ELECTROSEA CLEARLINE CL-990-X1.5 User manual

(888) 384-8881

(952) 475-8084

www.electrosea.com

Operation Manual Model CL-990-X1.5

CLEARLINE®System

Table of Contents

1

U.S. and Foreign Patents Pending

COPYRIGHT © 2020

No part of this publication may be reproduced, translated, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise

without prior written consent by ElectroSea, LLC. Every precaution has been taken in the preparation of this manual to ensure its accuracy. ElectroSea assumes no responsibility for errors and

omission. Neither is any liability assumed for damages resulting from the use of this product and information contained herein.

1

Introduction

Table of Contents 1

ElectroSea® and CLEARLINE® 2

Safety Considerations 2

System Features

User Interface 3

Operating Modes and Feature Overview 4-5

Optimal Performance and Flow Alert 6

CELL Indicator 7

ClearCell®

ClearCell Internal Screen Care 8

ClearCell Internal Screen Access 9-13

CLEARLINE® System Updates

Factory Default and Firmware Updates 14

Inspection

Periodic Inspection 15

Important Information

Specifications 16

Modes & Troubleshooting

Table of Modes, Descriptions and Actions 17-18

Warranty

Warranty Terms and Conditions 19-20

2

U.S. and Foreign Patents Pending

Introduction 2

ELECTROSEA®

ElectroSea was created when the owners of a sportfishing yacht invented “a better way” to prevent unwanted marine growth in their

seawater lines. Solving complex technical problems is their expertise. With more than 100 issued U.S. patents and 350+ foreign patents

in advanced technologies, our Executive Management Team has been developing innovative solutions for more than 50 years. With an

expert team of ‘old salts’ who eat, sleep, and breathe boating, ElectroSea will improve your time on the water.

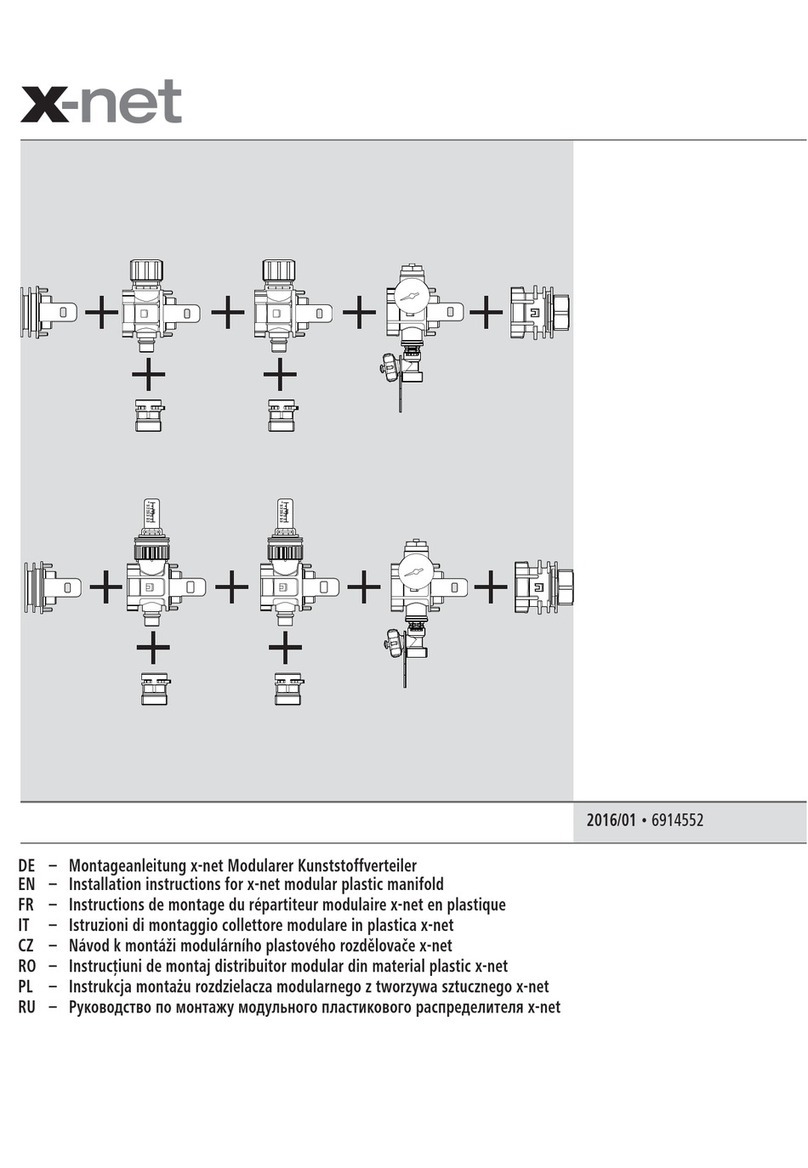

CLEARLINE®System

CLEARLINE is an innovative marine electrochlorination system that prevents biofouling and barnacle growth in your vessel’s seawater lines.

