Electrovert Aquastrom 200 User manual

i

Aquastorm 200

Aqueous Cleaning System

Instruction Manual

Copyright © 1996 Electrovert®

No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means: electronic, mechanical, photocopying, recording, scanning, or otherwise

without the prior written permission of Electrovert.

Published, December 17, 1996

Manual Part Number

2-9316-621-00-0

Text Part Number

2-9316-622-00-0

ii

Aquastorm 200™

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

Congratulations on your purchase of an Aquastorm 200™ Aqueous Cleaning System. The Aquastorm 200™ is a powerful,

efficient aqueous cleaner designed for the removal of contaminated fluids and particles left behind from wave soldering and/

or reflow processes on complex surface mount and mixed technology PWAs. Each section of the Aquastorm 200™ has

been carefully integrated and balanced to achieve the best cleaning and drying capability for its size and cost, available in the

industry.

The purpose of this manual is to help obtain the greatest possible return on your investment. It is suggested that new

operators study the applicable sections of this manual thoroughly before operating the equipment. It is further suggested

that the manual be used as a reference by maintenance personnel and as a text for training of new maintenance personnel.

This manual includes operating instructions for this equipment available at the time this manual was approved for printing.

Electrovertreservestherighttomakechangesindesignandspecificationsand/ormakeadditionstoorimprovementsinthe

product without imposing any obligations upon itself to install them on previously manufactured products.

Electrovert Sales and Service OfficesElectrovert Sales and Service Offices

Electrovert Sales and Service OfficesElectrovert Sales and Service Offices

Electrovert Sales and Service Offices

Regional Service CentersRegional Service Centers

Regional Service CentersRegional Service Centers

Regional Service Centers

North East Regional Service Center

472 Amherst St. Suite 6

Nashua, NH 03063

Fax: 603-880-8757

Tel: 603-883-2488

South East Regional Service Center

200 Technology Dr.

Alpharetta, GA 30005

Fax: 770-442-1987

Tel: 770-475-6100

North Central Regional Service Center

580-A Tollgate Road

Elgin, IL 60123

Fax: 847-289-3797

Tel: 847-695-5750

North West Regional Service Center

2968 Scott Blvd.

Santa Clara, CA 95054

Fax: 408-727-0672

Tel: 408-727-4650

South West Regional Service Center

1111 W. North Carrier Parkway

Grand Prairie, TX 75050

Fax: 972-606-1700

Tel: 972-606-1900

Electrovert Main OfficesElectrovert Main Offices

Electrovert Main OfficesElectrovert Main Offices

Electrovert Main Offices

Product & Technology Center

Electrovert USA Corp.

1111 W. North Carrier Parkway

Grand Prairie, TX 75050

Fax: 972-606-1700

Tel: 972-606-1900

Technical Service Support Group &

Customer Service Parts Department

Electrovert USA Corp.

P.O. Box 709

Camdenton, MO 65020

Fax: 573-346-6878

Tel: 573-346-3341

Educational Services & Customer Support

Center

580-A Tollgate Road

Elgin, IL 60123

Fax: 847-289-3797

Tel: 847-695-5750

International Service CentersInternational Service Centers

International Service CentersInternational Service Centers

International Service Centers

Northern Europe & U.K.

Electrovert U.K. Ltd.

The Technology Centre

Unit 1, Pincents Kiln Industrial Park

Pincents Kiln

Calcot, Reading

Berks., U.K. RG31 7SO

Fax: 44 11-8-930-1401

Tel: 44 11-8-930-1400

Electrovert Singapore

10 Kian Teck Crescent

Singapore 628876

Fax: 65-861-7337

Tel: 65-861-1661

Japan

Electrovert-Seitec Co., Ltd.

1538 Kanoya-cho

Hachioji City, Tokyo 193 JAPAN

Fax: 81-426-23-8350

Tel: 81-426-23-7722

Northern Europe

Speedline Technologies S.A.R.L.

