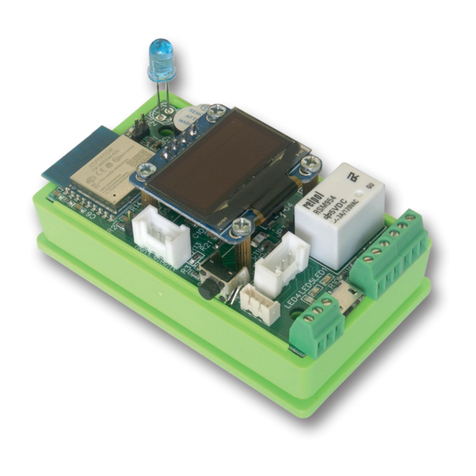

INSTALLATION EM-176A

Supply voltage 12-35VDC, ripple <30% at full load.

CAUTION ! Wrong polarity may damage the device.

CAUTION ! The device is not equipped with an internal

fuse.

SETTINGS AND ADJUSTMENTS

Set trimmers in center position. Current limit can be set in

the range of 0-15A. If an external voltage signal (0-5V) or

potentiometer is used to set the current limit, set the inbuilt

current limit trimmer to 0-position.

The compensation (RxI) is used as follows: first set the

motor running slowly. Then increase compensation until the

motor starts twitching. Now decrease compensation a little

so that the twitching ends. Finally test the operation: when

loading the motor, the rotation speed should almost remain

constant.

The acceleration- and braking ramp are set with trimmers in

the range of 0-3s (the time from zero to full speed or vice

versa). The speed can be set with potentiometer or with 0-5V

voltage signal. With the set value trimmer the set value

range can be scaled to match the motor rotating speed range.

If the use of bipolar control signal is desired, an auxiliary

card EM-A1 can be fitted onboard, which makes it possible

to use either ±5V or ±10V control voltage signals. EM-A1

card also gives -5V auxiliary voltage into pin8; this enables

potentiometer to be used to control both speed and direction

(forward-stop-reverse).

EM-176A WIRING AND INSTALLATION

EXAMPLE 2

CONTROLLING WITH VOLTAGES.

CURRENT 0-5V CORRESPONDS TO 0-15A.

CURRENT LIMIT TRIMMER IS SET TO MIN.

SPEED 0-5V CORRESPONDS TO 0-100%

SPEED. SCALE WITH TRIMMER.

DIRECTION, FREEWHEEL OR BRAKE

0-1V OR OPEN=OFF, 4-30V=ON.

EXAMPLE 1

CONTROLLING WITH SWITCHES.

SPEED SET WITH POTENTIOMETER.

SPEED RANGE ADJUSTABLE WITH

SPEED SET RANGE ADJUSTMENT.

CURRENT LIMIT CAN BE SET WITH

INBUILT TRIMMER. IF EXTERNAL

ADJUSTMENT IS USED, SET THE

INBUILT CURRENT LIMIT TRIMMER

TO MINIMUM.

EXAMPLE 3 (OPTIONAL)

EM-A1 BIPOLAR-CARD INSTALLED.

CONTROLLING WITH POTENTIOMETER

FORWARD/REVERSE OR WITH VOLTAGE

SIGNAL (±5V OR LARGER BIPOLAR

VOLTAGE). RANGE ADJUSTABLE WITH

RANGE SCALE TRIMMER ADJUSTMENT.

OTHER CONTROLS AS IN PREVIOUS

EXAMPLES.

10

BRAKE

GND 0V

4 5

FREEWH.

6 7

CURRENT

98

+5V

10

DIR.

SPEED

Im Um

BRAKE

54

GND 0V

FREEWH.

CURRENT SET

DIR.

SPEED

+5V

9876

REVERSE / FORWARD

POT. IN THE MIDDLE=STOP

10

BRAKE

FREEWH.

5

GND 0V

4 9

-5V

876

+5V

SPEED

+DIR.

EM-A1 card slot,

normally 2 jumps

set value

scale

V / 0-100%

BRAKE

CAUTION !

Wrong polarity can damage the device.

Select a fuse (1-16A) in accordance

with the application.

+12-32V

MOTOR

321

SUPPLY

DC-

-

+

4

GND 0V

72mm

66mm

10

0-5V

SPEED SET

5 6 7 8 9

DIR.

+5V

CURR. SET

FREEWH.

min

max

15

59mm

65mm

8

0-10

0-24V

0

3ramp / s

1

2

Motor

load

compensation

0current lim / A

4

ELECTROMEN Oy

www.electromen.com