5

CCoonntteennttss

A SAFETY INSTRUCTIONS .......................................................................................................................7

A.1 Children and vulnerable people safety...............................................................................................7

B GENERAL INFORMATION ......................................................................................................................8

B.1 Introduction.................................................................................................................................8

B.2 General safety instructions .............................................................................................................8

B.3 Additional indications.....................................................................................................................8

B.4 Definitions...................................................................................................................................8

B.5 Machine and Manufacturer’s identification data ................................................................................... 8

B.6 How to identify the technical data .....................................................................................................9

B.6.1 How to interpret the factory description .................................................................................... 9

B.7 Responsibility ..............................................................................................................................9

B.8 Keeping the manual .................................................................................................................... 10

B.9 Recipients of the manual .............................................................................................................. 10

B.10 Copyright.................................................................................................................................. 10

B.11 Personal protection equipment ...................................................................................................... 10

C GENERAL SAFETY RULES................................................................................................................... 11

C.1 Introduction ............................................................................................................................... 11

C.2 Guards..................................................................................................................................... 11

C.3 Safety signs to be placed on the machine or near its area.................................................................... 11

C.4 End of use ................................................................................................................................ 11

C.5 Instructions for use and maintenance.............................................................................................. 11

C.6 Reasonably foreseeable improper use ............................................................................................ 12

C.7 Residual risks ............................................................................................................................ 12

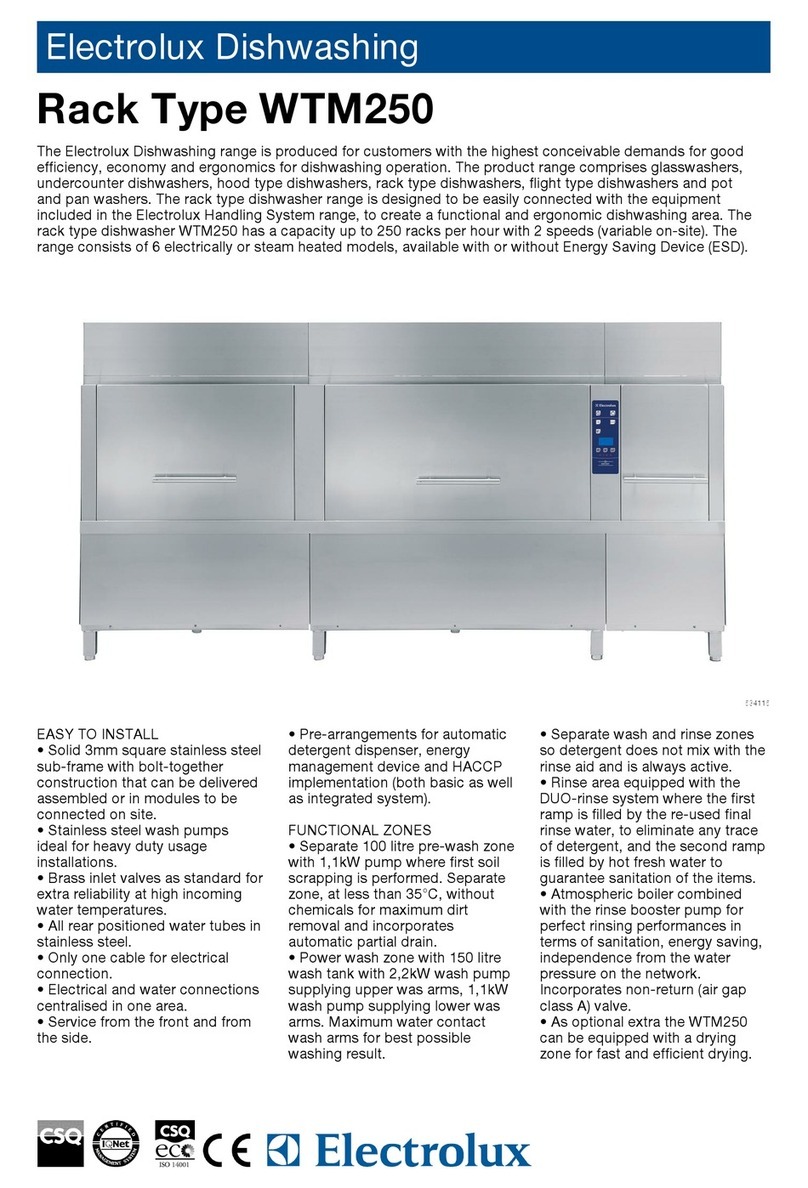

D TECHNICAL DATA .............................................................................................................................. 14

D.1 Main technical characteristics........................................................................................................ 14

D.2 Characteristics of power supply ..................................................................................................... 14

E TRANSPORT, HANDLING AND STORAGE .............................................................................................. 16

E.1 Introduction ............................................................................................................................... 16

E.2 Transport: instructions for the carrier............................................................................................... 16

E.3 Procedures for handling operations ................................................................................................ 16

E.4 Shifting..................................................................................................................................... 16

E.5 Placing the load ......................................................................................................................... 16

E.6 Storage .................................................................................................................................... 16

F INSTALLATION AND ASSEMBLY........................................................................................................... 17

F.1 Introduction............................................................................................................................... 17

F.2 Customer responsibilities ............................................................................................................. 17

F.3 Characteristics of the installation place............................................................................................ 17

F.4 Positioning ................................................................................................................................ 17

F.5 Disposal of packing..................................................................................................................... 18

F.6 Plumbing connections ................................................................................................................. 18

F.7 Plumbing circuits ........................................................................................................................ 19

F.8 Electrical connections.................................................................................................................. 20

F.8.1 Connections provided for energy control ................................................................................ 20

F.9 Safety devices ........................................................................................................................... 20

F.10 Detergent/rinse aid dispensers and prearrangements......................................................................... 20

F.10.1 Electrical connections for automatic detergent and rinse-aid dispensers........................................ 21

G COMMISSIONING ............................................................................................................................... 22

G.1 Preliminary checks, adjustments and operational tests ....................................................................... 22

H BEFORE FIRST USE ........................................................................................................................... 23

H.1 Manual activation ....................................................................................................................... 23

H.2 Setting the dispensers ................................................................................................................. 23

H.2.1 Peristaltic dispenser .......................................................................................................... 23

I CONTROL PANEL............................................................................................................................... 24

I.1 Control panel description.............................................................................................................. 24

I.2 Basic Controls ........................................................................................................................... 24

J NORMAL MACHINE USE...................................................................................................................... 25

J.1 Foreseen use ............................................................................................................................ 25

J.2 Characteristics of personnel enabled to operate on the machine ........................................................... 25

J.3 Starting .................................................................................................................................... 25

J.4 Wash cycles.............................................................................................................................. 25

J.5 Operation ................................................................................................................................. 25

J.6 Type of racks and loading............................................................................................................. 26

K MACHINE CLEANING AND MAINTENANCE............................................................................................. 27

K.1 End of service and daily cleaning ................................................................................................... 27

K.1.1 Cleaning the exterior surfaces.............................................................................................. 27

K.2 Regeneration cycle ..................................................................................................................... 27

K.3 Maintenance ............................................................................................................................. 29