Key Points

Before maintaining the machine, it is necessary to

read, understand and observe those safety rules,

operation instructions and maintenance instructions.

Only the trained and authorized personnel are allowed

to maintain the machine. It is necessary to always

keep this Manual along with the machine as a part of

it. Please contact with Hunan SINOBOOM Heavy

Industry Co., Ltd.

Table of Contents

Importance.......................................................2

Safety Rules ....................................................2

Product Performance Parameters....................4

Operating Procedures......................................8

Regular Maintenance Procedures ...................8

Procedure A...........................................13

A-1 Inspect All Manuals...............13

A-2 Inspect All Labels..................13

A-3 Inspect Damaged, Loose or

Lost Parts.......................................13

A-4 Inspect Hydraulic Oil Level ..14

A-5 Inspect Hydraulic Oil Leakage14

A-6 Functional Tests .....................14

A-7 Carry out Maintenance after 30

Days...............................................14

A-8 Inspect Battery.......................15

Procedure B...........................................16

B-1 Inspect Electric Wires ............16

B-2 Inspect Rim and Tire (Including

Mounting Nuts).............................16

B-3 Test Key Switch .....................17

B-4 Test Emergency Stop Buttons 17

B-5 Test Horn................................17

B-6 Test Braking Device ..............17

B-7 Testing Traveling Speed

(Platform in Lifted State)..............18

B-8 Testing Traveling Speed

(Platform in Fully Retracted State)18

B-9 Test Full Lifting and Full

Lowering Time..............................18

B-10 Inspect Hydraulic Oil...........19

B-11 Check the hydraulic tank

ventilation system .........................19

Procedure C...........................................20

C-1 Replace Air Filter of Hydraulic

Oil Tank ........................................20

C-2 Inspect Platform Weighing

System (Optional) .........................20

Procedure D...........................................20

D-1 Inspect Scissor Arm Installation

Bearing..........................................20

D-2 Inspect Base Frame Slider .....20

D-3 Replace Return Oil Filter of

Hydraulic Oil Tank........................20

Procedure E...........................................21

E-1 Inspect and Replace Hydraulic

Oil..................................................21

Maintenance Procedures ...............................22

Platform Components ...........................23

1-1 How to Remove Electric

Control Box from Platform...........23

1-2 How to Remove Platform.......23

1-3 How to Remove Extension

Platform.........................................23

Scissor Arm Part....................................24

2-1 How to Remove Scissor Arm .24

2-2 How to Remove Lifting

Cylinder.........................................24

Base Frame Components ......................25

3-1 How to dismantle the brake....25

3-2 How to dismantle the driving

motor .............................................25

3-3 How to Remove Storage Battery26

3-4 How to Remove Hydraulic

Valve Block...................................26

3-5 How to dismantle the hydraulic

power unit .....................................26

3-6 How to Remove Hydraulic Oil

Tank...............................................26

3-7 How to Remove Steering Oil

Cylinder of Front Wheel ...............27

3-8 How to dismantle the front

wheel bracket ................................27

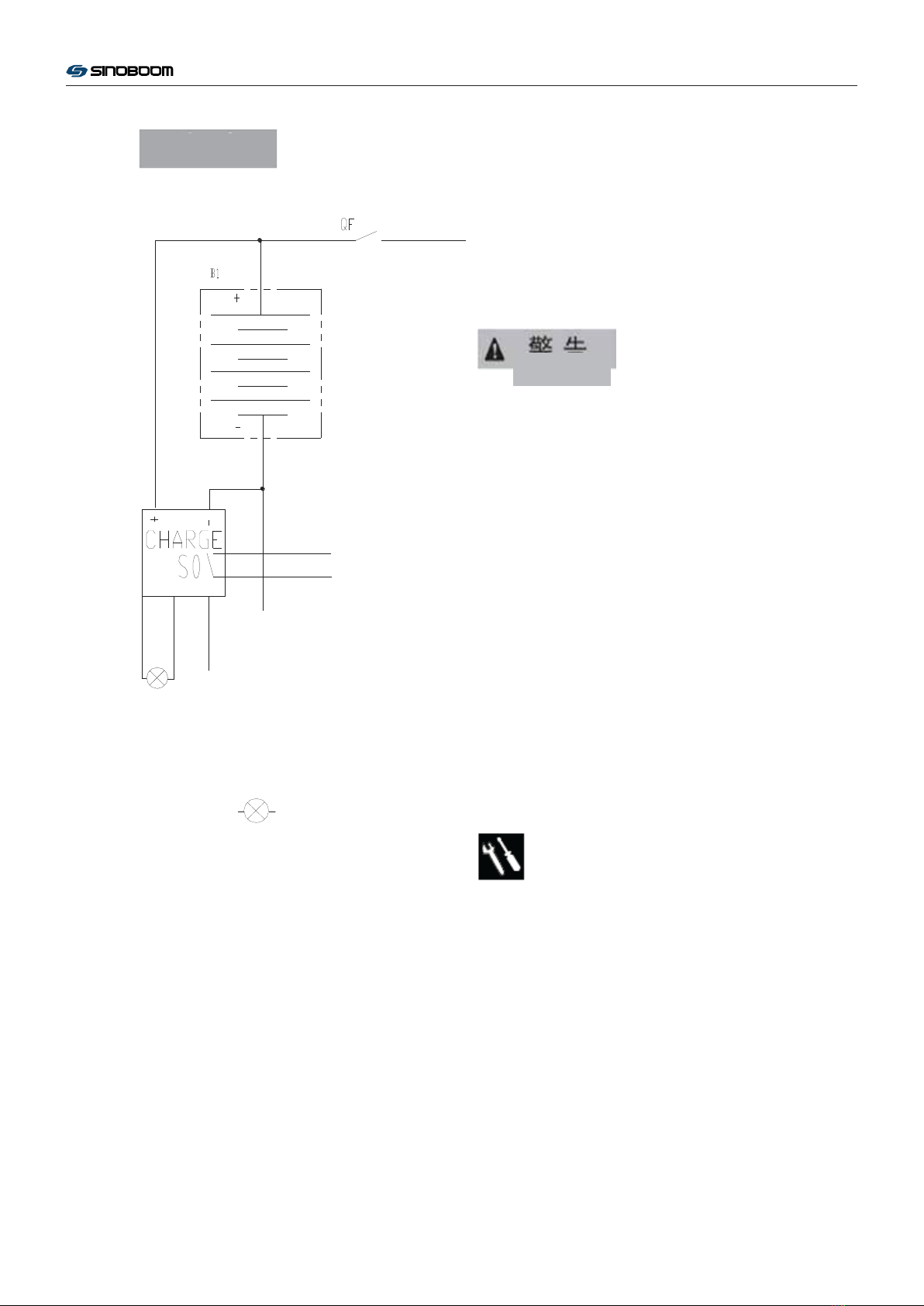

Hydraulic System..................................27

4-1 Detection of Function Pump...27

4-2 How to Remove Hydraulic

Pump .............................................28

GTJZ1412 & GTJZ1414 Maintenance Manual