Electro-Sensors Electry-Sentry 1 User manual

Electro-Sentry 1

Installation & Operation Manual

Part Number: 990-005500

Revision D

Electro-Sensors®, Inc.

6111 Blue Circle Drive

Minnetonka, MN 55343-9108

Contact us at:

Local: 952-930-0100

National: 1-800-328-6170

Fax: 952-930-0130

Web: www.electro-sensors.com

Sales: [email protected]

Support: [email protected]

Introduction To This Manual

What is in this

manual?

This installation and operation manual provides detailed technical information about the Electro-

Sentry 1. It should serve as your technical resource to install, set up, operate, and test the Electro-

Sentry 1.

Who should

use this manual

(audience)

Keep in mind that the function of the Electro-Sentry 1 installed in a mechanical process is to

monitor speed and temperature; therefore, it must be installed by qualified personnel only. This

manual is designed for persons who have the primary responsibility to install, set up, operate, and

test the Electro-Sentry 1.

The secondary audience would be those persons seeking technical information about the electrical

concepts and operation of the Electro-Sentry 1.

Knowledge

level

Persons installing, setting up, and operating the Electro-Sentry 1 should have good knowledge

and understanding of electrical and mechanical concepts and principles pertaining to speed and

temperature monitoring and associated alarms.

Again, the Electro-Sentry 1 should be installed by qualified personnel only.

Notices · Installing Electro-Sensors, Inc., products is the responsibility of the purchaser, and is in no way

guaranteed by Electro-Sensors, Inc.

· While the information in this manual has been carefully reviewed, Electro-Sensors, Inc., assumes

no liability for any errors or omissions in this manual. Additionally, Electro-Sensors, Inc.,

reserves the right to make changes to any part of the information in this manual or the product

described herein without further notices.

· No part of this manual may be photocopied, reproduced, or translated to another language

without the prior written consent of Electro-Sensors, Inc.

Copyright © 2012 Electro-Sensors, Inc. All rights reserved.

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Table of Contents

Quick Start Guide: .........................................................................................................................................I

Description.....................................................................................................................................................1

Front-Panel Displays......................................................................................................................................1

Front-Panel User Interface .............................................................................................................................1

Enclosure........................................................................................................................................................1

Ratings and Conduit Holes ......................................................................................................................1

Material and Recommended Minimum Installation Area........................................................................16

Dimensions, With and Without Mounting Feet .......................................................................................22

Modes of Operation: ......................................................................................................................................1

Normal Mode...........................................................................................................................................1

Program Mode .........................................................................................................................................1

Entering and Using Program Mode ...............................................................................................................1

How to reset the Electro-Sentry 1 to Factory Defaults ..................................................................................2

The UserVar Variables: ..................................................................................................................................2

Speed Variables (Var01 through Var10) ...................................................................................................2

Sensor Type Select Variable (Var11)........................................................................................................3

The Warning, Shutdown, and BIAS Setpt Temperature Variables (Var12 through Var25)......................4

Temperature Display Select (Var30)........................................................................................................5

System Variables (Var31 through Var36) .................................................................................................6

Electro-Sentry 1 Operation Notes Section:....................................................................................................9

Alarms......................................................................................................................................................9

Latching and holding of Alarms ..............................................................................................................9

How to ‘clear’ Alarms ..............................................................................................................................9

Using multiple Electro-Sentry 1’s in the same application......................................................................10

Built-in Test Features Section:.......................................................................................................................10

Temperature Rise and Speed Drop Alarm Test Features .........................................................................10

Troubleshooting Section: ...............................................................................................................................11

Standard Temperature vs. 4-20mA Temperature Sensors........................................................................11

‘Out-of-Range’ Sensor Detection.............................................................................................................11

LCD Display and 4-digit LED Speed Display Error Messages...............................................................12

Concerning the Var34 Disable/Enable Commands:.................................................................................14

The Green Indicator LEDs, the Replaceable Fuse F12, and the Resettable Fuses F1 through F11: .......15

Specifications Table .......................................................................................................................................16

Front Panel Drawing ......................................................................................................................................17

Terminal Block Connections..........................................................................................................................18

SW1 Vac Selection Switch.............................................................................................................................18

I/O Board - Terminal Drawing.......................................................................................................................19

Typical Wiring Connection Examples ...........................................................................................................20

User Variable List...........................................................................................................................................21

Here are the basic questions/steps the user needs to

perform to get the Electro-Sentry 1 (a.k.a. ES1) up

and running:

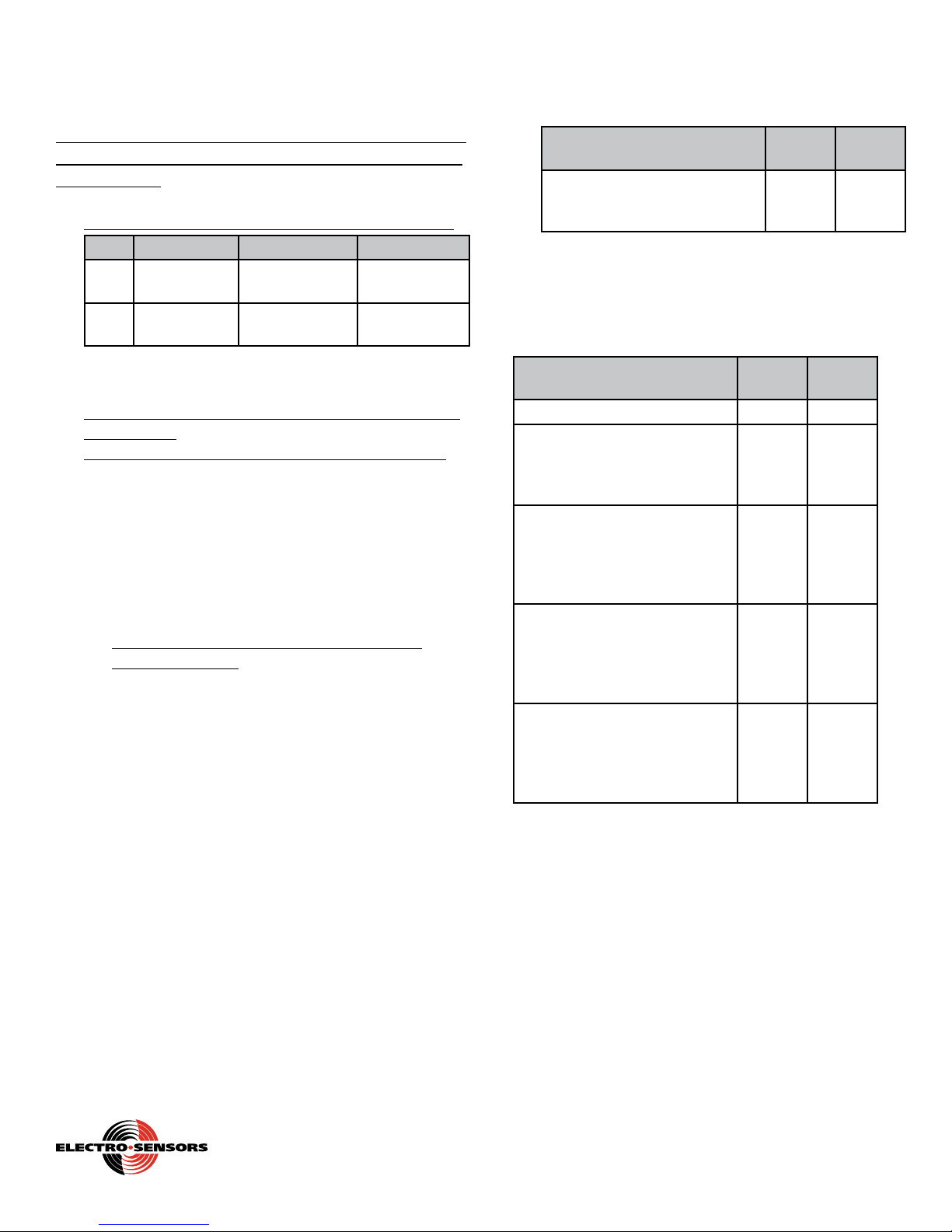

1) What is the application’s voltage? 115 or 230 Vac?

VAC SW1 Position Fuse F12 Notes:

115 Towards Right 115Vac/0.4Amp

Slo-Blo

Factory Setting

230 Towards Left 230Vac/0.2Amp

Slo-Blo

User Selectable

(The ES1 is shipped with one 230Vac/0.2 Amp Slo-Blo fuse,

and one extra 115Vac/0.4 Amp Slo-Blo fuse).

2) Do you need to display speed, or need Speed Alarm

Monitoring?

A) NO, Speed Display/Alarm Monitoring is not needed:

Skip User Variables Var01 through Var08.

Skip the setting of the SW9 3-DIP Switch.

Set Var09 Speed_Display_Select to either a ‘0002’

or a ‘0003’ to disable Speed Monitoring, as needed.

Skip Var10 MAX_ANALOG_RPM.

Skip Var34 Hour_and_Speed_Command_Select for

now. [If you plan to use the Hour Meter feature, we

will return to Var34 later in section (5) below].

B) YES, Speed Alarm Monitoring and/or Speed

Display is needed:

What type of Speed encoder are you using? A 4-20

mA Analog encoder or a Pulse-Train encoder?

Set Var01 Encoder_Type_Select, as needed:

‘0000’ = 4-20 mA Analog Speed Encoder Type

(speed signal is received at TB16).

‘0001’ = Pulse-Train Speed Encoder Type

(speed signal is received at TB30).

When Var01 = 0001, then you need to set

the SW9 3-DIP Switch for NPN or PNP/

5V logic-level Encoder Type, as needed

per your pulse-train encoder. The SW9

DIP switch is on the back side of the Front

Panel, to the left of the J7 ribbon cable.

The Factory default setting of SW9 is for

an NPN Pulse-Train Encoder (which is

SW9’s switch #1 = ON, switch #2 = OFF,

switch #3 = OFF).

Note: Electro-Sensors Pulse-Train

Encoders are NPN encoders.

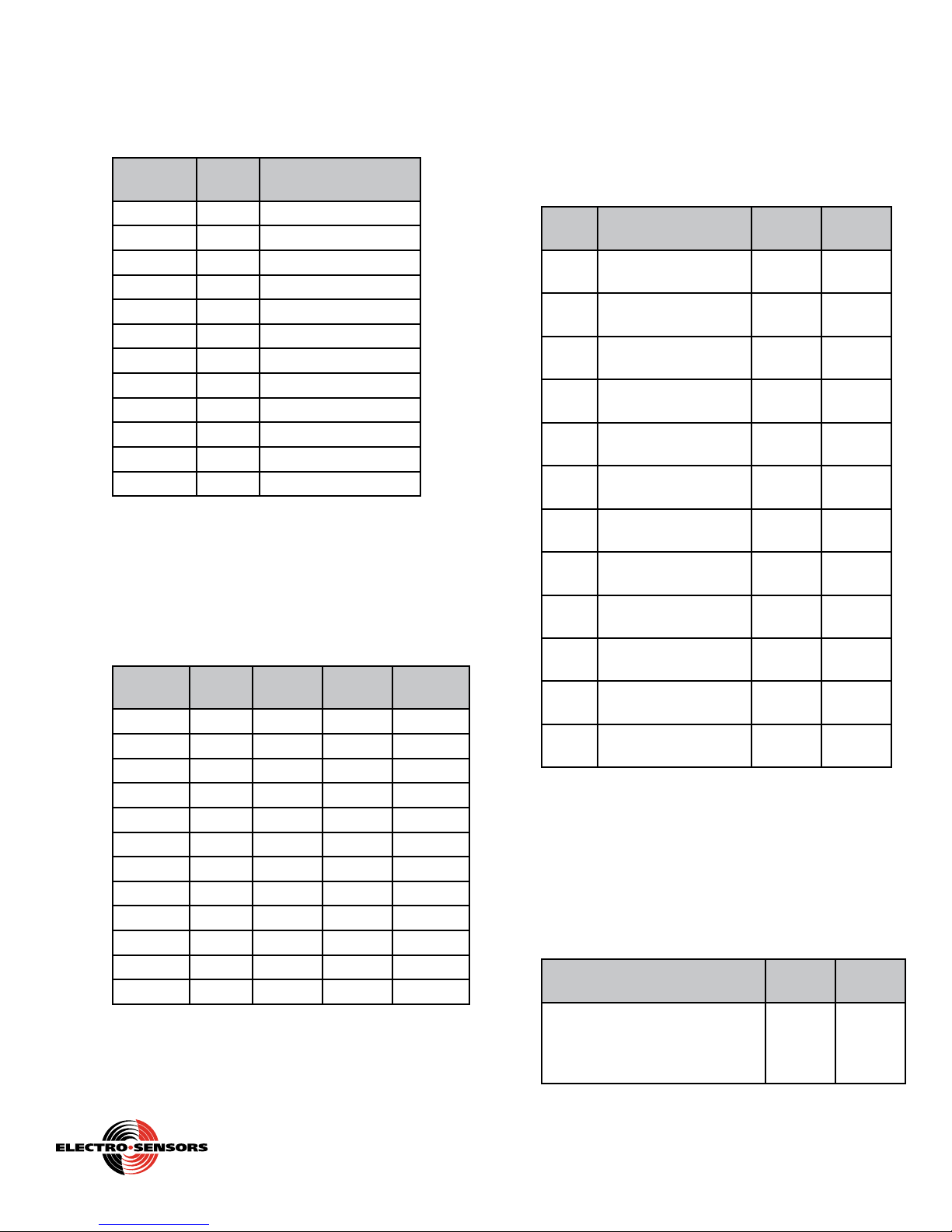

Variable Default

Value

User’s

Value

Var01 Encoder_Type_Select.

