Electric Druid Flangelicious Instructions for use

Electric Druid Flangelicious Flanger Project

(Using either 4KNOBFLANGE or MULTIFLANGE chips)

Overview!2

Build Instructions!2

Populate the PCB!2

1N4148 Diodes!2

Resistors!2

Cup of tea and soldering check!3

Power protection diode!3

IC sockets!3

Regulator!3

Transistor!3

Ceramic bypass capacitors!3

Film capacitors!3

Electrolytic capacitors!4

Preset resistors (Trimmers)!4

Second cup of tea and Power Test!4

Potentiometers!4

Install ICs!5

Off-board wiring!6

Adjustments and final testing!6

Bill of Materials!8

Offboard components!9

Component choices and substitutions!9

Ideas for potential upgrades or customizations!10

Adding CV inputs!10

Adding Expression pedal inputs!10

Adding more switches and options!10

Flangelicious Construction Guide

www.electricdruid.net

Page 1

Overview

The Flangelicious flanger project comes in two flavours,

depending on which FLANGE chip you fit - either the 4 KNOB

FLANGE or the MULTIFLANGE.Additional tonal variation is

possible by building the pedal with either a 256-stage or a 1024-

stage BBD.All four options use the same PCB and components.

The 4 KNOB FLANGE is a fairly standard four knob flanger, as

the name suggests. It offers Manual (Flanger frequency), Depth,

Rate, and Resonance (Feedback) controls.You can get a wide

range of classic flanging sounds from this pedal, from deep slow

whooshes to rippling wobbles.With the Depth at zero, you can

use the Manual control to set ‘static flanger’ sounds.

The MULTIFLANGE is a more experimental design. It offers

Rate, Depth,Waveform, and Resonance controls. In place of the

the sinewave LFO of the 4 Knob Flanger, this offers 7 different

waveforms and a ‘static’ position, where the flanger folllows the

Rate knob. It can also switch between top-down or bottom-up

flanging.

Build Instructions

You’re advised to have a read through of these instructions before starting work on the PCB.To

keep these instructions reasonably brief, it is assumed that you know how to orientate common

components.

Populate the PCB

The board should be populated in order from smallest components to tallest.The BOM on page 8

is arranged in this order, so start at the top and work your way down.You can tick off each line in

the “Done?” column on the far right.

If you hold the PCB with the “flangelicious” and “electric druid” logos the right way up, you’ll see

that the components are arranged in three rows.The top row is passive components.The centre

row is for the ICs, with a few other components.The bottom row is more passive components.

Underneath the bottom row are the connections for off-board components.

1N4148 Diodes

Start with the two 1N4148 diodes.These need to be the right way around and point in opposite

directions, so be careful. They’re on the left in the centre row.

Resistors

Next come the resistors.

•1K resistor x 1 - bottom row, far left

•1M resistor x 1 - top row, far left

Flangelicious Construction Guide

www.electricdruid.net

Page 2

•10K resistor x 6 - two on the top row, four on the bottom row

•100K resistor x 9 - six on the top row, three on the bottom row

•47K resistor x 7 - four on the top row, three on the bottom row

•24K resistor x 2 - one on the top row, one on the bottom row, both in the centre

•12K resistor x 1 - bottom row, on the right

•3K3 resistor x 1 - bottom row, on the right

•560R resistor x 1 - bottom row, far left

Cup of tea and soldering check

When you’ve finished doing the resistors, stop and have a cup of tea and spend a few minutes

looking over your solder joints and making sure everything’s ok so far.

Power protection diode

Install the fat black 1N4002 diode in the bottom right corner of the PCB.This protects the PCB

against reverse voltage, so be sure to check the orientation carefully.

IC sockets

All four 8-pin DIP sockets are arranged the same way around down the centre of the PCB. It helps

to solder only a couple of corner pins first, and then give the socket a check. If it’s sitting correctly

and orientated the right way around, you can solder the rest of the pins. If not, it’s much easier to

adjust it with only two pins soldered. Removing IC sockets from plated-through-hole PCBs like this

one is difficult and not recommended.

