Electriq Power WND-WR-MB User manual

Quick Install Guide

for the Electriq Power

PowerMeter

Model Number:

WND-WR-MB

V. 043120

The Smart Home Battery Solution

IMPORTANT SAFETY WARNINGS

PLEASE READ ALL INSTRUCTIONS AND CAUTIONARY MARKINGS ON

THE UNIT AND THIS MANUAL BEFORE USING THE POWERMETER.

AND, STORE THIS USER MANUAL WHERE IT CAN BE ACCESSED EASILY.

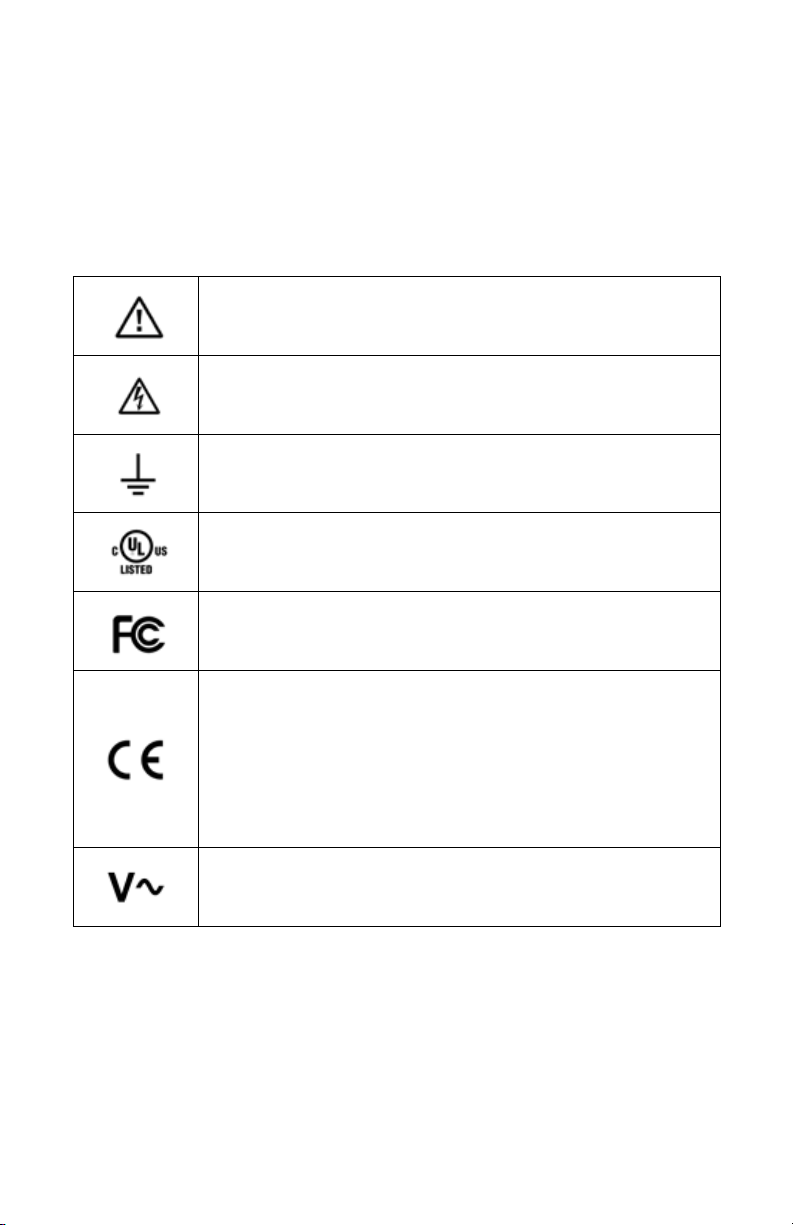

Safety Symbols

Read, understand, and follow all instructions

including warnings and precautions before

installing and using the product.

Potential Shock Hazard from Dangerous High

Voltage.

Functional ground; should be connected to earth

ground if possible, but is not required for safety

grounding.

UL Listing mark for U.S.A. and Canada.

FCC Mark. This logo indicates compliance with part

15 of the FCC rules.

Complies with the regulations of the European

Union for Product Safety and Electro-Magnetic

Compatibility.

• Low Voltage Directive – EN 61010-1:2010 (3rd Edition)

• EMC Directive – EN 61326-1:2006 Industrial Locations

This indicates an AC voltage.

1. Precautions

1.1 Symbols

• Only qualified personnel or licensed electricians should install

the PowerMeter. The mains voltages of 120 to 600 Vac can be

lethal!

• Follow all applicable local and national electrical and safety

codes.

Important Safety Warnings

Important Safety Warnings

• The terminal block screws are not insulated. Do not contact

metal tools to the screw terminals if the circuit is live!

• Verify that circuit voltages and currents are within the proper

range for the meter model.

• Use only CTs provided in the PowerMeter kit.

