Electro Industries HP-BTC Manual

02/22/2012 HI114

Electro Industries’

Buffer Tank Controller

Installation & Operating Instructions

Models HP-BTC, HP-BTC-24

Application

Correctly controls and balances up to 8 hydronic heating

zones plus 1 heating/cooling forced air water coil.

Supplies heat/cool “call” to Northern Heat Pump

geothermal systems, Electro Industries’ NorAire®system,

or any manufacturer’s Water to Water geothermal heat

pump.

This product conforms to UL standard 873

This product conforms to CSA Standard C22,2

Drawings: HX101

HH120

HH121

XX017

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR

FUTURE REFERENCE BY A SERVICE TECHNICIAN.

02/22/2012 HI114

Table of Contents

Introduction 1

Safety Considerations 1

Product Configurator 2

Electrical Data 2

Installation Overview 3

Installation and Hookup 3

Controller Setup 6

V2.00 Setup/Programming 12

Buffer Tank Operation 16

Troubleshooting 19

Drawings HX101

HH120

HH121

XX017

02/22/2012 1 HI114

Introduction

The use of a buffer tank and controller is an important part of most water-to-water or air to water heat pump

applications, particularly if a combination of a forced air coil and hydronic zones are utilized. Choosing the

right buffer tank controller is important, as the correct controller can make a big difference in efficiency and in

the smooth operation of the entire heat pump system. Electro Industries’ Buffer Tank Controller utilizes many

features you won’t find on most controllers. Outdoor reset (the sensing and utilization of the outdoor

temperature to determine tank target temperature), easy set-up, dual fuel system interfacing and solid design are

just a few of the features you will appreciate in this controller.

Other Features:

Control forced air water coils plus up to eight hydronic zones with one controller

Digital or Standard Thermostat Compatible

Fuse Protected, Control Board and Zone Valve Connections

Onboard LED troubleshooting lights indicate stat calls and pump power for each individual zone

Remote Data Communication between the hydronic board and buffer tank controller

All pumps powered from the controller simplifies wiring

Model HP-BTC features 120VAC outputs.

Model HP-BTC-24 features 24VAC outputs

Compatibility:

Although most of the drawings in this manual represent Northern Heat Pump North Star Series heat pumps, this

buffer tank controller can be easily incorporated into any manufacturers’ water to water heat pump system.

Heating/Cooling

The Buffer Tank Controller will satisfy heat calls utilizing a forced air water coil (if present) and the hydronic

water loops. The controller will satisfy a chilled water call (cooling) using the forced air coil loop only. The

Buffer Tank Controller will not send chilled water through the hydronic loops.

Initial Inspection

Be certain to inspect all cartons and crates as units are received before signing the freight bill. Verify that all

items received have no physical damage. Report any damage or shortages on the freight bill. The purchaser is

responsible for filing the necessary claims with the carrier. Concealed or hidden damages not discovered until

removing packaging must be reported to the carrier within 15 days of receipt.

Unit Location and Mounting

Locate the unit on a dry indoor wall near the buffer tank. There are 4 mounting holes in the rear of the Buffer

Tank Controller cabinet. Using proper fasteners (not provided), utilize these mounting holes to secure the

cabinet to the wall of the structure.

Safety Considerations

WARNING

BEFORE PERFORMING SERVICE OR MAINTENANCE OPERATIONS ON A SYSTEM, TURN

OFF MAIN POWER SWITCHES TO THE INDOOR UNITS. IF APPLICABLE, TURN OFF THE

ACCESSORY HEATER POWER SWITCH. ELECTRICAL SHOCK COULD CAUSE PERSONAL

INJURY.

Installing and servicing heating and air conditioning equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service personnel should install, repair or service heating and

air conditioning equipment. When working on heating and air conditioning equipment, observe precautions in

the literature, tags and labels attached to the unit and other safety precautions that may apply, such as the

following safety measures:

Follow all safety codes.

Wear safety glasses and work gloves.

02/22/2012 2 HI114

Product Configurator

HP-BTC-*

None = 120V

24=24V

Electrical Data

Model Voltage Static Amps

Maximum Load

Amps* Maximum Source

HP-BTC 120 0.20 9.8 15

HP-BTC-24 24 0.1 0.77 5.0

*Application/field installation determines zone controlling components activated by this controller.

