Electrolux Professional Dosave User manual

Installation manual

Dosave Dosing System

For washer extractors L6000 with Clarus Vibe

Original instructions

438917540/EN

2022.01.28

Contents

Contents

1 General safety information ...................................................................................................................5

2 Symbols .............................................................................................................................................6

3 Introduction.........................................................................................................................................7

4 Installation ..........................................................................................................................................8

4.1 Installation of the pump-stand .....................................................................................................8

4.1.1 Electrical connection....................................................................................................... 11

4.1.2 Selection of system/pumps .............................................................................................13

4.1.3 Pairing the pumps / Addressing the I/O board ...................................................................14

4.1.4 Priming the pumps .........................................................................................................15

4.1.5 Calibrating the pumps.....................................................................................................16

4.2 Installation of Flush manifold (option) ........................................................................................16

4.3 Installation of low level alarm (option) ........................................................................................19

4.4 Connection with low level sensors and flush manifold .................................................................19

5 Technical specification.......................................................................................................................21

6 Trouble shooting and service..............................................................................................................21

7 Disposal information..........................................................................................................................22

7.1 Disposal of appliance at end of life ............................................................................................22

7.2 Disposal of packing..................................................................................................................22

The manufacturer reserves the right to make changes to design and component specifications.

Installation manual 5

1 General safety information

These installation, operation and servicing instructions shall only be performed by qualified personnel.

The Dosave system must be installed in accordance with all applicable electrical and plumbing standards. All washer

extractor and dispenser power must be isolated during installation and/or any time the dispenser is maintained or

serviced.

•Always verify all voltage sources with a meter.

•Do not locate the pump-stand under plumbing fittings that could leak.

•Ensure that the installer has enough room to carry and lift the units when installing the

Dosave system.

•Do not pick up unit by supply cord.

•Wear PPE (Personal Protective Equipment) when dispensing chemicals or other mate-

rials or when working in the vicinity of all chemicals, filling, or emptying equipment.

•Always observe safety and handling instructions of the chemical manufacturers.

•You must follow all precautions as advised on the product safety data sheet.

•Always direct discharge away from you or other persons or into approved containers.

•Always dispense cleaners and chemicals in accordance with manufacturer's

instructions.

•Always exercise caution when maintaining your equipment.

•Always re-assemble equipment according to instruction procedures. Be sure all compo-

nents are firmly screwed or latched into position.

•Keep equipment clean to maintain proper operation.

•NOTE! This appliance is not be used by persons (including children) with re-

duced physical, sensory or mental capabilities, or lack of experience and knowl-

edge, unless they have been given supervision or instruction.

•This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the appliance in a

safe way and understand the hazards involved.

•Children shall not play with the appliance.

•Cleaning and user maintenance shall not be made by children without supervision.

•NOTE! Appliances connected to the water mains by detachable hose should use

hoses provided with the appliance and should not reuse previous.

•NOTE! If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualified person, in order to avoid a hazard.

•NOTE! A locally approved back-flow prevention device must be installed with the

appliance for safe and legal operation.

6Installation manual

2 Symbols

Warning/Caution

An appropriate safety instruction should be followed or caution to a potential hazard exists.

Dangerous voltage

To indicate a hazardous arising from dangerous voltages.

Protective earth (ground)

To identify any terminal which is intended for connection to an external conductor for protection against electric shock

in case of a fault, or the terminal of a protective earth (ground) electrode.

Refer to product manual

Read the instructions before using the machine.

Protective Personal Equipment

The use of appropriate eyewear shall be used.

Protective Personal Equipment

The use of appropriate safety gloves shall be used.

Protective Personal Equipment

The use of appropriate protective clothing shall be used.

Installation manual 7

3 Introduction

The Dosave system is designed to be connected directly to the washer extractor using two multi pin connectors.

The Dosave system can dispense measured amounts of product and product delays if required.

The Dosave system connected and supplied from the washer extractor 230V~ 50/60Hz. It also provides an interface

for the optional Flush manifold and the low level alarms.

The optional Flush manifold provides an alternative means of chemical transfer to the washer extractor. In flush con-

figuration, the Dosave is an integrated water flush chemical dispensing system.

