

STEAM OVEN 2004 SOLO MODEL

Technical training

GENERALS

- 4 - CU5-VAP2004-001UK-03/05

1 - GENERALS

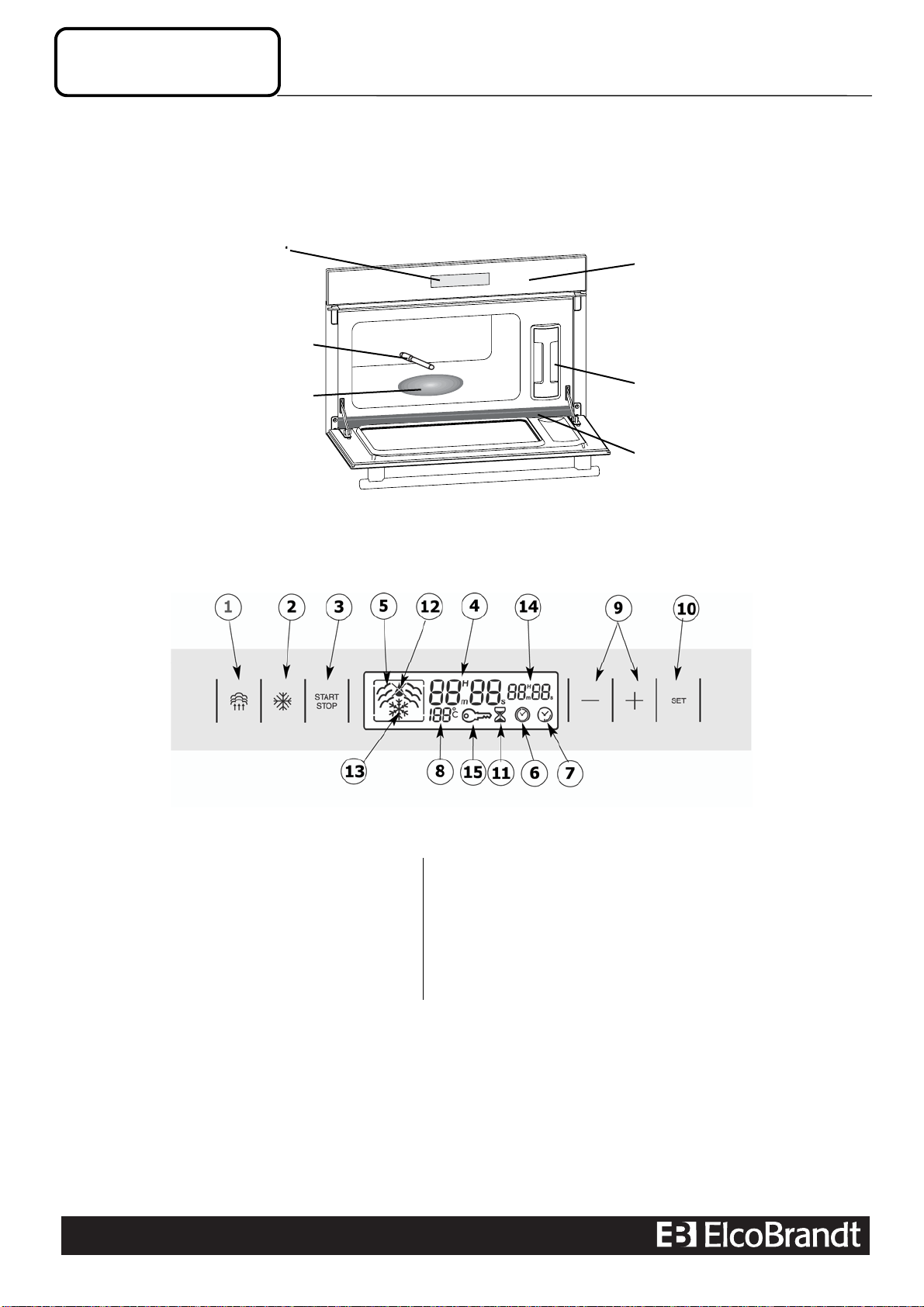

1.1. - Overview

1.2. - Control panel

The order and the number of keys depend on the reference.

The appliance is equipped with a single electronic board which manages at the same time, the control and the

switching of the power elements.