0000 = 4-20mA Analog Encoder.

0001 = Pulse-Train Encoder.

0000

For applications using a 4-20 mA Analog Speed

Encoder (i.e., Var01 = 0000):

Set the following variables as needed:

Variable Default

Value

User’s

Value

Var02 Pulse_Per_Rev Value. N.A.1N.A.1

Var03 RPM_at_20mA.

This is the analog encoder’s rated

RPM corresponding to 20mA.

(See Note2).

0200

RPM

Var10 MAX_ANALOG_RPM.

This is the peak RPM seen by the

analog encoder in the application,

and the 100% RPM on which the

speed setpts are based.

0200

RPM

Var04 Speed_Slowdown_Alarm_

SetPt %. (See Note3).

This is the ‘Yellow_Alarm’

speed expressed as a % of Var10

MAX_ANALOG_RPM.

0090

%

Var06 Speed_Shutdown_Alarm_

Setpt %. (See Note3).

This is the ‘Red_Alarm’ speed

expressed as a % of Var10

MAX_ANALOG_RPM.

0080

%

Note1: “N.A.” means not applicable to this portion of

Electro-Sentry 1 set-up.

Note2: The definition of Var03 is slightly different when

Var01 is programmed for an analog speed encoder

versus a pulse-train speed encoder.

Note3: If you only need to display the speed, without Speed

Alarm Monitoring, then you can skip setting Var04

and Var06. But you then need to set Var09 to either a

‘0002’ or ‘0003’ as needed per your speed viewing

needs. (More about Var09 on next page).

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

I

Electro-Sentry 1 Quick Start Guide

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

II

For applications using a Pulse-Train Speed Encoder

(i.e., Var01 = 0001): Set the following variables as needed:

Variable Default

Value

User’s

Value

Var02 Pulse_Per_Rev Value.

Most Electro-Sensors pulser

targets give 8 PPR.

0008

PPR

Var03 PULSE_MAX_RPM.

This is the peak RPM of the

rotating pulser target seen in the

application, and the 100% RPM

on which the speed setpts are

based. (See Note2).

0200

RPM

Var10 MAX_ANALOG_RPM N.A. N.A.

Var04 Speed_Slowdown_Alarm_

SetPt %. (See Note3)

This is the ‘Yellow_Alarm’

speed expressed as a % of Var03

PULSE_MAX_RPM.

0090

%

Var06 Speed_Shutdown_Alarm_

Setpt %. (See Note3)

This is the ‘Red_Alarm’ speed

expressed as a % of Var03

PULSE_MAX_RPM.

0080

%

For either type of Speed Encoder (i.e., Var01 = 0000

or 0001): Set the following variables as needed:

Variable Default

Value

User’s

Value

Var05 Speed_Slowdown_Alarm_

Delay

0001

sec

Var07 Speed_Shutdown_Alarm_

Delay

0001

sec

Var08 Underspeed_Start_Delay 0005

sec

Var09 Speed_Display_Select.

0000 = % and Enable.

0001 = RPM and Enable.

0002 = % and Disable

0003 = RPM and Disable

(See Note3)

0000

Var34 Hour_and_Speed_

Command_Select.

0000 = Maintained

Disable/Enable.

0001 = One-Shot Disable/Enable

with Disable = Closed.

0002 = One-Shot Disable/Enable

with Disable = Open.

0000

Factory default for Var34 is 0000 for a ‘Maintained’

Disable/Enable command needed at input TB34.

Note: See the “UserVar Variables” section in the Reference

portion of the User Manual for details on any of the

above mentioned VarXX’s, if so needed.

What Speed alarms do you need?

Is a Speed Slowdown Warning Alarm or a Speed

Shutdown Alarm needed?

If so, connect the application’s ‘alarm’ circuitry to the ES1’s

terminal blocks as shown in the following table:

Function Relay

Output#

Terminal

Blocks

Speed (or temperature)

Shutdown Alarm

4 TB24

TB23

Speed (or temperature)

Warning Alarm

3 TB22

TB21

Speed Only

Shutdown Alarm

2 TB20

TB19

Speed Only

Warning Alarm

1 TB18

TB17

(These four ES1 relay outputs are ‘Dual Form C SPDT’).

See Reference portion of the User Manual, pages 16, 18,

and 19, for details on any of the above mentioned terminal

blocks, if so needed.

3) How to set-up your Electro-Sentry 1 for

Temperature Monitoring:

A) The application’s Temperature sensors are typically

connected to the Electro-Sentry 1’s 4-20 mA

Analog Inputs as follows:

Terminal

Block

Analog

Input # Description

TB1 1 Head Bearing Left

TB2 2 Head Bearing Right

TB3 3 Head Rub Block Left

TB4 4 Head Rub Block Right

TB5 5 Knee Bearing Left

TB6 6 Knee Bearing Right

TB7 7 Knee Rub Block Left

TB8 8 Knee Rub Block Right

TB9 9 Tail Bearing Left

TB10 10 Tail Bearing Right

TB11 11 Tail Rub Block Left

TB12 12 Tail Rub Block Right

For the TB1 through TB12 terminal blocks:

Pin1 = +24Vout_A, Pin 2 = 4-20 mA Signal Input,

Pin 3 = Gnd_A.

B) All 12 Analog Inputs can be setup for sensors

having a Temperature proportional 4-20mA output.

Six Analog Inputs can also be setup for sensors

having a Contact Closure output, as shown in the

following table.

Terminal

Block

Analog

Input #

Temp

Sensor4

Contact

Closure Var11

TB1 1 Yes No N.A.

TB2 2 Yes No N.A.

TB3 3 Yes Yes See Var11

TB4 4 Yes Yes See Var11

TB5 5 Yes No N.A.

TB6 6 Yes No N.A.

TB7 7 Yes Yes See Var11

TB8 8 Yes Yes See Var11

TB9 9 Yes No N.A.

TB10 10 Yes No N.A.

TB11 11 Yes Yes See Var11

TB12 12 Yes Yes See Var11

If your application uses Contact-Closure sensors for Rub

Blocks, etc, then see page 3 of the Reference portion

of the User Manual for details on how to setup Var11.

Note4: Factory default for Var11 is 0000, for all

Analog Inputs are set for 4-20 mA

Temperature sensors.

C) For those Analog Inputs that you are not using

(i.e., those Analog Inputs having no Temperature sensors

or no Contact-Closure sensors connected to them):

You must turn ‘OFF’ the effect of any unused Analog

Inputs by setting their BIAS Temperature Setpts to

‘0999’. The BIAS Setpts are in Var14 through Var25,

and correspond to the 4-20 mA Analog Inputs as

follows:

Var# Description Default

Value

User’s

Value

14 Input #1 BIAS

Temperature SetPt.

0000

15 Input #2 BIAS

Temperature SetPt.

0000

16 Input #3 BIAS

Temperature SetPt.

0000

17 Input #4 BIAS

Temperature SetPt.

0000

18 Input #5 BIAS

Temperature SetPt.

0000

19 Input #6 BIAS

Temperature SetPt.

0000

20 Input #7 BIAS

Temperature SetPt.

0000

21 Input #8 BIAS

Temperature SetPt.

0000

22 Input #9 BIAS

Temperature SetPt.

0000

23 Input #10 BIAS

Temperature SetPt.

0000

24 Input #11 BIAS

Temperature SetPt.

0000

25 Input #12 BIAS

Temperature SetPt.

0000

The factory default settings for all the BIAS

Temperature Setpts Var14 through Var25 is 0000,

which enables all Analog Inputs, but which disables

their BIAS alarm feature. (More details about the

BIAS alarm feature later).

D) What temperature scale do you want to use, Fº

Fahrenheit or Cº Celsius?

Set Var30 Temperature_Display_Select as needed.

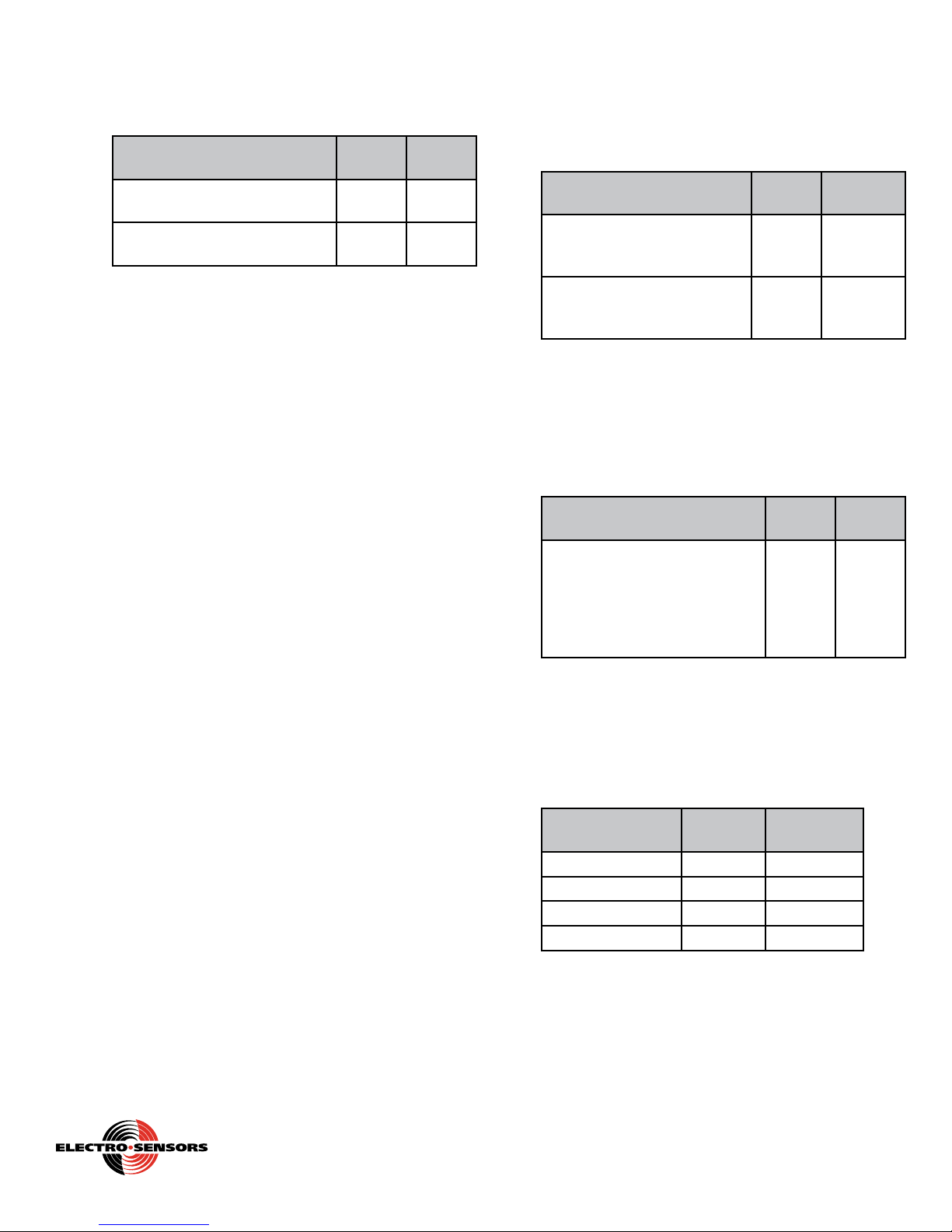

Variable Default

Value

User’s

Value

Var30 Temperature_Display_

Select.

0000 = Fahrenheit, Fº.

0001 = Celsius, Cº.

0000

(Fº)

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

III

E) What temperature levels do you want for the

‘Yellow_Alarm’ Warning Setpt, and the ‘Red_

Alarm’ Shutdown Setpt?

Set the following variables as needed:

Variable Default

Value

User’s

Value

Var12 Warning_Setpt_

Temperature (‘Yellow_Alarm’)

0160

degrees

Var13 Shutdown_Setpt_

Temperature (‘Red_Alarm’)

0175

degrees

F) Do you want to use the BIAS Temperature Setpt

alarm feature?

This is where the temperature difference (or deviation)

of a left-side temperature sensor triggers a BIAS Setpt

‘Yellow_Alarm’ if it exceeds its right-side companion

sensor by the left-side BIAS Setpt amount (and likewise

vice-versa). The BIAS Setpts are in Var14 through

Var25 (as shown in the table to the left).

The factory default settings for all the BIAS

Temperature Setpts Var14 through Var25 is 0000,

which enables all Analog Inputs, but which disables

their BIAS alarm feature.

See the table on page 5 of the Reference portion of the

User Manual for more details about left-side/right-side

temperature sensor BIAS companion pairs.

If you want to use the BIAS Temperature Setpt

alarm feature, then set the desired Analog Input’s

VarXX BIAS Temperature Setpt to the deviation

desired, in degrees.

