4. Guidelines for installation

Selection of the adequate positioning of the

sensor is a key factor to proper operation of

the heating system. It influences directly the

effectiveness of the protection, as well as the

future costs of operation.

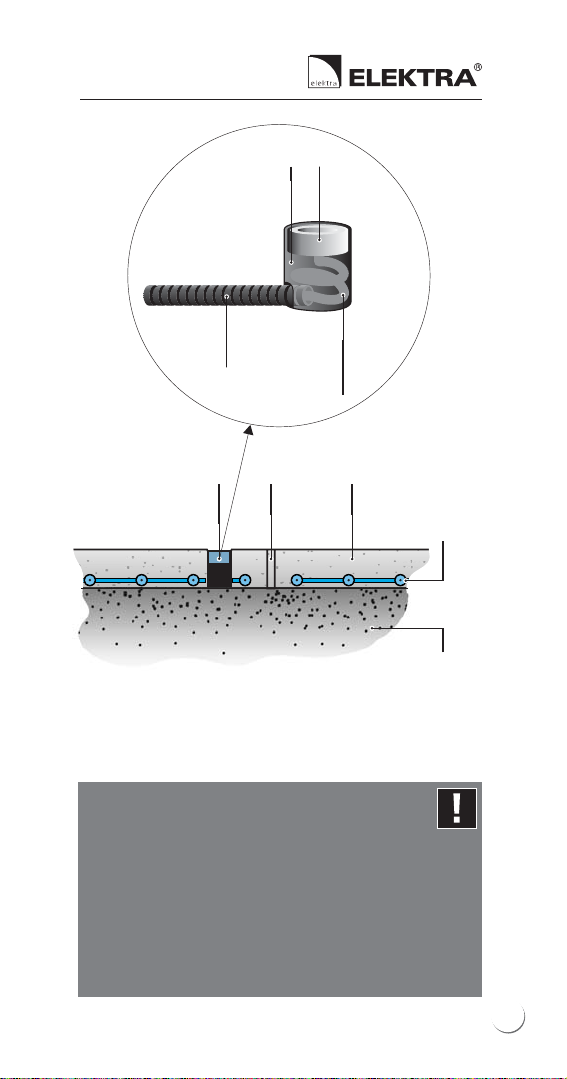

ETOG-56T sensors are to be installed within the

heated area, in an unsheltered position especially

vulnerable to longest expositions to moisture and

low temperatures. This position should also be

exposed to direct rain or snowfall.

In case of heating only the driving tracks, it is

recommended to install the sensor at the edge

of the tracks to be protected. It is possible thus

to avoid snow deposition on the tracks by

vehicles’ wheels. Small amount of snow falling

from the tyres does not constitute any danger

to safe driving, still can cause unnecessary

switching on of the heating system.

Installation should commence with mounting

of the ETOK-T type protection tube, included

in the set. Lead the protective conduit with the

so called “draw wire” to the planned position

of the sensor, and seal it (after the surface

works have finished, the conduit will help

feeding the sensor’s wire).

4.1 Positioning and installation of the

ETOG-56T sensor

6

Sensors for controllers

ETO2-4550 & ETR2-1550