Elgas miniELCOR SCR1 User manual

GAS-VOLUME CONVERSION DEVICE

miniELCOR

Device Description

Operation Manual

Technical Description

Mounting instructions

Device settings

Single-channel conversion device of gas volume at measurement conditions to

volume at base conditions. Approved for installation in potentially explosive

atmospheres.

January 2010

Rev. 6g

PRELIMINARY

Safety Measures

This measurement device can be operated only by an operator trained in

compliance with the technical terms, safety regulations, and standards. It is

necessary to consider any other legal and safety regulations stipulated for special

applications. Similar measures also apply for special applications. Similar measures

also apply for using the accessories. The operator training must be in compliance

with Decree no. 50.1978 Coll.

The information in this manual does not have the burden of a legal obligation from the

manufacturer’s side. The manufacturer reserves the right to implement changes. Any

changes in the manual or in the product itself can be performed at any time without any

previous alert, with the goal of improving the device or fixing any typographical or technical

mistakes.

TABLEOFCONTENTS

1Introduction.............................................................................................1

1.1Basicdevicedescription........................................................................................1

1.2Functionprinciple..................................................................................................2

1.3Devicedimensions.................................................................................................7

2Devicetechnicaldescription.....................................................................7

2.1Devicearchitecture...............................................................................................7

2.2Devicepowersupply.............................................................................................8

2.3Securitymarks.....................................................................................................11

2.4Productlabel.......................................................................................................13

3Safetyinstructions...................................................................................14

3.1General...............................................................................................................14

3.2Useinpotentiallyexplosiveatmospheres...........................................................14

3.3Risksofusage......................................................................................................14

3.4Specialconditionsofuse.....................................................................................15

3.5Usingdevicevariantsfordifferentgroupsofgas.................................................15

4Metrologycharacteristics........................................................................16

4.1Measuringtemperature......................................................................................16

4.2Measuringpressure.............................................................................................16

4.3Compressibilitycalculation..................................................................................17

4.4Volumemeasuringandcalculation......................................................................18

5Connectinginputsandoutputs................................................................21

5.1Inputs..................................................................................................................21

5.2Outputs...............................................................................................................25

5.3Addingofanotherpressureortemperaturetransducer......................................26

6Communicationwithdevice....................................................................29

6.1RS‐232andRS‐485interfaces..............................................................................29

6.2OpticalinterfaceIEC‐1107...................................................................................31

7Descriptionoffunction............................................................................33

7.1Measurandmarking............................................................................................33

7.2Instantaneousvalues...........................................................................................33

7.3Archives..............................................................................................................34

7.4Deviceparameterization.....................................................................................37

7.5Otherdevicefunctions........................................................................................38

7.6Securingthedeviceagainstachangeofmetrologyparameters..........................38

8Puttinginoperation................................................................................44

9Deviceoperation.....................................................................................45

9.1Keypad................................................................................................................45

9.2Menusystem.......................................................................................................46

9.3Mainmenu..........................................................................................................49

9.4Instantaneousvaluesmenu.................................................................................50

9.5Storedvaluesmenu.............................................................................................50

9.6Deviceparametersmenu.....................................................................................51

9.7Parametersettingsmenu....................................................................................52

9.8Systemdatamenu...............................................................................................53

9.9Diagnosticsmenu................................................................................................54

10Mountinginstructions.............................................................................57

10.1Mechanicalmountingofthedevice.....................................................................57

10.2Cableconnection,grounding...............................................................................61

11Accessories..............................................................................................63

11.1Assemblyaccessories..........................................................................................63

11.2Intrinsicallysafesupplysourcesforexternalpowersupply.................................63

11.3Separationandcommunicationmodules............................................................63

11.4GPRScommunicators..........................................................................................63

11.5Otheraccessories................................................................................................63

12Technicalparameters..............................................................................64

13Inexplosivenessparameters....................................................................70

14Devicesetting..........................................................................................72

14.1Standarddevicecontrolafterinstallation............................................................72

14.2DeviceconnectionwithPC..................................................................................73

14.3SettingofcommunicationbetweendeviceandPC..............................................73

14.4Passwordinthedevice........................................................................................84

15Configurationexamples...........................................................................86

15.1Deviceparametersdisplaying..............................................................................86

15.2Gasmeterconstantsetting..................................................................................86

15.3Pulseoutputssetting...........................................................................................89

15.4Analogueoutputsetting......................................................................................94

15.5Setpointsetting–limitvaluesofmeasuredquantity...........................................97

15.6Settingofexternalpowersupplyfailure.............................................................100

