Electro motive EMD 645 User manual

NAVAL

FACILITIES

ENGINEERING

SERVICE

CENTER

Port

Hueneme,

California

93043-4370

USER

GUIDE

UG-2022-ENV

USER

GUIDE

FOR

CONVERSION

TO

DUAL

FUEL

OPERATION

OF

EMD

645

ENGINES

ON

NAVY

MUSE

GENERATOR

SETS

by

Norman

L.

Helgeson,

Ph.D.

Scott

E.

Jensen,

Eugene

Conversions,

Inc.

Allen

E.

Willey,

POl

Delbert

Terrell,

P02

Dave

Vawter,

POl

Michael

Childers,

POl

March

1997

Sponsored

by

Naval

Facilities

Engineering

Command

19970825

130

DTIG

QUALITY

INSPECTED

S

Approved

for

public

release;

distribution

is

unlimited.

^\

Printed

on

recycled

paper

REPORT

DOCUMENTATION

PAGE

Form

Approved

OMB

No.

0704-018

Public

reporting

burden

for

this

collection

of

information

is

estimated

to

average

1

hour

per

response,

including

the

time

for

reviewing

instructions,

searching

existing

data

sources,

gathering

and

maintaining

the

data

needed,

and

completing

and

reviewing

the

collection

of

information.

Send

comments

regarding

this

burden

estimate

or

any

other

aspect

of

this

collection

information,

including

suggestions

for

reducing

this

burden,

to

Washington

Headquarters

Services,

Directorate

for

Information

and

Reports,

1215

Jefferson

Davis

Highway,

Suite

1204,

Arlington,

VA

22202-4302,

and

to

the

Office

of

Management

and

Budget,

Paperwork

Reduction

Project

(0704-0188),

Washington,

DC

20503.

1.

AGENCY

USE

ONLY

(Leave

blank)

2.

REPORT

DATE

March

1997

3.

REPORT

TYPE

AND

DATES

COVERED

Final

4.

TITLE

AND

SUBTITLE

USER

GUIDE

FOR

CONVERSION

TO

DUAL

FUEL

OPERATION

OF

EMD

645

ENGINES

ON

NAVY

MUSE

GENERATOR

SETS

5.

FUNDING

NUMBERS

6.

AUTHOR(S)

N.L.

Helgeson,

Ph.D,

S.E.

Jenson

(Eugene

Conversions,

Inc.),

A.

Wiley,

D.

Terrell,

D.

Vawter,

and

M.

Childers

7.

PERFORMING

ORGANIZATION

NAME(S)

AND

ADDRESSE(S)

Naval

Facilities

Engineering

Service

Center

1100

23rd

Ave

Port

Hueneme,CA

93043-4370

8.

PERFORMING

ORGANIZATION

REPORT

NUMBER

UG-2022-ENV

9.

SPONSORING/MONITORING

AGENCY

NAME(S)

AND

ADDRESSES

Naval

Facilities

Engineering

Command

Chief

of

Naval

Operations

200

Stovall

Street

2000

Navy

Pentagon

(Code

N45)

Alexandria,

VA

22332-2300

Washington,

DC

20350-2000

10.

SPONSORING/MONITORING

AGENCY

REPORT

NUMBER

11.

SUPPLEMENTARY

NOTES

12a.

DISTRIBUTION/AVAILABILITY

STATEMENT

Approved

for

public

release;

distribution

is

unlimited.

12b.

DISTRIBUTION

CODE

13.

ABSTRACT

(Maximum

200

words)

Conrversion

of

the

Navy's

Mobile

Utilities

System

Equipment

(MUSE)

diesel

generators

to

dual

fuel

(natural

gas

plus

diesel

fuel)

operation

to

reduce

their

NOx

(nitrogen

oxide)

emissions

is

described.

The

Navy

maintains

a

fleet

of

60

such

units,

powered

by

EMD

645

engines,

that

range

in

size

from

1,500

kW

to

2,500

kW.

A

means

for

providing

low-NOx

MUSE

generators

that

will

not

compromise

the

operational

capability

of

the

fleet

is

required.

This

guide

is

based

upon

the

experience

gained

from

converting

a

1,500

kW

MUSE

unit

to

dual

fuel

operation

(the

unit

is

currently

installed

and

operating

at

King's

Bay

Naval

Station

in

Georgia).

Information

on

the

conversion

process,

operation,

maintenance,

and

the

cost

of

the

dual

fuel

conversion

are

provided.

14.

SUBJECT

TERMS

Diesel

generators,

MUSE,

dual

fuel

conversions,

low-NOx

emissions,

EMD

645

engines,

and

natural

gas

operations.

15.

NUMBER

OF

PAGES

166

16.

PRICE

CODE

17.

SECURITY

CLASSIFICATION

OF

REPORT

I

Unclassified

18.

SECURITY

CLASSIFICATION

OF

THIS

PAGE

Unclassified

19.

SECURITY

CLASSIFICATION

OF

ABSTRACT

Unclassified

20.

LIMITATION

OF

ABSTRACT

UL

NSN

7540-01-280-5500

Standard

Form

298

(Rev.

2-89)

Prescribed

by

ANSI

Std.

239-18

EXECUTIVE

SUMMARY

Steps

are

described

for

converting

the

Navy's

Mobile

Utilities

System

Equipment

(MUSE)

diesel

generators

to

dual

fuel

(natural

gas

plus

diesel

fuel)

operation

to

reduce

their

NOx

(nitrogen

oxide)

emissions.

The

Navy

maintains

a

fleet

of

60

such

units,

powered

by

EMD

645

engines,

that

range

in

size

from

1500

kW

to

2,500

kW.

As

the

current

MUSE

diesel

units

meet

few

existing

local

NOx

emission

regulations,

newer

more-restrictive

regulations

(a

trend

now

ensured

with

the

proposed

further

tightening

of

the

National

Ambient

Air

Quality

Standards)

will

ensure

that

the

areas

accessible

to

MUSE

diesel

generators

will

continue

to

decrease.

Therefore

a

means

for

providing

low-NOx

MUSE

generators

that

will

not

compromise

the

operational

capability

of

the

fleet

is

required.

This

guide

is

based

upon

the

experience

gained

from

converting

to

dual

fuel

operation

a

1500

kW

MUSE

unit

that

is

now

installed

and

operating

at

the

King's

Bay

Naval

Station

in

Georgia.

Information

on

the

conversion

process,

operation,

maintenance

and

the

cost

of

the

dual

fuel

conversion

are

provided.

NOx

emission

reductions

of

70

percent

were

demonstrated

with

this

unit;

NOx

reductions

of

greater

than

90.

per

cent

are

achievable

using

an

additional

secondary

ignition

cell.

Capital

requirements

for

the

retro-fit

dual

fuel

conversion

of

a

2500

kW

MUSE

engine

generator

are

shown

to

be

$158.

per

kilowatt

(including

the

secondary

ignition

cells).

