-4-

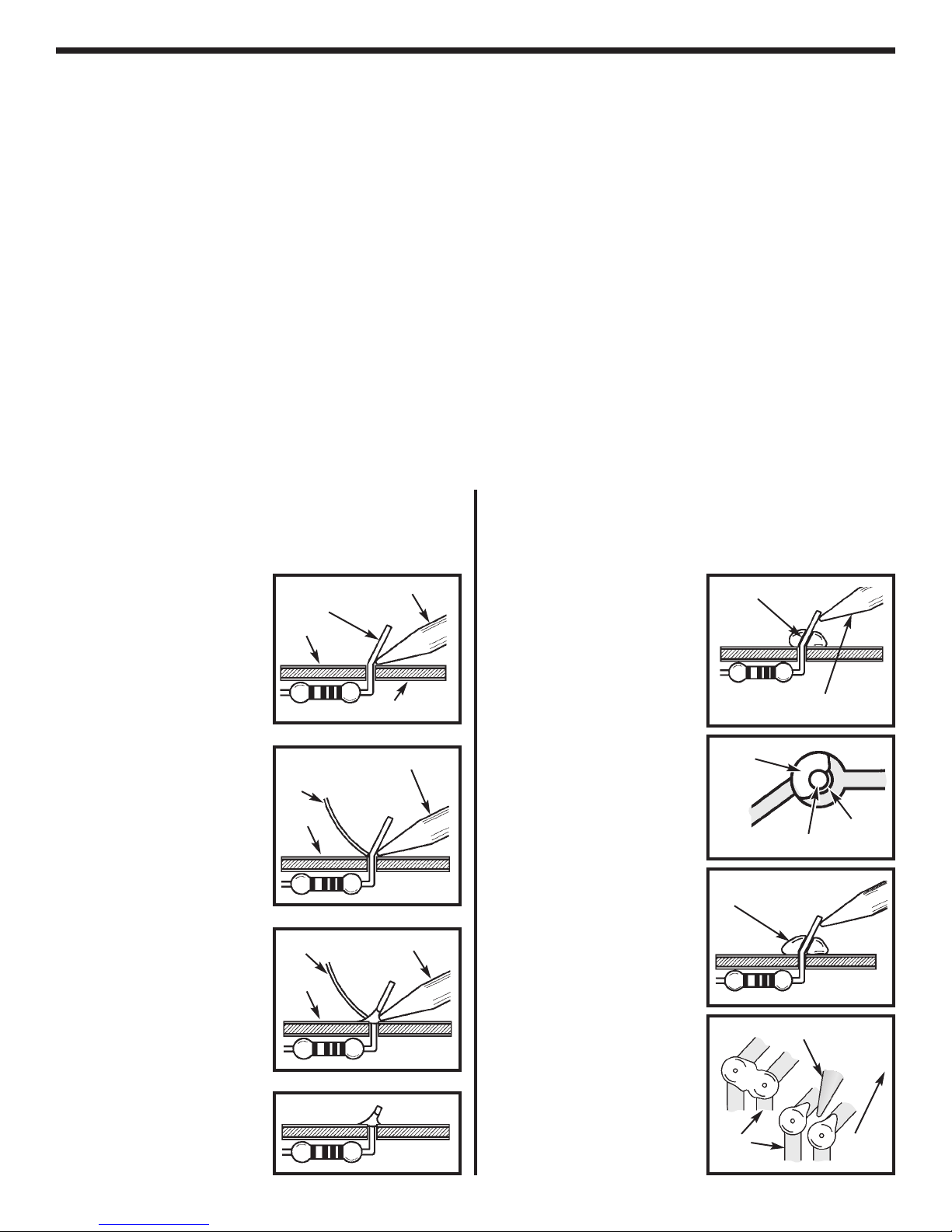

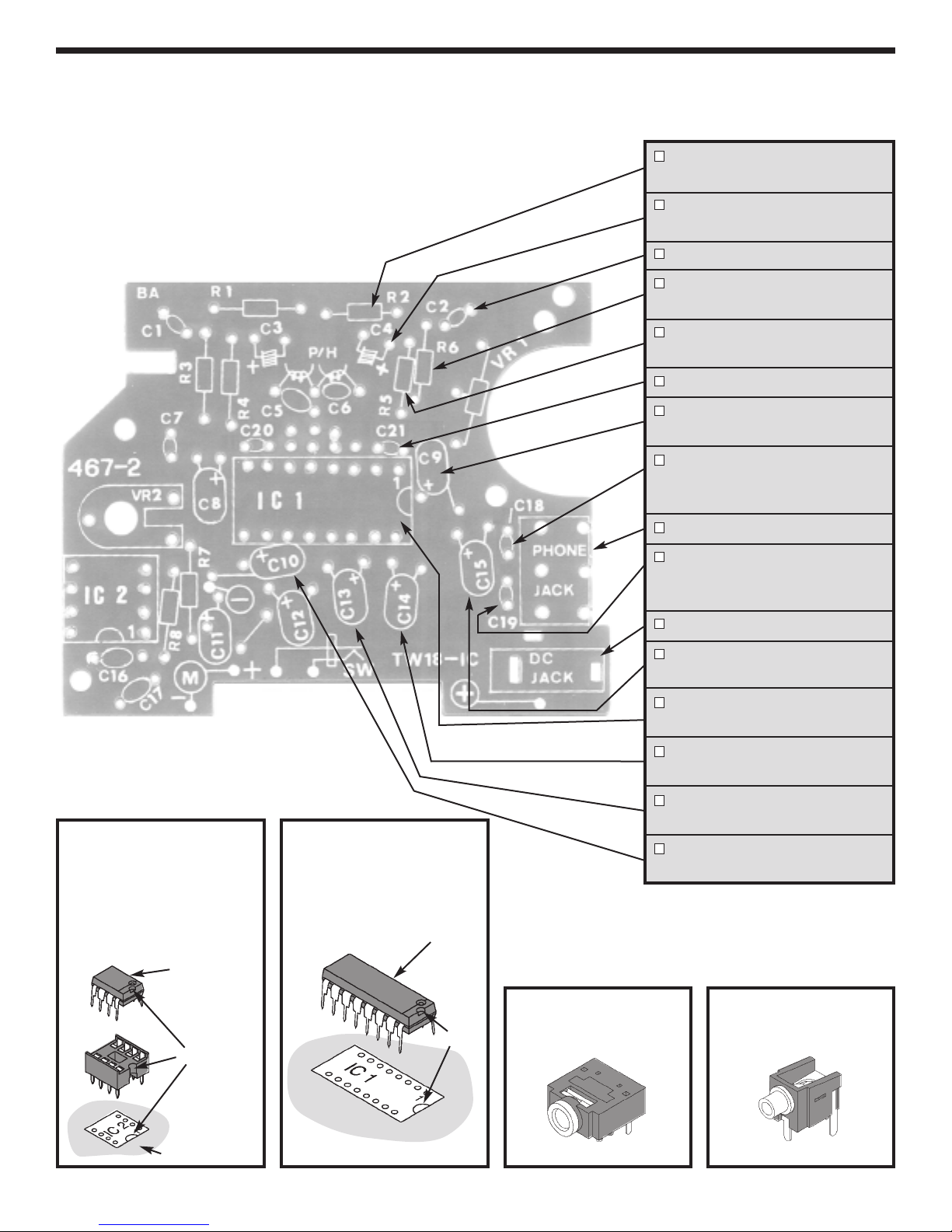

TAPE DECK ASSEMBLY

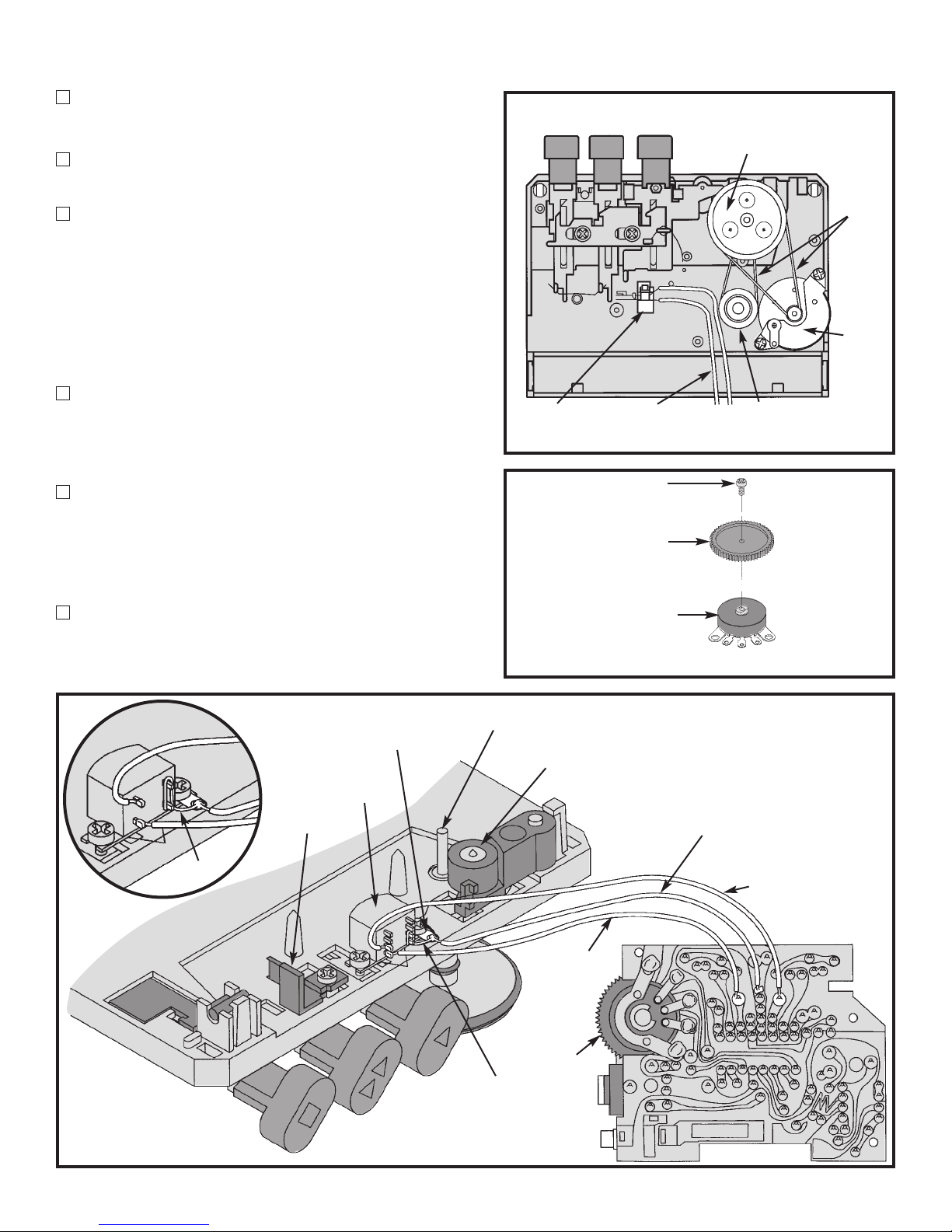

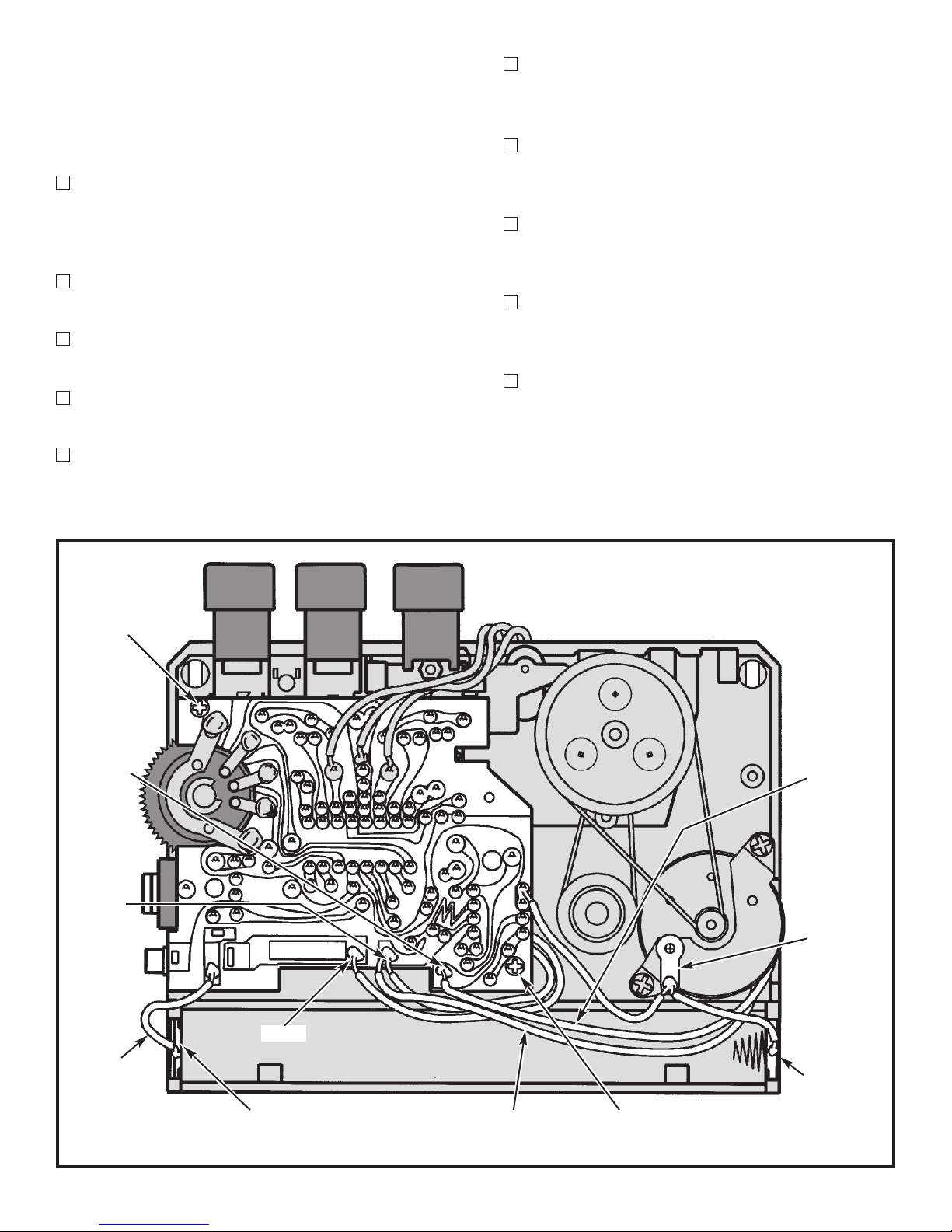

See Figures 5-3 and 5-5.

Tape Deck Assembly consists of three main parts:

1)

Tape Drive Train - The Tape Drive Train contains

a motor which turns at a constant speed. The

motor is connected by a drive belt to a large

pulley which turns the capstan. When the AK-200

is in Play Mode, that is, with the Play button

pushed, the pinch roller clamps the tape against

the capstan. This causes the tape to be pulled

across the head at a constant speed.

At the start of tape play, the tape is winding onto

an empty take-up reel. As the tape builds up on

the take-up reel, it takes more tape to go once

around the reel. Since the tape is moving at a

constant speed, the take-up reel must turn faster

at the start of tape play than at the end. A belt