CLEARLINE keeps your air conditioners, chillers and refrigerators operating at maximum flow rates, and sea strainers clean longer. The patent

pending CLEARLINE System includes CLEARLINE Control Unit which is the brain, and ClearCell® which is the heart of the system.

CLEARLINE operates automatically 24x7x365 and is built for flawless and reliable performance.

WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Indicates a hazardous situation which can cause damage to personal property, environment, or equipment.

Safety Considerations

NOTICE

3

U.S. and Foreign Patents Pending

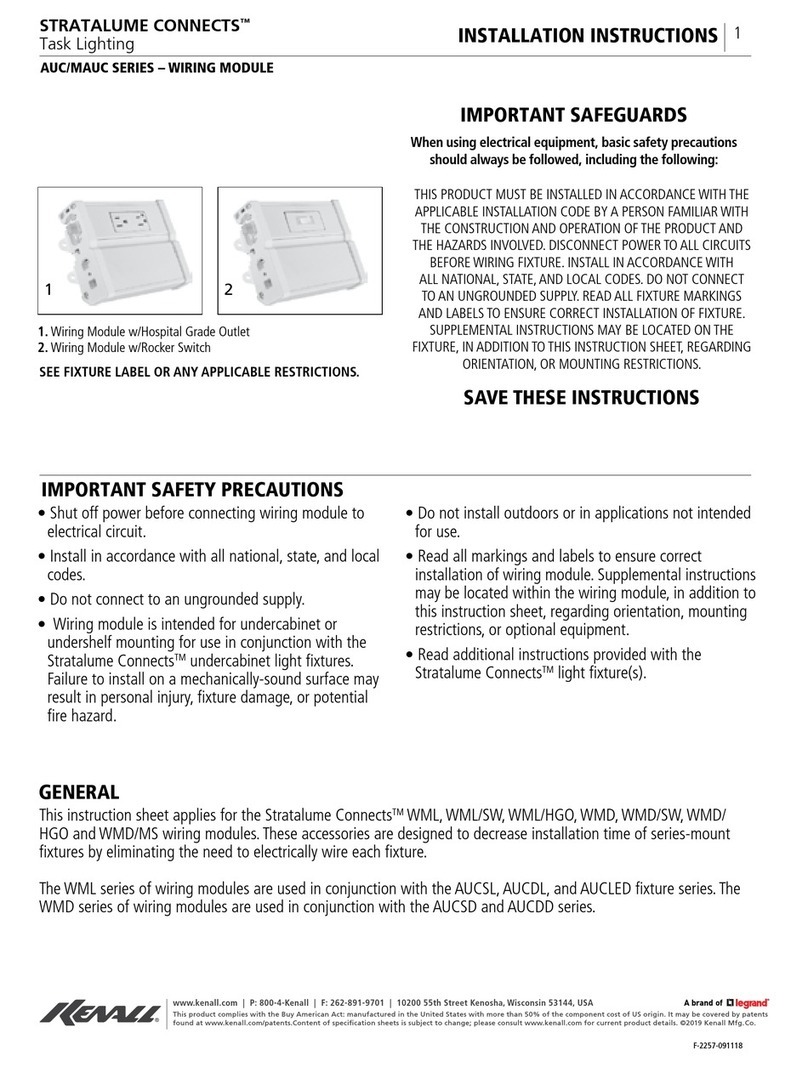

Status Screen

Operating Mode

Circuit Breaker

Features and Functions

1. Power on CLEARLINE. The Control Unit will complete a diagnostic self-test and then the green “POWER” light will be illuminated.