Regulator

The 78L05 +5V regulator REG1 is in the bottom right corner next to the power protection diode.

Be sure to line up the flat side and the curved side with the markings on the PCB. Don’t mix it up

with the similar-looking transistor.

Transistor

The 2N3904 transistor TR1 is in the centre row, far left.Again, be sure to line up the flat side and

the curved side with the markings on the PCB.

Ceramic bypass capacitors

There are three 100n ceramic power supply bypass capacitors, one beside the FLANGE chip, and

two more one either side of the 5V regulator you just fitted.These are not the 100n film caps on

the bottom row far left. Don’t mix them up!

Film capacitors

There are quite a few of these.Take your time.

•100n (104, 0.1u) capacitor x 2 - bottom row, far left

•1n (102, 0.001u) capacitor x 1 - bottom row, centre left

•150p (150) capacitor x 2 - one on the top row, one on the bottom, both centre left

•33n (333, 0.033u) capacitor x 1 - top row, far left

Flangelicious Construction Guide

www.electricdruid.net

Page 3

•470p (470) capacitor x 2 - one on the top row, one on the bottom, both in the centre

•3n3 (332, 0.0033u) capacitor x 2 - one on the top row, one on the bottom, both in the centre

•470n (474, 0.47u) capacitor x 3 - one in the centre row, far left, the other two on the top row

and bottom row, both right of centre.

Electrolytic capacitors

There are only three of these, but you need to watch the polarity.

•47u capacitor - bottom row, far right

•47u capacitor - top row, left

•1u capacitor - bottom row, right of centre

Preset resistors (Trimmers)

There are two trimmers, the 100K Resonance trimmer (marked “100K Res”) and the 10K clock

bleedthrough trimmer (marked “10K Bal”).The resonance trim is in the centre row, to the left of

the op-amps.The clock balance trimmer is top-right, next to the electric druid logo.

Second cup of tea and Power Test

Have a break. If you’ve got this far, you deserve it.Also, you need to be on top form for the next

part- testing the power.At this stage, you can power the board up and check the voltages with a

multimeter.There should be 9V power across pins 4 and 8 of each op-amp socket.There should be

5V power across pins 1 and pin 5 of the BBD socket and between pins 8 and 1 of the FLANGE

chip socket.

Check the soldering over one last time, since after you fit the pots, it’s a lot more difficult to get to

some of the PCB.

Potentiometers

Note that the pots mount on the back

(solder-side) of the PCB!

First, break the small anti-rotation tabs off

the pots with pliers.

Flangelicious Construction Guide

www.electricdruid.net

Page 4

Something is required to prevent the pots from shorting out the back of the PCB. Many things

work; all the way from expensive pot dust covers, to a couple of pieces of insulation tape stuck on

the back of the pots, to a piece of cardboard stuck between the board and the pots. My current

favourite solution is to cut a piece of stiff overhead transparency plastic and fit it between the PCB

and the pots. If you make holes in it for the legs of the pots to pass through, they hold it in place

once soldered and it can’t fall out.This is cheap (steal the plastic from work), simple (get a grown-

up to help you with the scissors), and effective (none have blown up yet).

Install ICs

If the voltage check was ok, you can install the four chips; two dual op-amps, the BBD, and the

Electric Druid FLANGE chip.

The PCB is done! Well done!

Drilling the enclosure

The PCB is designed to be mounted in landscape format in a Hammond 1590BB enclosure or

equivalent.The board is held in place by the pots.

Flangelicious Construction Guide

www.electricdruid.net

Page 5

Off-board wiring

This is the same for all pedals, pretty much.

There’s a power input, a stereo 1/4” jack which serves as the input and powers the pedal up when

something is inserted, a mono 1/4” jack for the output, and either a DPDT stomp switch, or a

3PDT stompswitch if you want an LED to show you the on/off status of the effect.