– For example, set left-side Input #1 temperature

sensor’s BIAS setpt Var14 to 0020 degrees

if you want a BIAS Setpt ‘Yellow_Alarm’ to

happen when Input #1’s temperature rises 20

degrees higher than its right-side companion’s

temperature at Input #2.

If you do NOT want to use the BIAS Temperature

Setpt alarm feature, then set (or leave) the desired

Analog Input’s VarXX BIAS Temperature Setpt to

0000 (to disable the BIAS Setpt feature).

See section (3, A) above for which Analog Input is a

left-side input and which Analog Input is a right-side

input (as set by the position of the Analog Input’s

corresponding 3-digit LED display on the ES1’s Front-

Panel).

See section (3, C) above for the correlation between

VarXX BIAS Temperature Setpts and the Analog Input

#’s.

See the “UserVar Variables” section in the Reference

portion of the User Manual for details on any of the

above mentioned VarXX’s, if so needed.

G) What Temperature or Contact Closure alarms do

you need?

Is a Temperature or Contact Closure Warning Alarm

or a Temperature Shutdown Alarm needed?

If so, connect the application’s ‘alarm’ circuitry to the

ES1’s terminal blocks as shown in the following table:

Function Relay

Output#

Terminal

Blocks

(Speed or) Temperature

Shutdown alarm

(N/A to Contact Closure)

4 TB24

TB23

(Speed or) Temperature/

Contact Closure

Warning alarm

3 TB22

TB21

(These two ES1 relay outputs are ‘Dual Form C SPDT’).

4) Do you need a Horn, a Red Light, a Yellow Light,

or a Green Light for audio/visual alarm indication,

whenever a Speed alarm, a Temperature alarm or a

Contact Closure alarm occurs?

A) If you need a Horn, then set Var33 Horn_Operation_

Select, as needed:

Variable Default

Value

User’s

Value

Var33 Horn_Operation_Select.

See details in Reference Section.

Note: A setting of 0999 is for

a solid blast until a manual

‘Silence_Horn/Alarm_RESET’

command is given.

0999

See Reference portion page 6 for details on Var33.

Then connect the application’s ‘Horn’ circuitry to the

ES1 as shown in the table below.

B) If you need a Red Light, a Yellow Light, or a Green

Light then connect the application’s ‘Light(stack)’

circuitry to the ES1’s terminal blocks as shown in the

following table:

Horn or

Light(stack)

Relay

Output #

Terminal

Block

Horn 8 TB28

Red Light(stack) 7 TB27

Yellow Light(stack) 6 TB26

Green Light(stack) 5 TB25

(These four ES1 relay outputs are ‘Single Form A

SPST’).

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

IV

5) Do you need to use the Hour Meter?

A) NO, the Hour Meter is not needed:

Skip User Variables Var31 and Var32.

Skip Var34 Hour_and_Speed_Command_Select

[unless you already set-up Var34 for Speed

Monitoring - then leave Var34 ‘as-is’].

B) YES, the Hour Meter is needed:

Set the following variables as needed:

Variable Default

Value

User’s

Value

Var31 Hour_Meter_Warning_

Time

9000

Hours

Var32 Hour_Meter_

Maintenance_Time

9500

Hours

Var34 Hour_and_Speed_

Command_Select.

0000 = Maintained

Disable/Enable.

0001 = One-Shot Disable/Enable

with Disable = Closed

0002 = One-Shot Disable/Enable

with Disable = Open.

0000

Note: The Hour Meter increments and its discrete Green/

Yellow/Red LEDs light-up only if all of the following

are true:

· If Var31 is non-zero.

(i.e., Var31 = 0000 disables the Hour Meter).

· AND If in Normal Mode, not in Program Mode.

(i.e., Being in Program Mode disables the Hour

Meter).

· AND If the Hour_and_Speed_Enable command

is present. (i.e., The Hour_and_Speed_Disable

command disables the Hour Meter).

If any one of these three prerequisites are NOT met, then

the Hour Meter does NOT increment hours, NOR do the

Hour Meter’s discrete Green/Yellow/Red LEDs light-up

as per the number of hours reached.

6) Leave Var35 Test Mode Select at the default value of

‘0000’, to operate the ES1 in the ‘real-live-data-mode’.

7) Please see the Reference Section of the User Manual

for details of any of the UserVars.

8) Please see the Reference Section of the User Manual

for details of the TBx terminal blocks (found on pages

18 and 19 of the Reference Section), or use the handy

diagram silkscreened into the back side of the Front-

Panel.

9) For easy reference, log your user variable values in the

chart on the inside of the Electro-Sentry 1’s front cover.

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

V

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Description

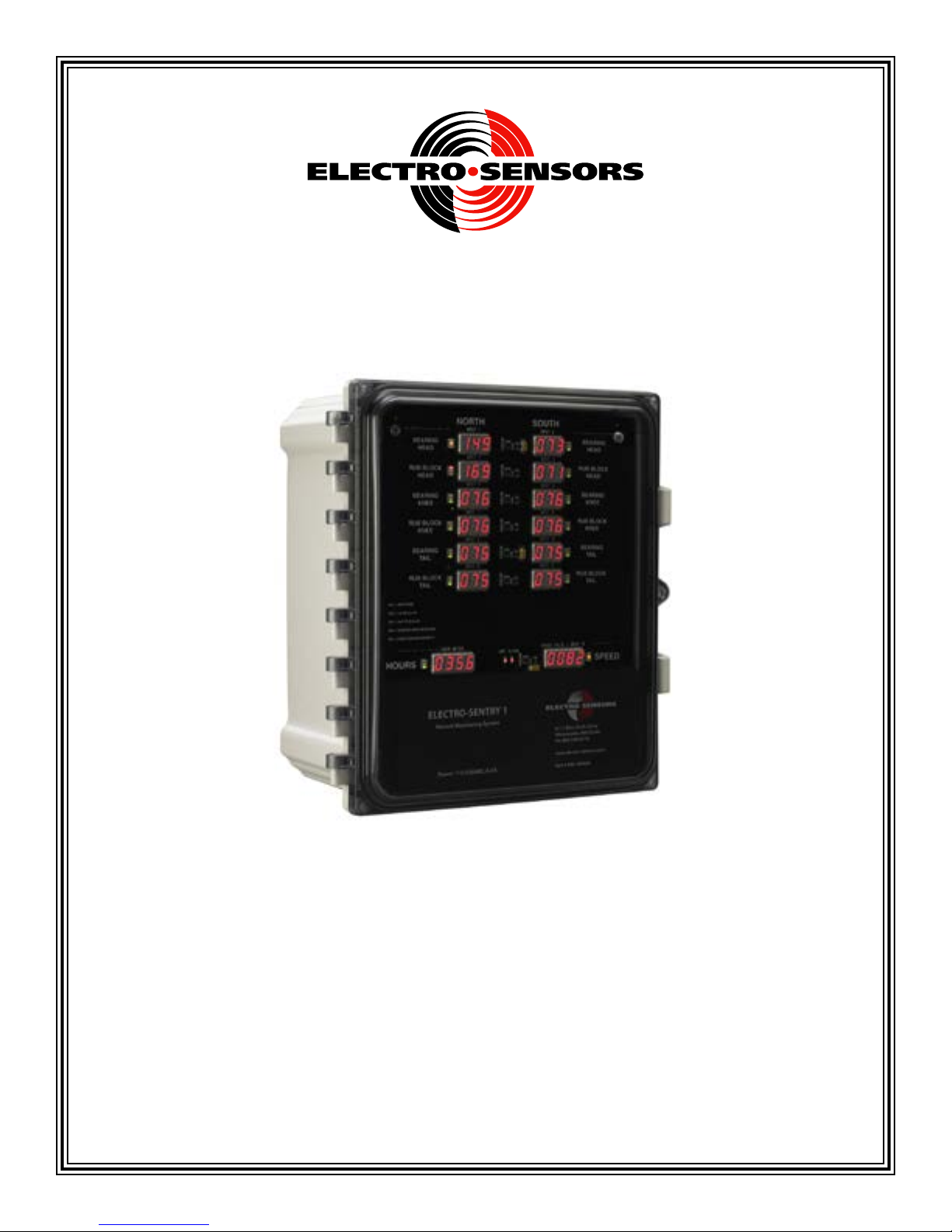

The Electro-Sentry 1 (a.k.a. ES1) is a Complete Single-Leg

Hazard Monitoring System. The ES1 contains the following:

At-a-glance Temp/Speed monitoring with alarm identification,

for up to twelve 4-20 mA analog Temperature sensors, and for

one 4-20 mA analog or pulse-train Speed sensor.

8 relay outputs, for Temperature/Speed alarms, for a Green/

Yellow/Red Lightstack operation, and for a Horn.

Built-in Hour Meter to aid in maintenance schedules.

Minimal end-user calibration and setup, with calibration stored

in non-volatile EEPROM memory.

Easy one-button tests of systems and alarms, for simulating

temperature increases and speed decreases.

Rugged, industrial-duty systems and sensors.

Front-Panel Displays

• Twelve Temperature 3-digit LED displays, each with its own

discrete Green/Yellow/Red status LED.

• One Speed 4-digit LED display, with its own discrete Green/

Yellow/Red status LED.

• One Hour Meter 4-digit LED display, with its own discrete

Green/Yellow/Red status LED.

• One Four-digit LCD display to aid in programming UserVars

(located in lower-left-corner of Front-Panel).

Front-Panel User Interface

• Four Push-buttons for programming UserVars. The buttons are

ENTER, SHIFT-LEFT, INCRement, and DECPT.

• One Push-button for Hour_Meter_RESET.

• One Push-button for Test_Left_Side_Temperature_Rise.

• One Push-button for Test_Right_Side_Temperature_Rise.

• One Push-button for Test_Speed_Drop.

Enclosure

The enclosure is rated: NEMA 3R, NEMA 4, NEMA 4X, and

NEMA 12. Customer to cut their own conduit holes, preferably in

the bottom wall of the enclosure.

Modes of Operation:

The Electro-Sentry 1 has two modes of operation, Normal Mode

and Program Mode.

When in either mode the Front-Panel temperature and speed

displays, and their alarms are active. The presence of either

mode can be seen by looking at the small four-digit LCD display

located in the lower-left-corner of the Front-Panel, as follows.

Normal Mode

This mode is the normal operation mode, and it is to be used

when the user is NOT changing any of the UserVars.

The Normal Mode is indicated by the absence of the “VAR”

icon in the lower-left-corner of the LCD display.

Program Mode

This mode allows the user to change the UserVar variables.

The LCD display will display the name of the present active

variable (as ‘PrXX’) or its value (as ‘XXXX’).

The Program Mode is indicated by the presence of the “VAR”

icon in the lower-left-corner of the LCD display.

Entering and Using Program Mode:

Programming is accomplished by using the four pushbuttons

located in the lower left corner of the Front-Panel.

The four UserVar programming buttons are ENTer, Shift-left,

INCRement, and DECPT.

a) Press the ENTer button. The “Var” icon will display on the

LCD and the 4 digits will show “PR01”.

b) Press the INCRement button repeatedly until you get to the

variable you want to change.

c) Press the ENTer button to access that variable.

d) While in that variable you must press the INCRement button

to change the active digit (flashing digit), then press the

Shift-left button to work your way through all accessible

digits. (Not all digits are accessible in all UserVars).

e) When you are done with that variable press the ENTer button

to save that new UserVar value, and return to the ‘PrXX’ list.

f) To step to the next variable in the ‘PrXX’ list press the

INCRement button.

g) To exit the Program Mode and get back to Normal Mode,

repeatedly press the INCRement button while in the ‘PrXX’

list until the “VAR” icon disappears, or simply press the

DECPT button while in the ‘PrXX’ list to make a ‘quick-

exit’ out of Program Mode.

Note: If the user does NOT manually exit the Program

Mode, and if there is no further activity in Program

Mode for one minute, then the ES1 automatically

exits the Program Mode.

When this ‘auto-exit’ is performed, any UserVar

that was changed and accepted by pressing the

ENTER button during the present Program Mode

session will have their new value properly retained.

If the LCD screen was displaying a UserVar’s value

(and not displaying the name ‘PrXX’) at the instant

the ‘auto-exit’ was performed, then that particular

UserVar value is restored to its previous value

(and its new unsaved value is lost). This since the

user had NOT pressed the ENTER button during

the present Program Mode session to accept the

present ‘flashing’ new value of that UserVar.

Note: Electro-Sentry 1’s UserVars all have the decimal point

locked in the far right position.

1

Electro-Sentry 1 Reference Manual

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

How to reset the Electro-Sentry 1’s UserVars back to

factory-defaults

Use this procedure to reset the Electro-Sentry 1’s UserVars back

to factory-default values:

1) Remove the Vac power.

2) Simultaneously press and hold the INCRement and ENTER

buttons (located just below the small four-digit LCD display

in the lower-left-corner of the Front-Panel).

3) Re-apply the Vac power.

4) When the small LCD display shows “rESE”, release the

buttons. (The UserVars have now been automatically reset to

their factory-default values).

The UserVar Variables:

Speed variables (Var01 through Var10)

The Electro-Sentry 1 has two speed signal inputs (only one at a

time can be programmed for use, as per Var01):

the first input accepts a 4-20 mA signal (TB16),

the second input accepts pulse train signals (TB30).