• Protect the line voltage conductors to the meter with fuses or

circuit breakers (not needed for the neutral or ground wires).

• Disconnect equipment from HAZARDOUS LIVE voltages before

access.

• If the meter is not installed correctly, the safety protections

may be impaired.

2. Overview

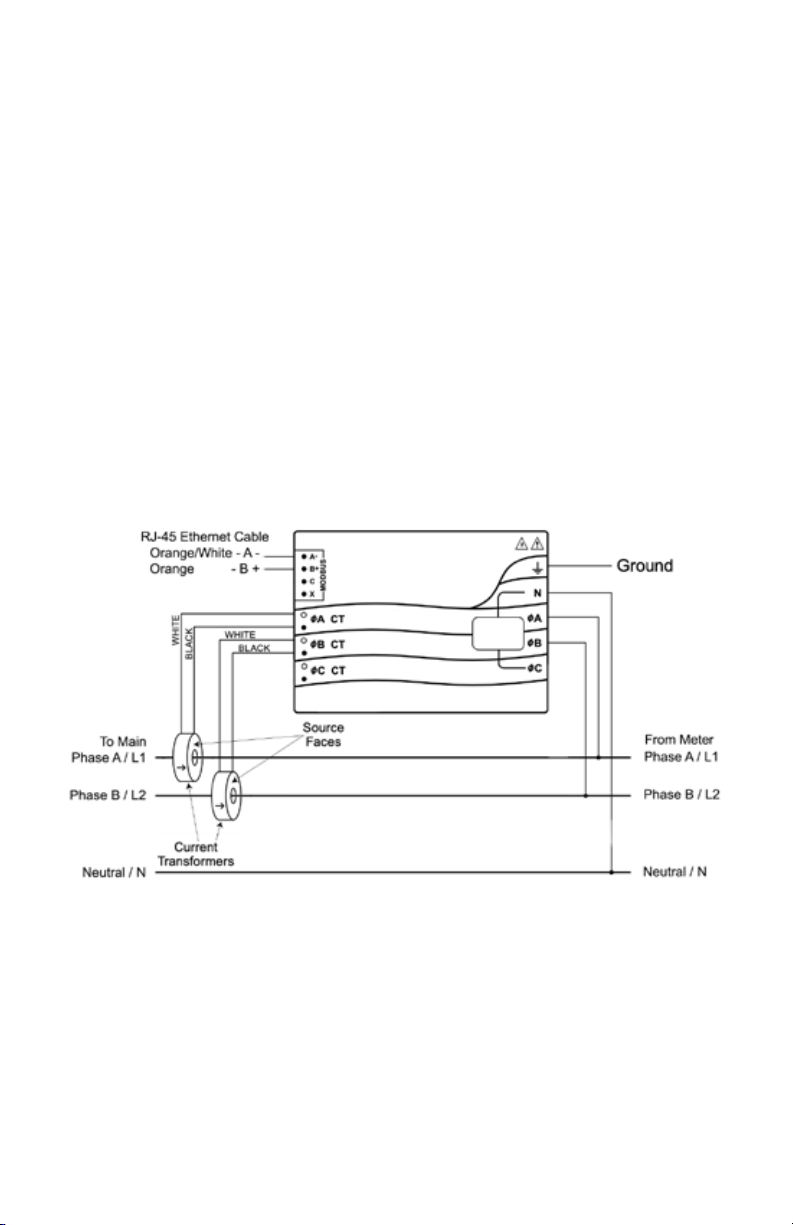

Figure 1: US Single-Phase Three-Wire with Neutral

3. Installation

3.1 Installation Checklist

See the sections referenced below for installation details.

qTurn o power before making line voltage connections.

qMount the meter (see 3.2).

qConnect circuit breakers or fuses and disconnects (see 3.3.1).

qConnect the line voltage wires to the meter’s green terminal

block (see 3.3.2).

qMount the CTs around the line conductors. Make sure the CTs

face the source (see 3.4).

qConnect the twisted white and black wires from the CTs to the

black terminal block on the meter, matching the wire colors to

the white and black dots on the meter label (s ee 3.4.1).

qCheck that the CT phases match the line voltage phases

(see 3.4).

qConnect the output terminals of the meter to the monitoring

equipment (see 3.5).

qCheck that all the wires are securely installed in the terminal

blocks by tugging on each wire.

qTurn on power to the meter.

3.2 Mounting

qProtect the meter from temperatures below –40°C (–40°F) or

above 75°C (167°F), excessive moisture, dust, salt spray, or other

contamination, using a NEMA rated enclosure if necessary. The

meter requires an environment no worse than pollution degree

2 (normally only non-con- ductive pollution; occasionally, a

temporary conductivity caused by condensation).

qThe meter must be installed in an electrical service panel or an

enclosure.

qDo not use the meter as a drilling guide; the drill chuck can

damage the screw terminals and metal shavings may fall into

the connectors. The meter has two mounting holes spaced

5.375 in. (137 mm) apart (center-to-center). These mounting

holes are normally obscured by the detachable screw terminals.

