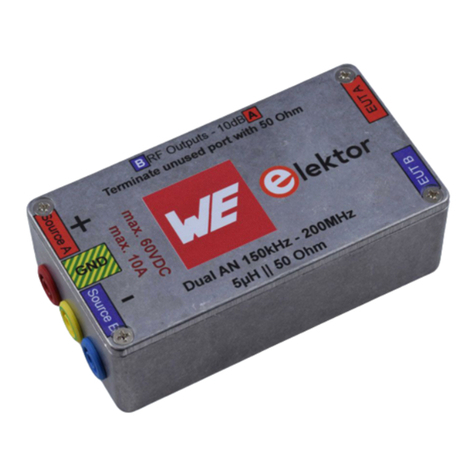

Elektor 19883 User manual

●1

32 pages

instructions

2 MHz LCR Meter Kit

Assembly & Calibration

Step-by-step instructions from

First Start-up to Final Adjustments

Jean-Jacques Aubry

V3.2

2 MHz LCR Meter Kit AU2019 Assembly Manual

●2

●3

2 MHz LCR Meter Kit

AU2019

Assembly and Calibration Manual

V3.2 - Last update 2021/10/25

This manual, initially printed and included in the kit, is also available as

a downloadable PDF. Corrections are made as we receive feedback. We

invite you to check that you are in possession of the updated version

of this essential document which you can find at the following address:

www.elektor.com/19883

Note: Small differences may exist between the kit as received compared to the

version pictured. These differences are inconsequential.

2 MHz LCR Meter Kit AU2019 Assembly Manual

●4

Main Technical Specifications

Display - Parameter values (principal and secondary)

- Equivalent circuit: series or parallel

- Frequency

- |Z|

- Φ

- Q or D

- Voltage and current of DUT (Vx and Ix)

- Test voltage (AC) and polarisation (DC)

- Range hold status (R_Hold)

- Labels for multi-function buttons (right-hand side)

Measurement range Parameter Value

L 10 nH →100 H

C 1 pF →100 mF

R, |Z| 10 mΩ →100 MΩ

Q 0 – 5000 for display

Φ – 90.00 ° / +90.00 °

Test frequencies 50 Hz to 2 MHz in 54 predefined steps or any frequency

within the range

PC software for Windows, macOS and Linux

Test conditions:

Open-circuit test voltage 4 options: 0.1 Vrms , 0.2 Vrms , 0.5 Vrms , 1 Vrms ± 5%

DC Polarisation For C : 0 to 5 V | For L : 0 to 50 mA

Accuracy of main parameter (R, L, C) :

Conditions* After calibration and with use of a suitable test

frequency for the DUT (at high frequencies

parasitic components become very important)

Accuracy Up to ± 0.1% ±1 of last digit

Various :

Test connections 4 wire Kelvin via BNC connectors

Supply voltage 5 VDC ± 5%, from mini-USB connector

Total current with MCU board + backlit display board

without polarization while polarizing the DUT

420 mA up to 620 mA

Backlit display board alone 82 mA

Power supply 5 VDC 1 A ± 5%, USB A (not included)

●5

Table of content

Main Technical specifications ..............................4

2 • Let’s mount the four BNC sockets ........................9

3 • Let’s preassemble the Hammond case.....................9

4 • My first start-up ................................... 11

5 • Calibration menu .................................. 13

6 • Final mounting in the Hammond case .................... 18

7 • Final adjustments .................................. 19

8 • Stand-alone mode ................................. 19

9 • Use in PC mode ................................... 24

10 • Updates ....................................... 27

Other information sources...............................28

Appendix (LCR6 texts v3.txt) ............................ 30

Assembled prototype.

Your kit has been carefully checked. Both boards have been tested

individually. This manual explains how to assemble and calibrate

your kit. Calibration will allow you to become familiar with the unit,

and to be able to repeat it if the need arises later.

(All photos Eurocircuits unless otherwise stated)

2 MHz LCR Meter Kit AU2019 Assembly Manual

●6

1 • Contents of your Kit

Check that the kit as received is complete. It must include:

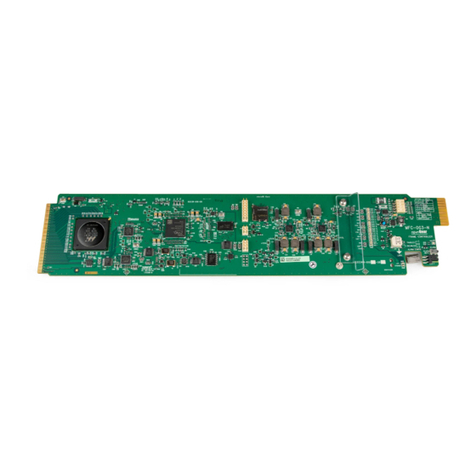

3. Assembled MCU board (BNC connectors not mounted).

4. Assembled Display board (without the button of the rotary switch).

Note: the LCD has a protective film so transparent that it can go

unnoticed. It has no tab, but it can be easily peeled off by gently

lifting it at an angle with your fingernail.