Var01. Encoder_Type_Select.

The Var01 range is limited to these below listed choices:

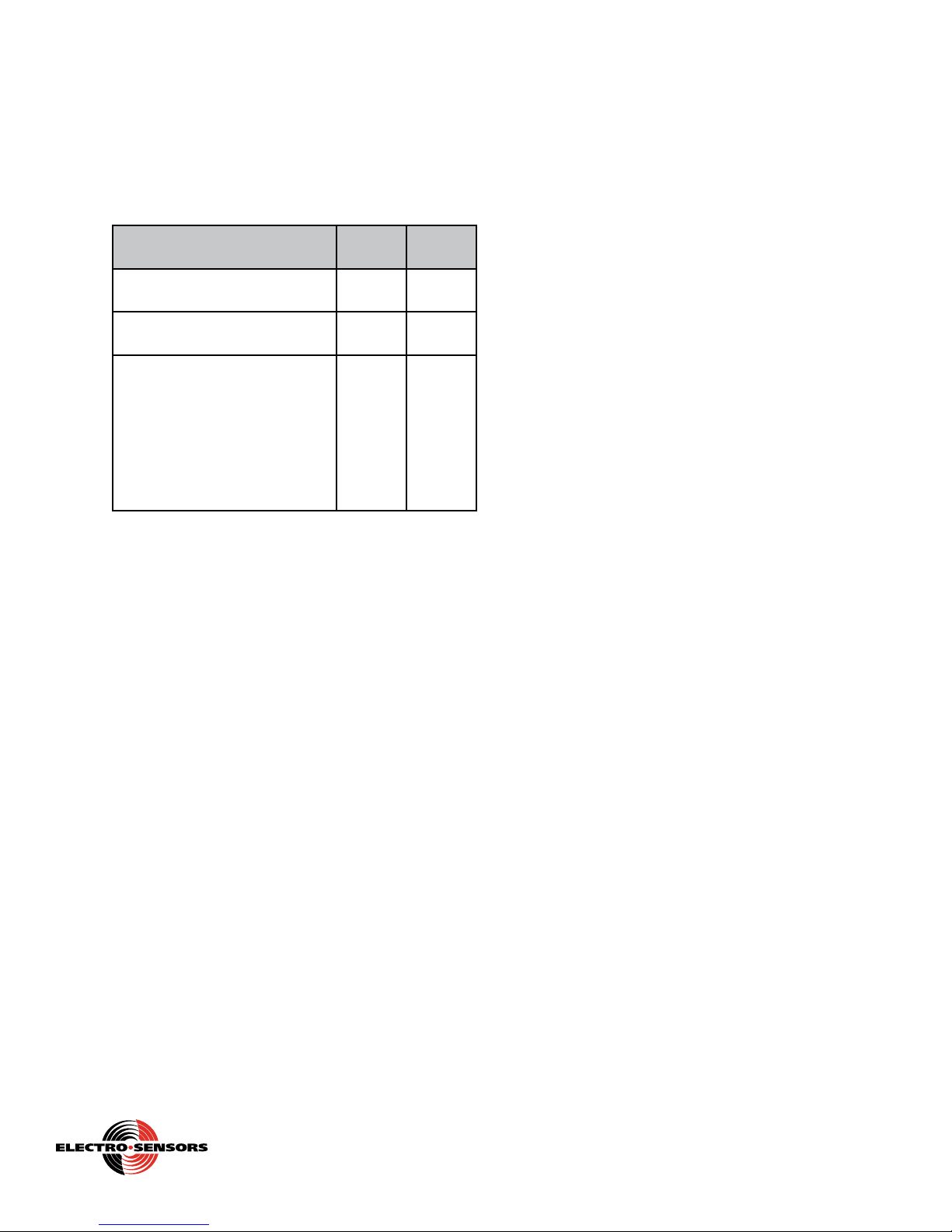

Var01

Value

Encoder

Type

Selection

Speed

Signal

Input

Speed vs. mA or RPM

Reference Points

0000 4-20mA

Analog TB16

0% speed = 4mA = 0 RPM.

20mA = Var03_RPM_at_20mA

(but this 20mA point is NOT nec-

essarily the 100% speed point. See

Var10 MAX_ANALOG_RPM for

related information).

0001 Pulse-

Train TB30

0% speed = 0 RPM.

100% speed = Var03_PULSE_

MAX_RPM

Factory default for Var01 is 0000 for 4-20 mA Encoder Type.

If Var01=0001 for Pulse-Train Encoder Type, then the NPN vs

PNP or 5V logic-level Encoder Type is further selected by SW9

(the 3-pin DIP switch located on the back side of the Front Panel,

to the left of the J7 ribbon cable) as follows:

SW9 Switch

Switch Pin # 1 Pullup 2 Pulldown 3 Cap filter

NPN ON OFF OFF

PNP, 5V Logic OFF ON OFF

Note: Switch ‘ON’ is towards your right when facing SW9.

Var02. Pulse_Per_Rev Value.

This is the number of pulses generated by the rotating magnetic

target.

Var02 range is 0000 to 9999 PPR.

Factory default for Var02 is 0008 PPR,

Note: If Var01=0000 for the 4-20 mA Analog Encoder Type,

then Var02 is irrelevant and its value is ignored, and

a value of 60 PPR is assumed for internal frequency

calculations.

Var03. PULSE_MAX_RPM or RPM_at_20mA.

If Var01=0000 for 4-20mA encoder type, then Var03 is the

encoder’s rated RPM that corresponds to a 20mA output.

If Var01=0001 for Pulse-Train encoder type, then Var03 is

the maximum RPM of the rotating magnetic target seen in the

application.

Var03 range is 0000 to 9999 RPM.

Factory default for Var03 is 0200 RPM.

Var04. Speed_Slowdown_Alarm_Setpt_%

Var04 is the speed at which a slowdown warning alarm occurs,

as expressed in % of Var03 PULSE_MAX_RPM for pulse-train

encoders, and % of Var10 MAX_ANALOG_RPM for 4-20mA

encoders.

(Alarms as: Speed display’s discrete Yellow-LED /

Yellow-Lightstack-Relay / Speed-Only-Warning-Relay /

Speed-Temperature-Warning-Relay / Horn-Relay).

Var04 range is 0000 to 2000 %.

Factory default for Var04 is 0090 %.

Var05. Speed_Slowdown_Alarm_Delay.

This is the number of seconds to wait after the speed has dropped

below the slowdown Setpt, before actually triggering the alarm.

Var05 range is 0000 to 0030 seconds.

Factory default for Var05 is 0001 second.

Var06. Speed_Shutdown_Alarm_Setpt_%.

Var06 is the speed at which a shutdown alarm occurs as

expressed in % of Var03 PULSE_MAX_RPM for pulse-train

encoders, and % of Var10 MAX_ANALOG_RPM for 4-20mA

encoders.

(Alarms as: Speed display’s discrete Red-LED /

Red-Lightstack-Relay / Speed-Only-Shutdown-Relay /

Speed-Temperature-Shutdown-Relay / Horn-Relay).

Var06 range is 0000 to 2000 %.

Factory default for Var06 is 0080 %.

Var07. Speed_Shutdown_Alarm_Delay.

This is the number of seconds to wait after the speed has dropped

below the shutdown Setpt, before actually triggering the alarm.

Var07 range is 0000 to 0030 seconds.

Factory default for Var07 is 0001 second.

2

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Var08. Underspeed_Start_Delay_Time.

This is the number of seconds to wait after an

Hour_and_Speed_Enable command has been given, before

enabling speed monitoring.

Var08 range is 0000 to 0030 seconds.

Factory default for Var08 is 0005 seconds.

Var09. Speed_Display_Select.

Show speed in % or RPM on the 4-digit LED Speed Display, and

Enable/Disable Speed Alarm Monitoring.

The Var09 range is limited to the display selections listed below:

Var09

Value

Display

Selection

Speed Alarm

Monitoring

0000 Speed in % Enabled

0001 Speed in RPM Enabled

0002 Speed in % Disabled

0003 Speed in RPM Disabled

Factory default for Var09 is 0000 for speed in ‘%’ and Speed

Alarm Monitoring enabled.

Var10. MAX_ANALOG_RPM.

When Var01=0000 for 4-20mA analog encoder type, then Var10

MAX_ANALOG_RPM is the maximum RPM seen by the

4-20mA encoder in the application.

Note: Var10 is meant to be used when the application’s

maximum speed is less than the analog speed encoder’s

rated 20mA RPM (i.e. a Var10 less than Var03).

Var10 range is 0000 to 9999 RPM.

Factory default for Var10 is 0200 RPM.

Note: If Var01 is set for Pulse-Train encoder type, then Var10 is

irrelevent and it’s value is ignored.

Sensor Type Select Variable (Var11)

Var11. Belt_Alignment_Sensor_Type_Select.

Var11 allows the Analog Inputs #’s 3, 4, 7, 8, 11, and 12, to be

programmed for either 4-20mA Temperature type sensors or for

Contact-Closure type sensors. Rub Block sensors are always

expected to be operated in pairs and are horizontally across from

each other on the ES1’s Front-Panel.

Var11 range is 0000 to 1111, with only 0’s and 1’s allowed.

The left-most-digit programs the Contact-Closure’s Sensor Logic.

The three-right-most-digits program the Analog Input pair’s

Sensor Type.

0Var11=

Tail Rub Block Pair (Inputs 11 & 12)

Sensor Type:

0 = 4-20mA

1 = Contact Closure

Knee Rub Block Pair (Inputs 7 & 8)

Head Rub Block Pair (Inputs 3 & 4)

0 0 0

Sensor Logic:

0 = Open ckt is “SAFE”, Closed ckt = Alarm

1 = Closed ckt is “SAFE”, Open ckt = Alarm

· Left-most-digit = ‘0’: programs the normally ‘Open-circuit’

case as the ‘non-alarm’ Green zone state, and the Contact-

Closure’s ‘Closed -circuit’ case as the ‘Yellow_Alarm’ state.

· Left-most-digit = ‘1’: programs the normally ‘Closed-circuit’

case as the ‘non-alarm’ Green zone state, and the Contact-

Closure’s ‘Open-circuit’ case as the ‘Yellow_Alarm’ state.

Factory default for Var11 is 0000, for all Analog Inputs are set

for 4-20 mA temperature sensors.

Notes for Var11:

· When a Contact-Closure sensor gives an alarm it is a ‘Yellow_

Alarm’ only (i.e., no ‘Red_Alarm’ for a Contact-Closure).

· When a Contact-Closure sensor ‘alarms’, it alarms with

the corresponding 3-digit display’s discrete Yellow-LED /

Yellow-Lightstack-Relay / Speed-Temperature-Warning-Relay

/ Horn-Relay, and the 3-digit LED display shows ‘ALr’. If

the Contact-Closure sensor were to return to the Green zone

‘non-alarm’ state, then the ‘Yellow_Alarm’ remains ‘latched’,

with the 3-digit LED display remaining at ‘ALr’. Once the

Contact-Closure sensor has returned to the Green zone ‘non-

alarm’ state, then to ‘clear’ the latched ‘Yellow_Alarm’ the user

must give a ‘Silence_Horn/Alarm_RESET’ command to the

ES1. (See Operating Note section “How to Clear Alarms” for

details.)

(Var11 continued on next page).

3

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

4

· When the message ‘bAd’ is shown on the Contact Closure’s

corresponding 3-digit LED display, the associated relays go

into a ‘Yellow_Alarm’ to indicate that something is NOT

normal. Most likely the user has programmed for a Contact-

Closure sensor, while they are still using a 4-20 mA type

temperature sensor. (‘bAd’ means verify sensor type).