Power Data

fig.X01323

• The washer extractor is provided with AMP Style power and interface connectors so no external power source is

needed for the pumps.

• The Dosave system is for indoor use only.

• Ensure that the units can be mounted in an accessible position above the height of the required discharge

location.

Note!

Above shoulder height would require steps or platform.

• The pump-stand shall be installed within 3 m of the washer extractor and close to product containers and at a con-

venient height for pump tube servicing, about 1–1.5 m.

• The input tubing from the chemical container to the pump-stand shall not be more than 2 m.

• The tubes must not be twisted and shall hang freely without any sharp bends. Longer tubes requires maintenance

more often.

• It is recommended to install a Flush manifold when the tubes between the pump-stand and the washer extractor

are more than 10 m.

Make sure there is free space under the pump-stand for a Flush manifold, water valve, and related plumbing.

• Max. 15 pumps (3 sets of Dosave system) and 15 low level alarms can be installed to the washer extractor. Max.

3 pumps can be run at the same time.

Dosave PNC’s Description

988930011 Complete kit with 2 pumps, Silicone tubes,350 ml/min

988930012 Complete kit with 3 pumps, Silicone tubes,350 ml/min

988930013 Complete kit with 4 pumps, Silicone tubes,350 ml/min

988930014 Complete kit with 5 pumps, Silicone tubes,350 ml/min

8Installation manual

4 Installation

4.1 Installation of the pump-stand

The wall where the pump-stand is to be mounted must support wall anchors and must be flat and perpendicular to

the floor.

Use the wall mounting bracket as a template and mark the location of the holes on the wall.

Drill the holes and put in suitable wall anchors. Fasten the wall mounting bracket with the screws. Make sure the wall

mounting bracket is in level.

Mount the pump-stand on the wall mounting bracket by pressing it downwards until it is in position.

There are different sizes of pump-stands, from 2 pumps up to 5 pumps. The figure shows a pump-stand with 5 pumps

as an example and the table show the measures for all versions of pump-stands.

A

B

C

D

E

F

G

H

I

J

fig.X01336B

A 61 mm Control box

B 196 mm 2 and 4 pumps

C 214 mm 3 and 5 pumps

D 257 mm 2 and 4 pumps

E 275 mm 3 and 5 pumps

F 336 mm 3 and 5 pumps

G 392 mm 4 pumps

H 453 mm 4 pumps

I 489 mm 5 pumps

J 550 mm 5 pumps

Installation manual 9

Connect the hoses to the pump-stand.

Connect the hose from the liquid detergent to the left on each pump.

The hose from the pump to the washer extractor is connected to the right on each pump.

fig.X01321

The washer extractor is prepared for connection of external dosing systems or water re-use systems etc.

The connections are closed at delivery. Open the connections (A) that shall be used by drilling a ⌀6 mm hole where

the hoses shall be connected.

NOTE!

Make sure there is no burrs left after drilling.

Connect the hose from the right side of the pump to the connection to be used on the washer extractor.

A

fig.X01322

If the hoses are made of a soft material such as silicone or similar, use a cable tie to fasten the hose on the connec-

tion. If the hoses are made of a hard material, it is not recommended to make the connection tighter by using a cable

tie.

NOTE!

Equipment for external dosing must only be connected to work on pump pressure

and not on network pressure.

10 Installation manual

Connections on the Dosave box

H

G

B

C

D

E

F

A

fig.X01320C

A Low level alarm port x 5 (cable glands)

B Data out

C Pairing button

D Data in

E Power in (from washer extractor 230V, 50/60Hz 3A Max)

F Power out

G Earth connection

H Connection for Flush manifold (the jumper shall be removed)

Installation manual 11

4.1.1 Electrical connection

The power supply to the dosing system must never be connected to the machine’s incoming terminal block or to

the edge connectors on the I/O-board.

Isolate the power to the washer extractor.

Disconnect the connector with termination resistor from the machine (B) and connect it to the (B) data out connection

on the Dosave box (1).

B

1

fig.X01168E

Connect the cables from Dosave box to connections A (power out) and B (data out) on the machine.

B

A

fig.X01169G

12 Installation manual

If two or three pump-stands are installed, the connector with termination resistor shall be connected to the Dosave

box on the last pump-stand.

