Electron Thermo 3684 Operating instructions

Models:

3684,

3686,

& 3688

Laboratory Refrigerators

Operating and Maintenance Manual

Manual No: 7003688 Rev. 9

Model 3680 Series ____________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes only. The

contents and the product it describes are subject to change with-

out notice. Thermo Electron Corporation makes no representa-

tions or warranties with respect to this manual. In no event shall

Thermo be held liable for any damages, direct or incidental, aris-

ing out of or related to the use of this manual.

MANUAL NO. 7003688

9 22052/FR-1762 2/2/04 Discontinued Models 3687 and 3689 ccs

8 21443 3/20/03 Removed strip chart recorder as an accessory aks

7 21377/IN-3086 2/13/03 Clarified condenser cleaning ccs

6 20358 10/2/01 Updated specs and refrigeration schematics for refrigerant amount change ccs

5 20201/FR-1531 7/13/01 Revised Section 3.1 refrigerator defrost function aks

4 19174/FR1404 7/31/00 Revised electrical schematics and parts lists aks

3 18542/IN-2738

18682/IN-2752 10/12/99 Updated 3688 schematic to include new defrost sensor 227960

Added schematics for 3687 and 3689 ccp

2 18454/FR-1312 7/19/99 Added breaker switch location ccp

1 18322 5/19/99 Added Models 3684 and 3686 ccp

0 IN-2697 4/15/99 Original manual ccp

REV ECR/ECN DATE DESCRIPTION By

Model 3680 Series ____________________________________________________________________

ii

Alerts the user to important operating and/or maintenance instructions. May be used alone or with other safety sym-

bols. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform the instructions and procedures associated with

this symbol.

Hazard. Do not touch. Instructions associated with this symbol should only be carried out when using special hand-

ing equipment or when wearing special, protective clothing.

Potential biological hazards. Proper protective equipment and procedures must be used when following instructions

associated with this symbol. Reference O.S.H.A. Regulation 1910-1030.

Potentially hazardous energy. Equipment being maintained or serviced must be turned off and locked off to prevent

possible injury. Reference O.S.H.A. Regulation 1910-147.

√ Always use the proper protective equipment (clothing, gloves, goggles, etc.)

√ Always dissipate extreme cold or heat and wear protective clothing.

√ Always follow good hygiene practices.

√ Each individual is responsible for his or her own safety.

Model 3680 Series ____________________________________________________________________

iii

Model 3680 Series ____________________________________________________________________

iv

Table of Contents

Section 1 - Installation and Start-Up . . . . . . . . . . . . . .1 - 1

1.1 Location and Unpacking . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2 Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.3 Connecting to Power . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.4 Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.5 Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Section 2 - Control Panel Procedures . . . . . . . . . . . . . .2 - 1

2.1 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.2 Key Lock Control . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.3 High and Low Temperature Alarm . . . . . . . . . . . . . .2 - 2

a. High Temperature Setpoint . . . . . . . . . . . . . . . . . .2 - 2

b. Low Temperature Setpoint . . . . . . . . . . . . . . . . . .2 - 3

2.4 Door Open Light . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

2.5 Audible Alarm Switch . . . . . . . . . . . . . . . . . . . . . . .2 - 3

2.6 Interior Lights Switch . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

2.7 Digital Temperature Display . . . . . . . . . . . . . . . . . . .2 - 3

2.8 Remote Alarm Terminal . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Section 3 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Defrosting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. Cycle Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

b. Forced Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.2 Cleaning Evaporation Tray, Condenser and Filter . . .3 - 1

a. Cleaning the Evaporation Tray . . . . . . . . . . . . . . .3 - 1

b. Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . .3 - 1

c. Cleaning the Condenser Filter . . . . . . . . . . . . . . . .3 - 1

3.3 Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.4 Replacing the Fluorescent Light . . . . . . . . . . . . . . . .3 - 1

Section 4 – Troubleshooting . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Discarding or Taking Refrigerator Out of Service . .4 - 2

Section 5 – Specifications . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Section 6 - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

Section 7 - Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 8 - Warranty Information . . . . . . . . . . . . . . . . .8 - 1

Section 1 - Installation and Start-Up

1.1 Location and Unpacking

This unit will operate most efficiently and safely under

these conditions:

• Indoor use

• Altitude up to 6562 ft. (2000m)

• Ambient temperature range 5°C to 40°C

• Maximum relative humidity 80% for temperatures up to

31°C, decreasing linearly to 50% relative humidity at 40°C

• Mains supply voltage fluctuations not to exceed ±10% of

the nominal voltage

• Transient overvoltages according to Installations

Catagories (Overvoltage Categories) II, which is the mini-

mum and normal category

• Pollution Degree 2 in accordance with IEC 664

Locate the unit on a firm, level surface in an area of mini-

mum ambient temperature fluctuation. Avoid installing the unit

near heat-emitting appliances, as heat can shorten component

life and cause inefficient refrigeration.

Avoid placing the unit in a contaminated area with an

excessive amount of dust, or where chemicals or gases are pres-

ent.