Different requirements will need different wiring, and there are many ways to arrange things, but

here’s a basic 3PDT layout with indicator LED.The LED resistor will need adjusting for your

particular LED.

Adjustments and final testing

Ok, it’s the moment of truth. Power it up and plug it in.With a bit of care and attention, you should

now have a working flangerlicious pedal! Let’s get it tuned up.

There are two trimmers on the PCB that need adjusting.The first is the resonance trim (“Res”).

Turn the resonance knob on the far right up to maximum. It’s possible that the pedal will start to

howl at you, but it’s more likely that nothing much will happen.Tweak the resonance trim until the

flanger starts to oscillate, and then back it off just a little. Or not, if you prefer. Up to you.

The other trimmer is the clock balance / bleedthrough trim (“Bal”).

Flangelicious Construction Guide

www.electricdruid.net

Page 6

If you have an oscilloscope (or a friend who does!) you can put the ‘scope probe on the test point

(marked “TP1” in the centre of the board) and adjust the trim for minimum clock bleedthrough. If

you don’t have an oscilloscope, you can do the same with a multimeter on a AC voltage range -

you should be aiming for 100mV or less.

You can also adjust the trim by ear.With no input signal (turn the guitar down to zero) turn the

amp up loud until you can hear the background noise, and then adjust the trim to minimize the

noise.

You’re done! Congratulations and enjoy your new pedal!

PS:We appreciate any feedback, suggestions, or thoughts you have about this pedal or any other Druid

project. Please get in touch through the website.Thanks!

