3/8

TECHNICAL SPECIFICATIONS

STANDARDS

EN61000-6-4 Electromagnetic emissions, industrial environment.

EN61000-6-2 Electromagnetic immunity, industrial environment.

EN60950 Safety

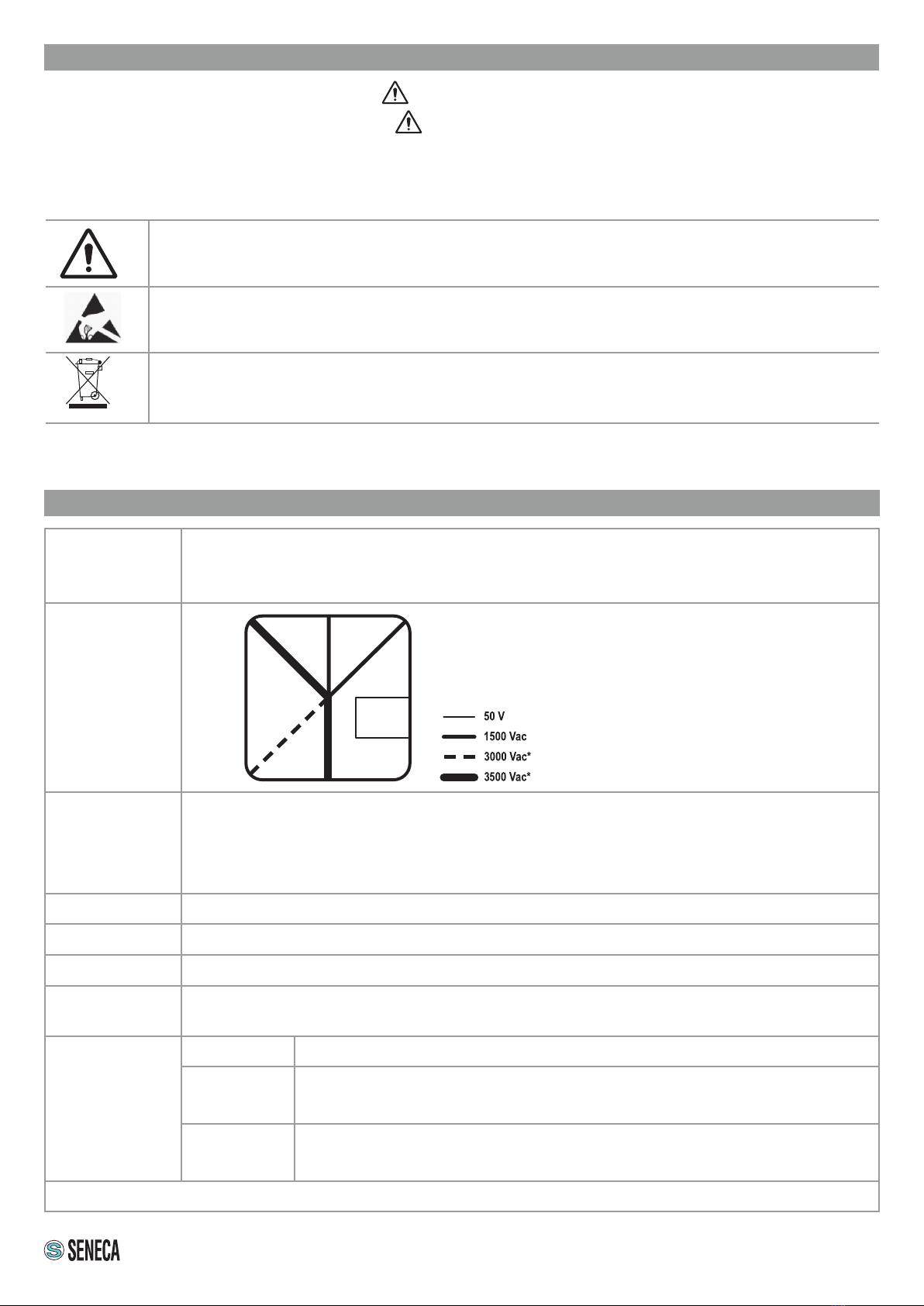

INSULATION

ENVIRONMENTAL

CONDITIONS

Temperature: -25°C ÷ +55°C

Humidity: 30% ÷ 90% non condensing.