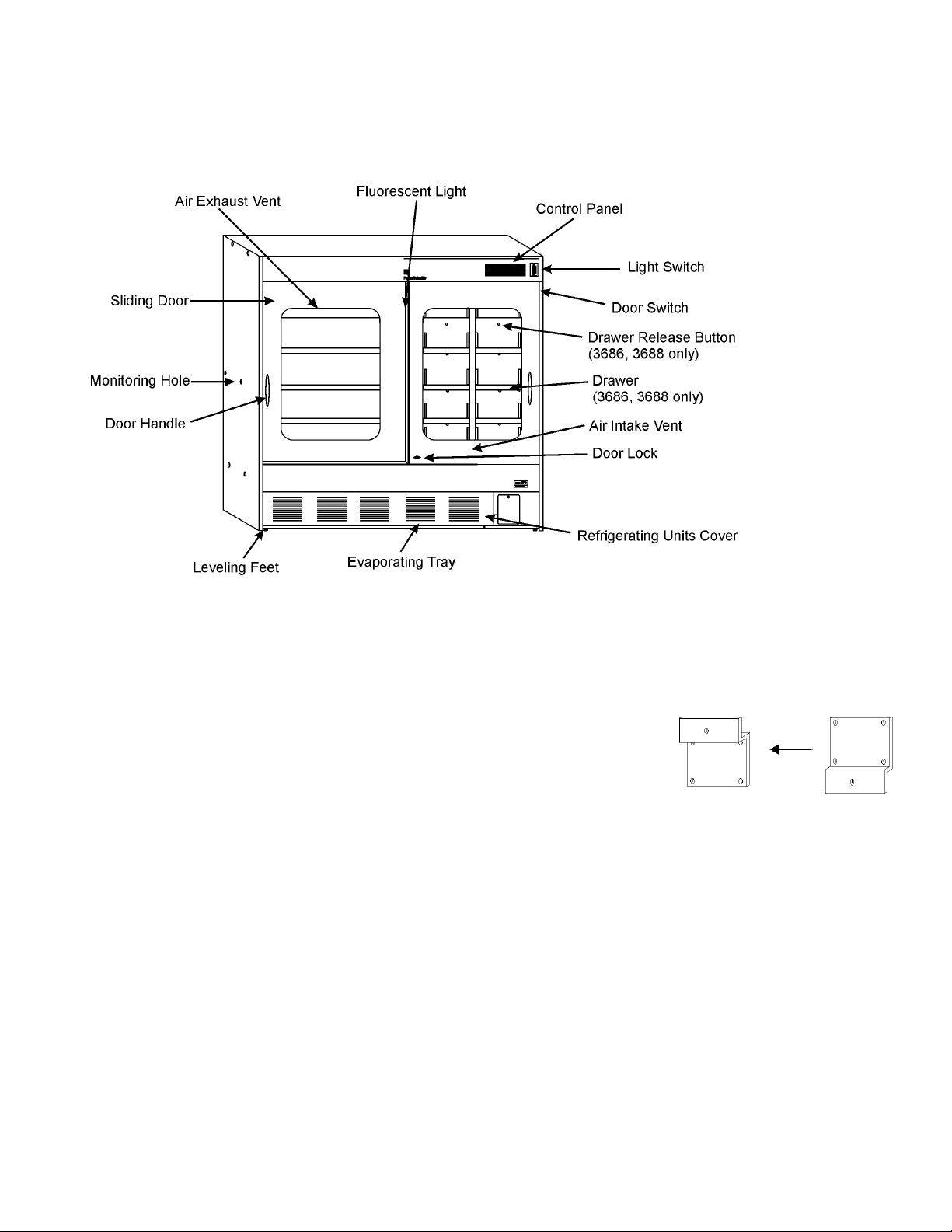

Chamber temperature is maintained through the circulation

of forced air. Ensure that the air intake and exhaust vents are

clear of obstruction at all times. Allow 4-5 inches (10cm) of

clearance on all sides of the unit to reduce power con-

sumption and allow free air circulation.

Two wall mounts are attached to the top rear of the unit.

Remove the wall mounts and reverse their position. Reattach to

the unit. Secure the single hole section of the mount to the wall.

A special bolt-nut is supplied for concrete walls.

Remove all packaging

materials and ventilate the

unit thoroughly.

1.2 Leveling

Adjust the feet on the bottom front of the unit to level the

cabinet. Turn each foot counterclockwise until it makes full

contact with the floor.

1.3 Connecting to Power

Connect the unit to a dedicated, grounded power source

using the three-prong power plug. Refer to the electrical data

plate on the unit for electrical specifications.

Model 3680 Series __________________________________________________________________Installation and Start-Up

1 - 1

1.4 Installing the Shelves

Adjust each shelf position by inserting the shelf support

clips into the slots at the desired level. Make sure that the

shelves are secure before placing product on them.

If the unit is equipped with drawers, press the release but-

ton on the bottom of the drawer to open. The drawer positions

are also adjustable.

Do not place anything on the floor of the cabinet.

