The

MH660C

is a 60 x 60 deg. two-way system

with mid-bass and high-frequency horns that

are coaxially mounted. The common acoustic

axes of these horns ensures smooth response

and coverage in the crossover region when the

appropriate signal delay is applied to the

high-

frequency driver.

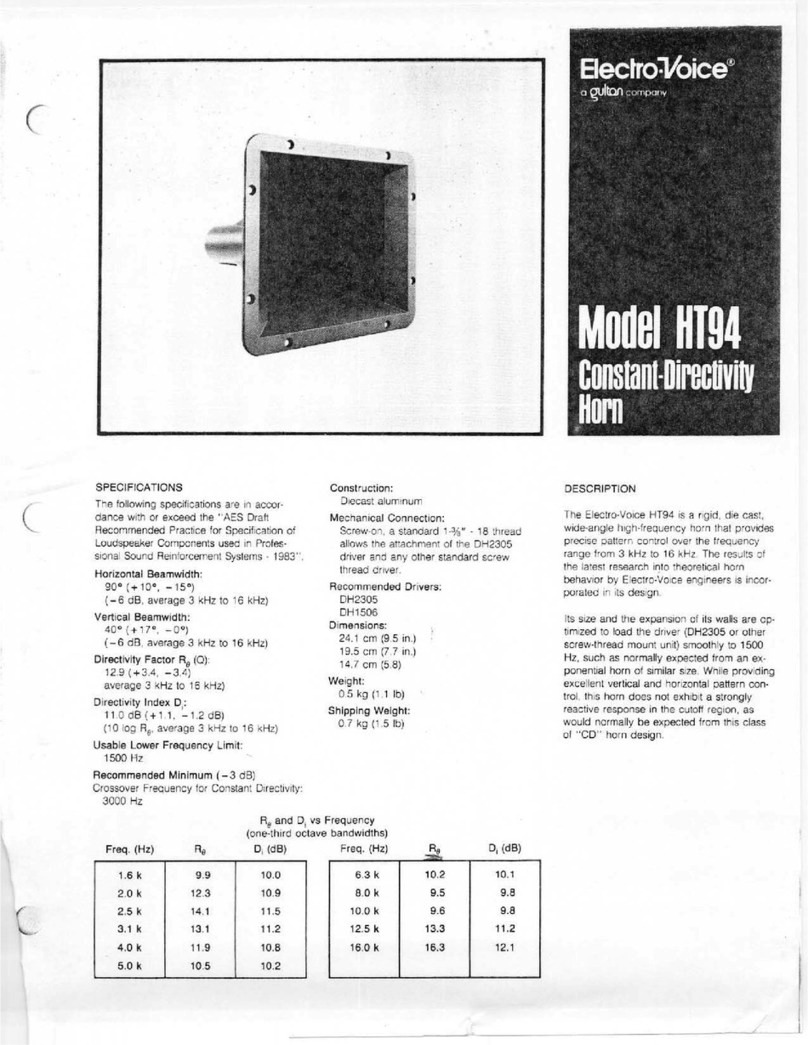

Delivering smooth and extended performance,

the high-frequency sectionoperatesfrom 1,600

to 20,000 Hz and consists of a specially

developed, low-profile

DH2As2

compression

driver coupled to an HP64 60 x 60

constant-

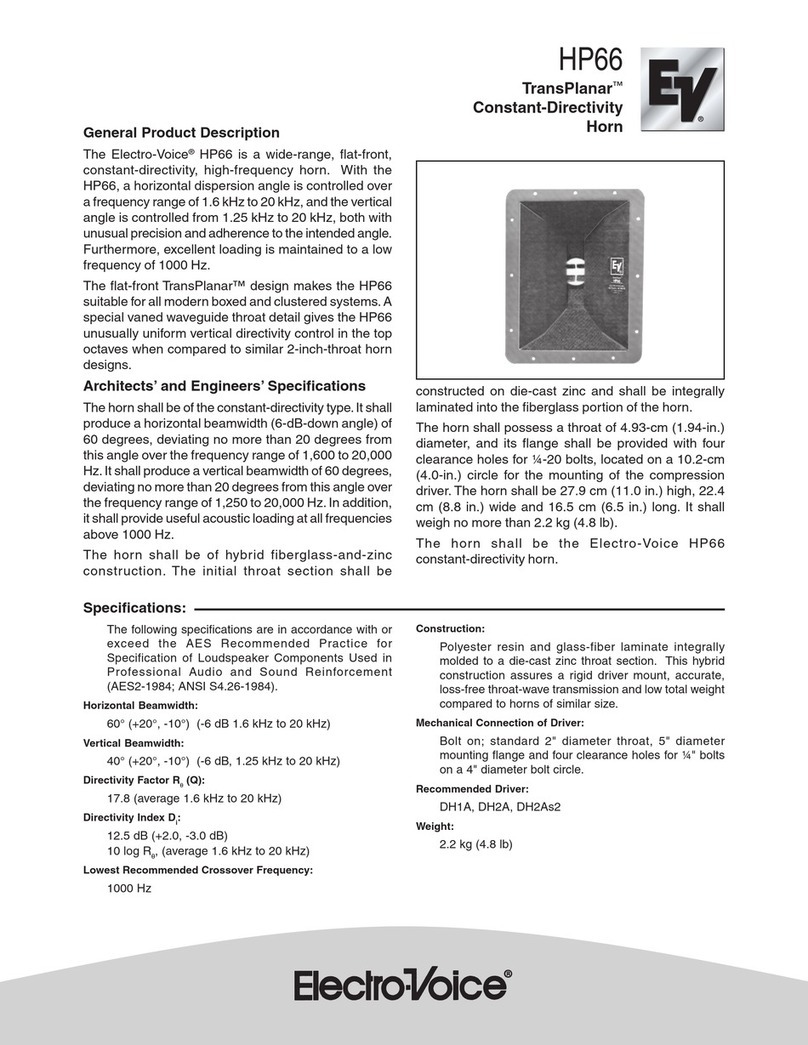

directivity horn. The HP66 horn features inte-

gral fiberglass-and-zinc construction for excep-

tional strength and performance.

Beamwidth-

control vanes in the horn throat correct all

coverage anomalies in the

10-

to

20-kHz

oc-

tave. This horn and driver combination is se-

curely mounted to the mid-bass horn by a

heavy-duty steel bracket.

The mid-bass system is composed of a

DL1

0X-SH 24.5-cm (10-in.) reproducer

mounted on a MH660 60 x 60 deg. mid-bass

horn. The

DL10X-SH

reproducer contains a

Kevlar epoxy

cone, which is twice as strong as

the conventional paper cone. The mid-bass

section operates between 140 and 1,600 Hz,

and features a proprietary phase plug (U.S.

patent no.

4,718,517)

which extends the

high-

end output to blend seamlessly into the coaxial

high-frequency section.

If the MH660Cis used in a full-range applica-

tion, additional low-frequency reinforcement,

such as the PI1 15L or a TL-series enclosure

will be required.

APPLICATIONS

The

MH660C

has been designed specifically

with the permanent installation market in mind.

Sports arenas, performing arts centers, audito-

riums and large gymnasiums are all candidates

for the

MH660C.

With its superior directivity

control, the

MH660C

is a system that can be

used in almost any situation. The

concert-

sound pedigree of the

MH660C

is evident by

the ease of installation and by the use of profes-

sional-grade components throughout the line.

SUSPENDING MH660C ENCLOSURES

Suspending any object is potentially danger-

ous and should only be attempted by individu-

als who have a thorough knowledge of the