If the connector with termination resistor is already connected to an existing pump-stand, the connector with termina-

tion resistor shall be moved from the first Dosave box and connected to the Dosave box on the last pump-stand.

fig.X01169H

Connect the cables from the second Dosave box to the connections on the first Dosave box or if three pump stands

are used, from the third Dosave box to the second Dosave box.

2x

fig.X01169I

It is possible to connect up to 3 Dosave systems and one ID Interface in a loop.

Warning

For continued safety, earth bonding cables should be fitted.

Installation manual 13

Chemical connections list (Default from factory, Reference from firmware 418810316 Ver. 2.3.0 )

Activated: Pumps/Chemicals

Pump Chemicals name (Output) Each Chemicals name (Output) are changeable to:

Pump 1 Detergent 0: Detergent

Pump 2 Softener 1: Softener

Pump 3 Bleach 2: Bleach

Pump 4 Floor care 3: Floor care

Pump 5 Desinfection 4: Desinfection

Pump 6 W01 - sensitive detergent 5: W1 - sensitive detergent

Pump 7 W02 - delicate detergent 6: W2 - delicate detergent

Pump 8 W03 - sensitive conditioner 7: W3 - sensitive conditioner

Pump 9 Detergent 2 8: Detergent 2

Pump 10 Bleach 2 9: Bleach 2

Pump 11 Floor care 2 10: Floor care 2

Pump 12 Floor care 3 11: Floor care 3

Pump 13 Preservation 12: Preservation

Pump 14 Impregnation 13: Impregnation

Pump 15 Descaling 14: Descaling

Pump 16 Sour 15: Special chemical

16: A02 - colour transfer reducer

17: A03 -leather care

18: Sour

19: Detergent 3

20: Detergent 4

21: Detergent 5

22: Softener 2

23: Softener 3

24: Softener 4

25: Softener 5

26: Booster 1

27: Booster 2

28: Floor care 4

29: Special chemical 2

30: Special chemical 3

31: None

Note!

The washing programs will order or require each chemical from above output, not from pump number. So

chemicals requirement in the wash programs must be matched with Chemicals name (Output). Otherwise,

the machine will wash without any chemical.

4.1.2 Selection of system/pumps

When the Dosave system has been installed the washer extractor must know which type of system/pumps that are

used in order to function in the correct way.

Proceed as follow:

• Enter the password set by the manager to access the Main menu.

• Activate the Pumps menu.

• Activate the Pumps menu.

A list with different types of systems/pumps will now be visible on the screen.

• Select 0: Peristatic for the Dosave system.

14 Installation manual

4.1.3 Pairing the pumps / Addressing the I/O board

• Enter the Advance manager password or Advance service password to access the Main menu.

• Activate the Settings menu.

• Activate the I/O board addressing menu.

Available I/O boards and addresses will now be visible on the screen as a drop down list. The different I/O boards

and addresses are marked with either a green or a grey light.

• Green light = in use.

• Grey light = not in use and available for addressing.

The Dosave system is set up as an I/O Type 22. All washer extractors are prepared to accept up to five I/O Type 22.

The first I/O Type 22 address in the list is reserved for I/O inside the washer extractor and shall not be used

for the Dosave system.

To pair:

• Select the second address for I/O Type 22 (A).

• Press Add to start the pairing function.

NOTE!

It is very important to select the second I/O Type 22 address when pairing the first

Dosave system. If not, the system will not work as expected.

A

fig.X01676

The following message will be displayed indicating that it is OK to pair.

fig.X01677

Installation manual 15

• Press and hold the pairing button (C) in the bottom of the Dosave box for about 1–2 seconds until the buzzer

beeps. The beep indicates successful pairing.

C

fig.X01320D

Also, a green light on the selected address will indicate that the pairing has been successfully done.

fig.X01678

Up to three Dosave systems can be connected to the washer extractor.

When the first Dosave system is correctly paired, select the next address in the list to pair the next Dosave system

etc.

4.1.4 Priming the pumps

• Enter the Advance manager password or Advance service password to access the Main menu.

• Activate the Pumps menu.

• Activate the Priming menu.

• Activate Pump 1 from the list to start priming the first pump.