Display

Water supply tube

Steam generato

r

Control panel

Tank

Channel

1. Steam cooking control 9. +/- controls for timer

2. Defrosting button 10. Selector button

3. Start/Stop control 11. Autonomous minute timer

4. Time and delay display or timed period 12. Water circuit problem signal

5. Steam cooking symbol 13. Defrosting symbol

6. Cooking time symbol 14. Display of the cooking period or delayed start time

7. End of cooking time symbol 15. Control panel locked

8. Tem

p

erature dis

p

la

y

STEAM OVEN 2004 SOLO MODEL

Technical training INSTALLATION

- 5 -

CU5-VAP2004-001UK-03/05

2 - FITTING

2.1. - Build-in the oven

The oven has a high-performance air flow system which gives remarkable results as long as the

following points are applied:

•The oven may be fitted either underneath a work top or in a suitable sized column unit.

•Cut a hole measuring 50 mm x 50 mm in the back wall of the insert space for the electric cable to

cross through (see diagram below).

•Centre the oven in the unit, and make that it is at least 2 mm from any other unit beside it.

•The oven must be disconnected from the power supply while it is being installed in the unit

•For greater stability, fix the oven in the unit with 2 screws in the holes on the side uprights.

380

560

50 386,5

20

595

405

544

378

550

STEAM OVEN 2004 SOLO MODEL

Technical training

- 6 - CU5-VAP2004-001UK-03/05

INSTALLATION

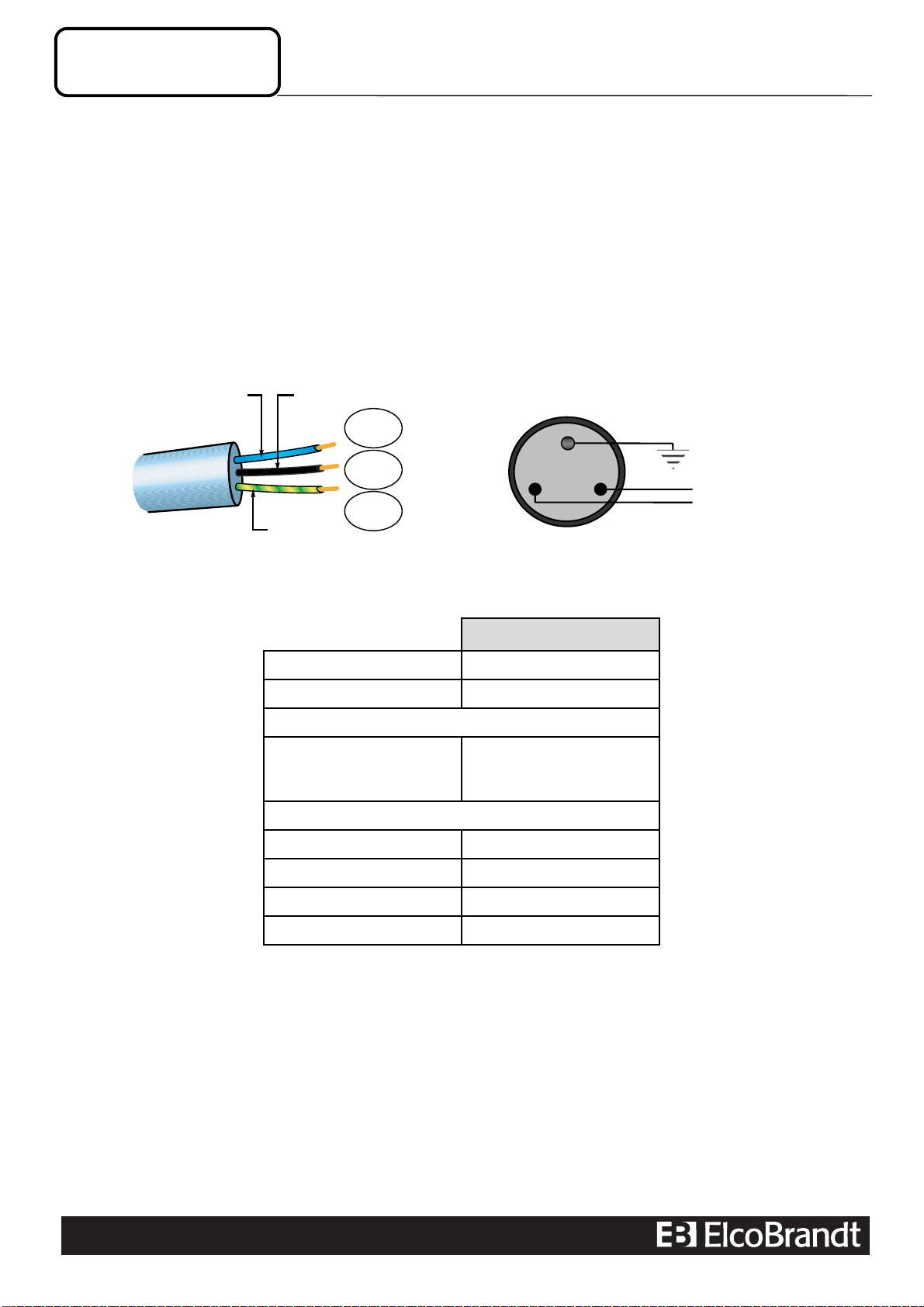

2.2. - Electrical connection

For a permanent connection, make sure an all-pole switch is placed into the supply line with a contact

distance of at least 3mm. The appliance must be placed in such a way as to leave the plug accessible

if it is flush-fitted.

Use of an earthed power socket, connected in compliance with current safety standards

The installation must be fitted with a 16 amp device for thermal protection.

Do not use the oven if the supply cord or its plug are damaged.

2.3. - Technical features

STEAM OVEN

Operating voltage 220-240V ~ 50 Hz

Total power 1,77 kW

Energy consumption

Heating to 100°C and

maintaining temperature

for 1 hour 0,71 kWh

Inside dimensions of oven

Width 38,5 cm

Height 18,2 cm

Depth 33,5 cm

Effective volume 23,5 litres

Earth

Live

(

L

)

Neutral (N)

Neutre

(N)

Phase

(L)

Terre

Fil vert/jaune

Fil bleu Fil noir, marron ou rouge

Blue Black, brown or red

Green and

Yellow

Neutral

(N)

Live

(L)

Earth

STEAM OVEN 2004 SOLO MODEL

Technical training

- 7 -