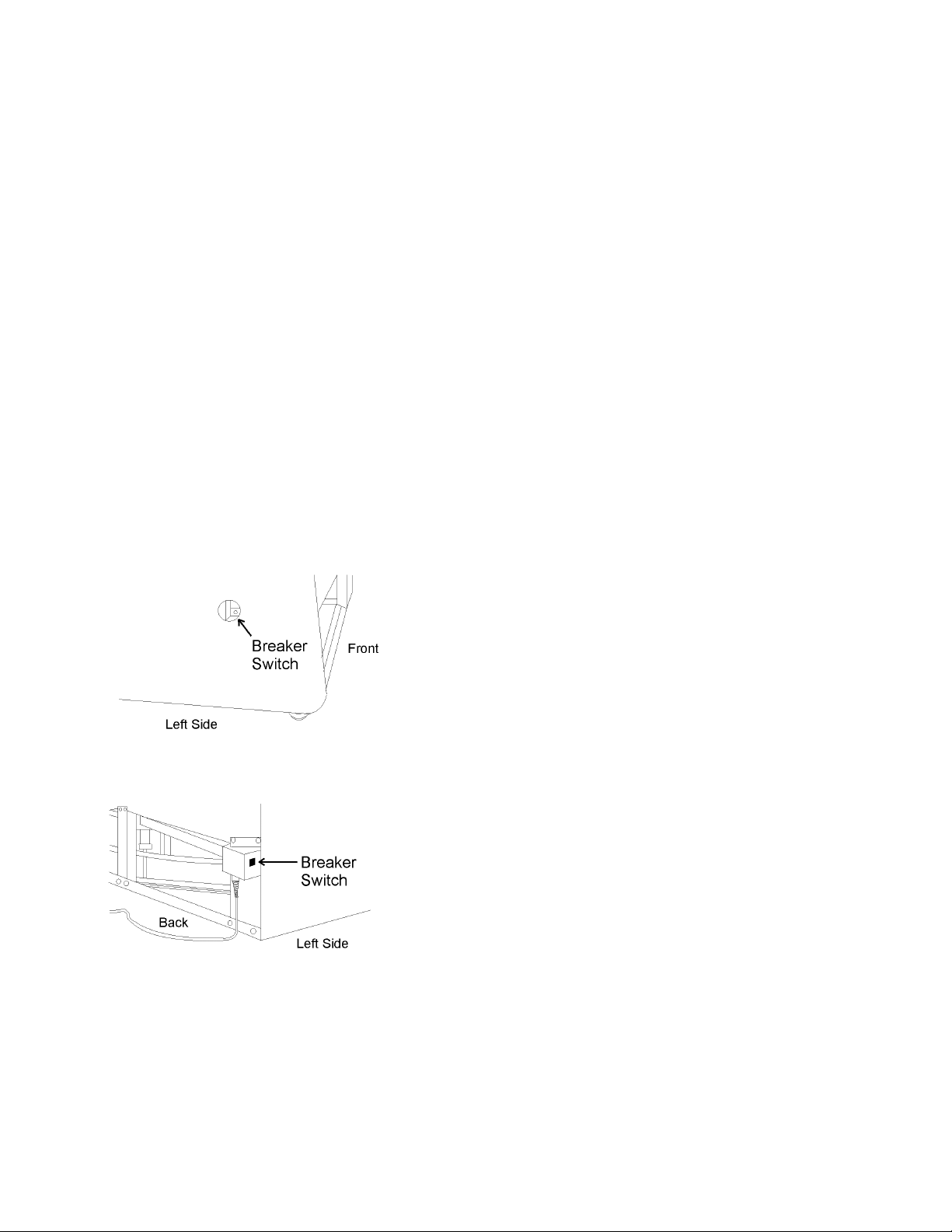

1.5 Start-Up Procedure

1. This unit is equipped with a circuit breaker on the side

or back. Turn this switch ON before starting this unit.

See illustrations below for breaker switch location.

2. Connect to a dedicated power source.

Note: When the unit is plugged in and the power switch turned

on, the audible alarm may sound. To temporarily silence the

alarm, open the control panel door and press the BZ button.

3. The factory setpoint for chamber temperature is 5°C.

Allow the unit to cool down to setpoint. The chamber

temperature is displayed on the temperature indicator

display on the control panel.

Note: Although the refrigerator will operate at under 2°C, it is

not suitable for prolonged use at this range. Always set the ther-

mostat above +2°C. When running the unit at the top of the

range (+14°C), the audible alarm may sound. In this case, it

does not indicate a malfunction. Press BZ on the control panel

to silence the alarm.

4. Turn the light switch to ON to verify its operation, then

turn it off for normal operation.

5. Make sure that the unit functions properly before plac-

ing product in the chamber. Add product to the chamber

gradually to prevent excessive temperature rise and sub-

sequent activation of the alarm system. Allow enough

space between the items to permit adequate air circula-

tion.

Model 3680 Series __________________________________________________________________Installation and Start-Up