Flangelicious Construction Guide

www.electricdruid.net

Page 7

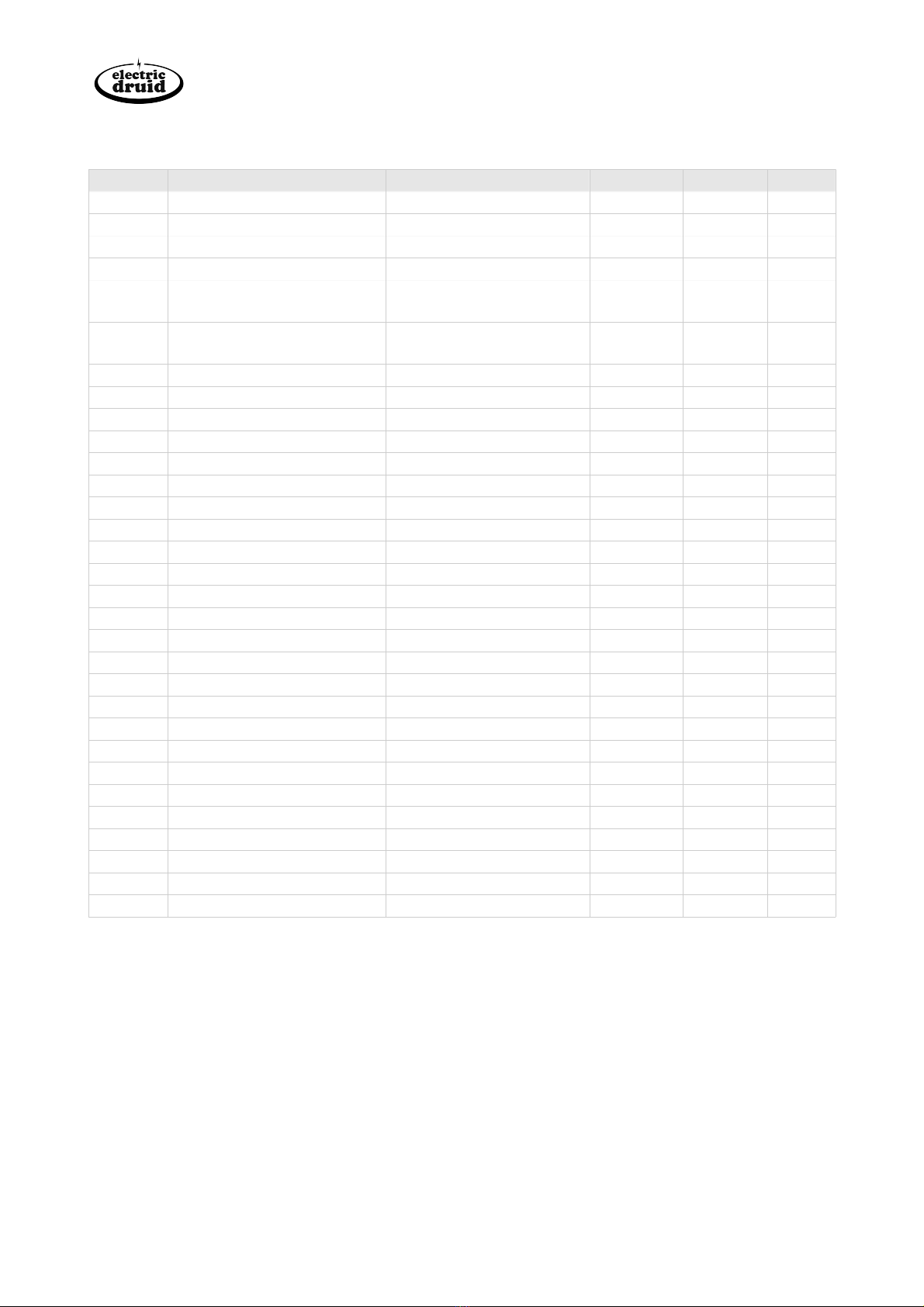

Bill of Materials

Order

Ref

Description

Value

Quantity

Done?

1

D1, D2

Signal Diode

1N4148

2

2

R1

1% Metal film resistor

1K

1

3

R2

1% Metal film resistor

1M

1

4

R3, R10, R12, R17, R28, R29

1% Metal film resistor

10K

6

5

R4, R6, R13, R14, R15,

R19, R22, R23, R26

1% Metal film resistor

100K

9

6

R5, R7, R8, R16, R21,

R24, R25

1% Metal film resistor

47K

7

7

R9, R11

1% Metal film resistor

24K

2

8

R18

1% Metal film resistor

12K

1

9

R20

1% Metal film resistor

3K3

1

10

R27

1% Metal film resistor

560R

1

11

D3

Rectifier Diode

1N4002

1

12

TL072, TL072, BBD, FLANGE

IC sockets

8-pin DIP

4

13

REG1

+5V Regulator

78L05

1

14

TR1

NPN Transistor

2N3904

1

15

C14, C17, C19

Ceramic capacitor

100n

3

16

C1, C2

Film capacitor

100n

2

17

C3

Film capacitor

1n

1

18

C4, C10

Film capacitor

150p

2

19

C5

Film capacitor

33n

1

20

C6, C8

Film capacitor

470p

2

21

C7, C9

Film capacitor

3n3

2

22

C11, C12, C15

Film capacitor

470n

3

23

C13

Electrolytic capacitor

1u

1

24

C16, C18

Electrolytic capacitor

47u

2

25

PR1

Preset (Resonance Trim)

100K

1

26

PR2

Preset (Balance Trim)

10K

1

27

VR1, VR2, VR3, VR4

16mm Pots

10K Linear

4

28

Unmarked

Pot dust covers or plastic

29

IC2, IC3

Dual audio op-amp

TL072

2

30

IC1

Bucket Brigade Delay

MN3209/07

1

31

uP1

PIC 12F1501

FLANGE

1

Additionally, you will need some/all of the offboard components listed on the

next page.

Flangelicious Construction Guide

www.electricdruid.net

Page 8

Offboard components

Note that the BOM above doesn’t include offboard components. These are a matter of taste, but

the basics are listed below.