techniques and regulations of rigging objects

overhead.

Electro-

Voice strongly recommends

that the

MH66OC

be suspended taking into

account a// current national, federal, state and

local regulations. It is the responsibility of the

installer to ensure the

MH660C

is safely in-

stalled in accordance with all such regulations.

If

the

MH660C

is suspended,

Electro-Voice

strong/y recommends that the system be in-

spected af

least

once a year.

If

any sign of

weakness or damage is detected, remedial

action should be taken immediate/y.

A manual entitled installing the MH Series is

available from Electro-Voice. It is included with

every MH system and should be followed care-

fully. A general overview is included here to

help the system designer. This overview does

not replacethe installing the

MHSeries manual,

which includes additional information on sus-

pending, configuring and equalizing the MH

series.

1.

Kevlar is

a

registered

trademark of

Dupont.

The

MH660C

can be suspended using the two

front brackets and the rear

“U”

bracket (see

Figure 5). Therear "U” bracket must be screwed

to the rear cover with the bolts provided. Each

of the mounting brackets contains a %-in.-

diameter hole through which a shackle or chain

link could pass. The MH660C can be oriented

in any direction. Electro-Voice strongly recom-

mends that each MH660C be suspended inde-

pendently using at least three of the four sus-

pension points provided.

If the

MH660C

is

suspended,it is recommended

that the unit be inspected at least once a year.

If any sign of weakness is detected, remedial

action should be taken immediately.

CAUTION: The

MH660C

speaker systems

should be suspended overhead

only In ac-

cordance with the procedures and

Iimita-

tfons specified in the installation manual

Included wlth the systems.

CONNECTIONS

Each frequency section can be individually

connected via#10 screw terminals. All drivers

are connected with the same polarity. A posi-

tive voltage applied to the positively marked

terminal produces a positive acoustic pressure

at the front of the system.

CROSSOVER, EQ AND SIGNAL DELAY

The

MH660C

is a two-way system which must

be biamped with a separate active crossover.