1 - 2

Model 3684, 3686 and 3687

Model 3684, 3686 and 3687

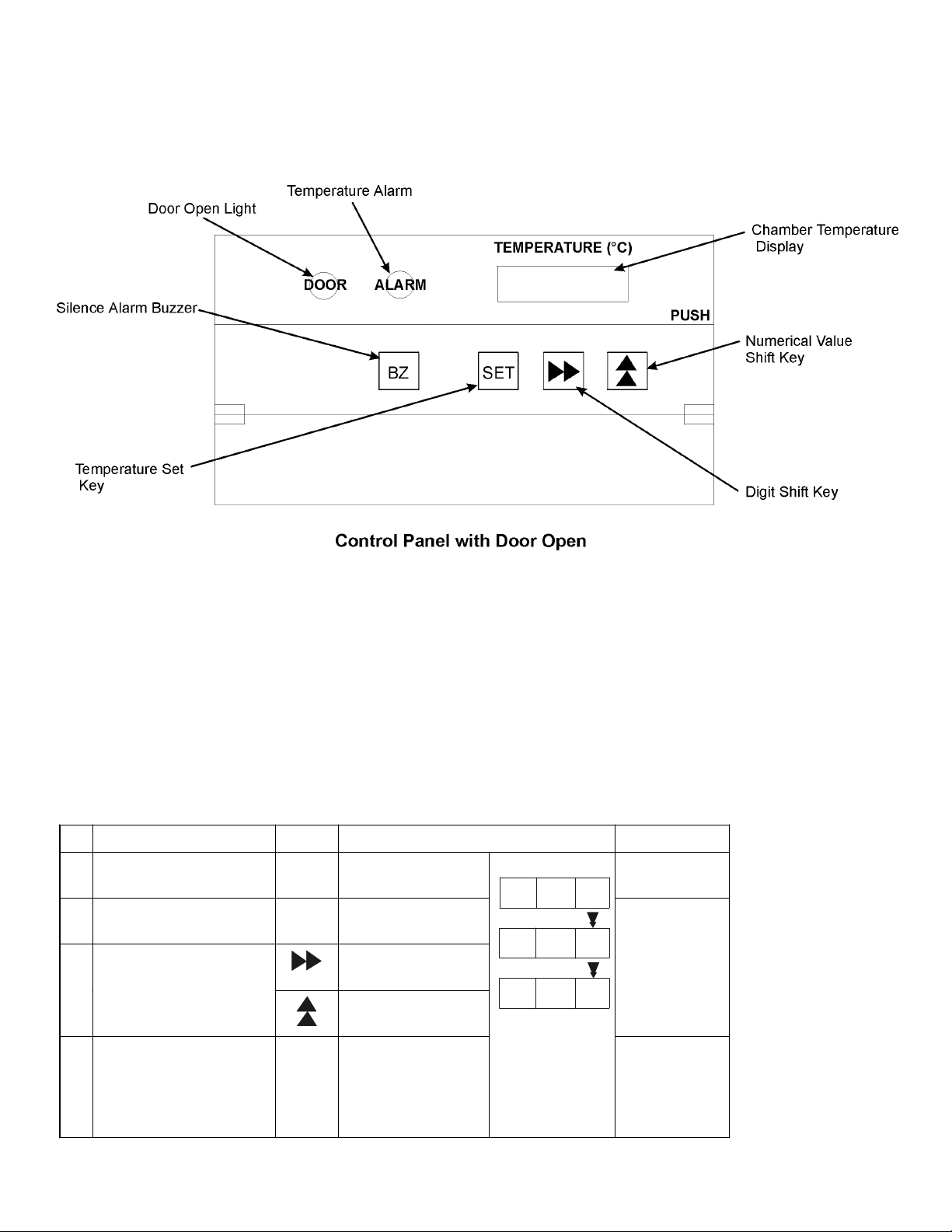

Section 2 - Control Panel Procedures

2.1 Temperature Control

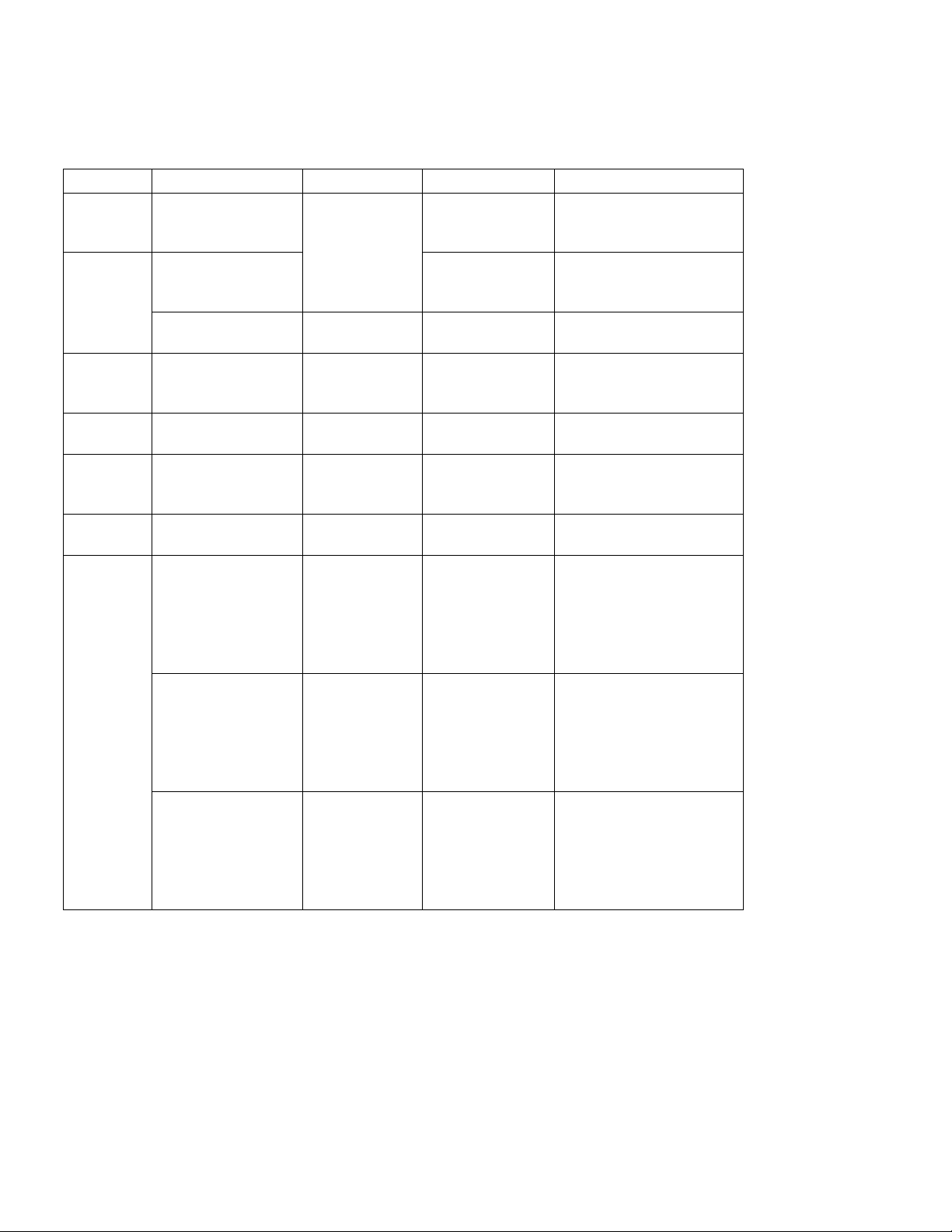

The table below shows basic operation procedures for the

keys indicated. Follow the sequence as shown.

The temperature setpoint range is between 2° and 14°C.

Factory setpoint is 5°C. A partial freeze may be possible when

the temperature is set lower than 3°C.

If no keys are pressed for 90 seconds in temperature set-up

mode, the display returns automatically to current chamber tem-

perature display. The chamber temperature setpoint does not

change.