02/22/2012 3 HI114

Installation Overview

This controller contains interface/logic devices, a buffer tank (BT) sensor, and an outdoor temperature (OT)

sensor. Based on the application, many other system components may be required to make your system operate

as desired. These components must be provided by the installing contractor. These components may include

but are not limited to:

- a geothermal or air-to-water heat pump

- a listed buffer tank

- water coil(s) and blowers (in the case of a forced air system)

- system pumps

- expansion tank and air eliminator

- hydronic valves and piping

- thermostats

- wiring

- transformer

- pump relays

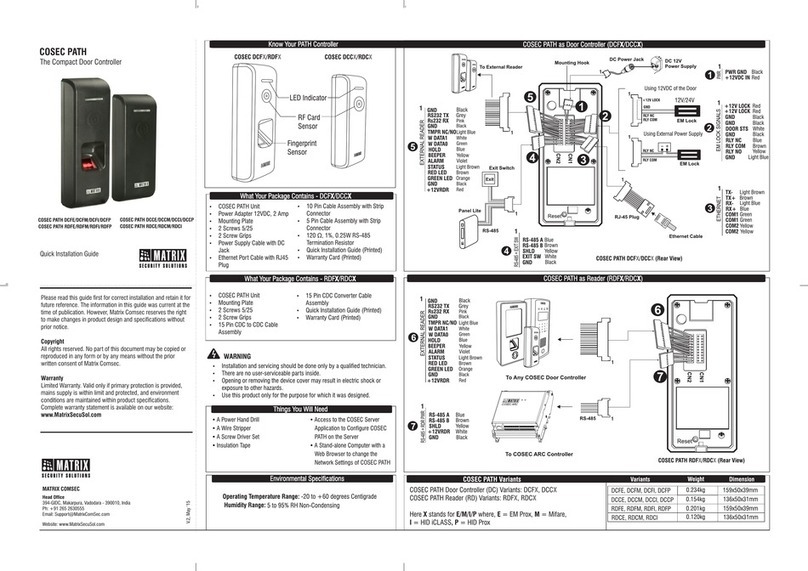

Refer to the HX101 diagrams in this manual which show various system configurations.

Installation and Hookup

Controller Power

A detailed hookup drawing (HH120) is included in this manual. A qualified electrician should perform all high-

voltage wiring tasks on this unit.

120V hookup – Model HP-BTC

120 VAC with a minimum of 10 amps of dedicated power is required to power the Electro Industries Buffer

Tank Controller model HP-BTC. We recommend wiring this product in such a way that power comes directly

from the power panel to the terminal block located inside of the lower half of the buffer tank controller

enclosure. Various “knockouts” in the controller’s enclosure are included for your use and convenience. Do not

apply power to the unit until full installation is complete.

24V Hookup – Model HP-BTC-24

The HP-BTC-24 unit will not include a transformer. The controller requires 24VAC from another power source

(heat pump, air handler, gas furnace or boiler) to power the control boards internal to the Buffer Tank

Controller. In this scenario, the zone output block will output 24VAC meaning all pumps will require one

isolation relay per pump.

Multiple System Transformers

In some installations, multiple transformers exist (such as in the furnace or air handler, heat pump, and others) in

the HVAC system. Refer to the installation manuals for these products to determine if multiple transformer

compatibility issues may occur.

IMPORTANT: MULTIPLE TRANSFORMERS IN THE SAME HVAC SYSTEM ARE KNOWN TO CAUSE

SYSTEMS TO MALFUNCTION. PLEASE REFER TO THE HOOKUP DIAGRAMS AT THE END OF THIS

MANUAL FOR THE CORRECT HOOKUP CONFIGURATION FOR YOUR PARTICULAR SYSTEM.

Note: • Model HP-BTC does include a transformer

• Model HP-BTC-24 does not include a transformer

This manual does include detailed suggested wiring for all instances with regards to low voltage wiring.

Fuses

The circuit boards and all external field connections/wiring are fuse protected with a self-resetting 3-amp fuse.

Gas furnace – if this is a “dual fuel” installation including a gas or oil backup furnace, only two wires are

required between this controller and the gas furnace. It is assumed the gas furnace logic will control its own

02/22/2012 4 HI114

blower based upon a gas-W heating call.

Gas or Electric Boilers – Only two wires are required between this controller and the auxiliary boiler. It is

assumed the boiler’s logic will control its own pumps based upon a gas-W heating call.

Thermostats

In all applications, there will be a necessity to interface thermostats for hydronic heating zones. There is also a

possibility that the HVAC system design will include a requirement to service forced air load. If this is the case,

there will be a requirement for hydronic thermostat hookup and forced air thermostat hookup. Below is

information on required thermostats for each heating system type.

Note: If no forced air load exists within the make up of this HVAC system, disregard the comments on forced

air hookup.

Forced Air Thermostat Information

1. To service the forced air coil loop, this Buffer Tank Controller requires a conventional heat/cool,

1H/1C, 4-wire thermostat. This thermostat will connect to the upper right hand corner of the logic

controller terminal labeled “STAT”.

2. In all forced air applications, a connection must be made between all thermostat terminals – R,W,G,Y

Hydronic Thermostat Hookup

1. Connect the slab stat or temperature sensing thermostat wires coming from the hydronic zones to the top

terminal block “R” and the numbered “W” terminal block located on the zone control circuit board. If

using Electro-Stat, a “Common” is required at each Electro-Stat. Connect the thermostat serving the

forced air coil loop to the “stat” terminal block located on the control board. Drawings included in this

manual show typical hookups for various thermostats. Connect per your selected thermostat.