65 Avenue du General De Gaulle

Immeuble le Promethee

77420 Champs-Sur Marne, France

Fax: 33 160-05-6129

Tel: 33 160-06-8181

Central Europe

Speedline Technologies, Gmbh

Daimlerstrasse 1E D-63303

Dreieich, Germany

Fax: 49 6103-832119

Tel: 49 6103-8320

Speedline Technologies Italy

Via Liguria 2/28

I-20068 Peschiera Borromeo (MI)

Italy

Fax:39- 2 - 5530.8468

Tel: 39- 2 - 5530.8339

iii

Aquastorm 200

ELECTROVERT

TYPE

SER #

ELEC

DATE

VOLT

KVA

PH

HZ

MAX. LINE AMPERAGE

LARGEST MOTOR/LOAD

SHORT CIRCUIT

INTERRUPT CAPACITY

MADE IN U.S.A.

AMP

AMP

AMP

The Serial Tag information is to be filled by the user for Technical Support Purposes. Please have

this information available when contacting Technical Support or when placing parts orders.

iv

Aquastorm 200

Date

Company name: Machine name:

Address: Model number:

Mech. serial #:

Telephone: Elect. serial #:

Facsmile: Item/kit description:

Requested by:

If your machine was retrofitted or modified, please specify retrofit number or description

of modifications.

If the parts you are ordering are described in a quote, please include the quote number.

Parts Order Sheet ELECTROVERT

Please Photocopy this form for further use

Fill out this sheet to order parts/kits for your machine

Part Number Description Quantity

i

DIVISION 1 - OVERVIEW

Table of Contents

SECTION 1 GENERAL ................................................................................................................................... 1-1

1.1 HAZARDS ......................................................................................................................................... 1-1

1.2 Safety Precautions .............................................................................................................................. 1-2

SECTION 2 DESCRIPTION............................................................................................................................ 1-4

2.1 Process Zone Area .............................................................................................................................. 1-4

2.2 Detailed Description............................................................................................................................ 1-5

Cabinet ........................................................................................................................................... 1-5

Plumbing......................................................................................................................................... 1-5

System Controls............................................................................................................................... 1-6

Prewash Section .............................................................................................................................. 1-6

Heated Recirculating Wash Hurricane Section ....................................................................................1-7

Dragout/ Enhanced Chemical Isolation Section ...................................................................................1-8

Heated Recirculating Rinse/ Hurricane Section ..................................................................................1-9

Final Rinse Section ........................................................................................................................ 1-10

Blower Drying Section #1 & #2 ....................................................................................................1-10

Stainless Steel Wire Belt Conveyor ..................................................................................................1-11

Noise Suppression Hood..................................................................................................................1-11

Stainless Steel Pressure Gauges.......................................................................................................1-12

Internal Slide Gate Dampers............................................................................................................1-12

Optional Checkmate™ Hold Down Conveyor .....................................................................................1-13

Optional Photocell Control ..............................................................................................................1-14

Auto Start Timer ........................................................................................................................... 1-14

Optional Detergent Injection System ................................................................................................1-14

Optional Interior Lighting................................................................................................................1-14

Optional Electrosonic™ Airknife ......................................................................................................1-15

Optional Digital pH Monitor ............................................................................................................1-15

Optional Digital Resistivity Monitor..................................................................................................1-15

Optional Utility Sink ...................................................................................................................... 1-15

Optional Convenience Package .........................................................................................................1-16

Angle Adjustable Transition Conveyor ...............................................................................................1-18

2.3 Standard Spray Manifold/nozzle configuration (Basic system) ...............................................................1-19

2.4 Optional Spray Manifold/Nozzle Configuration ....................................................................................1-19

2.5 Dimensions....................................................................................................................................... 1-20

SECTION 3 FACILITIES REQUIREMENTS...................................................................................................1-22

3.1 Water Requirements.......................................................................................................................... 1-22

Final Rinse .................................................................................................................................... 1-22

System Drain................................................................................................................................. 1-22

Fill................................................................................................................................................ 1-22

3.2 Exhaust Requirements ....................................................................................................................... 1-23

3.3 Electrical Requirements..................................................................................................................... 1-24

Reference Schematics .................................................................................................................... 1-24

Power ........................................................................................................................................... 1-24

3.4 Capacities......................................................................................................................................... 1-25

3.5 Specifications ................................................................................................................................... 1-25

-

Aquastorm 200

Overview 1-1

SECTION 1 GENERAL

1.1 HAZARDS

Operation of this equipment involves exposure to potential health hazards.