•Enclosure, PCB fits Hammond 1590BB or Eddystone 29830PSLA

•Stereo 1/4”/6.35mm Input jack

•Mono 1/4”/6.35mm Output jack

•Stomp switch, DPDT or 3PDT if you want an LED indicator

•Power Input socket, 2.1mm

•LED + LED holder + appropriate resistor

•4 x Knobs

•Another switch for the ‘Tap’ option, if required (See “Adding more switches and options” on

Page 10).

Because of the current drain of this pedal, we don’t recommend using batteries instead of a power

adaptor. Ok, *maybe*, if you’ve got 9V rechargeables.

Component choices and substitutions

Very few of the components in the circuit are especially critical and a unit built with non-ideal

components will likely still work fine. However, in the interests of lowest noise, we recommend

you use 1% metal film resistors and good quality polypropylene or polyester film capacitors.The

board allows either 0.2”/5mm or 0.3”/7.5mm lead spacing for the film capacitors.

Transistor choice is not critical. Any medium gain, low noise NPN device will work.The board

expects a transistor with the EBC pinout, like the 2N3904. If you only have transistors with the

alternative CBE pinout like the BC547, you can fit the transistor back-to-front.

Similarly, op-amp choice is not critical. Choose any 8-pin dual audio op-amp with the standard

pinout.TL072, LF353, or MC1458 will all work. Many more audiophile options are also possible!

The PCB is laid out with

holes for various types of

trimmer resistor. Any of the

following layouts work fine.

Multi-turn trimmers are

recommended for fine

adjustment.

The power protection diode suggested is 1N4002. Pretty much any diode from this series is ok.

1N4001 will work, 1N4003 or 1N4004 are fine too, although total overkill.

The 1N4148 signal diodes can be replaced with other small signal silicon diodes. 1N914 is a direct

replacement and can be considered identical.Their role is to limit the signal to a level the BBD can

handle (and to provide a soft clipping if driven too hard), so the forward voltage is the most

significant parameter.

Flangelicious Construction Guide

www.electricdruid.net

Page 9

Ideas for potential upgrades or customizations

Adding CV inputs

Since the Electric Druid FLANGE chips operate using 0-5V control voltages like many other Druid

chips, it is possible to add CV control of the Frequency, Depth, or Rate controls.

Adding Expression pedal inputs

It is also possible to use an expression pedal in place of

the pots. If a normally-closed stereo/TRS jack socket is

wired in, the front panel control can be used when an

expression pedal is not inserted.

The typical expression pedal wiring is for the Sleeve to

be grounded, the Ring to carry the reference voltage,

and the CV return on the tip.The diagram shows how

this wiring relates to the PCB, the jack, and the pot.

However, this is not the only possible wiring,

and expression pedal may not be this way!

Don’t worry too much about this wiring. So long as you

only use passive expression pedals, you can’t hurt

anything, even if it’s completely wrong. If you get it back-

to-front before you get it the right-way-around, no

matter.

Both versions of the chip allow you to manually sweep

the flanger with the farthest-left control (Manual or

Rate). Connecting an expression pedal instead of this

control would give you a foot-pedal wah-style flanger.

Adding more switches and options

Both the MULTI FLANGE and the 4 KNOB FLANGE make use of the switch input marked “Tap”

on the PCB.This input should have a switch which connects it to ground.

The MULTI FLANGE chip offers the option of top-down or bottom-up flanging.The switch could

be a slide or toggle, or could be added as a footswitch.The switch should be latching.

The 4 KNOB FLANGE chip uses the “Tap” input to reset the waveform phase to zero.This allows

you to keep the flanger in time, or can be used as a special effect, since you get a downsweep after

you tap.This input needs a momentary switch, and might be most useful as a footswitch.