Model 3680 Series __________________________________________________________________Control Panel Procedures

2 - 1

Operation Key Display Mode

1 Connect to power source

and turn on power switch

---- Current chamber

temperature

Temperature

Display

2 Press the SET key SET First digit of

temperature flashes

Chooses the next

digit to be changed

3 Using the shift keys to

change the temperature

setpoint Increases the value

of the flashing digit

Temperature

Set-up

4 Press the SET key SET The value is stored

in memory and the

display returns to

the current chamber

temperature

TEMPERATURE (°C)TEMPERATURE (°C)

0 2 0

0 0 5

0 0 6

Temperature

Display

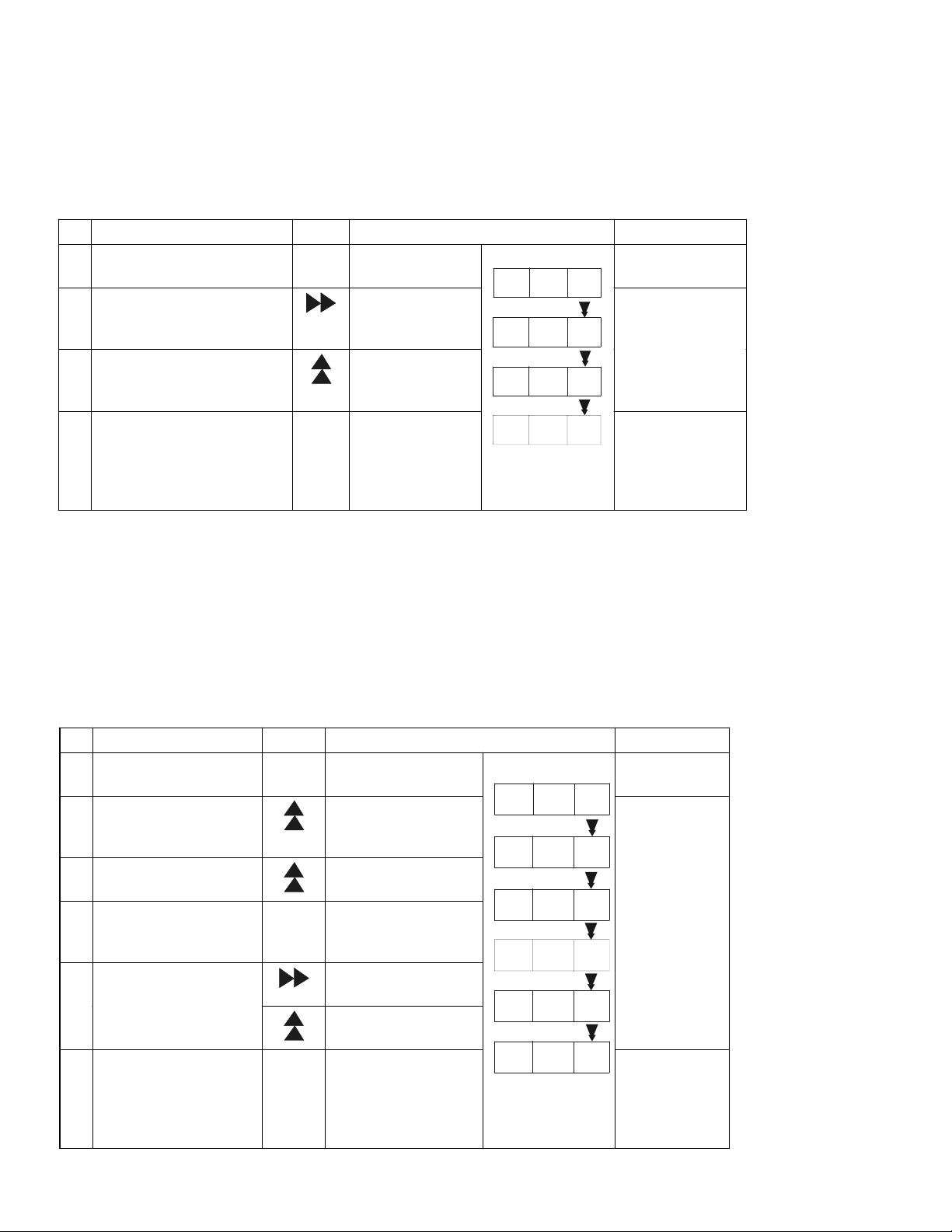

2.2 Key Lock Control

The key lock feature on this unit is to prevent unwanted

temperature setpoint changes. This feature is factory set to OFF.

To enter key lock mode, follow the sequence shown below.

2.3 High and Low Temperature Alarm

The temperature alarm set range is between +2° and

+14°C. The factory setting is +5°C.

a. High Temperature Setpoint

For example, if the high temperature alarm setpoint

required is 3°C greater than the chamber temperature or you

wish the alarm to go off when the chamber temperature is 3°C

greater than the temperature setpoint, set the first digit (step 5)

to “3”.

Depending on the setting of the high temperature alarm set-

ting, when a large amount of product is placed into the cham-

ber, the alarm system may activate. After the chamber tempera-

ture reaches its setpoint, the alarm is automatically cancelled.

Model 3680 Series __________________________________________________________________Control Panel Procedures

2 - 2

Operation Key Display Mode

1 ---- Current chamber

temperature

Temperature

Display

2

Press and hold for 5 seconds

The first digit of

the temperature

display flashes

3 Set flashing digit to “1” Increases the

value of the

flashing digit

Key Lock

LO is enabled

(key lock off)

L1 is disabled

(key lock on)

4 Press the SET key SET Key lock is ON

and the display

returns to the

current chamber

temperature

TEMPERATURE (°C)TEMPERATURE (°C)

4

L 0

L 1

4

Temperature

Display

Operation Key Display Mode

1 ---- Current chamber

temperature

Temperature

Display

2 Press for 5 seconds The first digit on the

temperature display

flashes

3 Set the first digit to “1” Increases the value of

the flashing digit

4 Press the SET key SET The first digit of the

temperature display

flashes

Chooses the next

digit to be changed

5 Set the temperature

difference required for

alarm setpoint Increases the value of

the flashing digit

High

Temperature

Alarm Set

6 Press the SET key SET The value is stored in

memory and the

display returns to the

current chamber

temperature

TEMPERATURE (°C)TEMPERATURE (°C)

