2

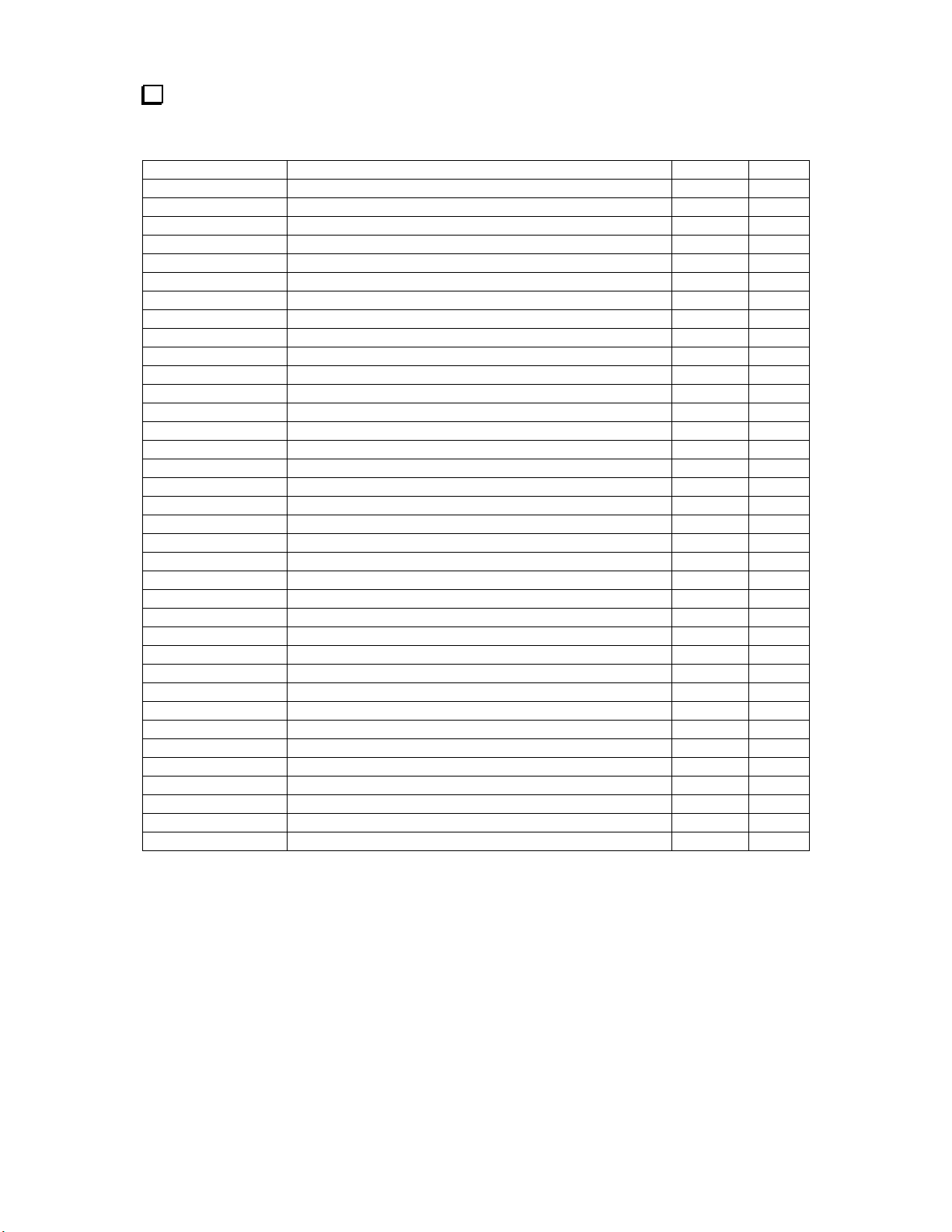

Parts Inventory

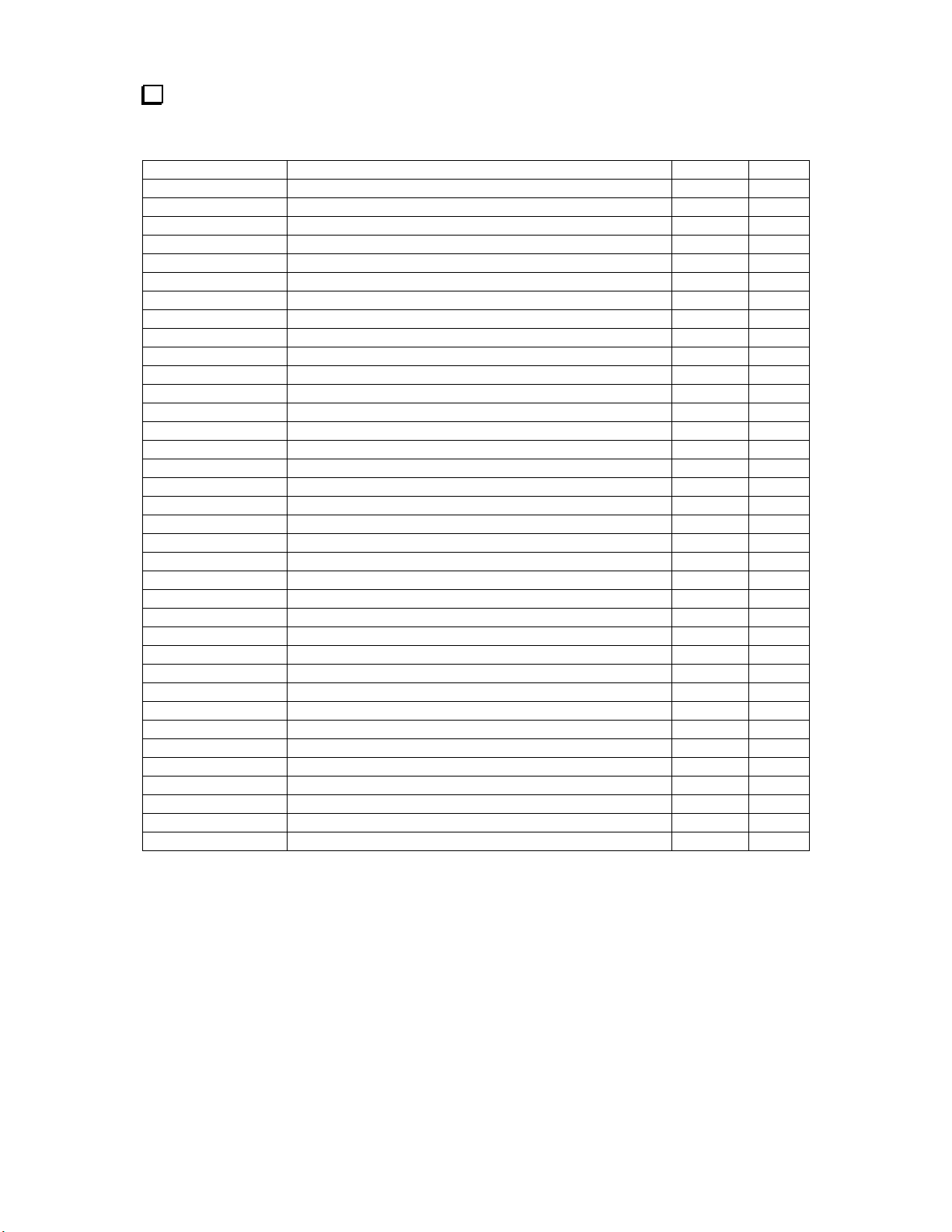

The table below lists all parts in four-band filter board kit. The photographs in Appendix A of the K1

owner's manual may be helpful in identifying components. If anything is missing, contact Elecraft.

Note: Some capacitors use lettered reference designators, e.g. "CA". This is explained later in the manual.

Ref. Descri

tion Part No.