5. Four PCB-mount BNC connectors.

1 • Contents of your Kit

●7

6. Flatcable (reversible).

7. Button, Ø 24mm.

8. USB cable (mini-USB / USB A).

9. Test clip with two Kelvin clips and 4 BNC connectors.

2 MHz LCR Meter Kit AU2019 Assembly Manual

●8

10. Four jumpers for settings during calibrations.

11. Screwdriver (trimming tool).

Hammond case.

- machined body

- machined and screen-printed front panel

- machined and screen-printed BNC side

- machined and screen-printed USB side

- 2 black plastic frames [+ special screws (8) and

rubber feet (4)]

12a. & b Machined and screen-printed Hammond case.

2 • Let’s mount the four BNC sockets

●9

Screws and bolts.

- 5 x M3 male-female standoffs, 6 mm high

- 5 x 4 mm Pozidrive countersunk M3 screws

- 1 flat washer DM3, thickness 0.5 mm

- 5 x M3 self-locking nuts

13. Bolts & nuts etc.

And of course the User Manual you are reading right now!

Tools needed for assembly: Phillips screwdriver, spanner (not included).

2 • Let’s mount the four BNC sockets

Preferably solder the sockets one at a time. Position each one precise-

ly using the positioning pins, press it secure against the board, then

solder the two electrical contacts.

Only one of the two positioning pins should be soldered (unlike the

video on elektorTV!). This allows you to slightly modify the position of the

sockets later, if you intend to use an HP standard test accessory (de-

signed for 22 mm distance between the BNC sockets).

Important: Do not use nuts to secure the BNC sockets to the side

panel of the enclosure.

3 • Let’s preassemble the Hammond case

Mount four 6 mm M3 male-female standoffs into the four corners of the

Display PCB, without tightening the nuts.

2 MHz LCR Meter Kit AU2019 Assembly Manual

●10

Position the front panel on this board and secure it with 4 x 4 mm

countersunk screws, then tighten the nuts.

4 mm

M3 (Prevailing Torque

Type Hex Thin Nut)

Front Panel

6 mm standoff MF

Display PCB

14a. Mounting of the M3 male-female standoffs.

14b. Positioning the front panel on this Display board.

Mount the knob on the rotary encoder shaft and connect the flatcable

to J1 on the Display board. Slide the MCU board between the first two

guide rails counting from the bottom of the case, with the front panel

slid in its own guides. Then connect the second header of the flatcable

to J14 on the MCU board.

Note: The hole in the bottom of the case must be on the side of J14.

4 • My first start-up

●11

15. Partially assembled LCR-meter during the settings.

(Photo:Jean-Jacques Aubry)

Both the front panel and the MCU board can be slid out of the case,

giving access to all the adjustment points without the risk of accidental

electrical contact between the two boards!

If the MCU board does not slide smoothly, it may be necessary to

slightly file the edges of the PCB

Note: Completion of the assembly takes place later (§6, p.18).

4 • My first start-up

On the MCU board, turn switch SW1 to the OFF position. Then con-

nect the USB cable between J1 on the MCU board and a USB power

supply (e.g. from your smartphone). Slide SW1 to the ON position.

The display should light up. The message < BOOTLOADER V1.X > is

displayed for a short time, followed by the welcome screen, the cali-

bration prompts and the measurement screen.

2 MHz LCR Meter Kit AU2019 Assembly Manual

●12

(All screendumps by Jean-Jacques Aubry)

16 a-b-c-d. Different displays during the start-up

of the assembled LCR Meter.

The five pushbuttons (to the right of the display) in conjunction with

the rotary knob (which is also a pushbutton) allow a dialogue between

the user and the device.

The [MENU] button provides access:

• to the user settings by a short press.

16 e. Use the rotary knob to navigate through the menus.

5 • Calibration menu

●13

Confirm your choice by pressing the [OK] button.

Press the [EXIT] button to leave all settings unchanged.

Choose your language (English, German, French, Dutch) in the corre-

sponding menu.

• to the calibration menus by a long press (the display responds to

the long press by flashing briefly).

16f. Use the rotary knob to navigate through the menus.

Confirm your choice by pressing the [OK] button.

Press the [EXIT] button to leave all settings unchanged.