Flangelicious Construction Guide

www.electricdruid.net

Page 10

Table of contents

Other Electric Druid Music Pedal manuals

Popular Music Pedal manuals by other brands

ToneWorks

ToneWorks Toneworks Pandora PX4 Easy start

mxr

mxr Dookie Drive DD25V3 manual

Behringer

Behringer CHROMATIC TUNER TU300 user guide

Taurus

Taurus Vechoor black line operating manual

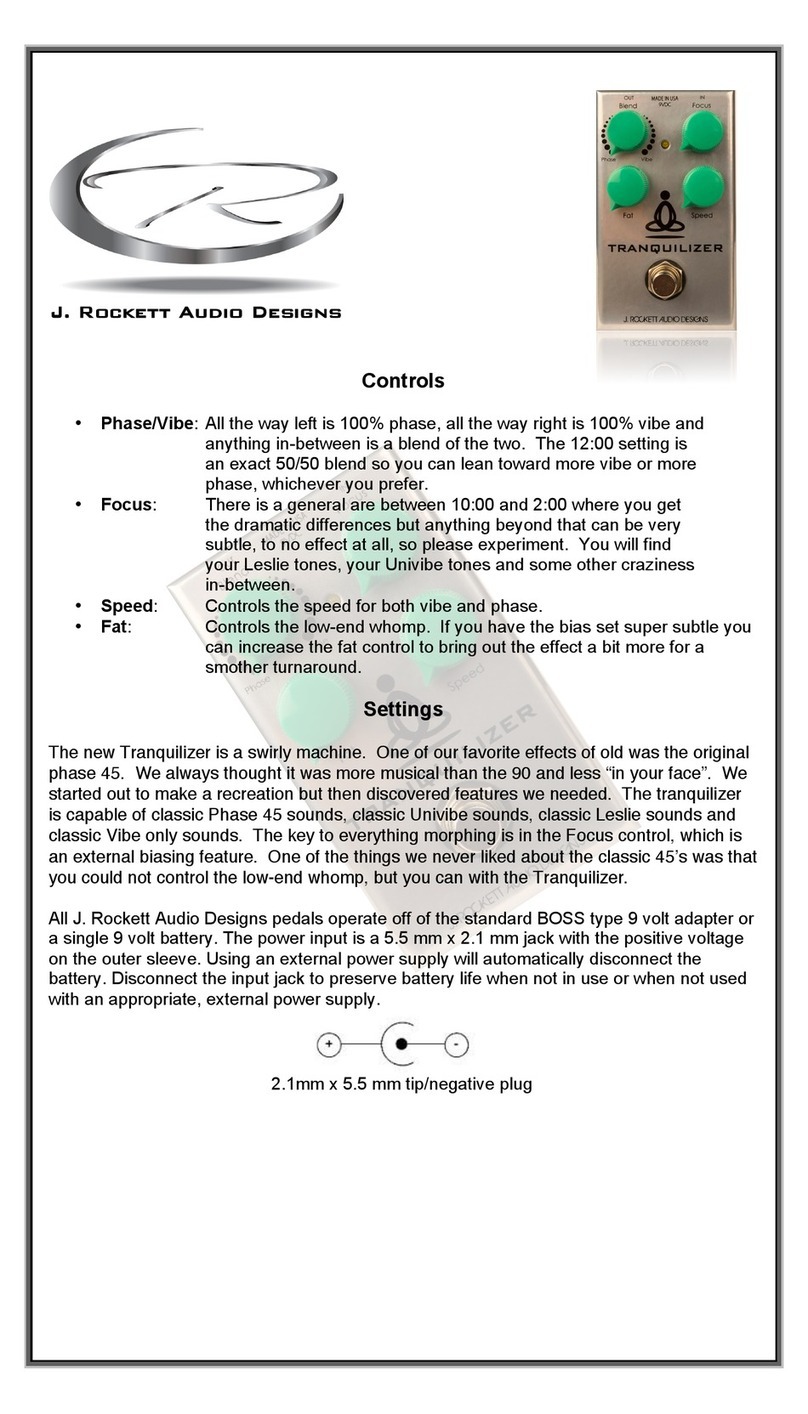

J. Rockett Audio Designs

J. Rockett Audio Designs Tranquilizer manual

Little Labs

Little Labs THE PEPPER Operator's manual