This

is

compared

to

the

cost

of

replacing

this

same

MUSE

unit

with

a

new

spark-ignited,

low-NOx,

natural

gas

engine.

The

cost

for

the

latter

is

$560.

per

kilowat.

For

a

2500

kW

MUSE

unit,

these

numbers

translate

into

a

capital

savings

of

over

$1.0

million

if

the

option

of

retro-fitting

for

dual

fuel

operation

is

chosen.

Operating

costs

for

dual

fuel

(natural

gas)

operation

of

MUSE

generating

sets

are

also

substantially

reduced

over

that

of

unmodified

diesel

operation.

For

the

case

evaluated,

the

cost

for

natural

gas

firing

is

4.1

cents

per

kW-hr

while

that

for

diesel

firing

is

8.9

cents

kW-hr.

A

further

major

operational

(strategic)

advantage

of

the

retro-fit

dual

fuel

unit

over

that

of

a

new,

spark-ignited,

natural

gas

engine

is

that

it

can

be

made

to

operate

as

either

a

full

diesel

or

a

full

natural

gas

unit.

DTIC

QUALFiT

ESBPi30'.i.'iSD

3

in

ACKNOWLEDGEMENTS

XT

,?

S

.

?

r0jeCt

WaS

fonded

by

the

Pollution

Abatement

Ashore

Progam,

managed

by

the

Naval

Facilities

Engineering

Command,

and

sponsored

by

the

Environmental

Protection

Safety

and

Occupational

Health

Division

(N45)

of

the

Chief

of

Naval

Operations.

This

project

would

not

have

been

possible

without

able

assistance

of

many

people

A

technically

challenging

aspect

of

the

project

was

automation

of

the

controls

which

was

required

to

ensure

the

safe

handling

of

natural

gas

within

the

engine

house.

Master

Chief

Petty

Officer

(retired)

Ronald

Kluender's

intimate

knowledge

of

the

original

MUSE

control

system

and

Scott

Jensen

s

thorough

understanding

of

the

ECI

dual

fuel

conversion

engine

control

unit

(ECU)

made

possible

the

successful

integration

of

those

two

control

systems.

John

Pesar

Program

Manager

for

MUSE,

made

available

a

1,500

kW

MUSE

engine

generator

set

to

serve

as

the

prototype

and

approved

use

of

MUSE

personnel

to

assist

with

the

conversion

to

dual

fuel

operation.

MCPO

Russell

Dominy,

MCPO

Jim

Riley,

POl

Anthony

Fourage,

and

POl

Rodney

Hood

also

assisted.

J

WAVS??

Keene

n

0

f

L

S

UBASE

Kin

§'

s

Ba

y

P

rovi

ded

a

field

test

site

along

with

funds

from

NAVSEA

to

install

the

dual

fuel

unit

at

King's

Bay.

He

and

Bill

Strickland

arranged

for

installation

of

the

unit

there,

oversaw

its

operational

schedule,

and

provided

a

strong

presence

in

resolving

field

operational

problems.

Their

assistance

was

invaluable.

Ralph

Kerwin

of

Gage

£

A°^C?

Safety

COnsuItants

)

heI

P

ed

t0

defi

"e

hardware

and

procedures

for

safely

operating

he

MUSE

engine

generator

while

using

natural

gas.

Kevin

Beaty

of

Southwest

Research

Institute

(SwRI)

recognized

the

potential

value

of

the

results

of

this

project

to

the

efforts

to

GasRail,

Inc

for

developing

lo-NO

x

engines

for

locomotive

use,

and

provided

flowrate

measuring

and

data

logging

instrumentation

for

the

project.

Jack

Smith

and

Butch

Quip

of

SwRI

installed

that

instrumentation.

_

George

Warren

and

Ed

O'Neil

of

NFESC

provided

structural

recommendations

for

the

installation

and

mounting

of

a

new

compressor

and

water

pump.

Wayne

Tanaka

of

the

Natural

Gas

Vehicle

Division

of

the

Southern

California

Gas

Company

(SCGC)

made

special

arrangements

for

weekend

use

of

the

SCGC

compressed

natural

gas

tanker

along

with

a

high-

capacity

pressure

reduction

manifold

and

the

personnel

to

operate

them

for

shakedown

tests

Manny

Perez,

Bob

Saunders,

Ken

Hanzlick,

and

Galen

Marks

of

NFESC

gave

up

their

weekends

to

assist

with

measurements

during

the

shakedown

tests.

pS

CONTENTS

Page

1.0

INTRODUCTION

1-1

1.1

Environmental

Compliance

and

Navy

Need

1-1

1.2

Selection

of

NO

x

Control

Technology

1-2

1.3

Installation

and

Testing

of

Prototype

Dual-Fuel

MUSE

Diesel

Generator

1-2

1.4

Organization

of

the

Guide

1-3

2.0

NO

x

REDUCTION

FOR

LARGE,

TWO-STROKE

DIESEL

ENGINES

2-1

2.1

Exhaust

Gas

Treatment

2-1

2.2

NO

x

Reduction

From

EMD

645

Dual-Fuel

Engines

2-2

2.3

Further

Rduction

of

NO

x

Emissions

2-3

3.0

ELEMENTS

OF

THE

ECI/EMD

DUAL-FUEL

CONVERSION

3-1

3.1

Natural

Gas

Fuel

3-1

3.2

Dual

Fuel

Characteristics

3-1

3.3

Engine

Operating

Sequence

3-2

3.4

Conversion

Kit

Components

3-3

3.4.1

Duel

Fuel

Heads

and

Pistons

3-3

3.4.2

Gas

Inlet

Valves

3-3

3.4.3

Pilot

Fuel

Control

and

Diesel

Injection

3-3

3.4.4

Low

Emission

Idle

(LEI)

3-4

3.4.5

Electronic

Control

Unit

3-4

4.0

SUB-SYSTEM

DESCRIPTIONS

AND

INSTALLATION

PROCEDURES

4-1

4.1

Engine

Modifications

4-1

4.1.1

Power

Pack

Assembly

4-1

4.1.2

Cylinder

Relief

Valves

4-1

4.1.3

Diesel

Fuel

Supply

4-1

4.2

Natural

Gas

Supply

System

4-2

4.3

Control

Air

System

4-2

Vll

CONTENTS

Page

4.4

Air

Throttle

4

"

3

4.5

Engine

Cooling

System

4

"

3

4.6

Sensors

4

"

4

4.6.1

Thermocouples

4

"

4

4.6.2

Water

Temperature

4

~

4

4.6.3

Control

Air

Pressure

4

"

4

4.6.4

Flywheel

Sensors

4

"

4

4.6.5

Air

Box

Temperature

4

~

4

4.6.6

Air

Box

Pressure

4

"

4

4.6.7

Natural

Gas

Sensors

4-4

4.6.8

Gas

Header

Pressure

4

"

4

4.7

Natural

Gas

Safety

System

4

"

5

4.8

Electrical

System

and

Controls

4_5

4.8.1

Engine

Control

Unit

4

"

6

4.8.2

Air

Service

Cabinet

and

Engine

Control

Panel

4-6

4.8.3

GIV

Wire

Harness

4

"

6

4.9

Switchgear,

External

Power

Hookups

and

External

Communications

4-6

4.10

Modification

of

MUSE

Schematic

Drawings

4-7

5.0

OPERATIONAL

PROCEDURES

5"

1

5.1

Diesel

Only

Operation

5-1

5.2

Natural

Gas

(Dual

Fuel)

Operation

5_1

5.3

Automatic

Control

5

"

2

5.3.1

Autostart

Software

5-2

5.3.2

ECU

Alarm

Logic

5

"

4

5.3.3.