Storage temperature: -30°C÷ + 85°C

Degree of protection: IP20

ASSEMBLY DIN rail 35mm IEC EN60715, wall or panel with screws.

CONNECTIONS Screw terminals 5 mm, 7.5 mm and 3.5 mm pitch (RS485), cable with section <2.5 mm2

POWER SUPPLY Voltage: 90 ÷ 264 Vac @ 50 ÷ 60 Hz, max. absorption 2.8 W, 5.4 VA

COMMUNICATION

PORTS

RS485: Baud rate: 1200 ÷ 115200 baud (for further information see the user manual).

USB: Micro-USB port for programming

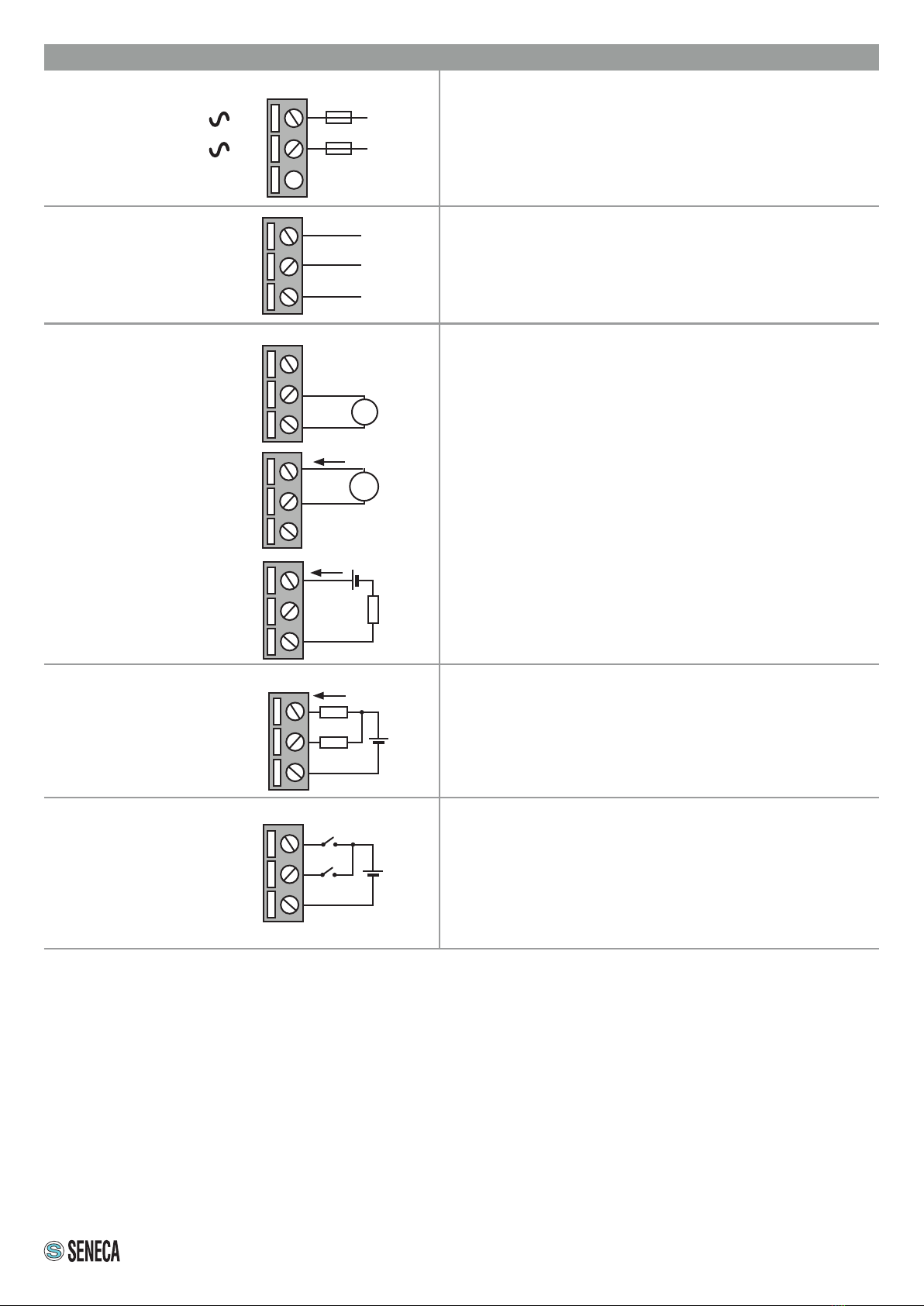

MEASUREMENT

INPUTS

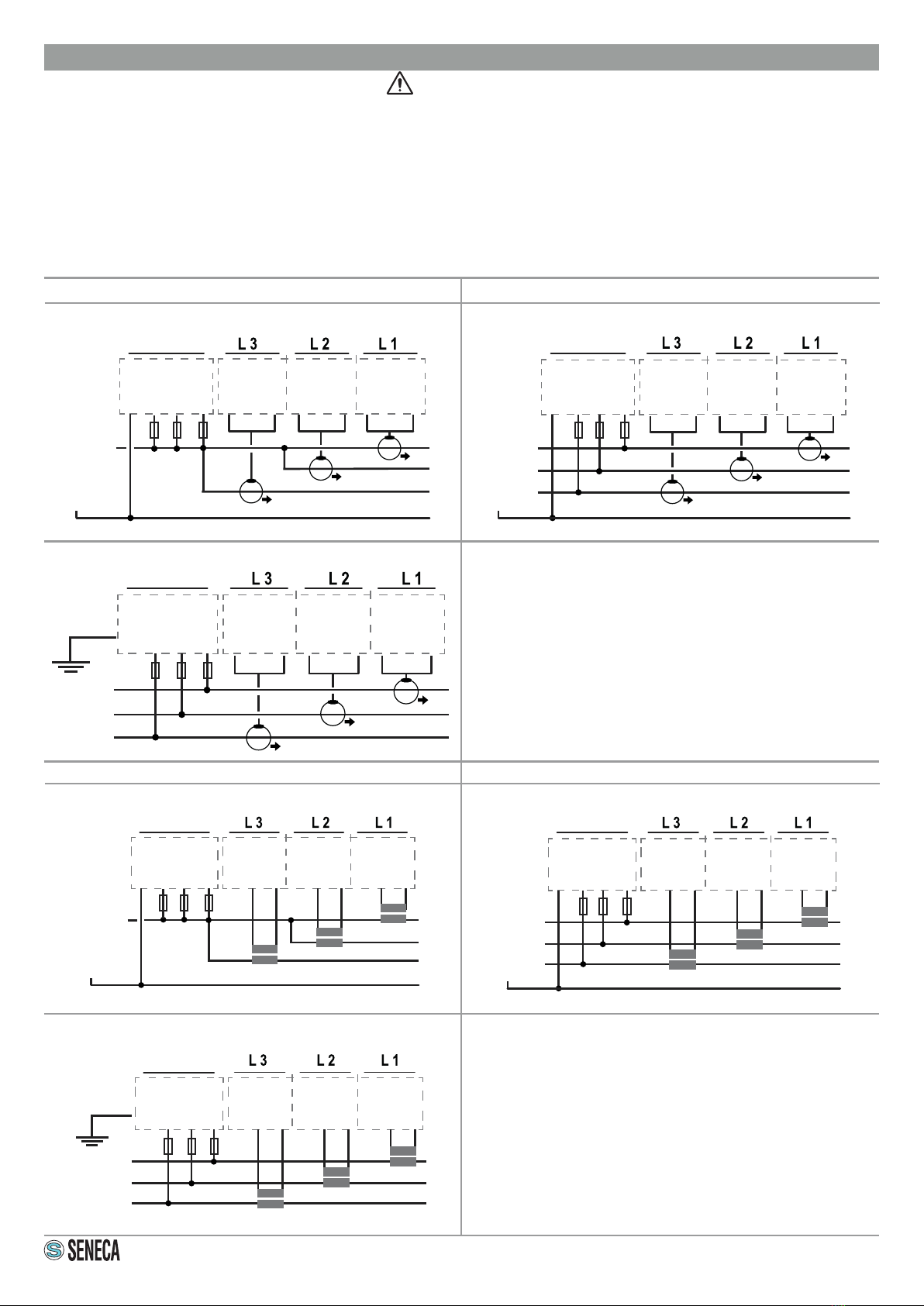