CU5-VAP2004-001UK-03/05

USING

3 - USING

3.1. - Setting the time

¾The first time the oven is turned on

•The display flashes on12.00

•Use the +and -buttons to adjust the time.

•Validate with SET (Validation is automatic after few seconds).

¾Changing the time

•Press on the + and - buttons simultaneously until the time starts to flash.

•Adjust the time using the + and - button.

•Validate with SET (Validation is automatic after few seconds).

3.2. - Possible functions

•Standard steam cooking: Temperature 100°C

•Defrosting : Temperature 60°C

•Independent timer: Accessible by the ‘SET’ button.

3.3. - Locking the control panel

The control panel can be locked. This can only be activated when you are not using timed or delayed

cooking features.

¾To lock

•Hold down the START/STOP button for a few seconds.

•A beep sounds and a “key” appears on the screen. From this moment, no button is live.

¾To unlock

•To unlock, hold down the START/STOP button for a few seconds. A beep sounds and the key

disappears.

3.4. - Cleaning the channel

Dismantle this channel by pulling upwards. Wipe it and replace it,

using the three notches provided for this purpose.

STEAM OVEN 2004 SOLO MODEL

Technical training

- 8 - CU5-VAP2004-001UK-03/05

PRINCIPLE

4 - GENERAL PRINCIPLE

The water contained in a removable tank is brought by an electrovalve on a heat generator where it is

transformed into steam. The steam obtained is maintained in the oven cavity by closing a flap.

This flap is bored several holes in order to avoid the pressurization of the cavity.

This cooking principle is different to a pressure-cooker where the obtained pressure is higher than the

atmospheric one.

Initially the oven will be saturated with steam and the temperature will be close to 100°C. In order to

avoid condensation, an electric blanket which covers the top will be supplied during all cooking time.

Tangential fan allows the constant cooling of the oven and the extraction of the steam when the flap

opens three minutes before the end of the cycle. A safety thermostat (210°C) protects the oven against

overheating. Two probes located in the cavity and in the generator allow the temperature control.

Steam generator Probe

Security thermostat

Electric blanket

Door switch

Thermal

activator Tangential fan

Tank

Probe

Valve

Power board

STEAM OVEN 2004 SOLO MODEL

Technical training

- 9 -

CU5-VAP2004-001UK-03/05

COOKING STEPS

5 - STUDY OF THE COOKING CYCLE

Cooking is divided into 5 steps.