ECU

Status

Messages

5_4

5.4

The

ECU

•

5_6

5.4.1

ECU

Status

Screen

5_6

5.4.2

Computer

Interface

5

"

6

5.4.3

Using

LCD

Screen

Editor

5

"

6

5.4.4

ECU

Dial-Up

Software

5

"

7

5.4.5

Static

Protection

Precautions

•••

••

5_7

Vlll

CONTENTS

Page

6.0

FIELD

SITE

INSTALLATION,

MAINTENANCE

AND

TRAINING

6-1

6.1

Site

Requirements

"

-1

6.2

Maintenance

Schedule

and

Procedures

6_1

6.3

Training

6_1

7.0

CAPITAL

AND

OPERATING

COSTS

7-1

8.0

REFERENCES

8_1

9.0

GLOSSARY

9_1

APPENDICES

A

-

Letter

Report

Regarding

Fire

Safety

Measures

for

Conversion

of

USN

MUSE

Diesel-Generator

Units

From

Diesel

to

Natural

Gas

Fueling

A-l

B

-

Schematic

Drawings

of

Dual

Fuel

1,500

kW

Conversion

of

Diesel

Power

Plants

B_1

C

-

Maintenance

Bulletins

and

Instructions

c_1

IX

1.0

INTRODUCTION

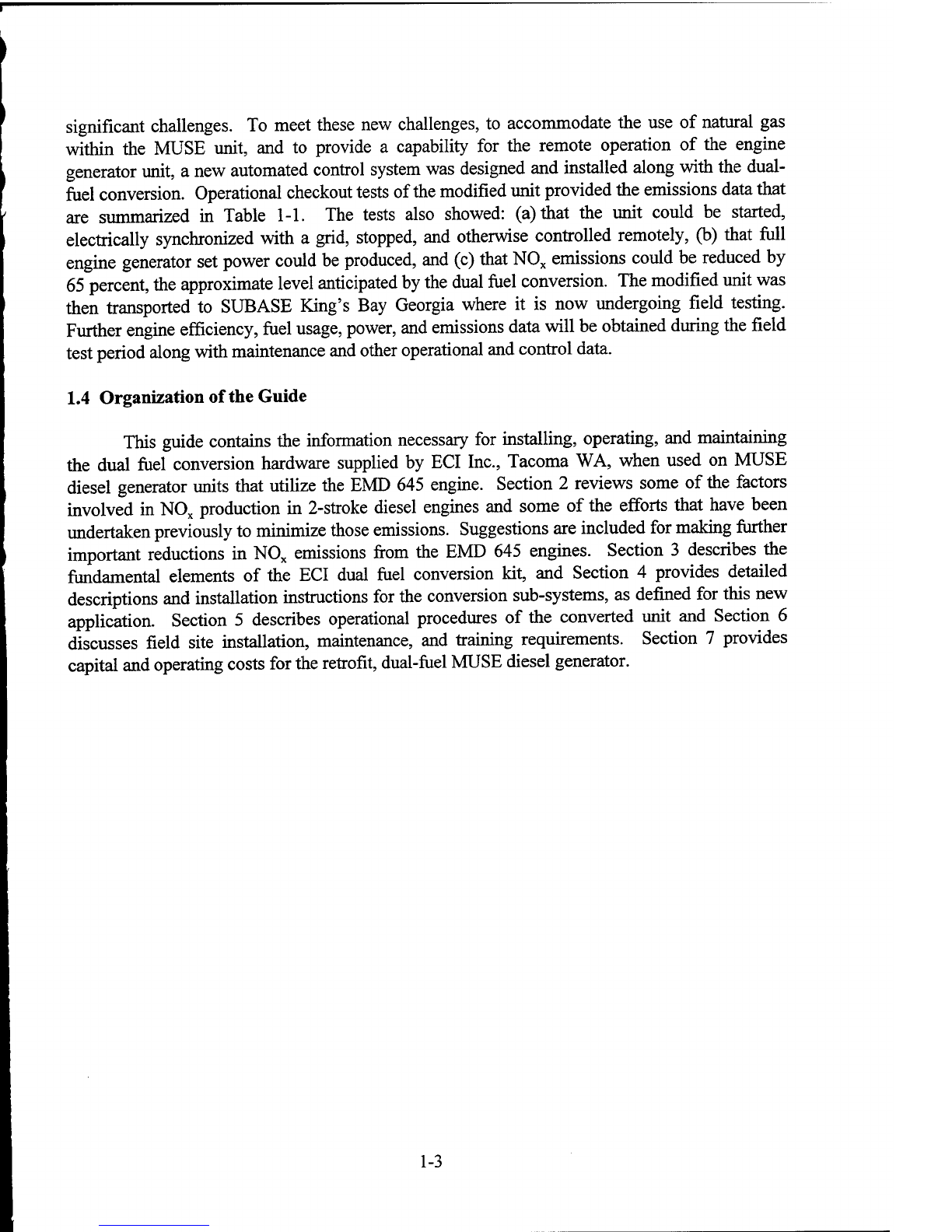

This

user

data

package

describes

steps

in

the

conversion

of

the

Navy's

Mobile

Utilities

System

Equipment

(MUSE)

transportable

diesel

generator

sets

from

diesel

to

dual

fuel

(natural

gas

plus

diesel

fuel)

operation.

These

diesel

generator

sets

are

part

of

a

fleet

of

60

such

units

maintained

by

the

Navy's

MUSE

detachment

for

deployment

to

Navy,

other

military,

and

sometimes

civilian

uses

throughout

the

world

(Ref

1-1).

The

units

range

in

size

from

750

to

2,500

kW

and

are

powered,

largely,

by

EMD

645

engines

manufactured

by

the

ElectroMotive

Division

of

the

General

Motors

Corporation.

The

engines

are

medium-speed

(750

or

900

RPM),

have

8

to

20

cylinders

with

cylinder

displacements

of

645

cubic

inches,

and

use

a

2-stroke

operational

cycle.