from the capstan drives a small pulley to turn the

take-up reel. This pulley, if it were rigidly

connected to the take-up reel, would drive the

reel much faster than required even at the start of

tape play. A slip clutch is therefore inserted

between the small pulley and the take-up reel to

allow the reel to turn at the different speeds

required to wind up the tape.

2) Push-button Controls - Three push-buttons

control tape play. Pushing any button places the

AK-200 in that mode until another button is

pushed.

Play - Pushing the PLAY button closes the ON

switch which supplies power to the motor, motion

control and audio amplifier electronics. In

addition, the head and tape guide are moved into

contact with the tape and the pinch roller clamps

the tape against the capstan. You may then listen

to the tape through the stereo headphones.

Fast Forward - Pushing FAST FORWARD closes

the ON switch which, as in PLAY mode, supplies

power to the motor, motion control and audio

amplifier electronics. The head, tape guide and

pinch roller are not moved into contact with the

tape. The tape is therefore driven solely by the

take-up reel. Since there is little drag, there is

little or no slippage in the slip clutch and the tape

moves forward at high speed. FAST FORWARD

is used to space forward to a particular section of

tape or, after using the tape over, for rewinding.

Stop - Pushing STOP takes the AK-200 out of PLAY

or FAST FORWARD mode and stops the tape. After

opening the lid, STOP may be used again to pop up

the tape cassette for easy removal.

3) Heads - The purpose of the heads is to convert

the magnetization on the tape into an electrical

signal. The AK-200 has two playback heads.

Each head plays one of the four tape tracks when

the cassette is inserted one way and another

track when the tape is turned over.

MOTION CONTROL

When the two 1.5V batteries are new, they put out

their full 3V rated voltage. In time, as the batteries

are used, this voltage drops. If the battery voltage

was applied directly to the motor, the motor would

slow down as the battery voltage dropped. Tape

speed would then decrease, causing music to be off

key and voices to sound too low. The Motion

Control Section is therefore used to keep a constant

voltage on the motor and insure uniform tape speed.

AUDIO AMPLIFIERS

The audio amplifier section consists of two separate

amplifiers, one for each head, each amplifier driving

one of the stereo headphone speakers. The gain of

both amplifiers is set by the thumb wheel on the side

of the tape player. The amplitude on the low

frequencies from the head is lower than that of the

high frequencies. The frequency response of the

amplifiers is therefore set to emphasize the lows

and thus equalize the overall response.