¾Rise in the temperature and steam generation (Step 1)

Immediately after starting, the valve, the tangential fan, the heater, the electric blanket and the thermal

activator are supplied. The steam generation is important in order to quickly obtain saturation in the

cavity. The valve is supplied by step of 15 to 30 sec as soon as the generator temperature exceeds

130°C.

¾Upholding of the steam level (Step 2)

The heat generator is regulated by the probe. The thermal activator, the electric blanket and the

tangential fan are still supplied.

¾Steam emptying and temperature decreasing (Step 3)

Three minutes before the end, the thermal activator and the electrovalve are not supplied any more.

The flap opens, the tangential air flow involves the steam out of the cavity. The electric blanket is

always supplied.

¾Keep warm (Step 4)

This step takes place only if the door remains closed after the end of cooking. The tangential and the

electric blanket are always supplied. The maximum duration: 1 hour.

¾Cavity drying (Step 5)

This step starts as soon as the door is open or after 1 hour and continues during 3 minutes. The

tangential and the electric blanket are supplied.

STEAM OVEN 2004 SOLO MODEL

Technical training

- 10 - CU5-VAP2004-001UK-03/05

AIR FLOW

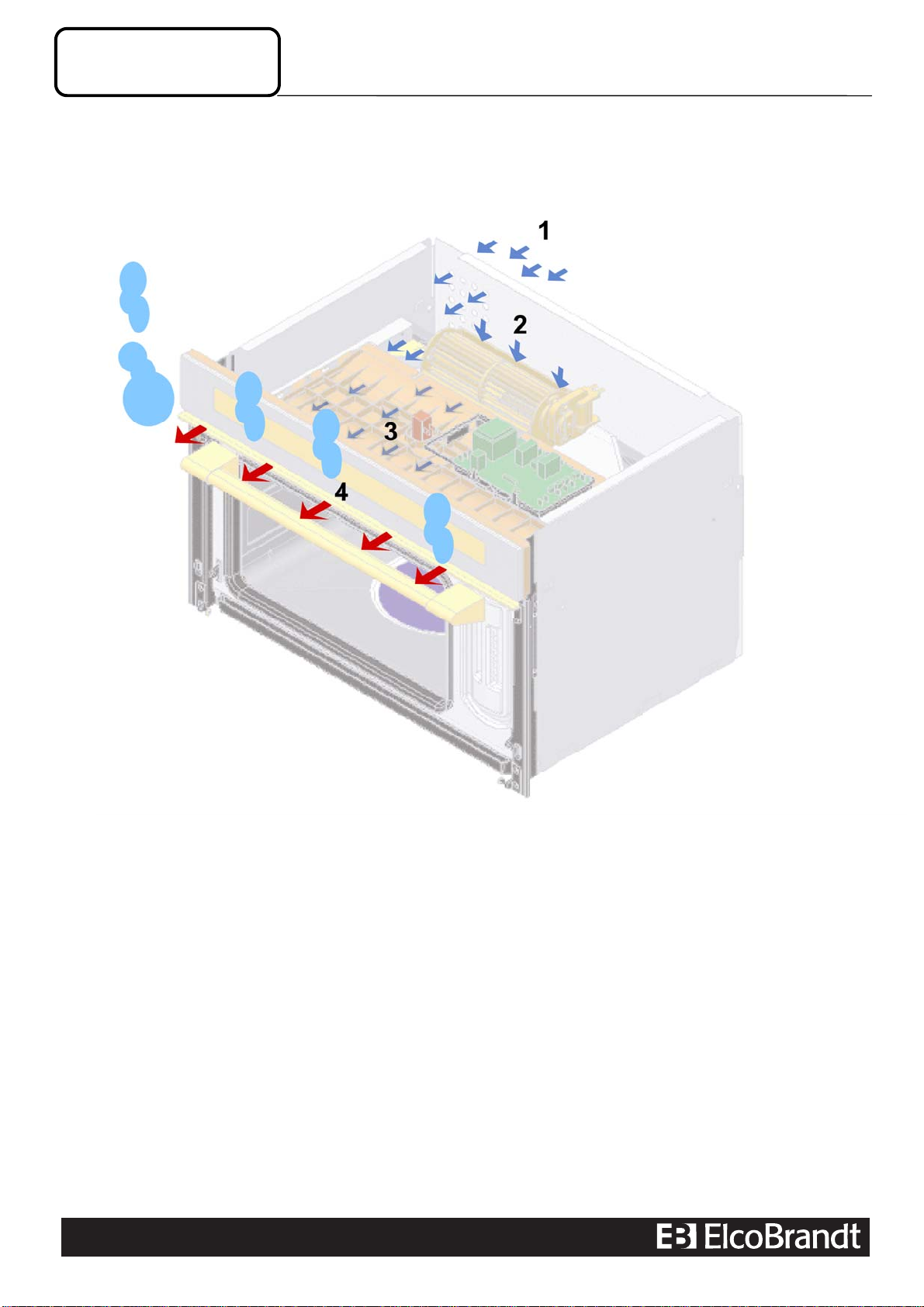

6 - AIR FLOW

STEAM OVEN 2004 SOLO MODEL

Technical training

- 11 -

CU5-VAP2004-001UK-03/05

COMPONENTS

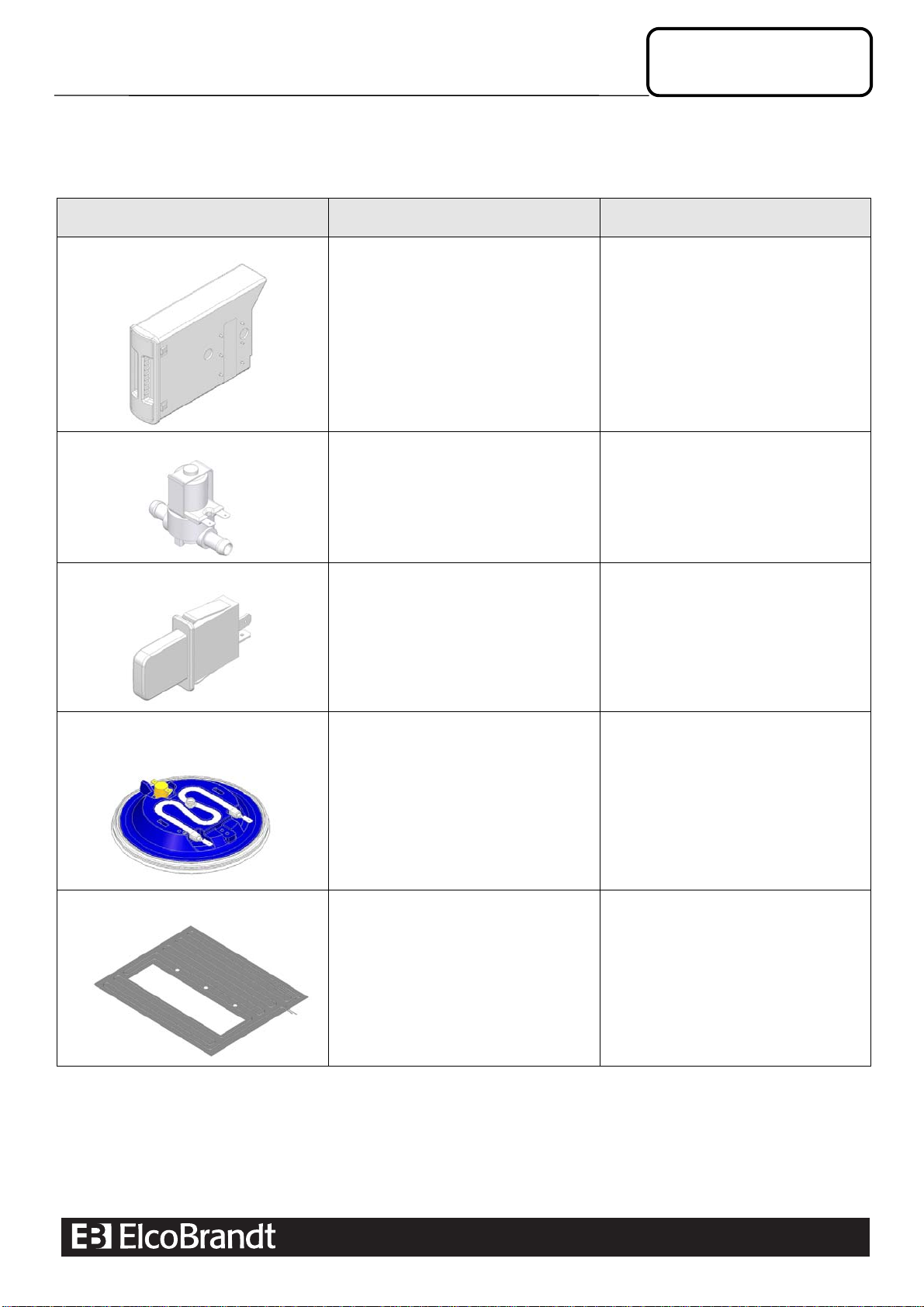

7 - DIFFERENT COMPONENTS

Designation Function Characteristics

Water tank The tank must be

•Full of water before each cooking.