This

guide

is

based

on

the

experience

gained

from

converting

to

dual

fuel

operation

a

1,500-kW

MUSE

unit

that

is

now

installed

and

operating

at

the

King's

Bay

Naval

Station

in

Georgia

(Fig.

1-1).

The

technology

used

for

this

conversion

was

provided

by

ECI

Inc.,

Tacoma,

Washington.

MUSE

personnel,

assisted

by

ECI

technicians,

installed

the

required

engine

modification

hardware

and

the

electrical

and

engine

skid

modifications.

1.1

Environmental

Compliance

and

Navy

Need

Of

the

Navy's

many

diesel

engines,

those

installed

in

its

MUSE

generating

equipment

for

temporary

(<4

years)

stationary

electrical

power

were

the

first

off-road

Navy

engines

to

be

affected

by

environmentally-mandated

nitrogen

oxide

(NO

x

)

emission

regulations.

As

MUSE

units

are

transportable

but

are

typically

employed

at

a

given

site

for

periods

exceeding

that

normally

used

to

define

'temporary

power'

(temporary

power

is

often

defined

as

service

not

exceeding

one

year),

they

must

comply

with

air

pollution

regulations

that

apply

to

stationary

power

generating

equipment.

But

regulatory

emission

standards

for

stationary

power

units

are

highly

variable

as

they

both

depend

upon

the

degree

of

nonattainment

in

the

surrounding

air

control

region

and

upon

the

air

control

district

in

which

the

region

is

located.

Therefore

MUSE

units

must

have

a

capability

for

meeting

these

variable

standards

as

the

units

are

moved

from

one

location

to

another.

Such

regulations

can

vary

from

none

to

those

applicable

in

the

South

Coast

Air

Quality

Management

District

(SCAQMD)

of

California,

where

emission

limits

are

<

1.0

gram/horsepower-hour

(gm/HpH).

As

NO

x

emissions

from

current

MUSE

units

range

anywhere

from

12

to

16

gm/HpH,

attempts

to

operate

them

in

areas

in

which

they

do

not

comply

with

emission

regulations

could

result

in

the

imposition

of

heavy

fines

and

as

well

as

ordered

shut-

down

by

civilian

authorities.

Therefore

a

means

for

reducing

NO

x

emissions

from

them

is

required.

The

following

factors

and

criteria

were

determined

to

be

important

in

evaluating

approaches

for

reducing

NO

x

emissions

from

MUSE

diesel

generator

sets:

(a)

most

MUSE

engine

generator

units

are

driven

by

an

EMD

645

engine,

(b)

when

burning

diesel

fuel,

these

EMD

engines

do

not

meet

the

emission

requirements

in

many

areas

of

the

country

where

the

Navy

operates,

(c)

although

transportable,

MUSE

units

must

comply

with

emission

regulations

that

apply

to

stationary

devices

because

of

their

extended

time

on

site,

(d)the

required

transportability

of

the

MUSE

units

limits

the

types

of

NO

x

emission

control

technology

that

can

1-1

be

used

with

them,

(e)

the

large

number

of

MUSE

units

in

inventory

and

the

cost

of

then-

replacement

requires

that

a

retrofit

rather

than

a

replacement

technology

be

acquired

for

reducing

NO

x

emissions,

(f)

a

capability

for

firing

diesel

fuel

must

be

maintained

to

meet

the

Navy's

operational

commitments,

(g)

full

generator

power

capability

must

be

maintained,

(h)

reliability

equal

to

or

better

than

that

for

the

diesel-only

configuration

is

needed,

(i)

the

technology

selected

must

be

within

the

technical

expertise

of

MUSE

and

onsite

personnel

who

will

be

required

to

operate

and

maintain

the

modified

units,

and

(j)

operational

costs

must

not

escalate

appreciably

beyond

those

incurred

when

the

MUSE

unit

is

operating

as

a

diesel-only

engine.

1.2

Selection

of

NO

x

Control

Technology

Two

general

approaches

can

be

used

for

reducing

NO

x

emissions

from

diesel

engines:

(a)

modification

of

the

engine

combustion

process

so

that

fewer

NO

x

species

(nitric

oxide,

NO,

and

nitrogen

dioxide,

N0

2

)

are

generated,

and/or

(b)

treatment

of

the

exhaust

gases

to

destroy

the

NO

x

species

generated

to

prevent

their

emission

into

the

atmosphere.

Of

the

many

variations

of

these

approaches

that

have

been

investigated,

two

were

considered

for

application

to

MUSE

diesel

generator

sets:

(a)

conversion

of

the

engine

to

dual

fuel

operation,

and

(b)

the

use

of

selective

catalytic

reduction

(SCR)

for

treatment

of

the

engine

exhaust

stream.

Although

SCR

offers

the

advantage

of

bringing

the

MUSE

engine

generators

into

immediate

full

compliance

with

the

most

restrictive

of

NO

x

emission

regulations,

its

application

would

add

significant

cost,

complexity,

and

size

(requiring

that

an

additional

module

be

transported)

to

the

transportable

MUSE

engine

generator

set,

and

would

also

introduce

ammonia

(NH3,

a

hazardous

chemical)

at

the

operating

site.

NH3,

which

is

used

as

the

chemical

reductant

for

NO

x

,

is

not

only

a

hazardous

chemical,

but,

itself,

presents

a

threat

to

the

environment.

Therefore

the

SCR

process

using

NH3

as

the

reductant

was

not

considered

to

be

a

practical

solution

for

reducing

NO

x

emissions

from

MUSE

diesel

generator

sets.

The

recommended

application

of

dual-fuel

technology

(or

alternative

fuel)

is

based

upon

a

retrofit

conversion

kit

designed,

specifically,

for

the

EMD

645

engine

by

Energy

Conversions,

Incorporated,

Tacoma,

WA.

The

performance,

reliability,

and

emissions

reduction

of

that

conversion

technology

have

been

demonstrated

in

a

single

application

on

two

tandem

locomotives

used

for

coal

line-haul

operations

on

the

Burlington

and

Northern

Railway

between

Montana

and

Wisconsin

(Ref

1-2).

Liquefied

natural

gas

(LNG)

from

a

separate

LNG

fuel

car

was

used

to

fuel

the

tandem

locomotives,

and

NO

x

reductions

of

nearly

70

percent

(to

4.0

from

the

12.0

gms./Hph

produced

when

burning

diesel

fuel)

were

achieved.

Because

of

these

demonstrated

results,

because

no

other

competing

technology

could

make

similar

claims

with

the

EMD

645

engine,

and

because

this

technology

satisfied

the

criteria

for

selection

of

a

MUSE

NO

x

reduction

technology

(discussed

above),

it

was

selected

for

installation

and

testing

on

a

1,500

kW

MUSE

diesel

generator

set.