• Press play to start priming and press stop when ready. (You can also use the pairing button (C) to start and stop).

The hose shall be filled all they way to the outlet of the hose.

Do the same for all the pumps.

16 Installation manual

4.1.5 Calibrating the pumps

• Enter the Advance manager password or Advance service password to access the Main menu.

• Activate the Pumps menu.

• Activate the Calibration menu.

• Activate Pump 1 from the list to start calibrating the first pump.

The different steps to be made when calibrating will now be visible on the screen.

1. Place a container with ml markings (minimum volume 300 ml) under the outlet tube of the pump to be calibrated.

2. Press play to start calibrating.

3. Press stop when there is 250 ml in the container.

4. Save the result for the pump.

The first pump has now been calibrated.

Do the same for all the pumps.

Note!

You can also use the pairing button (C) to start and stop the calibration.

250 ml

fig.8052

4.2 Installation of Flush manifold (option)

The Flush manifold is recommended in locations where the tubes between the pump-stand and the washer extractor

is more than 10 m. (Water pressure shall be min. 1.8 bar and max. 6 bar).

It can also be used for safety reasons in installations where dangerous chemicals are used.

The Flush manifold is used to flush the tubes clean when not in use.

Mount the Flush manifold on a suitable location under the pump-stand. The Flush manifold shall be mounted on the

wall by the wall hangers (A).

Installation manual 17

Caution

Electrical output for flush manifold is 24V~ Safety Extra Low Voltage (SELV). Isolate pumpstand from the electri-

cal supply before removing the jumper harness and connecting the flush manifold.

B B C

1

2

A

A

fig.X01683B

Connect the outlet tubes to the Flush manifold connections (B).

Connect one tube from the Flush manifold to the washer extractor (C).

Note!

It is recommended to heat up the tubes before connecting.

Connect the water inlet (D).

B

C

D

fig.8057B

18 Installation manual

Depress the locking tab (E) and remove the jumper harness (F) from the first pump-stand (save the jumper harness

for future use if the Flush manifold might be disconnected). Connect the electrical cable from the Flush manifold to

the connection on the pump-stand when removed.

E

F

fig.W01149A

When the Flush manifold has been installed the washer extractor must know which type of system/pumps that are

used in order to function in the correct way.

Proceed as follow:

• Enter the Advance manager password or Advance service password to access the Main menu.

• Activate the Pumps menu.

• Activate the Pumps menu.

A list with different types of systems/pumps will now be visible on the screen.

• Select 2: Manifold for the Flush manifold.

Installation manual 19

4.3 Installation of low level alarm (option)

Put the level probes in their respective product container.

The existing hoses connected to the pump-stand shall be replaced with the new hoses. Connect the hoses to the left

side of each pump on the pump-stand as before.

The cable (A) shall be connected to the Level control box and the hose (B) shall be connected to the pump-stand.

The level probes are fitted with a magnetic float switch (C). This switch should arrive in the correct position for your

application.

Should the switch work in reverse, remove the cross head screw securing the float magnet, remove the float magnet

and refit it in the opposite direction.

A

B

C

fig.X01692A

4.4 Connection with low level sensors and flush manifold

Open the control box before connection.

If low level sensors are installed, an error message will be displayed when any of the chemical tanks is low. The pro-

gram will however continue. As the A122 board is with 5 outputs for pumps but only 3 inputs for level sensing, some

low-level sensors must be connected in parallel. In such an installation the control system will be alarming low level

when any of merged sensors has triggered. The figure below is showing such a configuration along with flush

manifold.

Tank 1

Tank 2

Tank 3

Low level alarms Flush manifold

DOSAVE (1)

A122

OV +24VDC

6 7 83 4 5 17 18 19

1

RL1

2 3 4 5

fig.X01528

20 Installation manual

It is possible to display all the alarms separately by adding an ID interface.