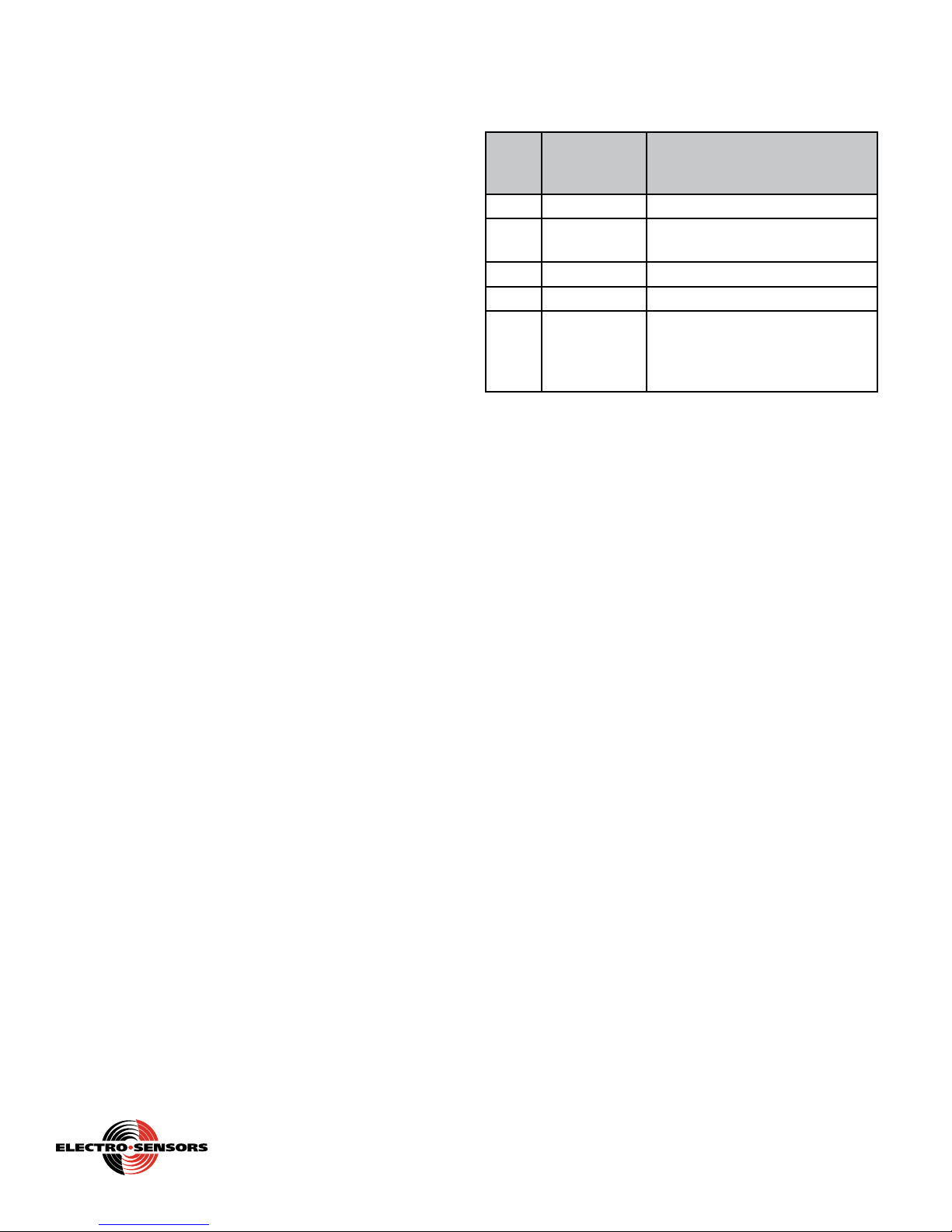

Contact Closure’s

Input

Current Range

Defined

State

Message on

3-digit

LED display

20.83mA or more Closed-Circuit

(Valid)

SAF or ALr,

as per Var11 (Valid)

1.1mA to 20.8mA Bad Sensor

(Invalid)

bAd

(Verify sensor type)

1mA or less Open-Circuit

(Valid)

SAF or ALr,

as per Var11 (Valid)

· Changes to the “Var11_Belt_Alignment_Sensor_Selection”

automatically clear any corresponding ‘orphaned’ alarms when

changing sensor pairs from Temperature sensors to Contact-

Closure sensors, and vice versa.

· A Contact-Closure input can be turned ‘OFF’ completely by

setting the input’s BIAS setpt to ‘0999’. See discussion on

Var14 through Var25 setpts below. (However note, the BIAS

feature itself is not applicable to Contact-Closure sensors).

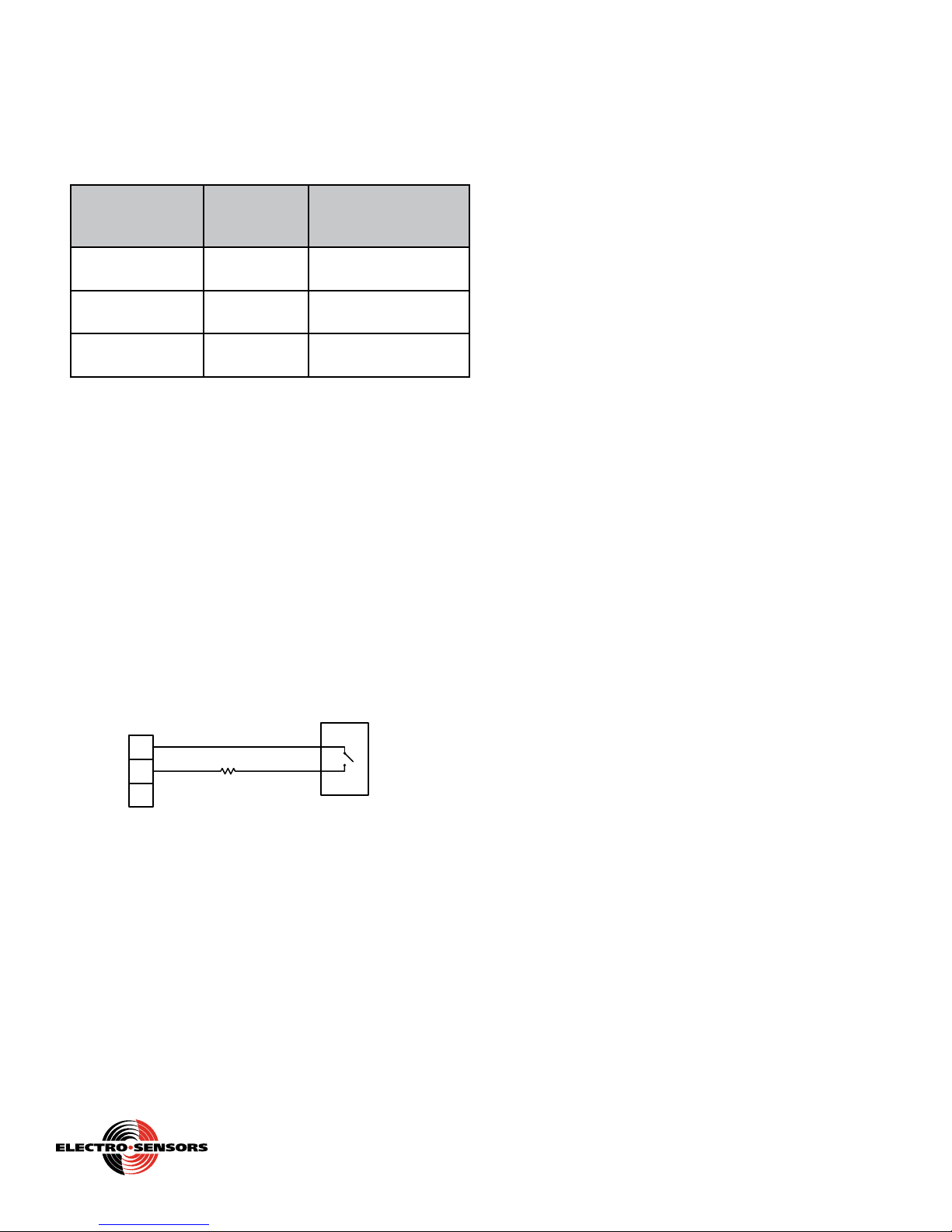

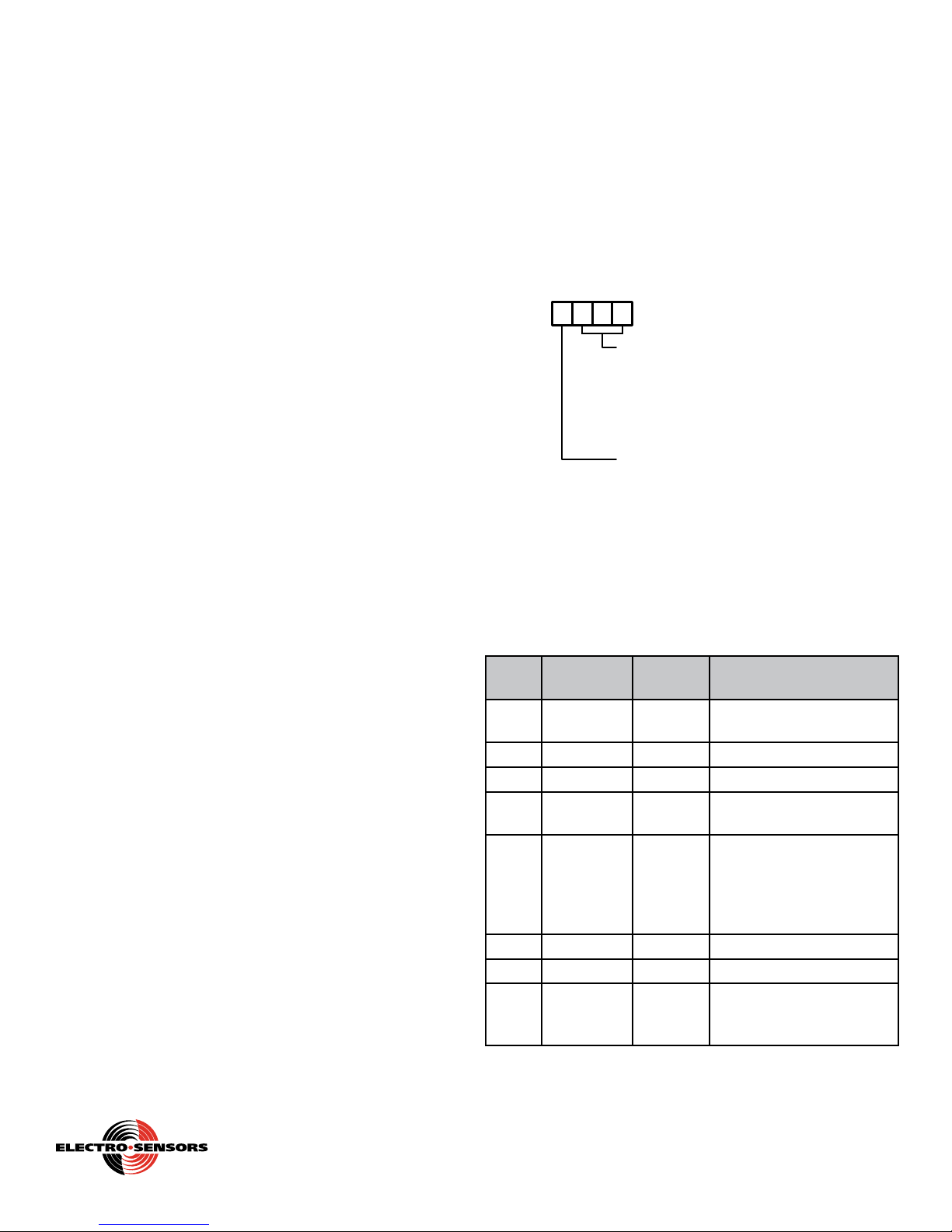

IMPORTANT NOTE: If an analog input is programmed for

use with a Contact-Closure type sensor, then an external resistor

between 360Ωto 390Ω(1 watt minimum) must be used

‘in-line’ with the corresponding Analog Input’s Signal terminal

(TBx pin2), as shown in the figure below.

The Electro-Sentry 1 is supplied with (8) eight 360Ω, 1 watt

resistors.

360Ω to 390Ω

1 watt minimum

Contact Closure

Type Sensor

ES1’s

4-20mA

Input

1

TBx

2

3

The Warning and Shutdown SetPt Temperature

Variables (Var12 and Var13)

Var12. Warning_Setpt_Temperature degrees (for all

temperature sensors).

If a Temperature Sensor exceeds this SetPt, then the ES1 gives an

alarm by the corresponding temperature display’s discrete

Yellow-LED / Yellow-Lightstack-Relay /

Temperature-Warning-Relay / Horn-Relay, and the 3-digit LED

display ‘Latches’ the highest value reached.

Var12 range is 0000 to 0250 degrees.

Factory default for Var12 is 0160 degrees.

Var13. Shutdown_Setpt_Temperature degrees (for all

temperature sensors).

If a Temperature Sensor exceeds this SetPt, then the ES1 gives an

alarm by the corresponding temperature display’s discrete

Red-LED / Red-Lightstack-Relay /

Temperature-Shutdown-Relay / Horn-Relay, and the 3-digit LED

display ‘Latches’ the highest value reached.

Var13 range is 0000 to 0250 degrees.

Factory default for Var13 is 0175 degrees.

Notes: For Var12 and Var13: To ‘clear’ the latched Yellow or

Red_Alarm the user must give a ‘Silence_Horn/Alarm_RESET’

command to the ES1 once the temperature has dropped below the

associated setpt. (See Operations Notes Section “How to Clear

Alarms” for details).

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

The BIAS Setpt Temperature Variables (Var14 through

Var25)

The below listed BIAS Setpts set the temperature difference

(or deviation) at which a left-side temperature sensor triggers a

BIAS Setpt ‘Yellow_Alarm’ if it exceeds its right-side companion

sensor by the left-side BIAS Setpt amount.

And likewise vice-versa if a right-side sensor exceeds its left-side

companion sensor by the right-side BIAS Setpt amount.

Each sensor input has its own BIAS Setpt, with range 0000 to

9999.

A BIAS Setpt = 0000 enables the Analog Input, but disables

its BIAS Alarm “Left-side sensor vs. Right-side sensor”

comparison feature.

A BIAS Setpt between 0001 and 0998 enables the Analog

Input, and enables its BIAS Alarm feature by giving it the

desired temperature deviation SetPt value.

A BIAS Setpt = 0999 disables an Analog Input completely

by turning ‘OFF’ that particular temperature sensor’s input

and its effects on the temperature alarms. The sensor’s 3-

digit LED display then shows ‘OFF”.

Note: Even though the BIAS setpts accept up to 0998 degrees,

typical ESI sensors only run up to 248 degrees.