1.3

Installation

and

Testing

of

Prototype

Dual

Fuel

MUSE

Diesel

Generator

The

retrofit,

dual

fuel

conversion

was

completed

in

July

1995

at

the

Construction

Battalion

Center

in

Port

Hueneme,

California.

Although

previously

tested

in

a

locomotive

application,

it

had

not

been

used

for

stationary

power.

And

although

the

application

to

stationary

power

is,

in

ways,

not

as

complex

as

that

for

locomotives,

it

is

different

and

presents

other

1-2

significant

challenges.

To

meet

these

new

challenges,

to

accommodate

the

use

of

natural

gas

within

the

MUSE

unit,

and

to

provide

a

capability

for

the

remote

operation

of

the

engine

generator

unit,

a

new

automated

control

system

was

designed

and

installed

along

with

the

dual-

fuel

conversion.

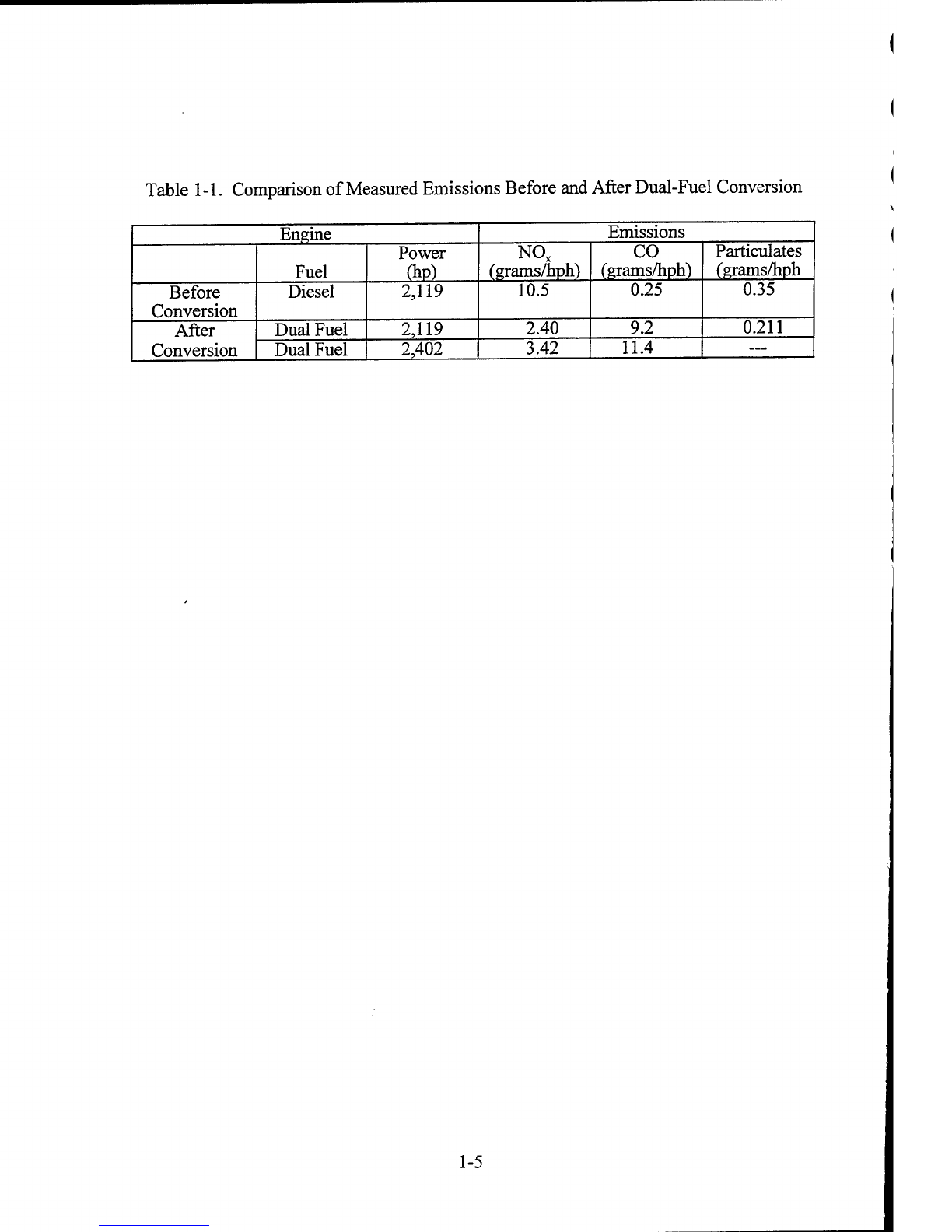

Operational

checkout

tests

of

the

modified

unit

provided

the

emissions

data

that

are

summarized

in

Table

1-1.

The

tests

also

showed:

(a)

that

the

unit

could

be

started,

electrically

synchronized

with

a

grid,

stopped,

and

otherwise

controlled

remotely,

(b)

that

full

engine

generator

set

power

could

be

produced,

and

(c)

that

NO

x

emissions

could

be

reduced

by

65

percent,

the

approximate

level

anticipated

by

the

dual

fuel

conversion.

The

modified

unit

was

then

transported

to

SUBASE

King's

Bay

Georgia

where

it

is

now

undergoing

field

testing.

Further

engine

efficiency,

fuel

usage,

power,

and

emissions

data

will

be

obtained

during

the

field

test

period

along

with

maintenance

and

other

operational

and

control

data.

1.4

Organization

of

the

Guide

This

guide

contains

the

information

necessary

for

installing,

operating,

and

maintaining

the

dual

fuel

conversion

hardware

supplied

by

ECI

Inc.,

Tacoma

WA,

when

used

on

MUSE

diesel

generator

units

that

utilize

the

EMD

645

engine.

Section

2

reviews

some

of

the

factors

involved

in

NO

x

production

in

2-stroke

diesel

engines

and

some

of

the

efforts

that

have

been

undertaken

previously

to

minimize

those

emissions.

Suggestions

are

included

for

making

further

important

reductions

in

NO

x

emissions

from

the

EMD

645

engines.

Section

3

describes

the

fundamental

elements

of

the

ECI

dual

fuel

conversion

kit,

and

Section

4

provides

detailed

descriptions

and

installation

instructions

for

the

conversion

sub-systems,

as

defined

for

this

new

application.

Section

5

describes

operational

procedures

of

the

converted

unit

and

Section

6

discusses

field

site

installation,

maintenance,

and

training

requirements.

Section

7

provides

capital

and

operating

costs

for

the

retrofit,

dual-fuel

MUSE

diesel

generator.

1-3

(a)

Side

view

of

switchgear,

interconnecting

cable

housing,

and

engine

house.

IM*fc*fci&i

(b)

End

view

showing

natural

gas

supply

line.

Figure

1-1.