To get accurate measurements, the measurement circuitry must be

calibrated. It is recommended to perform the calibration steps in the

order of the menus.

Note: The menu option Change display: INVERSE/NORMAL (fig. 16e)

which allows the display to be inverted (light/dark background) only

appears once version 3 of the file LCR6 texts v3.txt has been loaded

into the device. This update (see also §9.2.5) is described in the man-

ual LCR Meter AU2019 - EN Operating Instructions (§4.2.4 et §4.2.5).

5 • Calibration menu

All the steps for calibrating the instrument are accessible through this

menu. An external multimeter (not included in the kit) is required. Preci-

sion resistors (0.01% tolerance) fitted on the PCB for your conveni-

ence get connected to the measurement input via one of the jumpers

on J10 to J13.

At each step, a message on the screen indicates the state required for

various jumpers (i.e. closed or open).

2 MHz LCR Meter Kit AU2019 Assembly Manual

●14

Do not connect anything to the BNC sockets!

R_Hold must be OFF

5.1 Sinewave generator offset adjustment

Using your multimeter, measure the DC voltage at TP7 (this is the out-

put of U26C). Using R146, adjust it as close as possible to 0 V.

Press [OK] to exit the menu.

5.2 Measured value of Vref (DDS)

Measure the DC voltage at TP6 with your multimeter. With the rotary

knob, now adjust the displayed value to the measured value.

Press [OK] to confirm the entry or [Exit] to leave the menu

without changes.

5.3 CMRR of the differential amplifier U7C

This setting provides the maximum common-mode rejection of the

U7C differential amplifier.

Insert a jumper on headers J9 and J17. Adjust the displayed value to a

minimum value, first R31 for low frequencies (10 kHz) and then C44 for

high frequencies (1 MHz). Change the frequency with the rotary knob.

Due to a slight interaction, repeat these two settings at least once.

Press [OK] to exit the menu.

Any subsequent changes to these settings will require the steps in

§5.4 to 5.11 to be repeated.

5 • Calibration menu

●15

17. Location of the components mentioned in the instructions

for calibration. (Photo by Jean-Jacques Aubry)

2 MHz LCR Meter Kit AU2019 Assembly Manual

●16

The device has 54 predefined measurement frequencies:

50 60 Hz

100 120 150 200 250 300 400 500 600 700 800 900 Hz

1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 7.0 8.0 9.0 kHz

10 12 15 20 25 30 40 50 60 70 80 90 kHz

100 120 150 200 250 300 400 500 600 700 800 900 kHz

1.0 1.2 1.5 2.0 MHz

At each step of the calibration, the parameters of the measurement

chain in the instrument are calculated for each of the above frequen-

cies. This will take a few minutes each time!

At the end of each of the following steps you will be asked to confirm

to save the new values.

The old values (if any) will be deleted anyway.

5.4 PGA2: calibration in gain 3

Insert a jumper on headers J8, J9, and J11.

First, set C106 to have ⏐Phi⏐< 0.1 and, if good, press the [OK] button

that will appear. If not, exit by pressing [EXIT] and correct the problem!

The gain and phase for the PGA2 with a gain of 3 will then be calculated

at each of the preset frequencies.

18. Display while setting the phase.

5 • Calibration menu

●17

5.5 PGA2: Calibration at gain 10

Insert a jumper on J8, J9 and J11.

First, set C51 to have ⏐Phi⏐< 0.3 and, if good, press the [OK] button

that will appear. If not, exit by pressing [EXIT] and correct the problem!

The gain and phase for the PGA2 (with a gain of 10) will then be calcu-

lated at each of the predefined frequencies.

5.6 Calibration of range 1

Install a jumper on headers J8, J9, and J10. The calibration parameters

will be calculated for each of the predefined frequencies.

5.7 Calibration of range 2

Install a jumper on headers J8, J9, and J11. The calibration parameters

will be calculated for each of the predefined frequencies.

5.8 Calibration of range 3

Install a jumper on headers J8, J9, and J12. The calibration parameters

will be calculated for each of the predefined frequencies.

5.9 Calibration of range 4

Install a jumper on headers J8, J9, and J13. The calibration parameters

will be calculated for each of the predefined frequencies.

5.10 Trim <short circuit> all frequencies

Install a jumper on headers J8, J9, and J17. The short-circuit com-

pensation parameters will be calculated for each of the predefined fre-

quencies.

5.11 Trim <open circuit> all frequencies

Install a jumper on headers J8 and J9. The open-circuit compensation

parameters will be calculated for each of the preset frequencies.

Once the enclosure of the LCR Meter is fully assembled, these two

trimming operations must be repeated without the jumpers installed.

Remove all jumpers except J3!