t

C9 Capacitor, 2 pF ("2") or 2.2 pF ("2r2") E530047 1

CJ Capacitor, 2.7 pF ("2r7") or 3.3 pF ("3r3") E530065 1

C10, CK Capacitor, 4.7 pF ("4r7") or 5 pF ("5") E530048 2

C22, C26 Capacitor, 27 pF ("27" or "270") E530060 2

C29, C33 Capacitor, 56 pF ("56" or "560") E530015 2

C11-C14 Capacitor, 68 pF ("68" or "680") E530007 4

C24 Capacitor, 82 pF ("82" or "820") E530038 1

C21, C27, CN, CP Capacitor, 100 pF ("101") E530034 4

CL, CM Capacitor, 120 pF ("121") E530041 2

C31 Capacitor, 150 pF ("151") E530049 1

C23, C25 Capacitor, 180 pF ("181") E530008 2

C28, C34 Capacitor, 330 pF ("331") E530043 2

C30, C32 Capacitor, 560 pF ("561") E530052 2

C19, C35-C45 Capacitor, .001 µF ("102"), 0.1" lead spacing E530074 12

C15, C16, C17 Capacitor, .047 µF ("473") E530025 3

C46 Capacitor, 0.1 µF ("104"), 0.1" lead spacing E530020 1

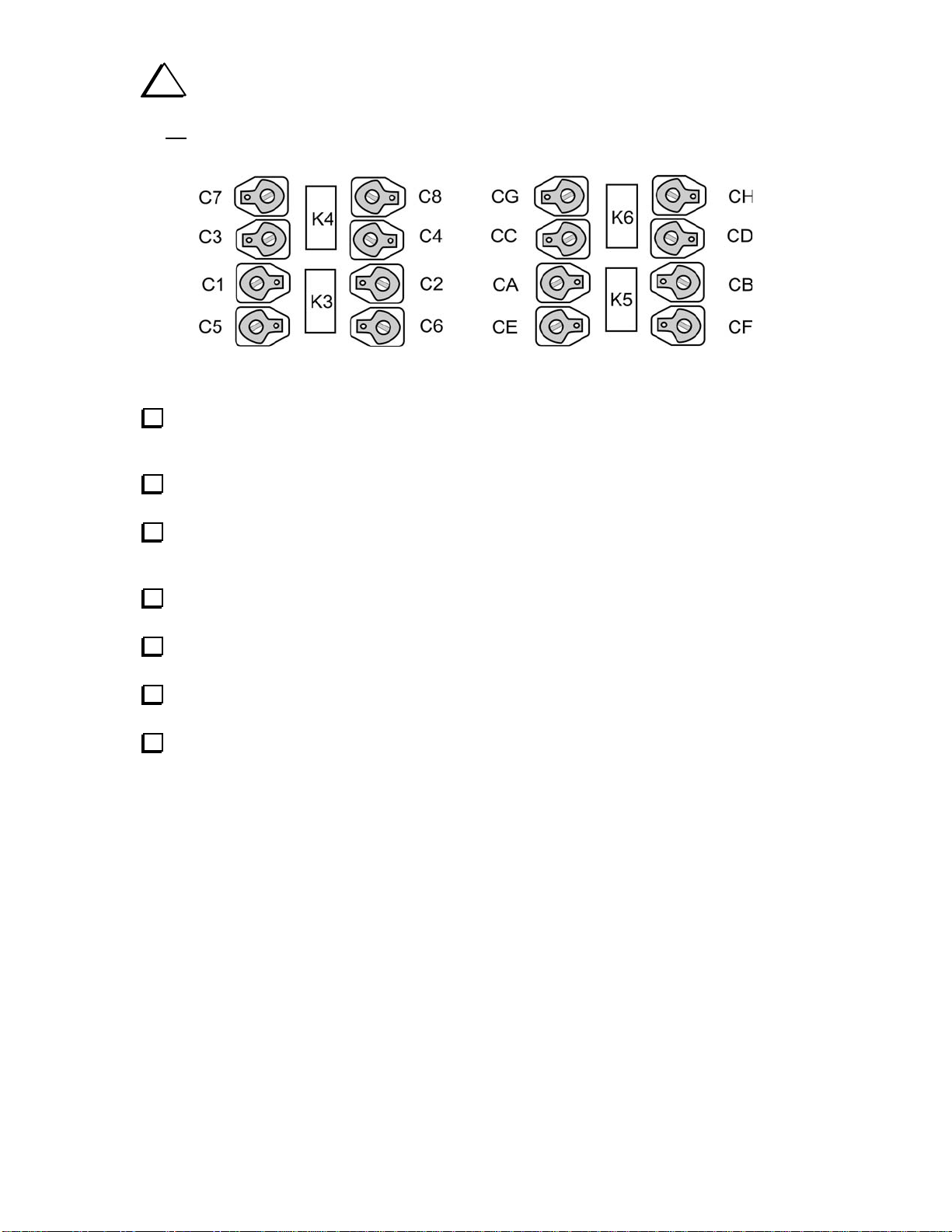

C1-C8,CA-CH Trimmer capacitor, 1-40 pF E540002 16

J1 Conn., 3-pin female E620009 1