MUSE

1,500

kW

dual-fuel

engine

generating

set

at

SUBASE,

King's

Bay,

Georgia.

1-4

Table

1-1.

Comparison

of

Measured

Emissions

Before

and

After

Dual-Fuel

Conversion

Engine

Emissions

Fuel

Power

(hp)

NO

x

(grams/hph)

CO

(grams/hph)

Particulates

(grams/hph

Before

Conversion

Diesel

2,119

10.5

0.25

0.35

After

Conversion

Dual

Fuel

2,119

2.40

9.2

0.211

Dual

Fuel

2,402

3.42

11.4

—

1-5

2.0

NO

x

REDUCTION

FOR

LARGE,

TWO-STROKE

DIESEL

ENGINES

Of

the

many

combustion

devices

having

large

commercial

usage,

diesel

engines

have

provided

the

greatest

technical

challenges

to

achieving

significant

NO

x

reductions.

Two

general

approaches

can

be

used

to

reduce

NO

x

emissions

from

them:

(a)

modification

of

the

engine

combustion

process

so

that

fewer

NO

x

species

(nitric

oxide,

NO,

and

nitrogen

dioxide,

N0

2

)

are

generated,

and/or

(b)

treatment

of

the

exhaust

gases

to

destroy

the

NO

x

species

generated

and

to

prevent

their

emission

into

the

atmosphere.

As

diesel

engines

are

lean-burn

(stoichiometrically,

fuel

lean),

the

catalytic

reactors

used

by

spark-ignited

gasoline

engines

to

reduce

NO

x

and

hydrocarbon

emissions

and

which

require

near-stoichiometric

combustion,

are

not

effective

for

reducing

the

concentrations

of

the

same

pollutant

species

from

diesel

exhausts.

Further,

diesel

engines

operate

at

higher

compression

ratios

than

gasoline

engines

and

combustion

in

them

proceeds

according

to

a

complex,

heterogeneous

diffusion

process

as

opposed

to

the

simpler,

easier-to-control,

homogeneous

flame

propogation

that

characterizes

gasoline

engine

combustion

(see

Fig.

2-1).

The

higher

compression

ratio

of

the

diesel

engine

leads

to

its

greater

efficiency

and

the

diffusion-controlled

combustion

is

what

permits

its

operation

at

higher

pressures

without

the

occurrence

of

destructive

knocking.

However,

both

of

these

factors

lead

to

higher

combustion

temperatures

and

increased

NO

x

production

in

the

diesel

engine.

Most

of

the

work

for

reducing

NO

x

emissions

from

diesel

engines

has

been

with

smaller

sized

engines.

Little

research

has

been

carried

out

on

engines

as

large

as

the

EMD

645.

And

as

the

complexity

of

combustion

increases

and

one's

ability

to

control

those

processes

decreases

with

engine

size,

progress

in

NO

x

emissions

reduction

from

larger

engines

has

been

comparably

slow.

However,

as

characterization

of

the

fundamental

processes

in

diesel

engines

improves,

the

results

for

controlling

NO

x

emissions

from

both

large

and

small

engines

may

improve.

The

Navy's

Office

of

Naval

Research

(ONR)

is

sponsoring

fundamental

research

(see

Refs

2-1,

2-2,

and

2-3)

on

the

control

of

NO

x

emissions

from

the

larger

engines

used

for

boat

and

ship

operations.

Those

results

could

also

find

an

application

with

MUSE

engines.

However,

the

practical

application

of

that

research,

if

successful,

is

several

years

in

the

future.

A

further

complication

with

the

EMD

645

engines

is

that

they

are

2-stroke

engines.

This

reduces

the

number

of

engine

parameters

available

for

controlling

or

altering

the

internal

engine

processes

for

the

purpose

of

NO

x

reduction.

Further,

most

work

on

NO

x

reduction

from

diesel

engines

has

been

on

those

of

the

4-stroke

design.

Therefore,

the

quantity

of

engine

research

to

draw

on

for

reducing

NO

x

emissions

from

the

EMD

645

engine

is

limited.

2.1

Exhaust

Gas

Treatment

Exhaust

gas

treatment

provides

one

option

for

significantly

reducing

NO

x

emissions

from

diesel

engines,

although

the

additional

equipment

and

chemicals

required

for

its

implementation

works

against

its

application

on

MUSE

units.

Two

such

approaches

are

available

commercially;

others

are

being

developed.

Those

available

commercially

use

a

chemical

reductant

either

with

catalysts

(selective

catalytic

reduction

(SCR)),

or

without

catalysts

(selective

non-catalytic

reduction

(SNCR)).

The

reductants

used

are

usually

ammonia

or

a

related

compound

such

as

2-1

urea.

Other

than

the

identification

of

a

useful

chemical

additive,

the

development

of

an

appropriate

catalyst

is

the

major

technical

problem

in

the

development

of

a

useful

SCR

approach.

Although

SNCR

requires

no

catalyst,

other

chemical

routes

and

temperatures

for

the

destruction

of

NO

x

must

be

used.

The

general

features

and

flow

paths

of

the

two

approaches

are

contrasted

in

Figure

2-1.

Ammonia

has

been

the

chemical

most

used

for

NO

x

reduction,

but

recent

years

have

seen

development

of

the

use

of

related

chemicals

(e.g.,

urea

and

cyanuric

acid).

Ammonia

and

urea

have

both

been

used

in

SNCR

and

SCR

processes,

but

the

temperature

window

of

their

application

for

SNCR

is

too

high

to

be

useful

with

diesel

exhausts.

The

use

of

urea

in

SCR

processes

is

a

rather

recent

development

and

offers

significant

advantages

over

that

of

ammonia.

SCR

(urea)

provides

at

least

the

NO

x

reduction

that

SCR

(NH

3

)

provides

(both

>90

percent),

but

without

the

burden

of

being

either

a

hazardous

chemical

or

an

environmental

threat.

The

use

of

SCR

(urea)

was

developed

in

Europe

and

is

currently

available

only

from

European

suppliers.

Cyanuric

acid

has

been

used

for

SNCR

(non-catalytic)

processes.

Its

major

claim

is

that

it

is

more

effective

than

either

ammonia

or

urea

at

the

lower

temperatures

characteristic

of

diesel

exhausts.

2.2

NO

x

Reduction

From

EMD

645

Dual-Fuel

Engines

Several

efforts

have

been

undertaken

to

use

natural

gas

with

2-stroke

diesel

engines.

Those

of

interest

to

the

MUSE

engine

generator

program

are

summarized

in

Table

2-1.

The

first

line

provides

operating

data

from

current

MUSE

EMD

645

diesel

engines

as

a

baseline

for

comparison.

The

remaining

cases

are

for

engines

from

the

same

locomotive-type

engine

series

(the

EMD's

567,

645,

and

710,

cylinder

displacement

in

cubic

inches)

and

the

Detroit

Diesel

92

(a

truck-sized

engine).