The BIAS Setpts are in Var14 through Var25, and all have a

factory default of 0000, which enables all analog inputs, but

which disables their BIAS alarm feature.

The left-side/right-side BIAS ‘companion’ pairs are listed

below with their associated analog input, UserVar variable, and

nomanclature.

Input # Variable Nomanclature

1 Var14 Head Bearing Left BIAS SetPt

2 Var15 Head Bearing Right BIAS SetPt

3 Var16 Head Rub Block Left BIAS SetPt

4 Var17 Head Rub Block Right BIAS SetPt

5 Var18 Knee Bearing Left BIAS SetPt

6 Var19 Knee Bearing Right BIAS SetPt

7 Var20 Knee Rub Block Left BIAS SetPt

8 Var21 KneeRub Block Right BIAS SetPt

9 Var22 Tail Bearing Left BIAS SetPt

10 Var23 Tail Bearing Right BIAS SetPt

11 Var24 Tail Rub Block Left BIAS SetPt

12 Var25 Tail Rub Block Right BIAS SetPt

13 Var26 Unused / Reserved

14 Var27 Unused / Reserved

15 Var28 Unused / Reserved

16 Var29 Unused / Reserved

When a BIAS Setpt’s deviation value is exceeded, it gives an

alarm by turning ON the corresponding temperature display’s

discrete Yellow-LED, plus putting the Yellow-Lightstack-Relay

/ Speed-Temperature-Warning-Relay / Horn-Relay, all into their

alarm states.

Also, once a sensor goes into a BIAS Setpt ‘Yellow_Alarm’,

its 3-digit LED display ‘Latches’ the highest value reached. To

‘clear’ the latched BIAS Setpt ‘Yellow_Alarm’ the user must give

a ‘Silence_Horn/Alarm_RESET’ command to the ES1 once the

temperature has dropped below the BIAS setpt. (See Operations

Notes Section “How to Clear Alarms” for details).

Var30. Temperature_Display_Select. (Temperature in Fº

Fahrenheit or Cº Celsius).

The Var30 range is limited to these below listed choices:

‘0000’ = display temperatures in Fº Fahrenheit.

‘0001’ = display temperatures in Cº Celsius.

Note: If you setup your ES1 to display temperatures in

Fahrenheit Fº and have your temperature setpts in Fº, and

then later change Var30 to Celsius Cº, the ES1 does NOT

automatically convert the setpts over to equivilent Cº

values, (or vice versa Cº to Fº)

Factory default for Var30 is 0000 for degrees Fahrenheit.

5

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

System Variables (Var31 through Var36)

Var31. Hour_Meter_Warning_Time in Hours.

(Alarms as: Hour Meter display’s discrete Yellow LED only, with

no relays involved).

The Hour Meter keeps track of how long the system has been in

operation, assuming a few prerequisites are first met.

The Hour Meter increments and its discrete Green/Yellow/Red

LEDs light-up only if all three of the following cases are true:

If Var31 is non-zero.

(i.e., Var31 = 0000 disables the Hour Meter).

AND If in Normal Mode, not in Program Mode.

(i.e., Being in Program Mode disables the Hour Meter).

AND If the Hour_and_Speed_Enable command is present

at TB34. (i.e., The Hour_and_Speed_Disable command

disables the Hour Meter).

If any one of these three prerequisites are NOT met, then the

Hour Meter does NOT increment hours, NOR do the Hour

Meter’s discrete Green/Yellow/Red LEDs light-up as per the

number of hours reached.

The Hour Meter value is automatically saved once every 10

minutes, because of this at most only 10 minutes of operating

time is ignored if the ES1’s Vac power is lost.

For normal Hour Meter operation once the Var31 Hour value is

exceeded, then the Hour Meter’s discrete Green LED turns ‘OFF’

and its discrete Yellow LED turns ‘ON’.

When operation exceeds the Var32 Hour value, then the Hour

Meter’s discrete Yellow LED turns ‘OFF’ and its discrete Red

LED turns ‘ON’.

The Hour_Meter feature does NOT trigger the Horn-Relay alarm,

nor the Yellow-Lightstack-Relay alarm, nor the

Red-Lightstack-Relay alarm, nor the Unit_Alarm_LEDs.

If not manually cleared after 9999 hours, the Hour Meter holds at

9999 hours with its discrete Yellow or Red LEDs ‘ON’.

There is an Hour_Meter_RESET button on the Front-Panel, and

an AUX_Hour_Meter_RESET at input TB31:1,2, that can be

used to ‘clear’ the Hour Meter. When an Hour_Meter_RESET

command is given for longer than 3 seconds it returns the meter

to 0000 and turns OFF the Hour Meter’s discrete Yellow/Red

LEDs, and turns ON the Hour Meter’s discrete Green LED.

Note: A Var31 = ‘0000’ disables the Hour Meter (i.e., keeps it

from growing), and also turns ‘OFF’ the Hour Meter’s

discrete Green/Yellow/Red LEDs. This Var31 = 0000

feature does NOT clear the Hour Meter, but rather keeps

it from growing any further when an Hour_and_Speed_

Enable command is present.

Note: If the UserVar programming LCD screen is in Program

Mode, then the Hour Meter feature is disabled and the

Hour Meter cannot increase (even if an Hour_and_Speed_

Enable command is present). Also when in Program Mode

the Hour_Meter_RESET command is disabled.

Var31 range is 0000 to 9999 Hours.

Factory default for Var31 is 9000 Hours.

Var32. Hour_Meter_Maintenance_Time in Hours.

(Alarms as: Hour Meter display’s discrete Red LED only, with no

relays involved).

Var32 range is 0000 to 9999 Hours.

Factory default for Var32 is 9500 Hours.

Var33. Horn_Operation_Select.

Var33 selects how the user wants the Horn-Relay to sound.

Var33 range is 0000 to 1999.

The Var33 value is limited to these below listed choices.

X

Var33=

The left-most digit selects Horn ‘type’:

0 = the Horn is a solid blast.

1 = the Horn is an oscillating blast.

(1 sec ON, 3 sec OFF, etc.).

The three right-most digits set the

Horn sounding ‘time’:

000 to 998 = the number of minutes to

sound the Horn.

(See Note5).

999 = sound the Horn indefinitely.5

X X X

Note5: The user can always give a manual ‘Silence_Horn/

Alarm_RESET’ command at any time to turn OFF the

Horn, and keep it OFF, until the Horn sounds again for

the next alarm event.

The usable values of Var33 are 0000 to 1999. Some examples are

shown in the table below:

Var33

Value

Horn

Type

Horn

Time Notes

0000 Solid Blast Indefinite This has the same effect as

Var33=0999

0001 Solid Blast 1 Min. ---

0030 Solid Blast 30 Min. ---

09996Solid Blast Indefinite Solid Horn until a ‘Silence_

Horn/Alarm_RESET’ given

1000 Oscillating 0

This is an oscillating blast

for ‘0’ minutes, consisting

of only one ‘beep’ lasting

1 second ON and then a

continuous OFF

1001 Oscillating 1 Min. ---

1030 Oscillating 30 Min. ---

1999 Oscillating Indefinite

Oscillate Horn until a

‘Silence_Horn/Alarm_

RESET’ given.

Note6:Factory default for Var33 is 0999 for solid blast until a

‘Silence_Horn/Alarm_RESET’ command is given.

6

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Note: The Var33 Horn_Operation_Select can be changed at

any time, whether or not an alarm event is present. Also,

while the Horn Relay #8 is sounding, Var33 can be

changed ‘on-the-fly’ from solid blast to oscillating blast,

or from oscillating blast to solid blast, and its effects are

immediately heard (as long as the Horn ‘time’ has not

expired following an alarm event.)

Note: The Horn-Relay is also used to tell the user that a

‘Silence_Horn/Alarm_RESET’ command has existed

for 60 or more seconds. This happens independently of

how Var33 is programmed. See Troubleshooting Section

“LCD Display and 4-digit LED Display Error Messages,

Err6” for details.

Var34. Hour_and_Speed_Command_Select.

Var34 selects how the Disable/Enable commands are given to the

ES1 for operating the Hour_Meter and for Speed_Monitoring.

The Var34 range is limited to these below listed choices:

‘0000’ = Disable (i.e., Stop) the Hour_Meter and Speed_

Monitoring by a ‘maintained’ open input at TB34 (i.e.,

TB34 pin 1 disconnected from pin 2).

Enable (i.e., Run) the Hour_Meter and Speed_

Monitoring by a ‘maintained’ closed input at TB34 (i.e.,

TB34 pin 1 connected to pin 2).

‘0001’ = Disable (i.e., Stop) the Hour_Meter and Speed_

Monitoring by a ‘maintained’ closed or

a ‘one-shot’ closed input at TB32 pins 1 and 2.

Enable (i.e., Run) the Hour_Meter and Speed_

Monitoring by a ‘one-shot’ closed input at TB34 pins

1 and 2, (but if-and-only-if the ‘Disable’ input at TB32

pins 1 and 2 is open).

‘0002’ = Disable (i.e., Stop) the Hour_Meter and Speed_

Monitoring by a ‘maintained’ open or

a ‘one-shot’ open input at TB32 pins 1 and 2.

Enable (i.e., Run) the Hour_Meter and Speed_

Monitoring by a ‘one-shot’ closed input at TB34 pins

1 and 2, (but if-and-only-if the ‘Disable’ input at TB32

pins 1 and 2 is closed).

Note: When Var34 = 0001 or 0002, then the Disable command

takes precedence over the Enable command. Because of

this, the Enable (Run) command at TB34 is only effective

if the Disable (Stop) command at TB32 is not present.

Note: If not using Speed Monitoring, then see Var09 for how to

disable Speed Monitoring completely, which then leaves

the Var34 settings to apply to just the Hour_Meter.

Factory default for Var34 is 0000 for a ‘maintained’ closed

input is needed at TB34 for an Enable command.

Note: See the “Troubleshooting Section” for related discussion

of ‘Concerning the Var34 Disable/Enable Commands’ vs.

the Speed Display’s discrete LED’s and speed alarms.

Var35. Test_Mode_Select.

This variable selects whether to operate the ES1 in the ‘real-live-

data-mode’ or in a ‘test-data-mode’.

The Var35 range is limited to these below listed choices:

Var35

Value

LED Display

Operation

Mode

Method of Relay Output Testing

0000 Live Data N.A.

0001 Test Data In simulated alarm events

(as described below)

0002 Test Data All relays held ‘energized’

0003 Test Data All relays held ‘de-energized’

0004 Test Data

Test each of the 8 digital inputs

with each of the 8 relay outputs.

(See next table for details on

Var35 = 0004).

When Var35 is set to a ‘0001’, a ‘0002’, a ‘0003’, or a ‘0004’,

then the LCD and LED displays cycle through and display all

‘0000’, all ‘1111’, all ‘2222’, etc, all the way up to all ‘9999’,

then wrap back around to all ‘0000’, repeating the cycle

indefinitely.

Also when Var35 is set to ‘non-zero’ the following happens:

When the LCD/LED displays all show ‘0000’, then the small

discrete LED warning lights are all OFF, and all four of the

LCD’s decimal points are ON as ‘0.0.0.0.’.

- And with Var35 = ‘0001’ the 8 output Relays are all

de-energized.

When the LCD/LED displays all show ‘1111’, ‘2222’, or

‘3333’, then the small discrete LED warning lights are all

Green.

- And with Var35 = ‘0001’ the 8 output Relays simulate a

‘Green zone’ event (i.e., all is okay – no alarms present).

When the LCD/LED displays all show ‘4444’, ‘5555’, or

‘6666’, then the small discrete LED warning lights are all

Yellow.

- And with Var35 = ‘0001’ the 8 output Relays simulate a

‘Yellow_Alarm’ event (i.e., a warning event).

When the LCD/LED displays all show ‘7777’, ‘8888’, or

‘9999’, then the small discrete LED warning lights are all

Red.

- And with Var35 = ‘0001’ the 8 output Relays simulate a

‘Red_Alarm’ event (i.e., a shutdown event).

(Var35 continued on next page).

7

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

When Var35 is set to a ‘0004’, then the ‘test-data-mode’

correspondence between the 8 digital switch/button inputs and

the 8 Relay outputs is shown in the table below.

(Momentarily closing the following Remote Switch Digital

Inputs or pressing the associated Front Panel button will

momentarily de-energize the following relay, otherwise the relay

is energized):

Input Nomanclature Relay

TB32 Hour_and_Speed_Disable command 8

TB33 Silence_Horn/Alarm_Reset 7

TB34 Hour_and_Speed_Enable command 6

TB31:

1-2

Aux_Hour_Meter_Reset or

HOUR_METER_RESET button on Front

Panel

5

TB31:

3-4

Aux_Test_Left_Side or

TEST_LEFT_SIDE button on Front Panel 4

TB31:

5-6

Aux_Test_Right_Side or

TEST_RIGHT_SIDE button on Front Panel 3

TB31:

7-8

Aux_Test_Speed or

TEST_SPEED button on Front Panel 2

TB31:

9-10 Aux_Silence_Horn/Alarm_Reset 1

CAUTION: Doing this Var35 test may cause actual system

alarms.

Factory default for Var35 is 0000 for operate in ‘real-live-

data-mode’.