WARNING Risk of Electric Shock:

Operation of this equipment exposes the operator to situations which may result in electrical

shock if procedures are not properly adhered to. Pay close attention to Warnings of this nature

throughout the context of this manual.

When performing maintenance procedures using ammeters, volt meters or ohm meters,

electrical shock hazard is present. These procedures must be performed only by an authorized

electrician, electrical engineer or service technician familiar with testing live voltage.

WARNING Hot Surfaces/Burn Hazard:

During normal operation this equipment and some of its components operate at temperatures

up to 60-71 oC (140-160 oF). The operator must use extreme caution and wear the

recommended safety garments prior to coming in contact with hot surfaces or components.

Closely follow and adhere to the Warnings in this manual which pertain to hot surfaces.

Use extreme caution when working with or around hot components. Allow hot components to

cool before handling whenever possible.

WARNING Skin Irritation:

When using certain chemicals such as descalers or saponifiers, it is important to follow the

MSDS (Material Safety Data Sheet) guidelines for proper handling and usage. Appropriate

clothing and safety articles must be worn when using descaler solutions. Skin or eye irritation

will occur if not handled properly.

Aquastorm 200

1-2 Overview

1.2 SAFETY PRECAUTIONS

Good housekeeping and cleaning of equipment on a continuously monitored maintenance schedule is extremely

important to the safety and reliability of the equipment's operation.

Electrical work should only be performed by qualified electricians and maintenance personnel.Always shut OFF

Main Power before performing any repairs on electrical circuits.

Prior to applying power for the first time, ensure that the system is properly grounded.

Post "NO SMOKING" signs in the work area and provide measures for enforcement.

Exercise caution when using strong cleaning agents, solvents and other chemicals. Manufacturers' Data provided

(bythechemical manufacturer)contains specificusesand safetyprecautionswhich mustbe thoroughlyunderstood

and strictly adhered to. If in doubt about any caution, contact the manufacturer for clarification.

Avoid prolonged skin contact and inhalation of chemicals and fumes.

Operating this equipment may introduce burn hazards.Avoid contact with all hot surfaces, hot water and steam.

The viewing glass will reach temperatures in excess of 79 oC (175 oF). Extreme caution should be taken to avoid

touching the glass surfaces.Water temperatures will reach and/or exceed 71 oC (160 oF). Steam may escape from

the system cabinet when access windows are removed during operation or for maintenance procedures. Steam

will cause serious burns.Avoid contact with steam.

Protective clothing is required for servicing hot machine components or areas of the machine which come in

contact with chemical applications . Protective clothing includes ANSI (American National Standard Institute)

approve Safety Goggles, NIOSH (National Institute for Occupational Safety and Health) or MSHA (Mine,

Safety and HealthAdministration)Approved Respirator, steel toe safety shoes, high temperature, acid and water

resistant gloves, apron and a long-sleeved garment.

Fumes can be generated from certain saponifiers, defoamers, descalers, and cleaning solvents, during operation.

Precautions must be taken to avoid accumulation of flammable vapors. Whenever harmful fumes are present, a

proper extraction (exhaust) system must be provided. Refer to the manufacturers for information and safety

precautions concerning their products and system exhaust specifications.

Refer to specific Chemical Manufacturers' Material Safety Data Sheets for disposal and/or removal and handling

of waste materials resulting from chemical operating processes.

Under the previously mentioned circumstances, all operators should be provided with an NIOSH or MSHA

Approved Respirator, to provide the operator effective protection from airborne residue resulting from certain

saponifiers, defoamers, descalers, and cleaning solvents.

Aquastorm 200

Overview 1-3

WARNING Warning notices are used in this manual to emphasize

hazardous voltages, high currents, high temperatures or

other conditions that could cause personal injury.

DANGER Danger notices are used in this manual to warn the

operator that DEATH may result if a procedure is omitted

or improperly performed.

CAUTION Caution notices are used to call attention to a situation

that could cause damage to the equipment.