2. The main status screen will be displayed.

User Interface

3

Selection Buttons

ON/OFF

USB Port

Programming Menu

Flow Rate

4

U.S. and Foreign Patents Pending

Operating Modes

Modes and Features 4

The Operating Mode displays the state of the CLEARLINE System. Modes include:

• OFF: CLEARLINE is powered, but is in the OFF mode and not Cleaning.

• START-UP: CLEARLINE is performing a diagnostic self-test. This mode lasts for approximately 30 seconds.

• CLEANING: CLEARLINE is ON and Cleaning. This is the normal operating mode for the CLEARLINE System.

• FLOW ALERT: CLEARLINE is ON and Cleaning, but the flow rate measured is less than or equal to the value set manually in the Flow Alert feature.

• CELL INDICATOR: CLEARLINE will continuously attempt to generate chlorine and automatically resume standard operation when conditions are resolved.

Feature Overview

• Flow Rate (GPM): Monitors the flow rate in gallons per minute (GPM) or liters per minute (LPM) of seawater at the output of the CLEARLINE System. The flow rate is

displayed for values of 4–50 GPM. (15–189 LPM) CLEARLINE CL-990-X1.5 should not be used with flow rates >50 GPM (>189 LPM).

• Flow Alert: An alert that indicates the flow rate is at or below a threshold level for a period of time. Flow Alert is manually set by the user.

• Display Contrast, Backlight, Imperial and Metric Units: Adjustment of LCD display contrast and backlight levels from Lo to Hi. Selection of Imperial and Metric units

for flow in GPM or LPM.

• Default Update: Process to restore CLEARLINE to original factory default settings. Allows the user to update CLEARLINE Control Unit firmware from a USB memory drive

supplied by ElectroSea.

5

U.S. and Foreign Patents Pending

During normal operation the Control Unit will flash “Cleaning” and the green Cleaning LED will be illuminated. This indicates the CLEARLINE System is electrochemically

generating chlorine to prevent biofouling in the vessel’s seawater circuit. The System will display the flow rate at the output of the CLEARLINE System in gallons per minute

(GPM) or liters per minute (LPM). If the flow rate drops below 4 GPM (15 LPM), then the display will indicate Min Flow. The CLEARLINE System will automatically stop generating

chlorine if Min Flow (1–3 GPM/3.8–11.4 LPM), or No Flow (0 GPM).

Power ON and Start-up Delay

Auto Mode

CLEARLINE -Menu

Cleaning XX GPM

Auto

Set Backlight, Contrast, or Units: The LCD display backlight, contrast, and imperial / metric units can be set. Use the Up or Down arrows to select and change settings.

Display Backlight, Contrast and Imperial / Metric Units

Cleaning Mode

Power ON the CLEARLINE System. The Control Unit will complete a diagnostic self-test and then the green “POWER” LED will be illuminated. “START-UP” will be displayed for 30 seconds.

The CLEARLINE System automatically and continuously calculates the optimal level of chlorinated seawater to prevent biofouling in lines based on multiple input parameters

including seawater flow rates, key electrical parameters, and environmental temperature.

>

Modes and Features

5

6

U.S. and Foreign Patents Pending

Modes and Features 6

Flow Alert: The Flow Alert feature monitors seawater flow through the ClearCell. This feature allows the user to set a minimum flow rate threshold value and time

duration. If the seawater flow rate drops below a minimum value for a period of time, then “Flow Alert” will appear on the display (no audible alert).

This feature notifies the user that some part of the seawater circuit such as the intake, strainer, pump, or internal screen on the ClearCell requires cleaning or is

not functioning properly. Flow rate can be set in GPM or LPM, and time duration in minutes. To set the Flow Alert value go to MENU, Flow Alert, and enter desired

threshold flow rate and time duration for notification.

Flow Alert feature is default OFF from ElectroSea and must be set-up by the installer or end user.

CLEARLINE will continue generating chlorine even after a Flow Alert occurs. Flow Alert does not prevent CLEARLINE from operating.

If a Flow Alert occurs:

1. Check vessel’s strainers and intake grates for blockage

2. Check seawater pump operation

3. Check ClearCell Internal Screen (see Pg. 8)

Optimal Performance

Constant Chlorinated Seawater Flow: The CLEARLINE System should be powered ON and have seawater flowing through the ClearCell at all times.

This provides the vessel’s seawater circuit with constant chlorinated seawater to prevent unwanted marine growth. Intermittent or stagnant

seawater that is not continuously electrochemically treated allows growth of marine microorganisms. Barnacles have the innate ability to close themselves

off and survive intermittent exposure to biocidal agents.