Var36. Software Identification. (Read Only)

This variable shows which version of software is loaded into

the Electro-Sentry 1. Var36’s value is viewable only, with NO

changes allowed.

Note: The Software Identification is also shown for 2

seconds on the LCD display during power-up.

8

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Electro-Sentry 1 Operation Notes Section:

Alarms

1) The Unit_Alarm_LEDs blink when there is an alarm on the

unit, so operator can identify which unit has the alarm.

2) Speed alarms are active only when the Hour_and_Speed_

Enable command is present at TB34 AND if Var09 has

Speed Monitoring Enabled.

3) Temperature and Contact Closure alarms are always active,

independent of the Hour_and_Speed_Disable/Enable

commands.

Latching and holding of Alarms

4) Concerning the Temperature displays and ‘setpt violation

latching’:

During any Temperature ‘Yellow_Alarm’ or ‘Red_Alarm’

(i.e., a BIAS Setpt Alarm, a Warning Alarm, or a Shutdown

Alarm), the corresponding 3-digit LED temperature display

is only allowed to increase in value as the violation escalates.

This means that if the temperature input cools down on

its own accord, the maximum temperature reached will be

‘latched’ on the display, the discrete Yellow/Red LEDs will

‘latch’, and the associated relays will ‘latch’. To return the

3-digit LED temperature display to show ‘live’ temperatures,

the user must manually acknowledge the alarm by giving a

‘Silence_Horn/Alarm_RESET’ command.

5) Concerning the Contact-Closure displays and ‘alarm

latching’:

When a Contact-Closure sensor ‘alarms’, it alarms with

the corresponding 3-digit display’s discrete Yellow-LED /

Yellow-Lightstack-Relay / Speed-Temperature-Warning-

Relay / Horn-Relay, and the 3-digit LED display shows ‘ALr’

(for “Alarm”). If the Contact-Closure sensor were to return

to the Green zone ‘non-alarm’ state, then the ‘Yellow_Alarm’

remains ‘latched’, with the 3-digit LED display remaining

at ‘ALr’. Once the Contact-Closure sensor has returned to

the Green zone ‘non-alarm’ state, then to ‘clear’ the latched

‘Yellow_Alarm’ the user must give a ‘Silence_Horn/Alarm_

RESET’ command to the ES1. After that, the 3-digit LED

display then shows “SAF” (for “Safe”).

6) Concerning the Speed display and ‘setpt violation

latching’:

The ES1’s ‘setpt violation latching’ feature is slightly

different for the 4-digit Speed display than it is for the

Temperature displays. For the 4-digit Speed display during

a ‘Yellow_Alarm’ or ‘Red_Alarm’, the Speed’s discrete

Yellow/Red LEDs and Speed Alarm relays do ‘Latch’ once

the speed drops below one of the Speed Setpts, but the

actual 4-digit Speed display itself does NOT ‘Latch’. This

is because for safety reasons, we want to show ‘live’ speeds

at all times, whether or not the speed sensor has previously

dropped below one of the Speed Setpts and then since

recovered on its own.

How to ‘clear’Alarms

7) There are four ways to give a manual ‘Silence_Horn/Alarm_

RESET’ command to the ES1.

By ‘closing’ the regular ‘Silence_Horn/Alarm_RESET’

input at TB33 pins 1 and 2.

By ‘closing’ the AUXILARY ‘Silence_Horn/Alarm_

RESET’ input at TB31 pins 9 and 10.

By simultaneously pressing the Front-Panel’s TEST_

LEFT_SIDE and TEST_RIGHT_SIDE Temperature

Rise test buttons.

By simultaneously ‘closing’ the AUX_TEST_LEFT_

SIDE and AUX_TEST_RIGHT_SIDE inputs at TB31

pins 3-4 and 5-6.

A ‘Silence_Horn/Alarm_RESET’ command is used to first

turn OFF the Horn-Relay unconditionally, and further used

to ‘clear’ a Speed, Temperature, or Contact Closure alarm

(provided the alarm event has dissipated).

Note: There are a few instances where an active existing

Speed, Temperature, or Contact Closure Alarm, is

‘automatically cleared’ without the user having to give a

manual ‘Silence_Horn/Alarm_RESET’ command to the

ES1, and these are the following cases:

A Speed Alarm is automatically ‘cleared’ when the

‘Hour_and_Speed_Enable’ command is removed,

or when the Var09 Speed Monitoring selection is

changed from ‘Enabled’ to ‘Disabled’, or when the

Var01 Encoder Type Select is changed.

A Temperature or Contact Closure Alarm is

automatically ‘cleared’ when a sensor with an active

alarm (either a Temperature Setpt ‘Red_Alarm’ or

‘Yellow_Alarm’, or a BIAS Setpt ‘Yellow_Alarm’,

or a Contact Closure Alarm) has its BIAS Setpt

changed to ‘999’ to turn ‘OFF’ that sensor.

A Temperature or Contact Closure Alarm is

automatically cleared if the sensor type is changed.

A Contact Closure Alarm can be automatically

cleared when Var11’s Logic Selection is changed.

If one of the TEST_Features have been used (i.e.,

the TEST_LEFT_SIDE or the TEST_RIGHT_SIDE

Temperature Rise tests, or the TEST_SPEED

features), and if a ‘Red_Alarm’ or ‘Yellow_Alarm’

was generated by one of those tests, then that alarm

will automatically ‘clear-out’ 60 seconds after the

last TEST_Feature was used.

Also, if a ‘real’ alarm event has dissipated

during those 60 seconds following a

TEST_Feature operation, then it too will be

automatically ‘cleared’ 60 seconds after the last

TEST_Feature was used.

9

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

Using multiple Electro-Sentry 1’s in the same

application

7) Multiple Electro-Sentry 1’s can be connected together to the

same external Green/Yellow/Red Lightstack status indicator

to monitor a larger overall system, as follows:

Connect all of the individual ES1’s Green-Lightstack-

Relays in series with each other and with the external

Lightstack.

Connect all of the individual ES1’s Yellow-Lightstack-

Relays in parallel with each other and with the external

Lightstack.

Connect all of the individual ES1’s Red-Lightstack-

Relays in parallel with each other and with the external

Lightstack.

With multiple Electro-Sentry 1’s connected together as

described, the following alarm behavior is seen:

The external Green Lightstack is lit if-and-only-if all

ES1’s have no alarms present.

The external Green Lightstack is unlit if any ES1 has

any alarm present.

The external Yellow Lightstack is lit if any ES1 has a

‘Yellow_Alarm’ present.

The external Yellow Lightstack is unlit if-and-only-if all

ES1’s have no ‘Yellow_Alarms’ present.

The external Red Lightstack is lit if any ES1 has a ‘Red_

Alarm’ present.

The external Red Lightstack is unlit if-and-only-if all

ES1’s have no ‘Red_Alarms’ present.

Built-in Test Features Section:

Temperature Rise and Speed Drop Alarm Test Features

1) Press and hold the ‘TEST_LEFT_SIDE’ button on the

Front-Panel to artificially increase the temperature readings

in the left side column of temperature displays. Keep the

button pressed-in to increase the temperatures to levels

above the Var12_Warning_Setpt_Temperature, the Var13_

Shutdown_Setpt_Temperature, and/or the individual BIAS_

Temperature_Setpts. (This test can also be accessed by TB31

pins 3-4). This test can be used to test the effectiveness of

how the temperature alarm output relays will work with the

overall application. Give a manual ‘Silence_Horn/Alarm_

RESET’ command to the ES1 to ‘clear’ any alarms generated

by this test. (See Operations Notes Section “How to Clear

Alarms” for details).

CAUTION: This test will cause actual system alarms.

2) Press and hold the ‘TEST_RIGHT_SIDE’ button on the

Front-Panel to artificially increase the temperature readings

in the right side column of temperature displays. Keep

the button pressed-in to increase the temperatures to levels

above the Var12_Warning_Setpt_Temperature, the Var13_

Shutdown_Setpt_Temperature, and/or the individual BIAS_

Temperature_Setpts. (This test can also be accessed by TB31

pins 5-6). This test can be used to test the effectiveness of

how the temperature alarm output relays will work with the

overall application. Give a manual ‘Silence_Horn/Alarm_

RESET’ command to the ES1 to ‘clear’ any alarms generated

by this test. (See Operations Notes Section “How to Clear

Alarms” for details).

CAUTION: This test will cause actual system alarms.

Note: Concerning the TEST_LEFT_SIDE and TEST_

RIGHT_SIDE temperature tests, only one of these

tests can be performed at a time. If both of these

temperature tests are attempted at the same time, then

the test feature is disabled, and the dual activation

is actually an “Alarm_RESET” command. (See the

Operation Notes “How to Clear Alarms” for details).

3) Press and hold the ‘TEST_SPEED’ button on the Front-Panel

to artificially decrease the Speed Display value. Keep the

button pressed-in to decrease the speed to levels below the

Var04_Slowdown_Setpt and the Var06_Shutdown_Setpt.

(This test can also be accessed by TB31 pins 7-8). This test

can be used to test the effectiveness of how the speed alarm

output relays will work with the overall application. Give a

manual ‘Silence_Horn/Alarm_RESET’ command to ‘clear’

any alarms generated by this test. (See Operations Notes

Section “How to Clear Alarms” for details).

Note: For the ‘TEST_SPEED’ button feature to work, the

following requirements must first be met:

• Var09 must be set for Speed Monitoring Enabled.

• An Hour_and_Speed_Enable command must be

present at TB34.

CAUTION: This test will cause actual system alarms.

10

Troubleshooting Section:

Standard Temperature vs. 4-20mA Temperature

Sensors

As a quick troubleshooting guide for any of the 4-20 mA

Temperature Sensors, the following voltages can be seen at the

4-20 mA Input terminals TB1 thru TB12 (voltages as measured

between pin 2 Signal and pin 3 Analog Ground), corresponding

to the following standard temperatures:

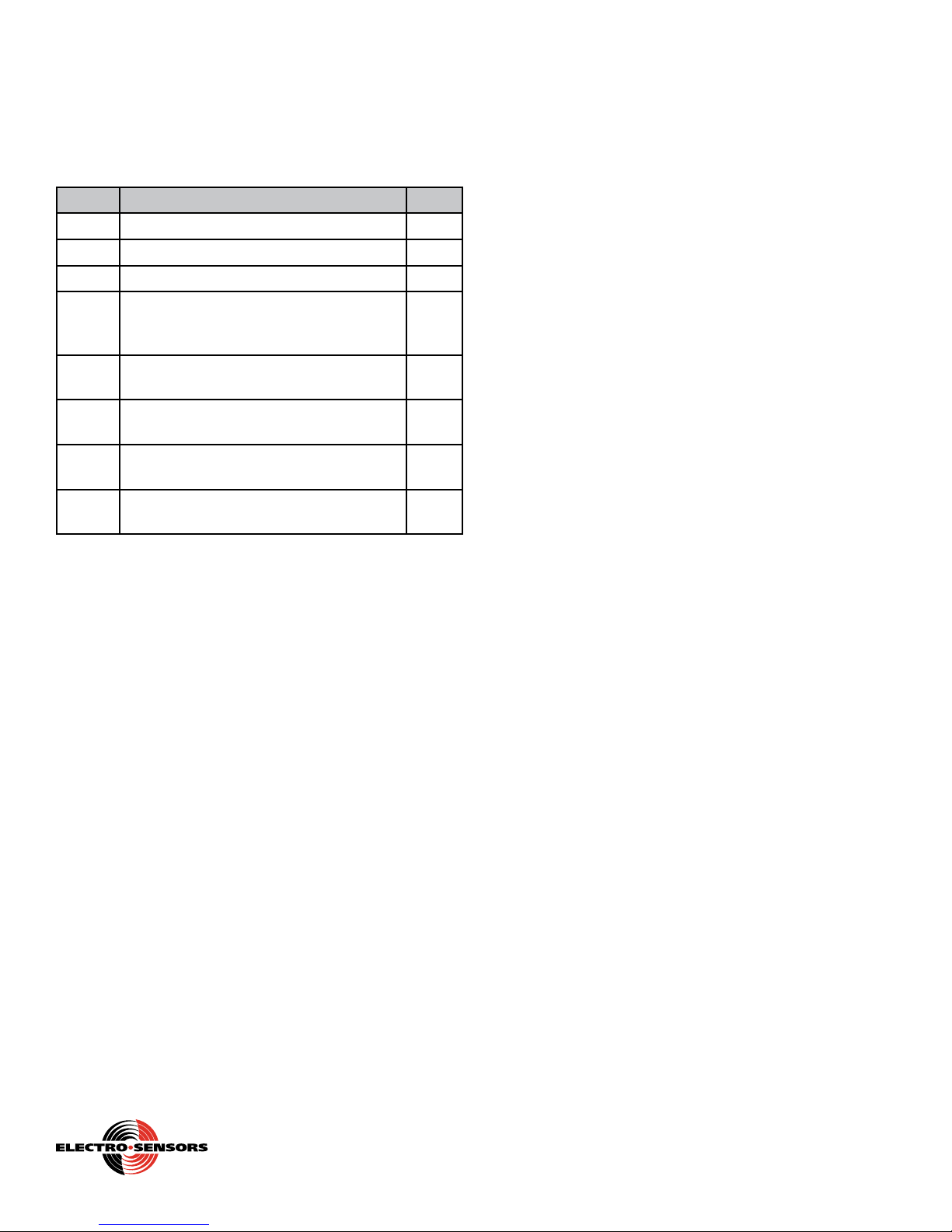

Fº Cº mA TBx Vdc

248 120 20.000 9.60

212 100 18.000 8.64

175 79.44 15.944 7.64

160 71.11 15.111 7.25

100 37.78 11.778 5.65

80 26.67 10.667 5.11

70 21.11 10.111 4.85

60 15.56 9.555 4.58

32 0 8.000 3.85

0 -17.78 6.222 2.99

-40 -40 4.000 1.92

‘Out-of-Range’ Sensor Detection

1) A 4-20 mA out-of-normal-range Temperature Sensor

Detection feature works as shown in the table below:

Temperature

Sensor’s Input

Current Range

Message shown

on 3-digit

LED Display

Type of Alarm

3.9mA to

20.1mA

N.A. (Live

Temperature)

N.A.