Aquastorm 200

1-4 Overview

SECTION 2 DESCRIPTION

The Aquastorm 200™ Aqueous Cleaning System provides automated, aqueous

cleaning and removal of contaminated fluids and particles from PWAs (Printed

Wiring Assemblies), resulting from wavesoldering and reflow processes, in

the following sequence:

2.1 PROCESS ZONE AREA

(See figure below for zone locations)

1. Prewash - 36 cm (14 inches)

2. Heated Recirculating Wash - 122 cm (48 inches)

3. Drag Out/ Enhanced Chemical Isolation - 91.44 cm (35 inches)

4. Heated Recirculating Rinse - 122 cm (48 inches)

5. Fresh Water Final Rinse - 46 cm (18 inches)

6. Blower Drying Station #1 - 76 cm (30 inches)

7. Blower Drying Station #2 - 76 cm (30 inches)

Optional Additional Drying Stations - (Not pictured)

8. Blower Drying Station #3 - 76 cm (30 inches)

9. Blower Drying Station #4 - 76 cm (30 inches)

1234567

Process Zone Areas of the Aquastorm 200™

Aquastorm 200

Overview 1-5

2.2 DETAILED DESCRIPTION

Cabinet

The Aquastorm 200's TM futuristic design is constructed of custom textured gray polypropylene. The removable

front and rear access panels are composed of light weight, molded ABS (Acrylonitrile-Butadiene-Styrene).

Its one piece construction is comprised of 1/2and 1/4inch textured gray polypropylene with triple welded

tanks. The textured gray polypropylene resists scratching and is aesthetically pleasing.

The cabinet's overall gray color, combined with darker gray molded ABS curved front access panels, and an

accent of light blue trim separating the two (2) shades of gray, make the system's appearance an attractive

one to any manufacturing production line.