Fuel

type

is

either

dual

fuel

(DF)

or

natural

gas

(NG),

and

charging

of

the

engine

cylinders

with

natural

gas

is

described

as

either

early

or

late

in

the

compression

stroke.

For

early

injection

(El),

a

low

injection

pressure

(100

to

300

psi)

can

be

used.

Air

flow

and

mixing

patterns

within

the

cylinder

then

produce

a

nearly

homogeneous

fuel/air

mixture

prior

to

ignition.

For

late

cycle

injection

(LCI),

a

much

higher

pressure

(>3,000

psi)

is

required,

and

as

pre-mixing

of

the

fuel

and

air

is

not

achieved

prior

to

ignition,

a

diesel-type

combustion

takes

place.

Ignition

of

the

natural

gas

charge

in

both

of

these

cases

is

by

injection

of

a

pilot

quantity

of

diesel

fuel

(4

to

7

percent

of

the

amount

required

for

full

diesel

operation)

into

the

cylinder

at

the

time

of

ignition.

Significant

NO

x

reduction

is

achieved

with

the

El

process.

NO

x

reduction

is

much

more

difficult

to

achieve

for

the

LCI

process.

Anticipated

advantages

of

LCI

are

increased

engine

thermal

efficiency

(a

higher

compression

ratio

diesel

cycle

can

be

used)

and

avoidance

of

the

combustion

"knock"

that

limits

power

production

in

Otto

cycle

(homogeneous

combustion)

engines.

Disadvantages

of

LCI

are

the

technical

problems

and

high

cost

of

providing

natural

gas

at

pressures

greater

than

3,000

psi

and

the

difficulty

in

achieving

reduced

NO

x

emissions

in

higher-pressure,

higher-temperature

combustion

environments.

The

advantage

of

reduced

fuel

costs

due

to

the

use

of

natural

gas

rather

than

diesel

fuel

is

provided

by

both

approaches.

The

data

of

Case

1

were

obtained

in

1982

from

a

locomotive

engine

fueled

from

compressed

natural

gas

cylinders

carried

on

a

railroad

flatcar

(Ref

2-4).

The

major

limitation

observed

in

that

test

operation

was

the

reduction

(20

to

30

percent)

of

available

engine

power

2-2

caused

by

the

onset

of

combustion

knocking.

In

Case

2,

the

Department

of

Energy

(DOE)

sponsored

single-cylinder

engine

tests

(Refs

2-5

and

2-6)

to

determine

if

improved

engine

thermal

efficiencies

and

power

production

could

be

obtained

with

a

diesel-type

(late

cycle

injection)

combustion

process

for

dual

fuel

operation.

Although

substantial

progress

was

made

in

these

tests,

engine

efficiency

and

exhaust

emission

objectives

were

not

achieved.

The

DD

92

spark-ignited,

truck-sized

engine

(Case

3)

had

significantly

different

requirements

than

those

for

the

larger

locomotive

engines.

Its

manufacture

was

discontinued

after

several

years'

production.

Case

4

was

undertaken

by

many

of

the

same

parties

involved

in

Case

1,

but

with

several

changes.

These

included:

using

turbocharging

rather

than

positive

displacement

compressors

for

charge-air

compression;

changing

the

piston

crown

design

to

improve

fuel-air

mixing

and

to

reduce

the

compression

from

14.5

to

12.8;

altering

the

head

configuration

to

allow

admission

of

natural

gas

into

the

chamber

using

electronic

rather

than

mechanical

controls;

incorporating

additional

charge-air

cooling

for

the

engine;

modifying

the

controls

of

the

injector

rack;

and

incorporating

single-bank

engine

idling

to

reduce

emissions

and

improve

engine

efficiency

(Ref

2-7).

The

results

achieved

were

sufficient

to

convince

the

Burlington

and

Northern

Railway

to

install

retro-fit

packages

designed,

specifically,

for

the

EMD

645

engine

on

two

tandem

locomotives

for

coal

line-haul

operations

between

Montana

and

Wisconsin.

Liquefied

natural

gas

(LNG)

was

used

as

the

fuel,

and

a

separate

LNG

fuel

car

was

constructed

to

provide

fuel.

An

LNG

refueling

station

for

the

round

trip

was

provided

in

Minnesota.

The

performance,

reliability,

and

emissions

reduction

of

that

technology

were

demonstrated

in

a

program

that

continued

for

over

two

years.

The

technology

represented

by

this

demonstration

test

appears

to

be

the

only

engine-related

retro-fit

technology

available

for

achieving

significant

NO

x

reductions

with

the

EMD

645

engine.

The

last

entry

in

Table

2-1

is

for

development

tests

that

have

been

underway

at

the

Southwest

Research

Institute

(SwRI)

for

development

of

the

late,

high-pressure

injection

of

natural

gas.

Data

regarding

the

performance,

emissions,

cost,

and

reliability

of

this

technology

have

not

yet

been

published.

2.3

Further

Reduction

of

NO

x

Emissions

Although

the

70

percent

reduction

in

NO

x

demonstrated

by

the

results

of

Case

4

is

an

important

step

forward,

further

NO

x

reductions

appear

to

be

available

with

some

additional

modification

of

the

dual-fuel

EMD

645

engine.

These

have

centered

on

the

use

of

pre-ignition

chambers

and/or

separate

diesel

injection

igniters

(see

Table

2-2).

The

results

presented

in

this

table

show

that

NO

x

emissions

for

dual

fuel

injection

can

be

reduced

to

the

level

of

1.0

gram/hph

while

the

required

pilot

fuel

is

reduced

to

about

1.0

percent

(Reference

2-8

and

2-9

indicate

that

CO,

hydrocarbon,

and

particular

emission

are

also

significantly

reduced.).

Although

the

use

of

pre-chambers

in

engines

is

a

familiar

concept,

their

use

with

dual

fuel

engines

has

been

limited

and

their

significant

advantages

have

not

been

widely

explored.

In

the

cases

shown,

the

Wartsilla

is

a

somewhat

complex

multi-fueled

application

requiring

high

pressure

injection

(Ref

2-10).

It

would

not

be

useful

for

Navy

MUSE

units.

Cooper

Bessemer

(Cases

2

through

5)

conducted

tests

that

started

with

the

objective

of

improving

the

operation

of

large

spark-ignited

natural

gas

engines

and

resulted

in

major

improvements

in

their

dual

fuel

engines

as

well

(see

Fig.

2-2,

Ref

2-8).

The

Cooper

Bessemer

engines

were

all

four-stroke

units.

Fairbanks-Morse

(Ref

2-9)

achieved

results

similar

to

those

of

Cooper

Bessemer

with

a

900-rpm,

two-stroke,

2-3

opposed-piston

engine.