• DO NOT turn off seawater pumps, air conditioner, or chiller for an extended period of time.

Inspect the vessel for problem areas:

• Pre-existing biofouling in seawater lines prior to CLEARLINE installation.

• Clogged seawater strainers and intakes.

• Impacted, blocked or occluded lines from debris lodged in plumbing.

• Sporadic demand valve areas; depending on the system, valves that turn on and off can foster unwanted marine growth.

Flow Alert

>-Flow Alert -Update

-Display

-Cell

-Default -Exit

NOTICE

NOTICE

7

U.S. and Foreign Patents Pending

CELL Indicator

7

CELL Indicator: The Control Unit will display “SALINITY/CELL”, “% OUTPUT” and illuminate the red CELL LED in various conditions. This is not an immediate cause for concern

and may be temporary depending on seawater salinity level. CLEARLINE will continuously attempt to generate chlorine and automatically resume standard operation when

conditions are resolved. The CELL indicator will be illuminated if any of the following conditions occur for multiple consecutive days:

• Water salinity is below 20 parts per thousand (most common cause of CLEARLINE CELL indicator notice)

• ClearCell cable or its connectors has been compromised

• ClearCell Electrode has excessive mud or other debris

• ClearCell Electrode is at the end of its useful life

Water Salinity

• Vessels often encounter brackish or freshwater when cruising inland, and from extended storms and freshwater run-off.

• Low salinity is the most frequent cause of CLEARLINE CELL Indicator.

• CLEARLINE will not display “CLEANING” or generate chlorine while vessel is operating in freshwater.

RESOLUTION: Vessel returns to seawater with adequate salinity.

ClearCell Cable

• The ClearCell cable and connections must not be spliced, cut, compromised, or damaged.

• Inspect the Control Unit to ClearCell cable carefully. Look for any corrosion at the connectors.

RESOLUTION: Replace the ClearCell cable if it is compromised.

Excessive Mud or Other Debris

• If there is excessive mud or other debris, then the ClearCell Electrode may require a brief rinse with freshwater.

RESOLUTION: Follow instructions on Pg. 8-13.

ClearCell Electrode at End of Life

• When the ClearCell Electrode has reached the end of its useful life it can no longer generate chlorine. The ClearCell Electrode life is dependent on flow rate, hours of use,

seawater quality and other factors. The ClearCell Electrode will be effective for many years before replacement is required.

RESOLUTION: Contact your CLEARLINE dealer or ElectroSea directly.

CELL Indicator

ESTUARY

OCEAN

8

U.S. and Foreign Patents Pending

Low seawater flow may damage cooling system and

other components that depend on this water for proper operation. It is

the owner’s responsibility to monitor the vessel’s seawater flow and

perform any maintenance on the vessel’s seawater pumps, strainers,

and screen in ClearCell.

Internal Screen: The ClearCell contains an internal screen to catch debris before it reaches the flow sensor (debris, tiny shells, or other foreign materials that

pass through the vessel’s main strainer). The internal screen should be cleaned periodically, and whenever debris gets caught in the screen and decreases

seawater flow. Before accessing the ClearCell Electrode, double-check the list of Alerts and Indicators on Pg. 6 and 7, because the ClearCell infrequently requires

rinsing.

NOTICE Low Salinity is the most frequent cause of a CELL Indicator notice. Do not open ClearCell canister if you suspect the CELL indicator notice is

due to low salinity.

Internal Screen

NOTICE

Spray screen with

freshwater

to remove debris

NOTICE

• DO NOT PERFORM ACID DESCALING OF SEAWATER CIRCUIT AFTER

THE CLEARLINE SYSTEM HAS BEEN INSTALLED.

• DESCALING ACIDS OR CLEANING CHEMICALS WILL DAMAGE THE

CLEARCELL CANISTER, CLEARCELL ELECTRODE AND VOID THE WARRANTY.

• DO NOT TOUCH THE CLEARCELL ELECTRODE PLATES OR USE ANY TYPE OF

MECHANICAL BRUSH.

• THE CLEARCELL ELECTRODE PLATES CONTAIN A SPECIAL METAL OXIDE

COATING THAT WILL BE PERMANENTLY DAMAGED IF YOU HANDLE IT.