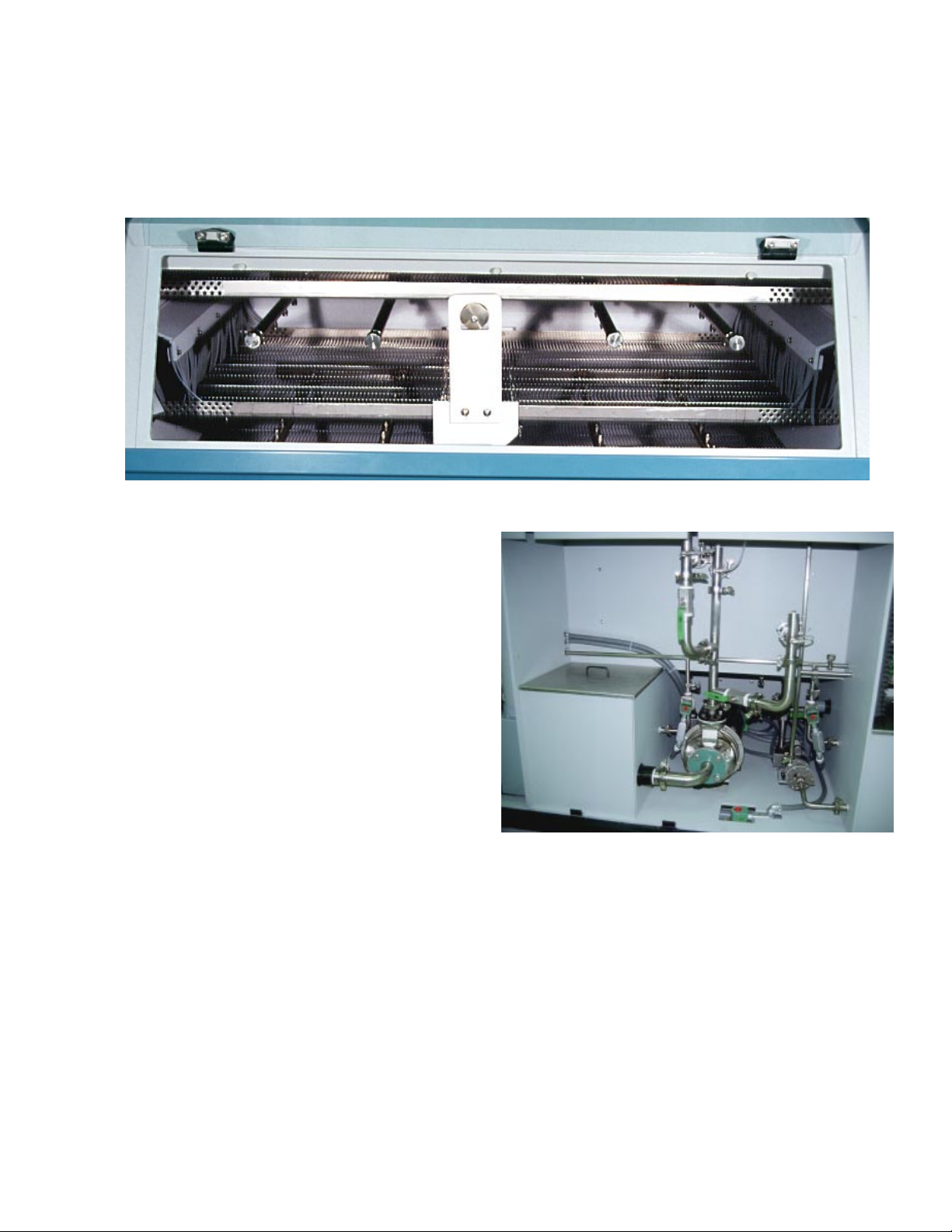

Plumbing

All rear plumbing, including fill and final rinse

inlets, is comprised of 3/4, 1 1/2and 2.0 inch

orbitally welded, tubular stainless steel pipe with

"Kwik Clamps". Smooth transition, orbitally

welded stainless steel plumbing minimizes

pressure drops and eliminates leaks.

"Kwik Clamps" with TeflonTM O-rings provide for

easy maintenance and field upgrades. Both can

be performed with unprecedented ease.

All internal upper and lower spray manifold

plumbingis stainlesssteel,reducing the corrosion

and maintenance factors normally introduced

with CPVC type spray manifold systems.

All drain lines are 1 1/2inch CPVC with brass

solenoid drain valves. Stainless steel solenoid

valves are optional.

Aquastorm 200

1-6 Overview

System Controls

Aquastorm 200™ operator controls are

incorporated into a single custom control panel

at the entrance end of the system. All system

control functions are via a membrane touch pad

panel with graphic symbols, a multi-line LCD

(Liquid Crystal Display) with membrane keypad,

and an internal 486 computer with fiber optic

interface connections. Indicator lights provide

system status of water levels, temperature levels,

operatingindication of pumps,blowers,fill/ drain

solenoids, radiant heaters, and conveyor.

Prewash Section

The Prewash section is 36 cm (14 inches) long

consisting of two (2) upper spray manifolds and

two (2) lower spray manifolds. Power cascade is

from the Recirculating Wash tank. Prewash can

be directed to drain or to cascade to recirculating

wash.

NOTE When operating the prewash

direct to drain, the prewash

operating pressure must be set

lower than the pressure at the

finalrinse,to preventexcesswater

consumption in the wash section.

Aquastorm 200

Overview 1-7

Anoptional HurricaneJetTM performancekit may

be configured which includes a 10 HP pump in

lieu of the standard 5 HP pump. The Hurricane

JetTM manifold is configured between the

standard four (4) upper spray manifolds.

The water level in the wash tank is monitored by

means of liquid level float switches. If the tank

fluid level falls below the low level float switch,

the tank heaters shut off and trip the tank level

alarm indicator on the front control panel along

with an audible alarm.

Tank filling is automatic via the fill solenoid,

activated by the low and/or operating liquid level

float switch(es) in the wash tank. When the

system is initially activated and the tank is empty,

the fill solenoid activates to fill the system tanks.

During normal operation, if the water level falls

below normal operating level, the fill solenoid

activates to fill the tank.

Heated Recirculating Wash

Hurricane Section

The Recirculating Wash section is 122 cm (48

inches) long consisting of four (4) upper spray

manifolds and four (4) lower spray manifolds,

powered by a 5 HP pump (standard

configuration). A 303 liter (80 gal.) tank is

standard with two (2) 16 kw immersion heaters.

Temperatures are displayed via the LCD (Liquid

Crystal Display). The computer continually

monitors and corrects the temperature in the

wash tank by means of a thermocouple device. If

the temperature exceeds 82 oC (180 oF), the

tank's high temperature alarm indicator

illuminates, the audible alarm sounds and the

tank heaters shut off.