2. If using hydronic priority feature, zone 1 and connected stat 1 must be the priority zone.

3. This buffer tank controller is not compatible with power robbing thermostats.

Thermostat Heat Anticipator/CPH Setting

If your thermostat has an anticipator setting, set the anticipator to 0.2 or less. If your thermostat has a “cycles

per hour” setting, set it to 2 cycles per hour.

02/22/2012 5 HI114

Buffer Tank Sensors:

Included with this buffer tank controller are two sensors. One buffer tank sensor (BT) and one outdoor sensor

(OT). The Outdoor Sensor (OT) and the buffer tank temperature (BT) sensor are wired into a common

connection plug. Below is instruction and a description of each:

Outdoor Sensor (OT)

Extend OT sensor to an outdoor location properly sampling the outdoor

temperature. Select a location away from direct sunlight and where the sensor

will not pick up false temperature from the heat pump outdoor unit, refrigerant

line sets, dryer vent, reflection off of steel siding, etc. Do not install the sensor

in any type of enclosure, as this will falsely trap and pick up radiant sun

temperature. Mount the sensor horizontally on the structure using the screws

provided.

Buffer Tank Temperature (BT) Sensor

Install the Buffer Tank Temperature (BT) Sensor in the buffer tank. To obtain an accurate temperature sample,

the sensor should be placed in the center of the tank. If the temperature sensor is being installed in an Electro

Industries buffer tank, the location of the tank fittings ensure the sensor is properly located. For easy sensor

cable disconnect and reconnect, the control board is equipped with a plug-in 4-place terminal block.

Temperature Sensor Plug

Before disconnecting the temperature sensor wires from the sensor plug, you will notice two red wires are under

the red screw and two white wires is under the COM screw. The black wire carries data information from each

sensor and must be connected to the appropriate OT (Outdoor Temperature) or ST (Buffer Tank Temperature)

screw. The sensor has a specific polarity and is sensitive to incorrect voltage, so it must be protected from

incorrect voltages. Do not cross connect or inadvertently short out sensor wires with power on. Permanent

sensor damage may result. If the installation requires you to disassemble and reassemble the wiring to the plug,

take great care duplicate the original wiring exactly.

Other Sensor Related Comments

If additional cable length is required, you must use the following rules for extending the cable.

• Use unshielded (low capacitance, preferred twisted) 3 or 4-wire low voltage cable.

• 50 (15 meters) feet is maximum (total) wire length.

• Do not, under any circumstances, use leftover wires within the normal thermostat cable.

• Route the sensor cable making sure you do not crimp, cut, staple, or damage the cable in any way.

• Keep sensor cables at least 12” (30 cm) away from any line voltage wiring, romex, etc.

Controller Setup

02/22/2012 6 HI114

Circuit Boards

Inside the Electro Industries Buffer Tank Controller’s cabinet, you will find 3 circuit boards:

1. Located on the hinged door is the system controller board which makes all logic decisions as well as

interfaces the heat pump, standby heat source (if applicable) and forced air room thermostat (if

applicable)

2. A small relay circuit board, which interfaces and controls the main pump and A-Coil Pump, is located

on the side panel.

3. A larger zone control board which interfaces the hydronic zone thermostats and zone pumps is located

on the rear of the cabinet.

All system adjustments will take place on the system controller circuit board.

02/22/2012 7 HI114

UNDERSTANDING OUR TERMINOLOGY REGARDING “ZONES” – IN AN ATTEMPT TO CLEARLY

DESCRIBE THE FUNCTION AND FEATURES OF THE BUFFER TANK CONTROLLER, THIS MANUAL REFERS

TO THE FORCED AIR WATER COIL LOOP AND THE HYDRONIC HEATING ZONES AS SEPARATE

APPARATUSES. WE DO NOT CONSIDER THE FORCED AIR COIL A “ZONE”.

Function of the Buffer Tank During Heat Calls vs. Chilled Water Calls

The hydronic zones are enabled in heating mode only. The hydronic zones will not respond to a “Y” (cooling)

call from the thermostat. The cooling function will be performed by the forced air water coil only.

NOTE: Not all installations will have a cooling load.

Zoning Pumps – HP-BTC

1. The 120-volt source for the zone pumps is derived from the same external 120V source used to power

the transformer. Therefore, the board connectors labeled “OUPUT” are energized (L1) and ready to be

used with zone pumps.

2. The “common” connections of each zone pump are tied together back to neutral on the zone control

board.

3. Pump circuits are protected with a 10-amp use located on the zone control board.

Zone Valves – HP-BTC-24

1. The 24VAC source for the zone valves is derived from the same external 24VAC source used to power

the transformer. Therefore, the board connectors labeled “OUPUT” are energized (24VAC) and ready to

be used with zone valves

2. The “common” connection of each zone valve are tied together back to common on the zone control

board.

Hydronic Zone Priority – Zone 1 Only

Located on the top right corner of the hydronic zone controller is a switch labeled “priority”. With priority

switch in the ON position, all heating resources are dedicated to hydronic zone 1. The remaining hydronic

zones, along with the forced air coil, are operational only when hydronic zone 1 is satisfied.