•Emptied after each cooking

In case of too hard water, it’s better to

use a noncalcareous water.

The use of demineralized water is

disadvised.

•Capacity: 1 litre

Electrovalve The electrovalve supplies the

generator in water

•220/240V~

•2L/min

•3,7 kΩ

Door switch This switch allows to modify the cycle

when the door is open.

Door open= Switch is off

Door closed = switch is on

Heat generator

(upside down view)

The generator transforms water into

steam. It is made to receive back the

condensations at the time of cooking.

2 security thermostats (KX1 and KX2),

located underneath, protect against

overheating (T°C: 210°C).

•220/240V~

•1600 W

•35 Ω

Electric blanket During all cooking, the electric blanket is

supplied in order to avoid any risk of

condensation. It covers the top of the

cavity. Its temperature is close to 100°C.

It is protected by a thermal fuse.

•220/240V~

•350 Ω

•160 W

•Thermal fuse : 120°C

STEAM OVEN 2004 SOLO MODEL

Technical training

- 12 - CU5-VAP2004-001UK-03/05

COMPONENTS

Designation Function Characteristics

Double thermostat The double thermostat protects the oven

against overheating.

It’s located under the heat generator.

•220/240V~

•Opening T°C : 210°C

Thermal activator It maintains the flap closed during

cooking.

•220/240V~

•5 W

•1 KΩ

Tangential fan The tangential fan allows the constant

ventilation of the oven during all the cycle

and the extraction of the steam during the

last three minutes of the cycle.

•220/240V~

•10 W

•500 Ω

Cavity and generator probes

The probes measures

•The heat generator temperature

•The cavity temperature

They are recognized automatically by the

microprocessor. There is no possibility of

error in wiring.

N.T.C

•55KΩ at 20°C

•4,7KΩ at 90°C

STEAM OVEN 2004 SOLO MODEL

Technical training

- 13 -

CU5-VAP2004-001UK-03/05

DIAGNOSTIC

8 - DIAGRAM

STEAM OVEN 2004 SOLO MODEL

Technical training

- 14 - CU5-VAP2004-001UK-03/05

DIAGNOSTIC

9 - TEST PROGRAM

9.1. - Important instructions

•Connect (if possible) an ammeter to oven power supply.

•Entirely execute the test program.

•Record discrepancies noticed as the test program is running

•Next, check and replace if necessary the incriminated component(s).

•Perform right-operation check by executing the test program again.

9.2. - Preliminary steps

•Fill in the tank and put it in the right position

•Disconnect for 10 seconds minimum and connect again

•The time before entering the test mustn’t exceed 1 minute

•Press successively each key from left to right and maintain the right key during 3 seconds.

9.3. - Run of the test program

An action on the keys other than + and - or 3 min without action allows to quit the test program.