2 MHz LCR Meter Kit AU2019 Assembly Manual

●18

Note:

As long as all calibrations are not carried out at least once, no cor-

rection is made to the measured value. That's why "open-circuit" and

"short-circuit" calibration should be completed without the Kelvin ca-

bles. From then on, values displayed are compensated for the internal

measurement path, up to the BNC connectors!

After that, whatever external measuring device will be used, you have

to repeat the "open-circuit" and "short-circuit" with this device in place.

6 • Final mounting in the Hammond case

Slide the MCU board slightly out of the case and fit the 6 mm M3

male-female (MF) standoff into the hole next to the “J15” marking

using the last nut.

M3 (Prevailing Torque

Type Hex Thin Nut)

MCU PCB

6 mm standoff MF

Washer (thickness = 0.5 mm)

Screw M3 (length = 4 mm)

Hammond Case

19. Final securing of the MCU PCB in the Hammond case.

Align the MCU board so that the threaded hole in the 6 mm standoff

faces the hole in the bottom of the case. Slide in the 0.5 mm thick

washer and secure the assembly with the 4 mm M3 countersunk screw.

Note: For the fixing of the main PCB to the case it is more conven-

ient to put the 0.5 mm flat washer under the PCB (on the male part

of the standoff).

Mount the USB and BNC sides using the plastic frames and the spe-

cial screws. The bag usually contains a spare screw. Pay attention

to the sequence! Mount the black frames first, then screw on the

aluminum flanges. Not the other way around, otherwise tightening

the screws could break the corners of the plastic frames.

7 • Final adjustments

●19

Important: Do not use nuts to secure the BNC sockets to the side

panel of the enclosure.

Finish the assembly by installing the four rubber feet.

7 • Final adjustments

Connect the Kelvin cables to the BNC connectors. Repeat the Trim

procedures (§5.10 and §5.11) to compensate for the new, interfering

components.

The device is now ready for use!

Note: Before a test, at any given frequency, it is possible and

even desirable, to perform both TRIM corrections by pressing the

corresponding button (the second from the top). The new param-

eters (as well as those already modified at other frequencies) can

be saved by a long press on the same button. Saving is indicated

on the display, e.g. by the message Save the Trim Data..., before

returning to the measurement screen!

8 • Stand-alone mode

Equipped with the Display board, the device can work without a com-

puter. This is the stand-alone mode. The instrument automatically

starts in this mode when an external 5 V USB power supply is used. If

the LCR meter is powered from a PC, it can operate in PC mode, but if

you want to use it in stand-alone mode, simply press the top button

on the front panel while powering up the unit (this new mode is

then stored and no further action is required at the next start up). The

same action is required to return to PC mode.

When the measurement screen is displayed, the rotary knob (encoder)

changes the measurement frequency to one of 54 preset values (see

table in §5).

A long press on the rotary knob allows you to enter the menu for se-

lecting a user frequency (from the current frequency). The number to

be changed is selected with the two upper buttons while the rotary

2 MHz LCR Meter Kit AU2019 Assembly Manual

●20

knob changes the value. After validation, this value is used. It is dis-

played in negative and can no longer be changed by the rotary knob.

A further long press on the rotary knob is required to exit this mode.

The saved value will be proposed at the next request.

The button labels are displayed on the screen and changed according

to the settings you choose.

For some buttons, the action changes depending on whether the pres-

sure is short or long. The display flashes briefly acknowledging

the long button press.

• The first button (from the top) switches the representation of

the component:

- From AUTO (default) to SERIES or PARALLEL.

• The second [TRIM] button starts the TRIM procedure for

the current frequency (OPEN or SHORT depending on the

measured impedance). A long press on this button starts the

procedure of saving all TRIM measurements made since the

last start-up.

• The third button [AVG S] or [AVG F] changes the number

of measurements used (for averaging) before the result is

displayed, and thus the responsiveness of the instrument. It

toggles between slow (Average SLOW on display) and fast

display (Average FAST on display).

20a. Slow display. Pressing the

[AVG F] button will switch the

display to fast.

20b. Pressing the [AVG S] button

will switch the display to slow.

• The fourth button [R-HOLD] is used to freeze (or not) the

current range.

This manual suits for next models

1

Table of contents

Other Elektor Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Hanna Instruments

Hanna Instruments HI96719C instruction manual

TechnipFMC

TechnipFMC Smith Meter MMRT Specifications/Installation/Operation

abem

abem WalkTEM 2 Abridged user manual

Endress+Hauser

Endress+Hauser Proline Promass E 200 operating instructions

TQC

TQC DC9000 operating instructions

Waltron

Waltron 2410 instruction manual