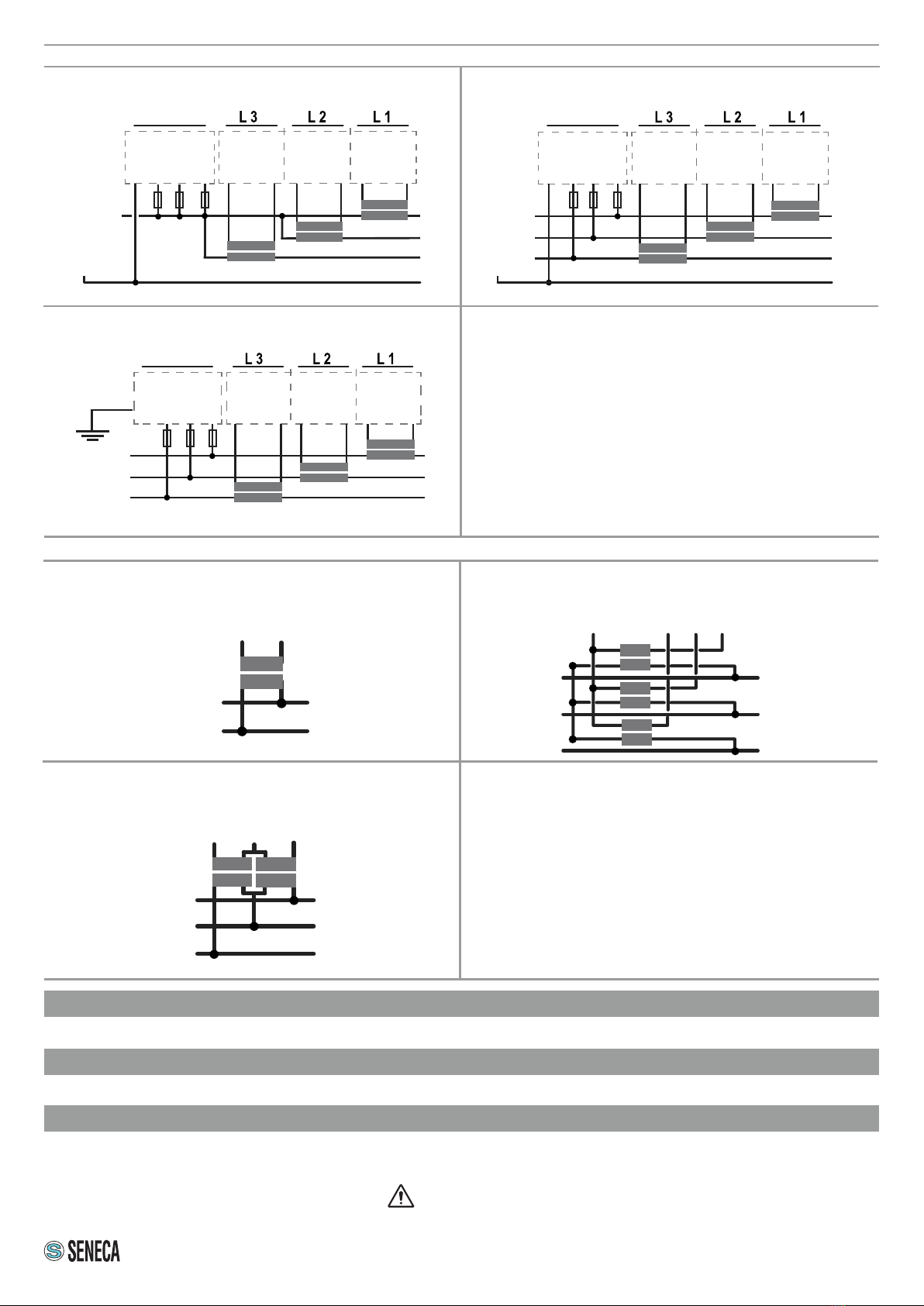

Voltage up to 600 Vac, frequency 45 ÷ 65 Hz

Current

Input

Current input for CT: 1 ÷ 5 Full scale.

voltage input (mV) for CT with voltage output or Rogowski: up to 333 mV full scale.

Base prec.

(*)

Network frequency: 50 ÷ 60 Hz. Voltmeter: 0.2 %

Ammeter: 0.2%, wattmeter: 0.5%

(*) See the user manual for the error limits.

WARNING: The full content of this manual must be read before any operation. The module must only be used by

qualied electricians. Specic documentation is available via QR-CODE shown on page 1.