0 0 4

F 0 0

F 0 1

0 0 5

0 0 3

0 0 4

Temperature

Display

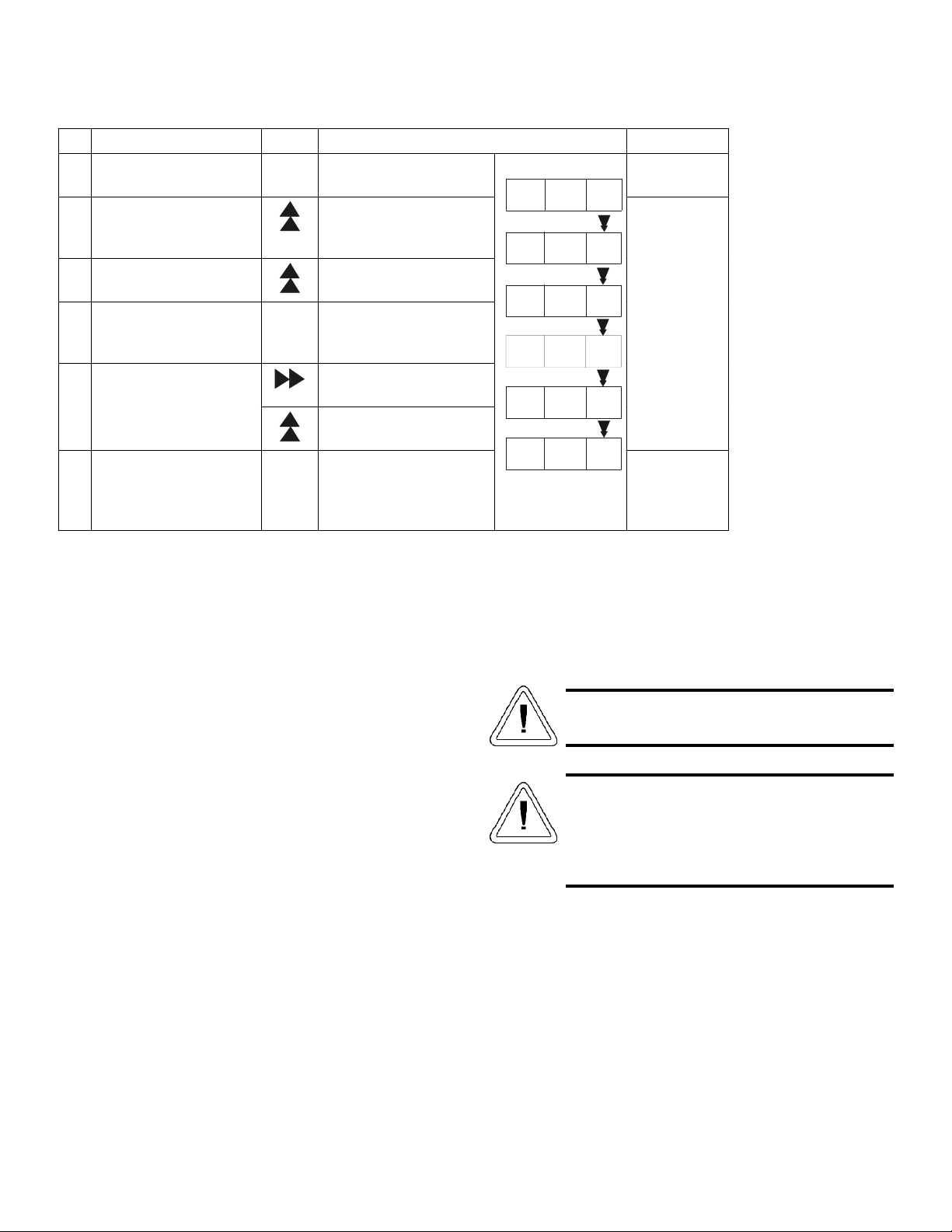

b. Low Temperature Setpoint

For example, if the low temperature alarm setpoint

required is 3°C less than the chamber temperature, or you wish

the alarm to go off when the chamber temperature is 3°C under

the temperature setpoint, set the first digit (step 5) to “3”.

Regardless of the low temperature alarm setting, if the

chamber temperature falls below 0°C, the alarm system will

activate to prevent freezing.

2.4 Door Open Light

When the door is opened, the DOOR indicator lights. This

light goes out automatically when the door is closed.

The alarm will activate if the door is open longer than 2

minutes. Press BZ to temporarily silence this alarm or it will

automatically deactivate when the door is closed.

2.5 Audible Alarm Switch

The audible alarm sounds when the chamber temperature

is above the high alarm setpoint for 15 minutes, when the

chamber temperature is below the low alarm setpoint for 15

minutes, or if the door remains open for 2 minutes.

Note: To silence the alarm, press BZ on the control panel.

2.6 Interior Lights Switch

The LIGHTS switch controls power to the lights inside the

chamber. Note: The light should be off during normal refriger-

ator operation and turned on when viewing the inside of the

chamber.

Model 3680 Series __________________________________________________________________Control Panel Procedures

2.7 Digital Temperature Display

TEMPERATURE display shows chamber temperature.

2.8 Remote Alarm Terminal

Disconnect the unit from power before beginning

any installation or service procedure.

Do not turn the refrigerator ON within 5 minutes

of turning it off. The compressor may not operate

properly without this 5 minute interval. This also

protects the compressor from excessive pressure

build-up.

The remote alarm terminal is located in the box on the

back of the cabinet. The normally-open contact capacity is

30VDC, 2A.

Note: The alarm buzzer stop key (BZ) silences the remote

alarm as well as the alarm buzzer, except when the power sup-

ply plug has been disconnected from the unit.

1. Remove the cover from the terminal box on the back of

the cabinet.