24-dB-per-octave crossover slopes are as-

sumed for maximum performance and reliabil-

ity. For optimum performance, EQ and signal

delay are required. (Note: the delays noted

below are for fourth-order

(24-dB-per-octave)

Linkwitz-Riley crossover filter characteristics.)

The mid-bass section should be crossed over

to match the low-frequency section and at

1,600 Hz at the high end. No signal delay or

overall broadband EQ is required. The

high-

frequency section requires a

1,600-Hz

cross-

over and the typical constant-directivity-horn

high-frequency boost EQ. A

0.6-msec

signal

delay provides the smoothest response in the

crossover region. A low-frequency blocking

capacitor with a

3-dB-down

point of 800 Hz is

included.

An Electro-Voice XEQ-3 electronic crossover/

equalizer/time delay unit with EQW plug-in

module provides all of the necessary signal

processing. The

XEQ-3

is a three-way elec-

tronic crossover with adjustable crossover fre-

quencies utilizing Linkwitz-Riley 24-dB-per-oc-

tave filters and signal delay equalization to

achieve zero lobbing error.

FREQUENCY RESPONSE

The

MH660C

axial frequency response was

measured in Electro-Voice’s large

anechoic

chamber at a distance of 3 meters (10 feet) with

a swept sine-wave input (see Figure 1). It has

been normalized for 1 watt/l meter into the

mid-

bass section. Minimal level adjustment and

equalization have been used.

DIRECTIVITY

The directional characteristics of theMH660C

were measured in Electro-Voice’s large

anechoic

chamber, with a test signal of

one-

third-octave filtered pink noise at the frequen-

cies indicated. A full spherical measurement

system, which is fully compatible with Electro-

Voice’s

AcoustaCADD

computer-aided de-

sign program, was used. All directional infor-

mation was measured at 6.1 meters (20 feet).

Figure 6 illustrates the nominal horizontal and

vertical polar responses, with the long system

axis vertical. If the mid-bass/high-frequency

module is rotated, then the horizontal and ver-

tical polars should be interchanged.

Figure 2 illustrates the horizontal and vertical

beamwidths. Beamwidth is

the

angle at which

the horizontal and vertical polar responses

have decreased in level by 6

dB

when com-

pared to the on-axis frequency response.

Figure 3 represents the total directivity of the

MH660C

The directivity factor

R,

(Q)

is

the

relative value, at a point, when compared to an

ideal spherical response. The directivity index

(D,) is calculated by D, =

10log,,,Re

SERVICE

In the unlikely event the

MH660C

requires

service, each driver can be replaced or re-

paired. A service data sheet is available from

Electro-Voice.

POWER-HANDLING TEST

Electro-Voice components and systems are

manufactured to exacting standards, ensuring

they will hold up, not only through the most

rigorous of powertests, but also through contin-

ued use in arduous, real-life conditions. Two

main test specifications are used: the AES

Recommended Practice for Specification of

LoudspeakerComponents Used in Professional

Audio and Sound Reinforcement(AES2-1984/

ANSI

S4.26-1984)

and the EIA Loudspeaker

Power Rating Full Range

(ANSI/EIA

RS-426-A

1980). Both of these specifications use ran-

dom-noise spectrums which mimic typical mu-

sic and test the thermal and mechanical capa-

bilities of the components. Electro-Voice will

support relevant additional standards as and

when they become available. Extreme, in-house

power tests,

whichpush

the performance bound-

aries of the components, are also performed

and passed to ensure years of trouble-free

service.

Specifically, the MH660C high-frequency sec-

tion passes AES2-1984/ANSI S4.26-1984 with

the following values:

Z,,,

= 6.0 ohms at 7,000 Hz

P

= 60 watts

TestVoltage

= 19.0 volts rms,

38.0 volts peak

(+6

dB)

Selected decade =

1,500-15,000

Hz

The

MH660C

mid-bass section passes ANSI/

EIA RS-426-A 1980 with the following values:

R,,

=

6.9 ohms (1.15 x RJ

P

= 300 watts

Test Voltage

=

45.5 volts rms.

91 .0 volts peak

(+6

dB)

ARCHITECTS’ AND ENGINEERS’

SPECIFICATIONS

The loudspeaker system shall be a two-way,

active, horn-loaded type. The mid-bass

fre-

quencies shall be reproduced bya singleDL10X-

SH

25.4-cm

(10-in.) driver coupled to a

MH660

60 x 60 deg. constant-directivity horn. High

frequencies shall be reproduced by a

60-watt

DH2As2

2-inch

compression driver coupled to

an HP66 60x60 deg. constant-directivity horn.

The mid-bass andhigh-frequencydevicesshall

be coaxially mounted. The system will repro-

duce frequencies from 140 to 20,000 Hz and

have a nominal coverage pattern of

60

x

60 deg.

The directivity control shall be maintained down

to 500 Hz. The crossover frequency shall be

1,600 Hz. The module shall be capable of

producing average sound levels in excess of