Tank 2

Tank 5

Tank 4

Tank 1

Tank 3

ID INTERFACE

A122

Low level alarms Flush manifold

DOSAVE (1)

A122

Low level alarms

OV +24VDC

3 4 5 6 7 86 7 83 4 5 17 18 19

1

RL1

2 3 4 5

fig.X01528A

The system can be extended for dosing up to 15 chemicals by using three DOSAVE units:

Tank 5

Tank 6

Tank 4

Tank 10

Tank 8

Tank 11

Tank 7

Tank 9

DOSAVE (2)

A122

Low level alarms Low level alarms

DOSAVE (3)

A122

OV +24VDC OV +24VDC

6 7 83 4 5

6 7 8 9 10

6 7 83 4 5

11 12 13 14 15

fig.X01528D

Available inputs on A122 for low level sensing:

• The first DOSAVE in the loop: 5-7 (input 8 dedicated for flow switch).

• Remaining DOSAVE units: 5-8 (wire preconnected to input 8 can be removed and used for level sensing instead).

• ID Interface: 5-8.

Table of contents

Popular Measuring Instrument manuals by other brands

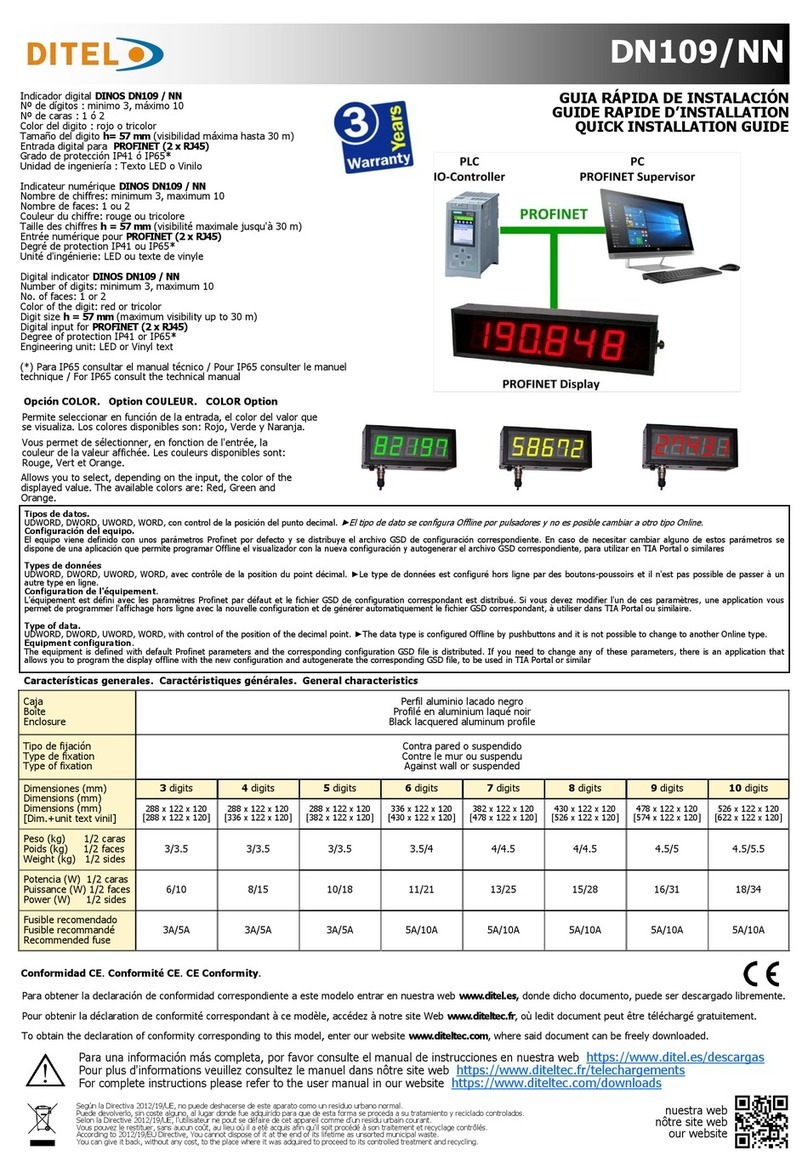

Ditel

Ditel DN109/NN Quick installation guide

Abaxis

Abaxis VetScan vs2 Operator's manual

Sper scientific

Sper scientific 300033 instruction manual

Hanna Instruments

Hanna Instruments HI 95762C instruction manual

Spectrum Technologies

Spectrum Technologies LightScout 3415Z product manual

Ametek

Ametek Drexelbrook Universal IV CM Installation and operating instructions