2. Connect the lead wire of the remote alarm equipment to

the terminal.

3. Reinstall the cover.

Operation Key Display Mode

1 ---- Current chamber

temperature

Temperature

Display

2 Press for 5 seconds The first digit on the

temperature display

flashes

3 Set the first digit to “2” Increases the value of

the flashing digit

4 Press the SET key SET The first digit of the

temperature display

flashes

Chooses the next digit

to be changed

5 Set the temperature

difference required for

alarm setpoint Increases the value of

the flashing digit

Low

Temperature

Alarm Set

6 Press the SET key SET The value is stored in

memory and the display

returns to the current

chamber temperature

TEMPERATURE (°C)TEMPERATURE (°C)

0 0 4

F 0 0

F 0 2

0 0 5

0 0 3

0 0 4

Temperature

Display

2 - 3

3 - 1

Section 3 - Maintenance

Disconnect the unit from power before beginning

any installation or service procedure.

Do not turn the refrigerator ON within 5 minutes

of turning it off. The compressor may not operate

properly without this 5 minute interval. This also

protects the compressor from excessive pressure

build-up.

3.1 Defrosting the Unit

a. Cycle Defrost

The defrost heater cycles automatically to clear any frost

accumulation on the refrigeration coils. This has no effect on

the chamber temperature.

b. Forced Defrost

If the ambient humidity is high or a large amount of damp

product is being stored in the chamber, the cycle defrost may

not be sufficient to remove all the frost from the refrigeration

coils and an automatic defrost function is initiated. This func-

tion is activated by a sensor located on the evaporator. When

this defrost function occurs, the current chamber temperature

and “dF” flashes alternately on the TEMPERATURE display.

The compressor will stop and a heater will be activated. When

the cycle is complete, normal operation resumes. The chamber

temperature may rise as much as 10° during this defrost cycle.

3.2 Cleaning Evaporation Tray and Condenser Filter

(Condenser, if applicable)

Clean the drain evaporation tray and condenser filter (con-

denser, if applicable) once a month.

a. Cleaning the Evaporation Tray

1. Remove the two screws securing the bottom front unit

cover.

2. Clean the cover.

3. Remove and empty the evaporation tray.

4. Clean the tray using a mild detergent and warm water.

Do not use hot or boiling water. Rinse the tray thorough-

ly and return it to the unit. Install the cover.

b. Cleaning the Condenser (3684, 3686)

Clean the condenser using a vacuum sweeper.

c. Cleaning the Condenser Filter (3688)

To prevent dust from clogging the condenser, a filter is

installed to the right of the evaporation tray.

1. Remove the bottom front cover, then hold the filter by

the leading edge and slide it to the left. Clean with

water, dry completely and return it to its original posi-

tion.

2. After cleaning both the evaporation tray and the con-

denser filter, secure the bottom front cover by aligning

the three pins at the top of the cover and installing the

two screws at the bottom.

3.3 Cleaning the Unit

Never splash or drip water on the outside of the

unit, as water can cause malfunctioning of the

electronic components.

Do not clean the unit with brushes, acid, benzene,

thinner, powdered soap, cleanser or hot water.

These agents can damage the cabinet’s finish and

any plastic or rubber components.

A dry cloth can be used to clean all areas of the unit

including the shelves and drawers. Any condensation that

forms on the front glass or frame may be wiped away.

Be sure to rinse completely with a clean cloth and water, if

using a mild detergent.

3.4 Replacing the Fluorescent Light

To replace the fluorescent light bulb, follow the procedure

below.

1. Turn the control panel light switch and power switch off.

Unplug the unit.

2. Remove all shelves from the left side of the chamber.

3. Grasp the light bulb assembly and pull it from the hold-

ing brackets.

4. Roll off the rubber connector protectors from each end

of the bulb.

5. Gently remove the bulb from the cover.

6. After placing the new bulb into the cover, reinstall the

rubber protectors.

7. Return the fluorescent light bulb assembly to its original

position.

Model 3680 Series ____________________________________________________________________________Maintenance

Section 4 – Troubleshooting

Note: When 2 or more alarm conditions occur simultaneously,

the lowest number code has priority on the display.

After a power failure, the unit will resume operation with

the set values that were in place before the power failure

occurred.

Model 3680 Series _______________________________________________________________________Troubleshooting

4 - 1

Type Symptom Indication Alarm Buzzer Safety Response

High

Temp

Alarm

Chamber temp

deviates from 2°C to

14°C above setpoint

Intermittent after

15 minute delay

Remote alarm is activated

after 15 minute delay

Chamber temp

deviates from 2°C to

14°C below setpoint

Alarm light

flashes

Temp display

flashes Intermittent Remote alarm is activated

after 15 minute delay

Low Temp

Alarm

If chamber temp is

lower than 0°C

--- --- Remote alarm is activated

Power

Failure

Alarm

Power failure or

accidental power

disconnect

--- --- Remote alarm is activated

Door

Alarm

Door is open DOOR light on Intermittent after

2 minute delay

---

Auto

Return

No keys pressed for

90 seconds in set

mode

Chamber temp

displayed

--- Set mode is cancelled

Key lock Key lock is on or set

to “1”

--- --- Key input is disabled

Temp sensor short

circuits

Alarm flashes

E1 and

chamber temp

flash

alternately on

display

Intermittent Remote alarm is activated

Defrost sensor operates

Defrost sensor short

circuits

Alarm flashes

E2 and

chamber temp

flash

alternately on

display

Intermittent tone Remote alarm is activated

Continuous running

Temp

Sensor

Problem

Defrost sensor 2

short circuits

Alarm flashes

E3 and

chamber temp

flash

alternately on

display

Intermittent Remote alarm is activated

Continuous running

Model 3680 Series _______________________________________________________________________Troubleshooting

4 - 2

4.1 Discarding or Taking the Refrigerator out of

Service

Federal regulations require that doors be removed

before being taken out of service or discarded.