Aquastorm 200

1-8 Overview

Dragout/ Enhanced Chemical

Isolation Section

The Drag Out/ Enhanced chemical isolation

section is 30.5 cm (36 inches) long, and may be

configured as one (1) of four (4) different

configurations:

1Standard Chemical Isolation - standard

configuration is without airknives or spray

manifolds. Excess water drips from

product as it passes through this section.

This allows fewer contaminants to be

carried over to the rinse section.

NOTE When saponifier is being added to

thewashsection and therinsewater

is recirculating, standard

configuration of the enhanced

chemical isolation will not provide

adequate separation.

2Level 1 Chemical Isolation - this level may

be configured as an option with a 7.5 HP

Turbine blower and three (3) tubular

stainless steel airknives. The blower

delivers air through two (2) upper and one

(1) lower air knife.

Blower Air removes and squeegees excess

water containing contaminants from the

product prior to entering the

Recirculating Rinse section of the

Aquastorm 200™. Excess water removed

via the first set of airknives is routed back

to the wash section. This helps in

preventing loss of saponifier as well as

reducing the risk of cross contamination

between cleaning sections.

3Level 2 Chemical Isolation - incorporates

the blower configuration in Level 1, and

adds two (2) stainless steel, one (1) upper

and one (2) lower, spray manifolds. The

spray manifolds are positioned between

the two (2) sets of airknives. The spray

bar water supply is via an exeternal feed,

customer supplied source. The spray bars

provide low volume spray to enhance the

removal of remaining saponifier solutions

remaining on the product. This

configuration of chemical isolation is

routed directly to drain, to eliminate cross

contamination.

4Level 3 Enhanced Chemical Isolation -

includes both level 1 and 2 configurations,

but is supplied with optional on-board, 95

liter (25 gallon) tank in lieu of an external

water source plumbing configuration.

A 1/8Hp internal recirculation pump

powers the spray manifolds. The tank is

also configured with one (1) 18 kW

immersion heater, auto fill, tank liquid

level floats, and rinse to chemical isolation

cascade. Level 3 provides increased

isolation while conserving water usage.

Aquastorm 200

Overview 1-9

Heated Recirculating Rinse/ Hurricane Section

The Recirculating Rinse section is 122 cm (48 inches) long consisting of four (4) upper spray manifolds and

four (4) lower spray manifolds, powered by a 5 HP pump (standard configuration). A 189 liter (50 gal.)

tank is standard with two (2) 16 kw immersion heaters.Temperatures are displayed via the LCD. The

computer continually monitors and corrects the temperature in the rinse tank by means of a thermocouple

device. If the temperature exceeds 82 oC (180 oF), the tank high temperature alarm indicator illuminates,

the audible alarm sounds and the tank heater shuts off.

Anoptional HurricaneJetTM performancekit may

be configured to include a 10 HP pump in lieu

ofthe standard 5HP pump. TheHurricaneJetTM

manifold is configured between the standard four

(4) upper spray manifolds.

The water level in the rinse tank is monitored by

means of liquid level float switches. If the tank

fluid level falls below the low level float switch,

the tank heaters shut off and trip the tank level

alarm indicator on the front control panel along

with an audible alarm.

Tank filling is automatic via the fill solenoid,

activated by the low and/or operating liquid level

float switch(es) in the rinse tank. When the

system is initially activated and the tank is empty,

the fill solenoid activates to fill the system tanks.

During normal operation, if the water level falls

below normal operating level, the fill solenoid

activates to fill the tank.

The recirculating rinse tank is configured with a

cascade pipe to the recirculating wash tank. Flow

through the cascade pipe, from rinse to wash, is

controlled via a ball valve. O/A (Organic Acid)

or water soluble applications should be run with

the valve in the open position. Rosin or saponifier

applications should be run with the valve in the

closedposition, not permittingcascadingto occur.

If the system is configured with an on-board tank

for Enhanced Chemical Isolation (Level 3), a

cascade pipe from the recirculating rinse tank to

the Chemical Isolation tank is supplied as well.

The valve supplied on this cascade pipe should

remain closed for O/A applications. When

running saponifier processes, the ball valve on

the cascade pipe to the Chemical Isolation tank

should be open slightly. This is to prevent the

chemical isolation tank from loading up with

excess saponifier. The amount this valve is open

or closed is dependent upon the type of saponifer

as well as the product mix or product

configuration.