ClearCell 8

9

U.S. and Foreign Patents Pending

1

2

3

Internal Screen Access

DO NOT UNSCREW

PLASTIC CAP NUTS

ClearCell

9

Before accessing the ClearCell Electrode, double-check the list of Alerts and Indicators on Pg. 6 and 7, because the ClearCell infrequently requires rinsing.

To access ClearCell Electrode:

1. Power OFF the CLEARLINE Control Unit.

2. Turn OFF ALL seacock valves in the seawater circuit at or below the

waterline. This includes any output seacocks to prevent back siphoning.

Failure to turn OFF ALL seacock valves

in the seawater circuit could result in sinking the vessel.

3. Disconnect the 1’ (30.5cm) cable labeled CELL that is located at the top

of the ClearCell unit. To disconnect this cable, do so at the cable connector.

DO NOT UNSCREW THE TWO BLACK PLASTIC CAP

NUTS ON TOP OF THE LID OR TITANIUM HARDWARE UNDER THE LID.

WARNING

NOTICE

10

U.S. and Foreign Patents Pending

4. Remove the pressure ring by turning

the wing nuts counterclockwise.

5. Remove the pressure ring.

4

5

6

6. Remove the Electrode Assembly by

lifting it straight up by the sides of

the black plastic top. Do not lift or

pull on the top cable connectors.

ClearCell 10

11

U.S. and Foreign Patents Pending

7. Spray the ClearCell Electrode Assembly with freshwater to remove any dirt or mud

between the plates or debris in the internal screen.

Spray plates and screen with freshwater

7

DO NOT TOUCH THE SURFACE BETWEEN THE

ELECTRODE PLATES, OR USE ANY TYPE OF MECHANICAL BRUSH.

THE CLEARCELL ELECTRODE PLATES CONTAIN A SPECIAL METAL

OXIDE COATING THAT WILL BE PERMANENTLY DAMAGED IF YOU

HANDLE IT.

DO NOT PUT ANY CHEMICALS, ACIDS,

DESCALING SOLUTIONS OR ZINCS IN THE CLEARCELL CANISTER

OR ON THE ELECTRODES. THIS WILL DAMAGE THE ELECTRODE.

NOTICE

NOTICE

ClearCell

11

12

U.S. and Foreign Patents Pending

8. Insert the ClearCell Electrode Assembly back into ClearCell canister.

The Electrode Assembly and lid are keyed and only can be inserted in one

direction. Align the Electrode Assembly key and the ClearCell canister key and

insert it into the ClearCell canister.

9. Add the pressure ring and begin tightening down the wing nuts evenly.

Bleed all air out of the ClearCell canister, and then finish securing the wing nuts.

DO NOT use any tools to perform this tightening process. Work in a star pattern

so they are all evenly secure.

10. Double check to ensure all fittings, hose clamps and wing nuts are secure.

10

9

Lid Key

8

Canister

Keys

8

ClearCell 12

13

U.S. and Foreign Patents Pending

11

12

13

11. Reconnect the ClearCell Cable to the CLEARLINE Control Unit.

12. Open the seacocks and check for any leaks.

13. Turn the seawater intake pump ON. The seawater intake pumps must be ON and

pumping seawater at normal flow rates for CLEARLINE to operate.

14. Turn ON the CLEARLINE System. The CLEARLINE Cleaning LED should be illuminated in

green and the display should state it is in Cleaning mode.

15. If the CELL Indicator is still active, then one of the following conditions still persists:

• Water salinity is below 20 parts per thousand

• ClearCell cable or its connectors has been compromised

• ClearCell Electrode has excessive mud or other debris

• ClearCell Electrode is at the end of its useful life

For further troubleshooting, see Pg. 8 or Pg. 19; or contact your CLEARLINE dealer

or ElectroSea.

Any air trapped in the ClearCell canister must be bled out.

Cycle the seawater intake pump and/or loosen the ClearCell canister wing nuts to

bleed out excess air then re-tighten the ClearCell canister.

DO NOT restrict seawater flow to ClearCell canister.

14

NOTICE

NOTICE

ClearCell

13

14

U.S. and Foreign Patents Pending

1. Default: This is the process to restore CLEARLINE to its original factory default settings. The user will press and hold the Up & Down arrows

simultaneously for 10 seconds to restore factory default settings.