Problem Possible Cause

Nothing operates even when turned on

•

Check electrical power

•

Electric power has failed or been

disconnected

Key Operation Unavailable •Is Key Lock set to OFF?

Poor Refrigeration

•

Temperature control not properly set

•

Too many warm items in the chamber

•

Frost on the evaporator

•

Freezer door opened and closed

frequently, or not closed tightly

•

Back of the refrigerator touching the wall

•Air exhaust vent blocked

•Unit in direct sunlight or too close to a

heat source

Alarm System Activated

•

Door not closed tightly

•

Too many warm items in the chamber

•Temperature setting changed

Section 5 – Specifications

Model 3684

Operating Temperature

+2°C (+35.6°F) to +14°C (+57.2°F)

Temperature Control

Electronic control with digital

temperature readout, readable to the

nearest °C.

Defrost Heater 148W

Fan Motor Chamber – output 3W (1)

Compressor 0.3 HP hermetically sealed

Refrigeration Forced cool air circulation

Refrigerant 5.6 oz. (158.8 grams) R134A

0.3 oz. (9.9 grams) N-Pentane

Capacity 17.3 cu. ft. (489 liters)

Interior Dimensions

31.44”W x 51.19”H x 18.31” F-B

(79.86cm x 130.02cm x 46.51cm)

Exterior Dimensions

35.44”W x 70.5”H x 23.63” F-B

(90.02cm x 179.07cm x 60.02cm)

Interior Light One 20W fluorescent light with

control panel-mounted switch

Insulation

Non-CFC foamed-in-place rigid

polyurethane

Shelving

Five adjustable shelves - 110.2 lbs.

(50 kg)/shelf load limit

Electrical 115 VAC, 1 PH, 60 Hz, 2.1 FLA

Weight 304.24 lbs (138 kg)

Model 3686

Operating Temperature

+2°C (+35.6°F) to +14°C (+57.2°F)

Temperature Control

Electronic control with digital

temperature readout, readable to the

nearest °C.

Defrost Heater 148W

Fan Motor Chamber – output 3W (1)

Compressor 0.3 HP hermetically sealed

Refrigeration Forced cool air circulation

Refrigerant 5.6 oz. (158.8 grams) R134A

0.3 oz. (9.9 grams) N-Pentane

Capacity 17.2 cu. ft. (486 liters)

Interior Dimensions

31.44”W x 51.19”H x 18.31” F-B

(79.86cm x 130.02cm x 46.51cm)

Exterior Dimensions

35.44”W x 70.50”H x 23.63” F-B

(90.02cm x 179.07cm x 60.02cm)

Interior Light One 20W fluorescent light with

control panel-mounted switch

Insulation Non-CFC foamed-in-place rigid

polyurethane

Shelving Five adjustable shelves – 44.0 lbs.

(20kg)/shelf load limit

Roll-out baskets 44.0 lbs. (20kg)/drawer load limit

Electrical 115 VAC, 1 PH, 60 Hz, 2.1 FLA

Weight 317.47 lbs (144kg)

Model 3680 Series ___________________________________________________________________________Specifications

5 - 1

Model 3688

Operating Temperature

+2°C (+35.6°F) to +14°C (+57.2°F)

Temperature Control

Electronic control with digital

temperature readout, readable to the

nearest °C.

Defrost Heater 175W

Fan Motor Chamber – output 9W (2)

Condenser – output 4W (1)

Compressor 0.4 HP hermetically sealed

Refrigeration Forced cool air circulation

Refrigerant 10.9 oz. (309 grams) R134A

0.7 oz. (20.1 grams) N-Pentane

Capacity 36.5 cu. ft. (1034 liters)

Interior Dimensions 66.88”W x 51.19”H x 18.31” F-B

(169.88cm x 130.02cm x 46.51cm)

Exterior Dimensions 70.88”W x 70.5”H x 23.63” F-B

(180.04cm x 179.07cm x 60.02cm)

Interior Light One 40W fluorescent light with

control panel-mounted switch

Insulation Non-CFC foamed-in-place rigid

polyurethane

Shelving Five adjustable shelves - 110.2 lbs.

(50kg)/shelf load limit

Ten roll-out baskets 44.0 lbs. (20kg)/drawer load limit

Electrical 115 VAC, 1 PH, 60 Hz, 3.1 FLA

Weight 562.18 lbs (255 kg)

Model 3680 Series ___________________________________________________________________________Specifications

5 - 2

Section 6 - Parts List

3684/3686 3688 Description

Stock # Stock #

227831 227929 Compressor

227774 227774 Starting Relay

227835 227775 Overload Relay

227936 227936 Overtemp Relay

227930 227930 Starting Capacitor

227931 227931 Running Capacitor

227933 227933 Undertemp Thermostat

227934 227925 Thermal Protector

N/A 227941 Condensing Fan Motor

227939 227939 Cooling Fan Motor, Right (3688)

N/A 227940 Cooling Fan Motor, Left (3688)

227942 227942 Thermal Fuse

227943 227944 Ballast

227945 227945 Lamp Switch

227946 227946 Door Switch

227935 227935 Power Relay

227938 227938 Power Supply

227871 227870 Main Power Switch/Circuit Breaker

227947 227190 Fluorescent Lamp Starter

227949 227950 Drain Pan Heater

227951 227952 Temp Control/Display Board

227953 227954 Temp Sensor

227937 227937 Defrost Sensor (black leads)

N/A 227960 Defrost Sensor (white leads)

Consult Consult Fluorescent Lamp 40W (3688)

Factory Factory Fluorescent Lamp 20W (3684/3686)

227948 Consult

Factory Defrost Heater

227989 227990 Display Board

Model 3680 Series _____________________________________________________________________________Parts List

6 - 1

This manual suits for next models

2

Table of contents