Note that during priority mode, furnace G is interrupted and no heat is being delivered to the forced air coil

during active hydronic zone 1 heat demand. With the priority switch in the “off” position, all zones plus the

forced air coil are considered equal.

Forced Air Priority Timer

The right-hand side of the system control board has a set of jumper pins labeled SW8. The jumper is engaged as

it ships from the factory. Used “as is”, the forced air water coil is treated the same as a hydronic zone during the

heating season. Removal of this jumper will initiate the start of an internal timer whenever the control board

receives a heat call from the forced air thermostat. At the conclusion of the timer period, the Buffer Tank

Controller will stop service to all hydronic zones in order to allocate 100% of the buffer tank resources to the

forced air coil for the remainder of the forced air call. The timer may be adjusted with the use of a PC computer.

Special software and a dedicated data cable are required to accomplish this. The “Buffer Tank Controller

software” and cable are available from Electro Industries. With the use of this software, the timer may be

adjusted anywhere from 30 to 90 minutes. The timer is set to 60 minutes from the factory.

02/22/2012 8 HI114

Tank Temperature Dial (Front Cover)

Located on the front cover of the buffer tank controller’s cabinet is a dial designed for the end user to adjust the

system’s comfort and efficiency levels during the heating season. The tank temperature can be controlled on

one of two ways – one with “outdoor reset” and one without (set point). When in the LO, MED, or HI

positions, the buffer tank controller utilizes “outdoor reset”, or outdoor temperature data to optimize and

determine the water supply target temperature. See the graph below which shows how the outdoor reset

function works.

Alternately, when the dial is set to the “SET POINT” position, the controller ignores the “outdoor reset”

function and targets the following set points as dictated by the Warm Air Dial:

Set point position (default pos. 3)

0 – 85° F

1 – 90° F

2 – 95° F

3 – 100° F

4 – 105° F

5 – 110° F

NOTE: Due to a feature known as “Maintain Tank Target Less Than OT”, the outdoor sensor must be

installed in all applications regardless of front dial setting.

Standby Switch

Located on the front of the Electro Industries Buffer Tank Controller is a two-position switch that can be used to

manually disable the system’s heat pump and utilize the system’s backup heat source only. When in the “up” or

STANDBY position, the heat pump will never be active for either heating or cooling purposes.

Enable/Disable Switch

Located on the front of the Electro Industries Buffer Tank Controller is a two-position switch that can be used to

turn the controller off, disabling the heat pump and buffer tank controller features. If the controller standby

switch is in the “up” position, the system’s boiler or furnace will remain active even if the controller if disabled.

02/22/2012 9 HI114

On-board Controller Dials

On the right-hand side of the controller board, you will find a series of dials which must be set correctly during

the initial set-up. The dial settings are designed to make the buffer tank, and, in turn, the entire HVAC system

operate as efficiently as possible. The graphic below will help you identify each dial and understand each dial’s

function. The dial operations are explained more thoroughly in elsewhere in this manual.

Forced Air Priority Jumper – Removal of this

jumper gives priority to the forced air coil over the

heating zones if the stat is not satisfied at the

conclusion of the pre-set time period. (p.)

Mode Dial - Selects the operational mode of the

system. This is dictated by the type of HVAC

components present and active in the system.

Switchover Temp Dial – During the heating

season, this dial determines the outdoor

temperature at which the heat pump is disabled

and the backu

p

heat source takes over.

(p

.

)

Warm Air Dial – When the “Tank Temperature

Dial” on the front of the cabinet is in the “Set Point”

position, this dial determines the set point

tem

p

erature.

(

see below

)

Stat Override Timer – This dial starts a timer,

which, at the timer expiration, initiates various

actions based on Mode and outdoor temperature.

02/22/2012 10 HI114

Mode Switch

Mode A – Non-standby mode. The entire heating and chilled water load will be serviced by the

heat pump only.

Mode B – Fossil fuel furnace standby mode. Use mode B when a standby (backup) fossil fuel

forced air heat source is present. This is the proper mode if your system will be using a forced air

furnace as a backup to take advantage of utility interrupt (off-peak) programs. When the system is

in “standby” condition (which can happen because of utility company interrupt or if the outdoor

temperature falls below the SW OVER setting), all hydronic zones are non-functional.

Mode C – Auxiliary boiler standby mode. Use mode C when a gas or electric boiler is present as a

standby heat source. The boiler will utilize the buffer tank target temperature. This setting may be

used with utility interrupt (off-peak) programs.

Mode D – Dedicated to Electro Industries’ NorAire®air source heat pump boiler system.