2. Update: This allows the user to update the firmware using a USB memory drive supplied by ElectroSea. To perform a firmware update:

1. Insert the ElectroSea USB memory drive.

2. Go to the Update menu. Line 1 displays the current firmware version of the unit. Line 2 displays the available firmware version that

is on the USB memory drive. It is possible to upgrade or downgrade the firmware version.

3. Press and hold the Up & Down keys simultaneously for 10 seconds, then release the keys once the update begins.

4. During the update, the Control Unit is in a locked mode and cannot be used. The bottom line of the display will show the update progress.

5. Once the update is complete, the Control Unit will reboot.

6. Confirm the update was successful by going back to the Update menu. The display will show that the FW X.X is up to date.

In the event that the firmware update fails, the Control Unit maintains a redundant copy of the existing firmware. The

screen will display a result message at the end of an update attempt to confirm the update was successful. Repeat the steps above to

retry the firmware update if required.

-Flow Alert -Update

-Display

-Cell

-Default -Exit

-Flow Alert -Update

-Display

-Cell

-Default -Exit

Factory Default and Firmware Updates

>

Reset to Factory

HOLD UP & DOWN

for 10 seconds

OK to Exit

FW X.X Current

OK to Exit

>

NOTICE

Factory Default and Firmware Updates 14

Inspection

15

15

U.S. and Foreign Patents Pending

The CLEARLINE System should be viewed during regular inspection of the vessel’s engine room. During normal operation, the CLEARLINE System status

screen will flash the message “Cleaning” and the green LED will be illuminated. This indicates the CLEARLINE System is generating a safe and effective low

level of chlorine preventing unwanted marine growth, barnacles, and biofilm in the seawater lines.

If there are any concerns during the regular inspection noted above, then perform a more thorough process:

• Visually inspect all wires and connections between the CLEARLINE Control Unit and the ClearCell.

• Disassemble the ClearCell and thoroughly flush and clean the internal screen (See Pg. 8-13).

• Visually inspect the Flow Sensor.

• Visually inspect seawater conduits to confirm marine growth prevention.

Inspection and maintenance are the responsibility of the vessel owner.

Periodic Inspection

NOTICE

Specifications 16

16

U.S. and Foreign Patents Pending

Specifications

CLEARLINE SYSTEM

Power: 24 VDC

7 Amp Max Peak Current

Normal Operating Flow: 18-50 GPM (68–189 LPM)

Maximum Pressure: 70 psi

CLEARCELL

Size: 10.2 inches (26cm) – height

8.4 inches (21.3cm)– diameter / width

CLEARLINE CONTROL UNIT

Size: 10.0 inches (25.4cm) – width

7.0 inches (17.8cm) - height (without cables)

3.25 inches (8.3cm) - depth

Summary Modes & Trouble-Shooting

17

17

U.S. and Foreign Patents Pending

Modes and Troubleshooting

Mode Description Action

OFF Unit is powered ON, but is in the OFF state. No seawater is flowing

through the CLEARLINE System. This is a normal operating mode provided there is no seawater flow.

Cleaning The mode for cleaning and preventing biofouling by chlorinating

seawater. This is a normal operating mode. See page 7 for Cleaning.

Auto

The mode for automatically optimizing the level of chlorinated

seawater based on multiple input parameters including flow rate,

key electrical parameters, and environmental temperature.

This is a normal operating mode. See page 7 for Auto Mode.

Min Flow The flow rate is 1–3 GPM (3.8–11.4 LPM), and is too low to

chlorinate seawater.

The Min Flow indicator will disappear when the seawater

flow rate >4 GPM (>15 LPM).

No Flow The flow rate is 0 GPM. The No Flow indicator will disappear when the seawater flow returns.

Flow Alert

Flow Alert is a user defined threshold value for visual alert and

notification purposes. The user should manually set the desired

Flow Alert value and time duration.

CLEARLINE will continue generating chlorine even after a Flow Alert occurs.

Flow Alert does not prevent CLEARLINE from operating.

Note: If the flow rate is less than or equal to 4 GPM (15 LPM), then a Min

Flow alert will occur and CLEARLINE will stop chlorinating seawater.

If a Flow Alert occurs:

1. Check vessel’s strainers and intake grates for blockage

2. Check seawater pump operation

3. Check all other components in the seawater intake fluid path

4. Check ClearCell Internal Screen and rinse according to ClearCell Internal

Screen instructions starting on Pg. 8-13.