J2 Conn., 10-pin female (dual row, 5 pins per row) E620045 1

K1-K8 Miniature DPDT relay E640010 8

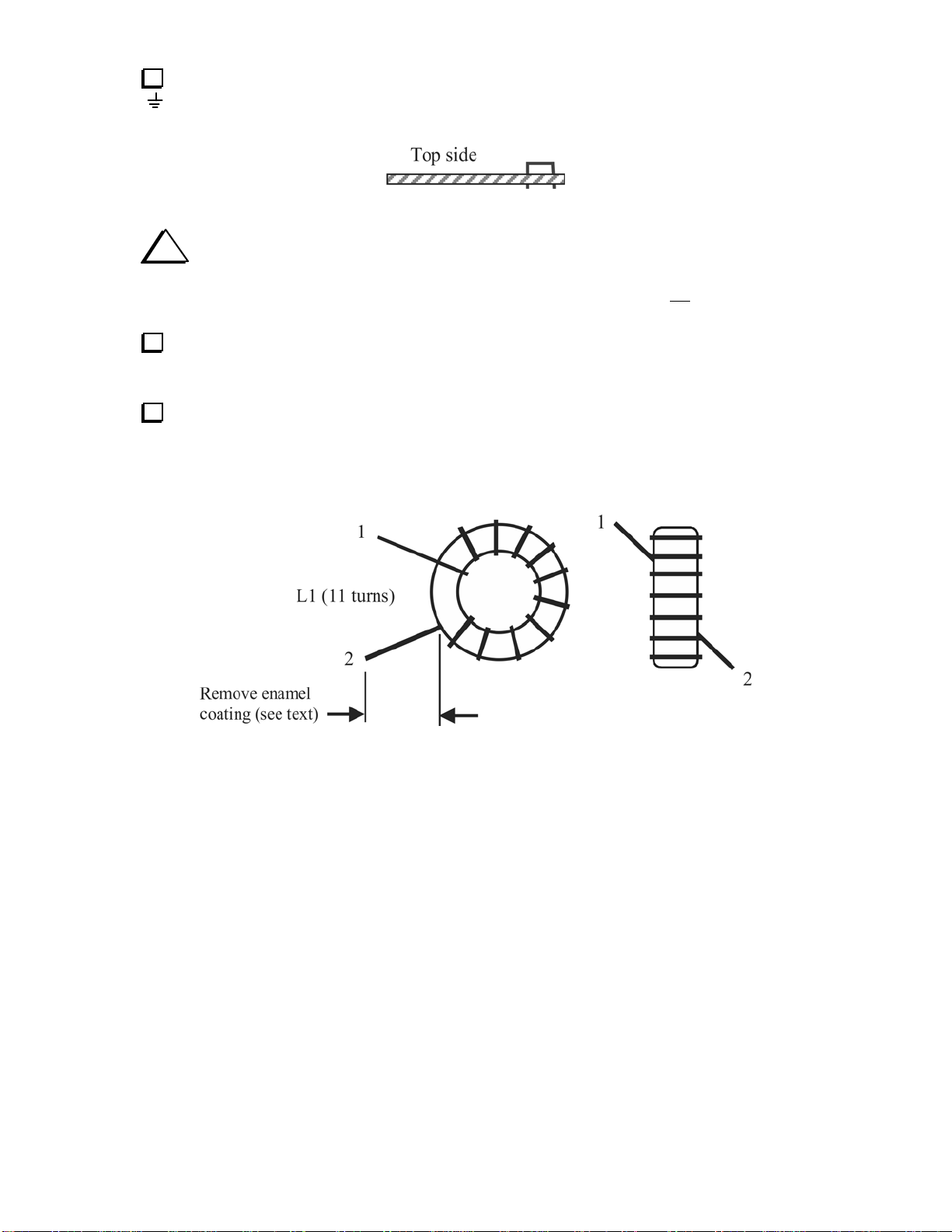

L1-L6, T1-T4 Toroidal inductor, T37-6 core (see text) E690013 10

P1, P2, P3 Conn., 8-pin male E620004 3

R1 Resistor, 100 ohms, 1/4 watt, 5% (brown-black-brown) E500010 1

RFC1 RF Choke, 100 µH (brown-black-brown; larger than R1) E690004 1

U1 IC, programmed microcontroller, PIC16C621A-04/P E610010 1

X1A Crystal, 29.000 MHz (for 21.0 MHz band) E660005 1

X1B Crystal, 26.050 MHz (for 18.0 MHz band) E660012 1

X2 Crystal, 22.000 MHz (for 14.0 MHz band) E660004 1

X3A Crystal, 18.100 MHz (for 10.1 MHz band) E660010 1

X3B Crystal, 18.000 MHz (for 10.0 MHz band) E660007 1

X4 Crystal, 15.000 MHz (for 7.0 MHz band) E660008 1

Z1 Ceramic resonator, 4 MHz E660001 1

Misc. Socket for U1 (18 pins) E620031 1

Misc. PC board, KFL1-4 E100129 1

Misc. Wire, #26 enamel, red E760002 12 ft

Misc. Wire, #26 enamel, green E760004 4 ft.