Electrical and electronic waste disposal (applicable in the European Union and other countries with recycling).

The symbol on the product or its packaging shows the product must be surrendered to a collection centre

authorized to recycle electrical and electronic waste.

The module must be repaired and damaged parts replaced by the Manufacturer. The product is sensitive to

electrostatic discharges. Take appropriate measures during any operation.

PRELIMINARY WARNINGS

The word WARNING preceded by the symbol indicates conditions or actions that put the user's safety at risk.

The word ATTENTION preceded by the symbol indicates conditions or actions that might damage the

instrument or the connected equipment. The warranty shall become null and void in the event of improper use or

tampering with the module or devices supplied by the manufacturer as necessary for its correct operation, and if

the instructions contained in this manual are not followed.

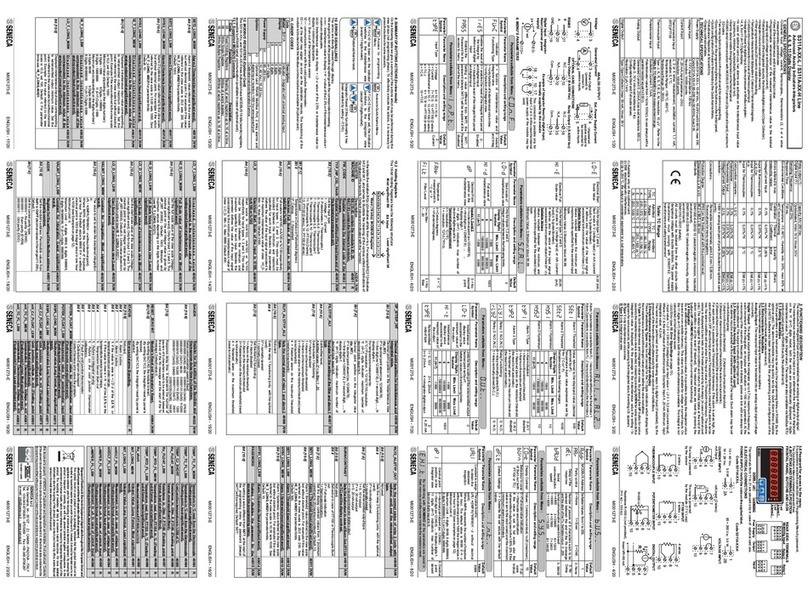

ETH1

LAN

ETH2

WAN

PWR USB

RS485

DIGITAL

I/O

ANALOG

INPUT

ANALOG

OUTPUT

* (Rated withstand voltage)