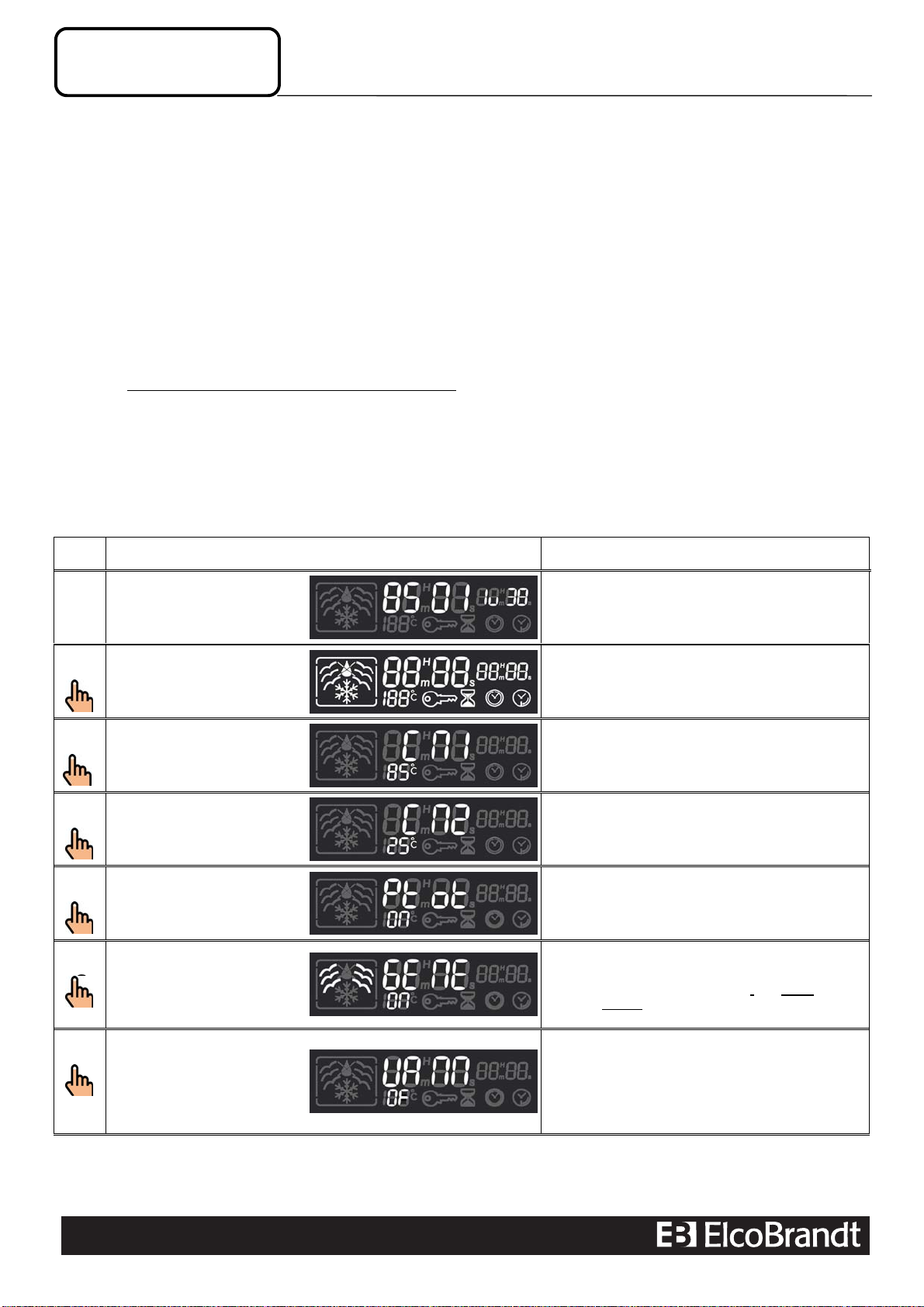

Step Run and display Remarks

1Start of the P.A.D. ⇒

•The test begins by indicative information on board

programming.

NO ⇒Do again the preliminary steps

Continue the test

2+Press once the +key ⇒

•All segments are lit.

NO ⇒Display board out of order.

Continue the test

3+Press once the +key ⇒

•NTC1 temperature in °C

Unusual value ⇒check the probe ‘55KΩat 20°C, 4,7kΩ

at 90°C’

Continue the test

4+Press once the +key ⇒

•NTC2 temperature in °C

Unusual value ⇒check the probe ‘55KΩat 20°C, 4,7kΩ

at 90°C’

Continue the test

5+Press once the +key ⇒

•All elements are supplied

Continue the test

6+Press once the +key ⇒

•The steam pictogram is flashing

•Heating element is supplied

I = 0 ⇒check the security thermostat, .the wiring and the

generator resistor. Lastly, change the power board

Continue the test

7+Press once the + key ⇒

•The valve has normally supplied the heating element

in water. If it’s not finished, the display is ‘VANN on’

VANN OF ⇒Open the door and check the water.

Take care : This opening is necessary to continue.