Summary Modes & Trouble-Shooting 18

18

U.S. and Foreign Patents Pending

Modes and Troubleshooting

Mode Description Action

CELL Indicator

The Control Unit will display “SALINITY/CELL”,

“% OUTPUT” and illuminate the red CELL

LED in various conditions. This is not an

immediate cause for concern and may be

temporary depending on seawater salinity

level. CLEARLINE will continuously attempt

to generate chlorine and automatically

resume standard operation when

conditions are resolved.

Water Salinity

• Vessels often encounter brackish or freshwater when cruising inland, and from extended storms and

freshwater run-off.

• Low salinity is the most frequent cause of CLEARLINE CELL Indicator.

• CLEARLINE will not display “CLEANING” or generate chlorine while vessel is operating in freshwater.

RESOLUTION: Vessel returns to seawater with adequate salinity.

ClearCell Cable

• The ClearCell cable and connections must not be spliced, cut, compromised, or damaged.

• Inspect the Control Unit to ClearCell cable carefully. Look for any corrosion at the connectors.

RESOLUTION: Replace the ClearCell cable if it is compromised.

Excessive Mud or Other Debris

• If there is excessive mud or other debris, then the ClearCell Electrode may require a brief rinse with

freshwater.

RESOLUTION: Follow instructions on Pg. 8-13.

ClearCell Electrode at End of Life

• When the ClearCell Electrode has reached the end of its useful life it can no longer generate chlorine.

The ClearCell Electrode life is dependent on flow rate, hours of use, seawater quality and other factors.

The ClearCell Electrode will be effective for many years before replacement is required.

RESOLUTION: Contact your CLEARLINE dealer or ElectroSea directly.

High Temperature Temperature inside the CLEARLINE System

is high.

Contact your installation Dealer or ElectroSea as the ClearCell Electrode may be at the end of its useful life

and needs to be replaced.

Warranty

19

19

U.S. and Foreign Patents Pending

ELECTROSEA, LLC

State Law and Implied Warranties: This warranty gives you specific legal rights, and you may also have other rights that vary from state to state.

Any implied warranties that apply to you, including implied warranties of merchantability and fitness for a particular purpose, are limited in duration

to the Warranty Period defined below. Some states do not allow limitations on how long an implied warranty will last, so the above limitation may

not apply to you.

Limited Warranty – What is Covered: ElectroSea, LLC (“ElectroSea”) warrants that this product (the “Product”) will be free from defects in

materials and workmanship when used for its intended purposes under normal usage conditions. As described below, there are limitations

to this Limited Warranty.

Who is Covered: This Limited Warranty is made only to this purchaser (the “Original Purchaser”):

1. The original end user purchaser of a Product directly from ElectroSea or an authorized ElectroSea Dealer (a “Direct Purchaser”); or

2. The original end user purchaser of a new vessel in which a new Product was installed by the manufacturer (a “Vessel Purchaser”).

3. This Limited Warranty is not transferable.

How Long Coverage Lasts – the Warranty Period: This Limited Warranty only applies for a two year period (the “Warranty Period”) that begins on:

1. For a Direct Purchaser, the date of the Direct Purchaser’s purchase of the Product; or

2. For a Vessel Purchaser, the date the vessel is delivered to the Vessel Purchaser by the manufacturer or one of its dealers.

What ElectroSea will Do: ElectroSea’s only obligation under this Limited Warranty is to, at ElectroSea’s election:

1. Repair the Product;

2. Replace the Product; or

3. Refund the original purchase price paid by the Original Purchaser for the Product.

This is the sole and exclusive remedy available under this Limited Warranty. ElectroSea’s maximum monetary liability under this Limited

Warranty is an amount equal to the purchase price paid by the Original Purchaser for the Product.

Other manuals for CLEARLINE CL-990-X1.5

1

Table of contents

Popular Control Unit manuals by other brands

Ampetronic

Ampetronic HLS-DM2 Installation handbook

Sonder

Sonder TELKAN 1 GSM 3G Manual of installation and use

TRIB

TRIB airCap HR user manual

Racal Instruments

Racal Instruments 7064R-S-1843 instruction manual

VAT

VAT 650 Series Installation, operating, & maintenance instructions

Elster Instromet

Elster Instromet 300 Series Operation, Installation & Repair Parts