Switchover Temperature (SW OVER)

This switch is shipped from the factory with a square “GAS” label. This label should be removed ONLY if a

secondary furnace or boiler is present and active in the system and the Mode Switch is set to “B” or “C”. The

installer should remove the label and adjust this switch only after reading this manual and understanding the

operation of the switch. Select the desired OT (Outdoor Temperature) where the heat pump is to be shut down

and the backup furnace is to be utilized. Even though this dial is only utilized when a gas furnace / boiler is in

the system, we recommend setting this dial to “0” position (disable) in modes 1 and 4. From the factory, this

switch is set to 0 (disable).

0 = Disable 4 = 5° F

1 = -15° F 5 = 10° F

2 = -10° F 6 = 20° F

3 = 0° F 7 = 30° F

Stat Override Timer (SOT)

The intent of the SOT Dial is to take care of very unusual heat/cool conditions or building matching situations,

the general sequence relating to OT temperature should take care of proper thermostat cycling without ever

reaching SOT timeout (end). Thus, it is recommended the SOT be a high number. The SOT is a “per call”

timer, and is reset as soon as the heat or cool call is satisfied.

0 = 30 minutes 2 = 180 minutes

1 = 90 minutes (default) 3 = 270 minutes

Buffer Tank Controller Dial Configurations

Below is a list of different configurations the Buffer Tank Controller system can be adapted to and the matching

appropriate Buffer Tank Controller settings. This section is in regards to possible heating source configuration,

interfacing and dial selection

Heat pump only

• Mode Dial: A

• SW Over Dial: 0

• SOT Dial: 0=30min 1=90min 2=180min 3=270min

Heat pump with fossil fuel furnace

• Mode Dial: B

• SW Over Dial: 0

• AUX EL: 0

• SOT Dial: 0=30min 1=90min 2=180min 3=270min

• Thermostat type: Conventional 1H/2C

02/22/2012 11 HI114

Heat pump with fossil fuel boiler

• Mode Dial: C

• SW Over Dial: 0

• SOT Dial: 0=30min 1=90min 2=180min 3=270min

Undersized heat pump with electric boiler

• Mode Dial: C

• SW Over Dial: 1=-15°F/ 2=-10°F/ 3=0°F/ 4=5°F/ 5=10°F/ 6=20°F/ 7=30°F

• SOT Dial 0=30min 1=90min 2=180min 3=270min

Heat pump with emergency electric boiler

• Mode Dial: C

• SW Over Dial: 0

• SOT Dial: 0=30min/ 1=90min/ 2=180min/ 3=270min

Undersized heat pump with fossil fuel boiler

• Mode Dial: C

• SW Over Dial: 1=-15°F/ 2=-10°F/ 3=0°F/ 4=5°F/ 5=10°F/ 6=20°F/ 7=30°F

• SOT Dial: 0=30min 1=90min 2=180min 3=270min

Undersized heat pump with fossil fuel furnace

• Mode Dial: B

• SW Over Dial: 1=-15°F/ 2=-10°F/ 3=0°F/ 4=5°F/ 5=10°F/ 6=20°F/ 7=30°F

• SOT Dial: 0=30min 1=90min 2=180min 3=270min

Electro Industries’ NorAire®Heat Pump Boiler

• Mode Dial: D

• All other dials disabled

02/22/2012 12 HI114

V2.00 Setup/Programming

Included with this Buffer Tank Controller is the Buffer Tank Controller PC software (CD and cable). The

software on the CD allows for the adjustment of many of the functions of the buffer tank controller. Below is a

screen shot of all factory defaults, which can be adjust to allow for better system operation for your application.

The installer should verify the correct parameters, see the CD HELP file.

This is the basic information section for the PC CD program. It is not necessary to perform all steps at this time.

When the appropriate sections appear in Prestart-up, Start-up, or Troubleshooting revert back to the following.

02/22/2012 13 HI114

1. The flat cable connector is plugged into the Logic controller J4 header connector. By looking at the end

of the cable female you will notice one pin has a dummy plug. Observing the logic controller board pins

you will notice there is one pin missing. This is the keying pin when inserting the cable flat connector.

2. Power must be on the Logic controller board, green LED on.

3. Plug the cable into the PC USB connector.

4. Load in the CD software. The screen should look like the image below.

5. Keyboard – Alt R, monitor field should be filled.

a. 2 temperature values

b. OT Temperature Heating - HI.

c. OT Temperature Heating - LO.

d. OT Temperature Cooling - HI.

e. BT Differential

f. Cool Mode Target.

g. Maintain Tank Temperature Less Than OT.

h. Coil Priority Time

i. W Call – Safety Run Time

j. Zone Call – Safety Run Time

k. HP 2 stage

l. Cool

m. Cool

n. Heat Mode Target Temperature

o. Buffer Tank Controller Software Version

6. Pull down the communication tab and observe the various functions.

a. Write is required to download any changes. Write downloads the complete screen and all

values, whether you change them or not.

b. Troubleshooting are convenience functions, see Troubleshooting section.

7. Read HELP file.

Description of software settings:

° F or ° C

This determines whether Fahrenheit or Celsius is used. When changing between these two you will notice

any temperature range will also change but any temperature entries made or uploaded from the board will

not change, you must make sure the entries are within the new range before writing the data back to the

board.