(Green zone.)

20.83mA

or higher

CLS

(Closed Circuit) Red_Alarm

20.1mA to

20.83mA

HI

(High_mA) Red_Alarm

1.0mA to

3.9mA

LO

(Low_mA) Yellow_Alarm7

1.0mA or

lower

OPn

(Open Circuit) Yellow_Alarm7

Note7: Because the ‘out-of-range’ Temperature Sensor LO and

OPn cases have 4-20mA signals less than 3.9mA, they are

not Var12 and Var13 over-temperature setpoint violations,

(but rather would be under-temperature cases). Because

the ES1 monitors for over-temperature behavior and not

under-temperature behavior, these cases are not outright

temperature violations. However, the Temperature Sensor

LO and OPn cases are treated as ‘Yellow_Alarm’ events

because the effected sensor could be programmed for the

BIAS setpt feature. And if a sensor goes ‘out-of-range’,

then the user needs to know this.

A) If a Temperature sensor fails as ‘LOW_mA’ or ‘Open_ckt’,

then its 3-digit display shows the “LO” or “OPn” message

respectively, and it alarms with its discrete Yellow-LED /

Yellow-Lightstack-Relay / Speed-Temperature-Warning-

Relay /Horn-Relay.

Also in this situation the opposite side companion sensor

does NOT go into a BIAS Setpt ‘Yellow_Alarm’ as a

BIAS response, for code is in place to see that the first

sensor failed. Because of this the second sensor does

NOT compare to a ‘out-of-range’ sensor.

B) If a Temperature sensor fails as ‘HI_mA’ or ‘Closed_ckt’,

then its 3-digit display shows the “HI” or “CLS” message

respectively, and it alarms with its discrete Red-LED / Red-

Lightstack-Relay / Speed-Temperature-Shutdown-Relay /

Horn-Relay.

Note: Since the ‘HI’ and ‘CLS’ cases have 4-20 mA signals

exceeding 20.1 mA, these cases must be treated as

over-temperature “Red_Alarms’.

C) Concerning the Temperature displays and ‘out-of-range’

sensor latching:

During any ‘out-of-range’ Temperature Sensor ‘Yellow_

Alarm’ or ‘Red_Alarm’ (the OPn, LO, HI, or CLS cases),

the corresponding 3-digit LED temperature display ‘latches’

the most recent message, and will not automatically

return to showing ‘live’ temperature values (even if the

sensor ‘recovers’). This means that once an ‘out-of-range’

Temperature Sensor has been detected, the corresponding 3-

digit LED display will show the most recent message. This

allows the ES1 to show if a Temperature Sensor’s condition

goes from bad to worse, such as a LO case turning into an

OPn case, or a HI case turning into a CLS case, and vice

versa. To return the 3-digit LED temperature display to show

‘live’ temperatures, the user must manually acknowledge the

alarm by giving a ‘Silence_Horn/Alarm_RESET’ command.

2) If an analog input is programmed as a ‘Contact-Closure’

input by Var11, then the 3-digit messages shown are SAF,

ALr, or bAd.

For ‘Contact-Closure’ sensors the SAF and ALr are normal

valid messages, and the bAd message is used for invalid

sensor indication. See Var11 Belt_Alignment_Sensor_Type_

Select section for details.

(Section continued on next page).

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

11

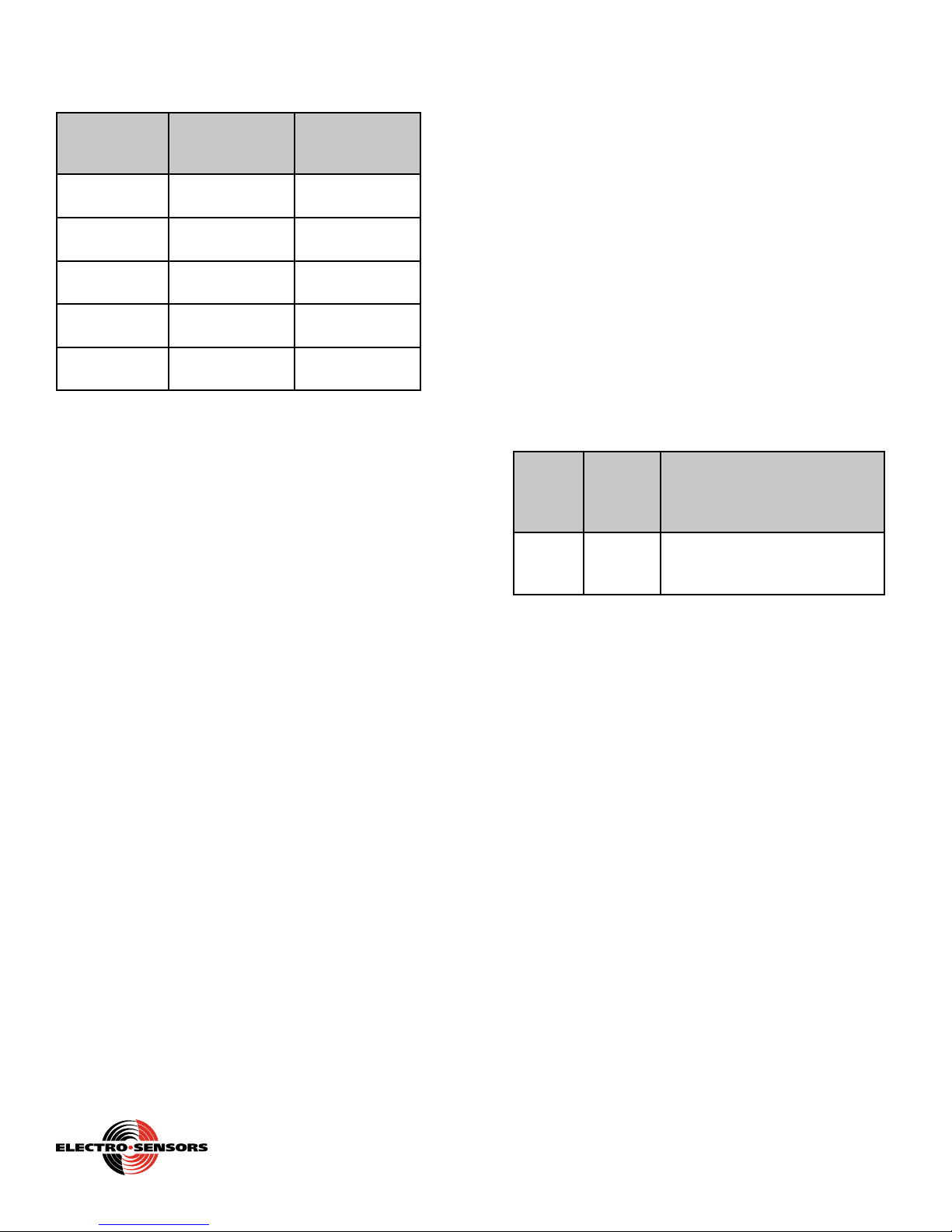

3) A 4-20mA out-of-normal-range Analog Speed Encoder

Detection feature works as shown in the table below (this is

when Var01 Encoder_Type_Select is set to 0000):

Speed Sensor’s

Input Current

Range

Message shown

on 4-digit

LED Display

Type of Alarm

3.9mA to

20.7mA

N.A.

(Live Speed)

N.A.9

(Green zone.)

20.83mA

or higher

CLS

(Closed Circuit) Yellow_Alarm 8

20.7mA to

20.83mA

HI

(High_mA)

N.A.8,9

(Green zone.)

1.0mA to

3.9mA

LO

(Low_mA) Red_Alarm

1.0mA or lower OPn

(Open Circuit) Red_Alarm

Note8: Because the ‘out-of-range’Analog Speed Encoder HI

and CLS cases have 4-20mA signals exceeding 20.7mA,

these cases are not Var04 and Var06 under-speed setpoint

violations (but rather are over-speed cases). Since the ES1

monitors for under-speed and not over-speed, the HI and

CLS cases are not outright speed violations.

However, if an Analog Speed Encoder has its 4-20mA

signal in the CLS range, then most likely the encoder

has been physically damaged. To alert the user to this

possibility the CLS range creates a ‘Yellow_Alarm’ if the

CLS condition exists for more then the Var05 time delay.

On the other hand, the LO and OPn cases have signals less

than 3.9mA. That means they are under-speed setpoint

violations, and create a ‘Red-Alarm’ if the LO or OPn

conditions exist for more than the Var07 time delay.

Note9: For Analog Speed Encoders, the acceptable signal range

extends up to 20.7mA to allow for display of slight

overspeeds such as 103%, 104%, etc. before ‘HI’ kicks-in.

(This is in contrast to temperature sensor signals having a

maximum acceptable signal of 20.1mA).

A) Concerning the Speed display and ‘out-of-range’ sensor

latching:

The ES1’s ‘out-of-range’ sensor latching feature is slightly

different for the 4-digit Speed display than it is for the

Temperature displays. For the 4-digit Speed display, IF the

Speed Encoder is of the 4-20 mA Analog Encoder type,

AND if it is detected as an ‘out-of-range’ sensor, THEN the

Speed Display will show the appropriate OPn, LO, HI, or

CLS out-of-range sensor message.

However, if the analog Speed Encoder ‘recovers’ on its own

to normal 4-20 mA ranges, then the Speed Display will NOT

‘Latch’ that alpha message, but rather will automatically

return to showing ‘live’ speed in % or in RPM. However,

the Speed’s discrete Yellow and Red LEDs and Speed

Alarm relays do ‘Latch’ once an out-of-range sensor has

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-005500 Revision D

12

been detected, but the actual Speed display itself does NOT

‘Latch’. This is because for safety reasons, we want to show

‘live’ speeds at all times whenever the speed sensor is within

the normal 4-20 mA range, whether or not the speed sensor

has previously strayed above or below the normal 4-20 mA

range, and then since recovered on its own.

LCD Display and 4-digit LED Speed Display Error

Messages

1) There are hardware error, calibration error, operational error,

and other messages, displayed on the LCD and the 4-digit

LED speed display.

These messages are listed in the following five tables

below, and are listed from highest rank to lowest rank.

(Higher ranking messages can have lower ranking messages

‘silently’ stacked-up behind them, so clearing a higher

ranking message may reveal the next highest ranking error

message behind it - if the prerequisite conditions are met).

The hardware error messages are (these are the highest

ranking):

LCD

Display

Message

LED

Speed

Display

Message

Definition

Err6 Err6 ‘Silence_Horn/Alarm_RESET’

command existing for a

continuous 60 seconds or more

Note: If the ‘Silence_Horn/Alarm_RESET’ command

exists for a continuous 60 seconds or more, then it is

assumed that one of the following has occured:

the ‘Silence_Horn/Alarm_RESET’ input at TB33

is ‘shorted-out’,

or the ‘AUX_Silence_Horn/Alarm_RESET’ at

TB31 Pins 9 and 10 are both ‘shorted-out’,

or the Front-Panel’s TEST_LEFT_SIDE and

TEST_RIGHT_SIDE Temperature Rise test

buttons are somehow both ‘shorted-out’.

or the AUX_TEST_LEFT_SIDE and AUX_

TEST_RIGHT_SIDE inputs at TB31 pins 3-4 and

5-6 are both ‘shorted-out’.

If any one of these four events occurs, then a

‘Yellow_Alarm’ or ‘Red_Alarm’’ could happen, but

the ES1 would not be able to latch those alarms and

they would automatically ‘clear’ once their offending

alarm event dissipated. This results in the user never

knowing an ‘Alarm’ came and went, unacknowledged.

This defeats one of the main reasons for using an ES1

in the first place (i.e., latch and hold alarms).

To warn the user of such a ‘short-out’, the Horn-

Relay goes into a 0.25 second ON, 0.25 second OFF,

repeating cycle, the LCD shows ‘Err6’ and the 4-digit

LED Speed Display shows ‘Err6’.

Table of contents

Other Electro-Sensors Accessories manuals

Popular Accessories manuals by other brands

IFM Electronic

IFM Electronic OPD100 operating instructions

Tobii Pro

Tobii Pro X3-120 installation guide

Girard Products

Girard Products G1000 installation manual

Phase

Phase TOCR02 user manual

American Standard

American Standard Culinair 7501.000 brochure

ekwb

ekwb EK-FB ASUS Z270/Z370 Strix Monoblock installation manual