A

plan

view

of

the

injector

arrangement

for

the

natural

gas,

diesel,

and

pre-chamber

injectors

of

the

Fairbanks

Morse

application

is

shown

on

Fig.

2-3.

When

the

engine

is

operating

in

the

diesel

mode,

both

diesel

injectors

are

used.

In

the

natural

gas

mode,

a

single,

low-pressure

gas

injector

is

used

along

with

a

diesel-fired

pre-ignition

chamber.

Figure

2-4

shows

Fairbanks-Morse

data

for

four

modes

of

engine

operation:

standard

diesel,

standard

dual

fuel,

spark

ignition,

and

Enviro

Design

pre-chamber.

The

numbers

within

each

region

of

the

figure

refer

to

the

number

of

data

points

used

to

define

that

region,

NO

x

emissions

and

thermal

efficiency

(brake-specific

fuel

consumption)

are

significantly

superior

for

the

Enviro-Design.

Pre-chamber

parameters

affecting

the

reliability

and

effectiveness

for

achieving

ignition,

minimum

emissions,

and

minimum

pilot

fuel

are

shown

on

Figure

2-5

(Ref

2-8).

Combustion

pre-chambers

can

be

used

with

dual

fuel

engines

to:

•

Further

lower

NO

x

,

hydrocarbon,

CO,

and

particulate

emissions.

•

Improve

engine

thermal

efficiency.

•

Reduce

the

required

diesel

pilot

fuel

for

both

two-

and

four-stroke

dual

fuel

engines.

This

technology

is

now

available

and

could

be

applied

to

the

EMD-645

to

achieve

further

important

improvements

in

exhaust

emissions

and

thermal

efficiency

for

dual

fuel

operation.

Such

efforts

would

require

a

modest

extension

of

the

existing

dual

fuel

technology

(low-pressure

injection)

already

demonstrated

on

B&N

RR

locomotives

and

the

Navy

MUSE

unit.

Successful

demonstration

of

a

dual

fuel

EMD-645

engine

with

pilot

ignition

would

bring

the

Navy's

stationary

dual

fuel

units

to

the

level

of

NO

x

required

by

the

most

restrictive

emissions

regulations

in

the

country

for

stationary

engines.

2-4

Combustion-

Gases

'.

Heat

Extraction

Heat

Extraction

Exhaust

Gases

1500

-

2000

F

V

NH3

—

Injection

(a)

Selective

non-catalytic

reduction

(SNCR).

Combustion-

Gases

-

Heat

Extraction

<

<

<

600

-

800

F

<

<

x

x

X

NH3

—

Injection

Exhaust

Gases

Catalyst

Bed

(b)

Selective

catalytic

reduction

(SCR).

Figure

2-1.

General

features

of

SCR

and

SNCR

NO

x

reduction

processes.

2-5

6.0

I

4

'

0

'

2.0

LO-

CO

Standard

dual

fuel

.

Pre-chamber

spark

ignition

Dual

fuel

pilot

\

+

+

■

6100

6300

6500

6700

BSFC

Figure

2-2.

Results

of

tests

conducted

by

Cooper

Bessemer

showing

NO

x

■

P

re-Chamber

with

Pilot

Injector

•Diesel

Injection

Nozzle

■

Diesel

Injection

Nozzle

■

Gas

Valve

Figure

2-3.

Plan

view

of

arrangement

of

natural

gas,

diesel,

and

pre-chamber

injection

for

Fairbanks-Morse

application.

2-6

10.

-

8.

_

fl

H

Standard

diesel

„

g/hph

at

_

■■

Standard

dual

fuel

°

A

z

4.

—

Enviro-Design

\

2.

6.

^B

^

■

H

Spark

1

^^^

l^^^l

1

1

1

1

1

0

6.2

6.4

6.6

6.8

7.0

BFSC

Figure

2-4.

Results

of

tests

conducted

by

Fairbanks-Morse

showing

NO

x

emissions

and

brake

specific

fuel

consumption

(Btu/hph).

Diesel

injector

Pre-chamber

parameters

Volume

Volume/Orifice

area

Orifice

shape

Location/Orientation

Quanity

pilot

fuel

F/A

Pilot

fuel

injector

(1-5%)

N.

G.

injector

in

M£±

■

Head

.

Pre-chamber

Main

combustion

chamber

Piston

Figure

2-5.

Schematic

outline

of

dual

fuel

cylinder

and

parameters

that

affect

pre-chamber

performance.

2-7

Table

2-1.

N0

X

Reduction

Technologies

Related

to

EMD-645

Case

Mfgr

Number

Strokes

Fuel

Type*

Natural

Gas

Injection

Pilot

Diesel

NO

x

g/hph

Other

Time

Pressure

%

Location

1

EMD-567

2

DF

Early

200

7

Main

—

Low

power,

1982

2

EMD-567

2

DF

Late

3,500

2.0

knock

limit

Main,

side

wall

5

Heavy

smoke,

reduced

efficiency

SwRI**

3

Detroit

Diesel

92

2

NG

Early

250

N/A

N/A

N/A

Discont'd

production

4

EMD-645

2

DF

Early

100

6

Main

4

Full

power

locomotive,

1992-1995

5

EMD-710

2

DF

Late

High

9

Main

?

Results

not

available

*DF

=

Dual

Fuel,

NG

=

Natural

Gas.

**Southwest

Research

Institute,

Inc.

Table

2-2.

Further

NO

x

Reductions

Using

Pre-Ignition

Chambers

Mfgr

Number

Strokes

Fuel

Type*

Natural

Gas

Injection

Pilot

Diesel

NO

x

g/hph

Other

Time

Pressure

(psig)

%

Location

Wartsilla

4

MF

Late

4,000

5

Main

5

New

and

Retrofit

Cooper

Bessemer

4

NG

Early

Low

Spark

Pre-

1.5

StdforDF

Cooper

Bessemer

4

DF

Early

Low

5

Main

5

Optimized

Cooper

Bessemer

4

DF

Early

Low

1

Main

4

Unstable

combustion

Cooper

Bessemer

4

DF

Early

Low

0.9

Pre-

1

Full

power,

improved

opacity

Fairbanks-Morse

Enviro

Op

2

DF

Early

Low

—

Main

4.5

—

Fairbanks-Morse

Enviro

Op

2

DF

Early

Low

1.4

Pre-

1

Full

power

*MF

=

Multi-fuel,

NG

=

Natural

Gas,

D

F

=

Dual

fi

id.

2-8

Table of contents

Popular Engine manuals by other brands

Viper

Viper 173CC owner's manual

KaVo

KaVo EWL 4041 Operating, Maintenance and Assembly Instructions

Kohler

Kohler Courage SV710 Service manual

Briggs & Stratton

Briggs & Stratton 120000 Operator's manual

Bosch

Bosch Rexroth MS2N operating instructions

ZIEHL-ABEGG

ZIEHL-ABEGG SM250.45B Original operating instructions