Special notes:

Temperature Conversions

Under the "Help" menu there are two conversion selections, ° F to ° C and ° C to ° F. When you select one

of these the conversion window opens up. Enter the temperature you desire to convert in the top box. Click

on the "Convert" button or press the "Enter" key to see the result in the bottom box. You can enter a

decimal number to convert but the result will be rounded to a whole number. Example: If converting ° F to

° C, and 45.6° F is entered, the result will be 8° C (actual value is 7.555555...). Because this window will

stay displayed, until you click on the "Exit" button or press the "Esc" key, you can move back and forth

between the conversion window and the main window.

Outdoor (OT) and Buffer Tank (BT) Offsets

Enter an offset to be added to or subtracted from the temperature read from the sensor. Example: To enter a

5 degree lower offset, enter: - 5.

02/22/2012 14 HI114

Outdoor (OT) and Buffer Tank (BT) Temperatures

These are the “read only” values read from the sensor and adjusted with their offsets. They are updated only

when a Read Data (Alt+R) is performed.

Note: This can be monitored, along with the Target Temperature, by selecting Monitor Data (Alt+M)

from the Communications menu.

OT Temperature Heating - HI

This setting is applicable with two stage heat pumps only. The purpose of this setting is to allow for the

heat pump to enter into second stage heating based on outdoor temperature.

System sequence:

• Outdoor temperature < OT Temperature Heating –HI = Stage one of the heat pump will be on upon

heat call from room thermostat. Stage two heat pump will turn on as a function of timeout (SOT TIME

DIAL)

• Outdoor temperature > OT Temperature Heating – HI = Stage two heat pump is on upon initial heat

demand.

Factory default is 20°F.

OT Temperature Heating - LO

This function is not applicable and should be ignored

OT Temperature Cooling - HI

This setting is applicable with two stage heat pumps only. The purpose of this setting is to allow for the

heat pump to enter into second stage cooling based on outdoor temperature.

System sequence:

• Outdoor temperature < OT Temperature Cooling – HI = Stage one of the heat pump will be on upon cool

call from room thermostat. Stage two heat pump will turn on as a function of timeout (SOT TIME DIAL)

• Outdoor temperature > OT Temperature Cooling – HI = Stage two heat pump is on upon initial cool

demand.

Factory default is 90°F.

BT Differential

After a heating or cooling demand has been initated, this temperature is used to develop an operating range

at which the actual tank temperature will be kept. The smaller the value the “tighter” the tank temperature

will be. The larger the number, the “wider” the operating temperature will be. This must be set with

application and heat pump cycling in mind.

Cool Mode Target

After a thermostat cooling call has been iniated, the buffer tank sensor will be referenced and compared to

this value. If the tank temperature is greater than or equal to this temperature, the buffer tank controller will

signal to the heat pump to begin cooling. If it is less than this value, the tank temperature will be considered

ideal for cooling mode operation and the heat pump will not be turned on.

Maintain Tank Target Less Than OT

This function determines the outdoor temperature at which the buffer tank controller will go into a “hot

tank” temperature mode. When in heating mode and above this value, the heat pump will not turn on unless

there is an active demand for heat from a room thermostat, regardless of buffer tank temperature. When

below this outdoor temperature, the buffer tank controller will work to maintain a “hot tank” and maintain

tank set point regardless of room thermostat demand.

Coil Priority Time

02/22/2012 15 HI114

This timer function allows for a means of providing a forced air priority over all hydronic zones. The value

entered is used for the timer which starts with the forced air thermostat. Once this timer expires, the

hydronic load is interrupted and the buffer tank energy is dedicated fully in an attempt to satisfy the forced

air coil demand. Once the forced air thermostat has been satisfied, the hydronic zones can again receive

heat energy from the buffer tank. The timer will begin once again on the next forced air thermostat heat

call.

NOTE: The COIL PRIORITY jumper must be removed to activate this timer.

Factory default is 60 minutes

W Call - Safety Run Time (SOT)

During a forced air heat call, there is potential for issues to arise within the heating system that are

undetectable via the buffer tank sensors. An example would be an incorrectly calibrated sensor. A timer

known as “W Call – Safety Run Time (SOT)” is used to detect such an issue. If this timer expires before

the heat call is satisfied, the buffer tank controller will go into an error mode delivering a portion of heat to

the space. The HP-Y1 output is also cycled ON/OFF every 15 minutes. HP-Y2 output is turned off.

Factory default is 90 minutes

Zone Call - Safety Run Time (SOT)

During a hydronic zone heat call, there is potential for issues to arise within the heating system that are

undetectable via the buffer tank sensors. An example would be an incorrectly calibrated sensor. A timer

known as “Zone Call – Safety Run Time (SOT)” is used to detect such an issue. If this timer expires

before the heat call is satisfied, the buffer tank controller will go into an error mode delivering a portion of

heat to the space. The HP-Y1 output is also cycled ON/OFF every 15 minutes. HP-Y2 output is turned off.