Aquastorm 200

1-10 Overview

Final Rinse Section

The Final Rinse section is 46 cm (18 inches)

longconsisting oftwo(2) upperand two (2)lower

stainless steel spray manifolds. Water is supplied

via a fresh water inlet (preferably heated DI

{deionized} water) from the facility water supply.

Final rinse water cascades into the recirculating

rinse tank.

Blower Drying Section #1 & #2

Both Blower Drying section #1 and #2 are each

76 cm (30 inches) long. Each section is

configured standard with two (2) upper, height

adjustable and one (1) lower, fixed, stainless steel

airknives. Air is delivered through the airknives

using a high velocity, high volume turbine blower.

The blower is configured as 7.5 Hp standard or

as 10 or 15 HP optionally (dryer section 1 only),

in lieu of the 7.5 HP blower. This ensures

maximum drying efficiency prior to product

exiting the system. Note that 15 HP blower

applications are usually for customers with large,

heavy boards. 15 HP blower configurations may

cause smaller boards to become airborne or to

become lodged in the conveyor system.

Each Blower Drying section is configured with

thermocouple sensors for temperature readout

only, via the LCD.

Blower Dryer section #2 may be configured

optionally with a radiant heater. The radiant

heater incorporates two (2) 1800 watt radiant

heater panels. One (1) 1800 watt upper radiant

panel,and one (1)1800watt lowerradiantpanel;

3600 watts total. Control and readout are

provided by a thermocouple sensor and the

computer system with digital readout via LCD.

NOTE Temperature readout is replaced

with temperature control when

this option is configured.

Aquastorm 200

Overview 1-11

Stainless Steel Wire Belt

Conveyor

The stainless steel wire belt conveyor is a

0.95 cm (3/8inch) pitch 50.8 cm (20 inch)

wide speed controlled wire mesh belt. The

conveyor belt transports product for

cleaning and drying in a single pass

through the Aquastorm 200™ system.

Note that the usable conveyor width is

limited to 46 cm (18 inches).

Optionally, the wire belt conveyor may be

configured with a 61 cm (24 inch) wide

belt; 56 cm (22 inch usable) width.

Noise Suppression Hood

The Noise Suppression Hood is standard with

the Aquastorm 200™. This feature incorporates

a 46 cm (18 inches) conveyor extension for easy

removal of product, and extends 15.24 cm (6)

inches past the exit end of the system's cabinet.

The noise level is equal to or better than 80 dBA

(maximum) measured 1 meter (3 feet) above the

floor and 1 meter (3 feet) from the Aquastorm

200™ enclosure.

Aquastorm 200

1-12 Overview

Stainless Steel Pressure

Gauges

The Aquastorm 200™ is configured standard

withfrontmountedstainless steel pressure gauges

for all wet sections. The gauges are visible from

thecustom operatorcontrol panel atthe entrance

end of the system for easy viewing and

monitoring.

Internal Slide Gate Dampers

Internal slide gate dampers are designed into the

one piece construction of the internal portion of

the cabinet to permit fine tuning of the system's

exhaust flow. The slide gate dampers are

completely adjustable and are included in the

Prewash,Dragout/Enhanced ChemicalIsolation,

Blower Dryer Section #1 and Blower Dryer

Section#2. These dampersmaybeadjustedfrom

either the front of the system, through the access

windows, or from the rear of the system at the

bulkhead wall. Once the dampers have been

adjusted for proper exhaust flow, the damper

positions may be set by simply tightening a thumb

screw.

Aquastorm 200

Overview 1-13

Optional Checkmate™

Hold Down Conveyor

The Checkmate™ Conveyor is designed for

product that can normally be jostled, elevated or

even flipped during cleaning processes.

The optional Checkmate™ Conveyor may be

configured with a 50.8 cm (20 inch) or 61 cm

(24 inch) wide conveyor. Note that the usable

widths directly correlate to those of the standard

conveyorbelt system.TheCheckmate™ Conveyor

consists of a double conveyor system that gently

restrains any sized product, through all washing,

rinsing and drying processes.