Continue the test

STEAM OVEN 2004 SOLO MODEL

Technical training

- 15 -

CU5-VAP2004-001UK-03/05

DIAGNOSTIC

Step Run and display Remarks

8+(After having opened

and closed again the

door ) Press once the +

key ⇒

•Tangential fan and heating cover are supplied. Open

the door to check the temperature of the cavity top. The

top must become very hot

•NO ⇒Check the wiring and the heating cover. The

ohmic value must be around : 350 Ω

Continue the test

9+Press once the +key ⇒

•‘Ver on’ is displayed and the thermal activator is

supplied. : The flap is closing slowly

NO ⇒Check the supply of the activator and its resistance

(1kΩ)

Continue the test

10 +Press once the +key ⇒End of the test

Brandt Customer Services

B.P. 69526 - 95060 Cergy-Pontoise cedex

SAS au capital de 2.500.00 € - RCS Pontoise B 440 303 303 - SIRET 440 303 303 00026 - APE 514F

Service formation : Agrément N° 11 95 00 685 95 - Fax : 33 (0)1 34 30 68 42 - E-mail : for[email protected]

©

Brandt Customer Services - Formation : CU5 – VAP2004- 001UK - 03/05

destinée aux : hôtesses d'accueil .chargés de clientèle

.gestionnaires de pièces détachées .responsables

techniques .techniciens .livreurs installateurs .formateurs

Table of contents

Popular Oven manuals by other brands

Alto-Shaam

Alto-Shaam COMBITHERM CTC Series Operation, Maintenance, Troubleshooting, Wiring Diagrams

Kenmore

Kenmore 911.41389 owner's manual

NEFF

NEFF B6ACM7AG0A User manual and installation instructions

Beko

Beko GEBM19300DXMPF user manual

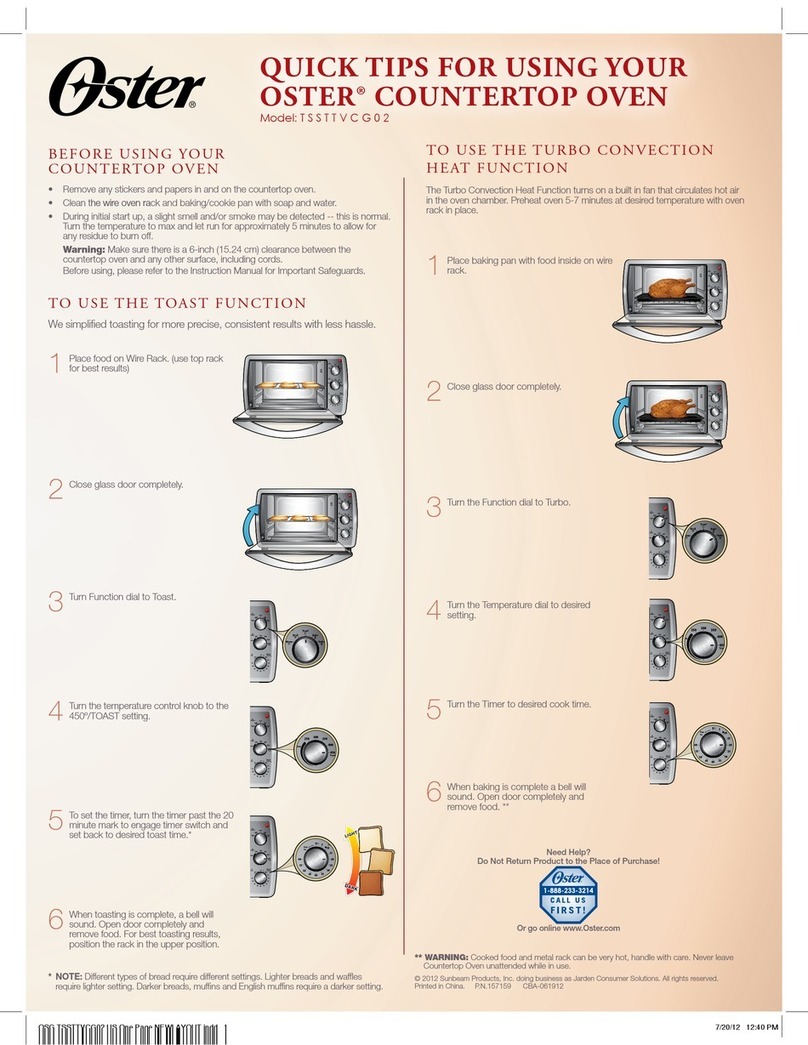

Oster

Oster TSSTTVCG02 Quick tips

Whirlpool

Whirlpool RB760PXT Use & care guide