Factory default is 240 minutes

HP 2 Stage

This informs the controller if the system heat pump is the 2-stage type. Select 'YES' or 'NO'.

Cool This is in regards to the forced air heating and cooling aspect of the HVAC system focusing on the

operation of the “coil pump”. The coil pump operates as such:

Upon heating or cooling call from the forced air thermostat:

• If the buffer tank (BT) temperature is greater than or equal to 60°F (16°C) and less than or equal to

80°F (27°C), the coil pump is disabled.

• If the BT temperature is outside of this range the coil pump is enabled.

Heat Mode Target Temperature:

This is the temperature the program is maintaining in the buffer tank when in a heating mode.

• If the front panel 'TANK TEMPERATURE DIAL' switch is in the SET POINT position, the target

temperature is determined by the 'WARM AIR' switch setting.

• If the 'TANK TEMPERATURE DIAL' switch is in position HI, MED or LO, the target temperature is the

internally calculated value from the actual OT, this switch setting, and the WarmFlo ramp-up curve.

Buffer Tank Controller Software Version

This is the current board software version and the mode the board is in.

The MODE dial switch is read only on a power up.

02/22/2012 16 HI114

Front LED Indicator Lights

The LED indicator lights on the front cover allow for fast, easy

identification of real time system conditions.

• Green PWR – solid = normal, 24VAC power

• 1 blink, bad BT sensor

• 2 blinks, bad OT sensor

• Status

• On = electric mode

• Off = standby (SB) or switchover

• Fast pulsing = Geo unit ICM board fault

• Slow pulsing = cool mode

• Fast pulsing with green LED off = mode switch

incorrectly set

• HP-STAGE1

• On = logic board is actively calling for heat pump stage 1

• Off = no requirement for heat pump stage 1 exists

• HP-STAGE2

• On = logic board is actively calling for heat pump stage 2

• Off = no requirement for heat pump stage 2 exists

• Thermostat (forced air only)

• On = room thermostat actively calling (heating or cooling)

• Off = no room thermostat demand

• STANDBY

• On = system is actively calling for backup heating source

• Off = system is in heat pump mode

Front panel stand-by/ electric switch (Mode B and C Only) – allows the user to condition the system to

select an energy source. This can be used for repair or troubleshooting of the furnace or simply “Power of

Choice” selection.

Enable / Disable switch – In some applications, it is advantageous to lockout the heat pump in times when it

use will not be required. Example would be cooling season with no cooling load in the HVAC system.

• With the switch in enable, the heat pump is enabled to operate based on room thermostat.

• With the switch in disable, the heat pump is disabled.

Buffer Tank Operation

Buffer Tank Turn-Over

One of the challenges involved in the operation of a hydronic buffer tank system is the inability to quickly and

efficiently change the system over from a heating system to a cooling system and vice versa.

During the buffer tank turn-over, the coil pump is disabled if water in the buffer tank is between the

temperatures of 60°F and 80°F.

Air Stat W and Y Collision

To eliminate the possibility of simultaneous, conflicting signals, a 7 second delay is active after the completion

of a W or Y call. At the completion of the delay, the controller can once again accept W oar Y calls.

IMPORTANT: It is important for the end user to understand that after the heating season, the first “Y” (cooling) call

switches the system to the cooling mode, beginning the process of lowering the temperature of the fluid in the buffer

tank. Likewise, the first “W” after a series of “Y” calls sets in motion the sequence for heat or hot water. Since this

“buffer tank turn-over” requires a substantial amount of energy, the frequency of this operation should be held to a

minimum.

02/22/2012 17 HI114

Heating

Hydronic

Whenever a “W” (heat) call is received from a hydronic zone, the corresponding “OUTPUT” lug on the zone

controller circuit board is energized with source voltage (see comments under the “Installation and Hookup”

section of this manual). When the Tank Temperature Sensor indicates a temperature is not at the desired levels,

the system controller sends a compressor on (Y OUT) call to the Geo unit, signaling the geo unit to start and the

main pump to turn on.

Forced Air

When the air stat servicing the forced air coil loop sends a “W” call, it starts the forced air coil pump (BT >

80°F) and furnace/air handler blower (F-G). When the coil pump is plumbed as shown on HH120, the buffer

tank fluid must be circulated through the geo with the use of the main pump. The Buffer Tank Controller

software ensures that whenever the coil pump is required, the main pump is on as well (not applicable in “B”

mode).

Chilled Water (cooling)

During the water chilling operation, the zone controller and zone pumps are inactive. When the buffer tank is

being chilled, the OT (outdoor temperature) sensor is utilized to determine if a 2-stage heat pump will operate

in “stage 1” or “stage 2”. The OT sensor is not utilized to adjust the target tank temperature during chilled

water operations. Rather, the temperature inside the tank is maintained at a certain set point. From the factory,

this set point is 50°F (Operational differential is 4° F) but can be adjusted anywhere from 40°F to 60°F with the

use of a PC computer and the appropriate software. The cooling operation requires a “Y” signal from the

thermostat servicing the forced air coil loop. When this happens, the buffer tank controller outputs a “Y” to the

heat pump. It also outputs an “O” to the heat pump signaling the heat pump’s reversing valve to reverse

refrigerant flow. If the heat pump is a 2-stage unit, first stage cooling (Y1) will be the usual operating condition.