Remove the screw terminals to mark the hole positions and

mount the meter. Self-tapping #8 sheet metal screws are

included. Don’t over-tighten the screws, as long-term stress on

the case can cause cracking.

Installation

Installation

3.3 Connect Voltage Terminals

3.3.1 Circuit Protection

The PowerMeter is considered “permanently connected equipment”

and requires a disconnect means (circuit breaker, switch, or disconnect)

and overcurrent protection (fuse or circuit breaker).

The meter only draws 10-30 milliamps, so the rating of any switches,

disconnects, fuses, or circuit breakers is determined by the wire gauge,

the mains voltage, and the current interrupting rating required.

qThe disconnect or circuit breaker must be clearly marked,

suitably located, and easily reached.

qUse circuit breakers or fuses rated for 20 amps or less.

qUse ganged circuit breakers when monitoring more than one

line voltage.

qThe circuit breakers or fuses must protect the mains terminals

labeled ØA and ØB. In the rare cases where neutral has

overcurrent protection, then the overcurrent protection

device must interrupt both neutral and the ungrounded

conductors simultaneously.

qThe circuit protection / disconnect system must meet IEC 60947

1 and IEC 60947-3, as well as all national and local electrical

codes.

3.3.2 Line Wiring

qAlways turn o power before connecting the line voltage

inputs to the meter.

qFor the line voltage wires, Electriq Power recommends 18 to 12

AWG stranded wire, type THHN, MTW, or THWN, 600 V.

qUse copper conductors only. The screw terminals are only rated

for copper wire.

qDo not place more than one wire in a screw terminal; use

additional wire nuts or terminal blocks if needed.

The screw terminals handle wire up to 12 AWG. Connect each voltage

line to the green terminal block as shown in Figure 1 above. After the

voltage lines have been connected, make sure both terminal blocks are

fully seated in the meter.

Connect each line voltage to the appropriate phase; also connect

ground and neutral.

Installation

3.4 Connect Current Transformers

qWARNING: To reduce the risk of electric shock, always open or

disconnect circuit from power- distribution system or service of

the building before installing or servicing current transformers.

qUse only the CTs provided in the meter kit. They are matched

and configured for the meter. The CTs are not suitable for Class

2 wiring methods and must be treated as Class 1 wires.

qSecure each current transformer and route the lead wires so

that they do not directly contact live terminals or buses.

qDo not install current transformers where they would: 1) exceed

75 percent of the wiring space of any cross-sectional area within

the equipment, 2) would block ventilation openings, or 3) would

be in an area of breaker arc venting.

qBe careful to match the CTs with the voltage phases. Make sure

the ØA CT is measuring the current on the same phase being

monitored by the ØA voltage input, and the same for phase B.

Use the supplied colored labels or colored tape to identify the

CT leads.

qFind the source arrow or label “THIS SIDE TOWARD GRID”

on the CT and face/point toward the source of current.

Install the CTs around the conductor to be measured and connect the

CT leads to the meter as shown in Figure 1 above.

Split-core CTs can be opened for installation around a conductor. A

nylon cable tie may be secured around the CT to prevent inadvertent

opening.

CTs are directional. If they are mounted backwards or with their white

and black wires swapped the measured power will be negative.

3.4.1 CT Wiring

The current transformers connect to the six position black screw

terminal block. Connect the white and black CT wires to the meter

terminals marked ØA CT and ØB CT (see Figure 1 above). Excess

length may be trimmed from the wires if desired. Connect each CT with

the white wire aligned with the white dot on the label, and the black

wire aligned with the black dot. Note the order in which the phases are

connected, as the line voltage phases must match the current phases

for accurate power measurement.

Installation

3.5 Connect the Modbus Signals

qRoute the provided CAT6 cable (black 4-pin connector) from

the main panel / PowerMeter location to the inverter panel

(RJ-45 male end).

qReplace the existing USB/RS-485 cable that connects the

PowerHub to the inverter with the one provided in the

PowerMeter kit (add the RJ-45 coupler on the inverter side).

qPlug the RJ-45 male end of cable into the coupler on the USB

RS-485 cable that connects to inverter (see Figure 2).

qPlug the 4-pin black connector into the RS-485/Modbus

socket on the PowerMeter (see Figure 1).

3.6 Maintenance and Repair

The PowerMeter requires no maintenance. It is not user serviceable and

there are no replaceable parts except the pluggable screw terminals.

There are no diagnostic tests that can be performed by the installer.

In the event of any failure, the meter must be returned for service

(contact Electriq Power Support for an RMA at support@electriqpower.

com).

Figure 2: USB/RS485 cable with RJ45 connector and barrow

Inverter

www.electriqpower.com

14451 Catalina Street

San Leandro, CA 94577

Table of contents