At the entrance end of the system, an upper

conveyoris gentlylaid across the topof the circuit

boards as they travel on the lower conveyor. Both

the upper and lower conveyors are synchronized

to operate at the same speed through the entire

system. Product is protected from lateral and

vertical movement.

An additional safety feature is provided using an

optical sensor at the exit end of the conveyor

that searches for entangled boards and initiates

system shutdown along with alarms.

Entrance End View With Maintenance Panel Removed

Photocell

Exit End View with Sound Enclosure Open

Aquastorm 200

1-14 Overview

Optional Photocell Control

The photocell provides automatic standby mode

via photo-eye sensor. The photo sensor is to be

used in conjunction with the optional Angle

Adjustable Transition Conveyor or optionally

withoutthe transitionconveyor. Thephoto sensor

and reflector are mounted on the inlet conveyor

or on the entrance end of the conveyor system,

dependingon thesystemconfiguration. Photocell

operation sequentially starts pumps, blowers and

final rinse as product passes the photocell. When

product has exited the conveyor (based on a fixed

time and distance), photocell operation stops

pumps, blowers and final rinse water. The

conveyorremainsin operation toadvance procuct

into the system. The system may be configured

to allow the blower to remain on with the

conveyor.

Auto Start Timer

By auto enabling the system fill solenoid and the

Wash and Rinse tank immersion heaters prior

to system start up, the Auto Start Timer

eliminates delays in production while the

Aquastorm 200™ system power is active.

Start and stop times for each day of the week

may be configured using the timer function

software and the LCD interface keypad.

Optional Detergent Injection

System

The Automatic Detergent Feed system provides

automatic feed with a calculated mixture of

saponifier or detergent from an internal 57 liter

(15 gallon) reservoir located just inside the rear

prewash section, into the wash section plumbing.

Anytime the fill solenoid is activated to add water

to the wash section, saponifier or detergent is

automatically injected into the wash plumbing as

water passes the venturi injector.

Optional Interior Lighting

The Aquastorm 200™ system may be configured

with three (3), 40 watt, 110 VAC, fluorescent

light fixtures which provide maximum viewing

capability as well as cost efficient lighting. The

interior lighting option permits the operator to

observe the entire cleaning process as product

passes through each stage of the system.

Aquastorm 200

Overview 1-15

Optional Electrosonic ™

Airknife

Theoptional Electrosonic™ Airknife replacesthe

standard airknife system in the dryer sections of

the Aquastorm 200™. The Electrosonic™

Airknife's unique teardrop design maximizes air

velocity as the air is forced through the airknife

slot. The slot is adjustable for optimization

depending on blower configuration. All

Electrosonic™ Airknives are adjusted according

to voltage, Hz, and blower size. The result, "a

sheet of air is produced", much less diffuse than

that of cylindrical airknives. This "sheet of air" is

also much less sensitive to the height from the

product. Based on residual weight gain testing

performed on a variety of boards run at 2, 4,

and 6 feet per minute, drying performance with

the Electrosonic™ Airknifes system was better

by 25 - 68% than that of the traditional

cylindrical airknife systems.

Optional Digital pH Monitor

Theoptional pH Monitorprovidesadigital display

via the LCD, of pH levels ranging from 0 - 14

for water in the wash tank. Displays are read in

millivolts (mV), degrees Celsius (oC) and pH.

Input to the monitor is supplied by means of a

pH sensor which is mounted through the wall of

the wash tank for easy accessibility and

maintenance. High and low process alarms are

adjustable via the LCD and interface keypad.

Optional Digital Resistivity

Monitor

The optional Resistivity Monitor provides

accurate digital display of resistivity levels with a

resistivity range of 0 - 18 Meg Ohms (M W) for

incoming water in the Final Rinse.

Optionaldigital resistivity isdisplayedviathe LCD

and has user adjustable high and low alarms.

Optional Utility Sink

The optional utility sink is located at the rear

exit end of the system, just behind the exit end

sound enclosure. The utility sink includes hookup

from the incoming fill line. A single goose neck

faucet and spray wand are supplied with the sink

option for easy cleanup. The sink drain is tied

into the system's main drain plumbing.

Electrosonic™ Airknife

Utility Sink with Goosenek Faucet and Spray Wand

Table of contents