The buffer tank system controller will only send a second stage cooling call (Y2) to the heat pump if unusual

conditions occur, such as:

1. The outdoor temperature is greater than 90° F

2. The expiration of SOT timeout if the outdoor temperature is less than 90° F

3. During buffer tank heat-to-cool “turnover” if the tank temperature is warmer than 60° F

See the attached charts for a further explanation of how the controller reacts under different operating

conditions.

Efficiency Feature Pertaining to an Idle System

Without a room-thermostat initiated call for heat, the Buffer Tank controller will allow the buffer tank

temperature to fall below the target temperature if the outdoor temperature is above a designated temperature

(See: Maintain Tank Target Less Than OT). This can allow for greater system efficiency during moderate

outdoor temperatures. The factory-set designated temperature where this feature is allowed is 10° F. However,

using the appropriate software (available from Electro Industries) this temperature can be adjusted up or down

as desired.

System Pump discussion:

A-Coil Pump and Main Pump: B & C Mode Only

This paragraph relates to the main pump and A-Coil pump relationship during standby mode operation.

In the case of mode B, the standby heat source is a fossil fuel furnace, therefore neither the main pump nor the

A-Coil pump are allowed to operate during standby mode operation (no water is being heated).

In the case of Mode C, the standby heat source is an auxiliary boiler, therefore both the A-Coil pump and the A-

coil pump will operate if there is a requirement for the A-Coil pump (forced air demand and BT > 80°F). This

functionality in mode C allows for proper operation in regards to suggested plumbing shown on HH120.

02/22/2012 18 HI114

Hydronic Zone Pumps or Valves: Mode B

The application for mode B is water to water geothermal heat pump and fossil fuel furnace (backup). Therefore

when the system is operating in standby (fossil fuel furnace), all zone pumps or valves are disabled due to the

fact that no water is actively be heated.

Circulating Zone Pump Exerciser

To reduce the chance of the circulating zone pumps seizing due to long periods of inactivity (summer time), the

circulating pumps will run for 30 seconds if they have not been run in the last seven days.

Special Notes in Regards to Modes:

Mode A Special Notes:

Mode A application is designed for heat pump only systems where no other form of system heating exists (fossil

fuel furnace or auxiliary boiler). Therefore there is no function as it relates to interruptible rates from the power

company (LMC) in the heating mode (no stand-by source). Cooling mode interrupt functions as detailed in this

manual.

Additional notes:

-SW OVER dial is not used and should be set to (0).

-All other dials are applicable in this setup and should be set accordingly as per described in the manual

Mode B Special notes:

Mode B application is heat pump in conjunction with a back up or standby forced air fossil fuel furnace.

Therefore, when in stand-by mode there is no means of heating the space via the hydronic heating. It is assumed

in the engineering of this device that forced air would be the predominant means of heating in the space in this

application due to no hydronic heating ability in standby mode. Special care must be taken with this concept in

design with regards to standby operation.

Example: It must be realized that when the SW OVER dial is “set” in this mode, there will be no hydronic

heating below set balance point. The same is true for power company interrupt rates as well as front over ride

switch.

Additional Notes:

-All dials are applicable in this setup and should be set accordingly as per described in the manual

-No SOT to fossil fuel exists within this controller

Mode C Special Notes:

Mode C application is heat pump in conjunction with an auxiliary boiler. Therefore when in stand-by mode both

hydronic heating and forced air heating is taken care of by the auxiliary boiler, buffer tank and buffer tank

controller combination.

In Mode C the auxiliary boiler could be an electric boiler backup (Electro Industries Boiler) or a fossil fuel

boiler. This should be noted in applications that include power company interruptible rates. This is because the

logic within the Buffer Tank Controller can not distinguish between the two boilers (gas vs. electric) and

therefore simply sends out a heat demand signal (W) upon demand from hydronic zones or forced air loop. If it

is desired to include an electric boiler in this type of application, the installing contractor must devise a means of

controlling both the electric boiler and the Buffer Tank Controller (SPDT relay).

Additional Notes:

-All dials are applicable in this setup and should be set accordingly as per described in the manual

-No SOT to auxiliary boiler exists within this controller

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Toshiba

Toshiba Prosec T-Series Operation manual

Zenty

Zenty ZT-117 user manual

EME

EME FINCOR 2230 MKII Series Equipment manual

ICP DAS USA

ICP DAS USA Compact Embedded Controller LinPAC-8x41 Hardware user manual

Mitsubishi

Mitsubishi MELSEC iQ-F FX5-4AD-TC-ADP Hardware manual

Koganei

Koganei FRZB Series manual