15.7SettingofcommunicationthroughMODBUSprotocol.......................................101

16Pressureandtemperaturesensor/transducerreplacement..................105

16.1Pressureandtemperaturesensor/transducerreplacementprocedurein

miniELCORdevice...............................................................................................105

16.2Softwaresettingsofdeviceforpropercommunicationwithnewtemperature

sensor.................................................................................................................105

16.3Softwaresettingsofdeviceforpropercommunicationwithnewpressure

transducer..........................................................................................................108

17Softwaresettingsofthedeviceforpropercommunicationwithexternal

digitaltemperature(EDT‐34)orpressuretransducer(EDT‐23)..............109

17.1Addingofdigitaltransducerintodevice’sparameters........................................109

17.2Addingofquantitymeasuredbydigitaltransducerintodevice’sarchives..........110

18Finalverificationofthedeviceafterreplacementofsensor/transduceror

addingofdigitaltransducer...................................................................111

19Whattodoifsomethingdoesnotwork................................................116

20Literature..............................................................................................119

21RelevantLiterature................................................................................119

22Software................................................................................................120

23Usedtrademarks..................................................................................120

24Listoffigures.........................................................................................121

25ListofTables.........................................................................................123

miniELCOR

1

Used symbols and definitions

Symbol Meaning Unit

AGA8-G1 ... Calculation method of gas compressibility factor

AGA8-G2 ... Calculation method of gas compressibility factor

AGA8-92DC ... Calculation method of gas compressibility factor

AGA NX-19 mod ... Calculation method of gas compressibility factor

ASC ... Accredited Service Center

BTS … Base Transceiver Station

CL 1 ... Module for realization of product output 4-20mA

CRC ... Checksum – used for data protection

CTR ... Communication protocol

DATCOM-Kx ... Some of the products of series DATCOM-K (DATCOM-

K1, DATCOM-K2, DATCOM-K3, DATCOM-K3/A,

DATCOM-K4, DATCOM-K4/A)

DLMS ... Communication protocol

DC ... Direct Current voltage

dE … addition (difference) of energy MJ

dV … addition (difference) of primary volume Vmor Vcm

3

dVb… addition (difference) of base volume m

3

dVc… addition (difference) of corrected primary volume m

3

dVm… addition (difference) of primary volume m

3

E … Energy MJ

Es … Estimated value of energy MJ

EDTxx … Digital pressure or temperature transducer EDT 23 or

EDT 34

EMC ... Electromagnetic compatibility and resistance

EMI ... Electromagnetic radiation

firmware, FW ... Software equipment loaded in the device

GOST NX-19 ... Method of gas compressibility calculation ( related with

AGA NX-19 mod) according to VNIMS directive (valid at

temperature range -23°C to +60°C)

GOST

NX-19

Hs... Combustion heat MJ/m

3

IS ... intrinsic safety, intrinsically safe

JBZ-0x ... Some of the JBZ-01, JBZ-02, JBZ-02/A products

Modbus ... Communication protocol designed by Modicon [15]

M900 ... Specific communication protocol

SGERG-88 ... Calculation method of gas compressibility factor, more

details in Chyba! Nenalezen zdroj odkazů.

SNAM ... Communication protocol

SW ... Software for PC

C ... Conversion factor -

K ... Ratio of compressibility factors (Z/Zb) -

k

p

... Gas meter constant (number of impulses per 1 m

3

) imp/m

3

N ... Number of input impulses from gas meter imp

p ... Absolute pressure at measurement conditions kPa

pb... Absolute pressure at base conditions kPa

miniELCOR

2

Notice :

This handbook issue describes device functions with firmware FW 4.xx which is

compatible with previous firmware version 2.xx. All different features will be

mentioned respectively.

Chapters describing new device features of FW ver. 4.xx are marked with (*).

Qm... Flowrate at measurement conditions ( further primary

flowrate)

m

3

/h

Qb... Flowrate at base conditions m

3

/h

T ... Absolute temperature at measurement conditions (T = t +

273.15)

K

t ... Gas temperature °C

Tb... Absolute temperature at base conditions K

V ... Volume Vmor Vc

Vm... Volume at measurement conditions (further primary

volume)

m

3

Vc... Corrected volume at measurement conditions ( volume

corrected based on correction curve of gasmeter)

m

3

Vb... Volume at base conditions (hereinafter also the

standardized volume)

m

3

Vbs ... Error volume at base conditions (hereinafter also the

error standardized volume)

m

3

Vs... Error volume at measurement conditions (hereinafter

also the error operational volume)

m

3

Vd... Difference of primary volume m

3

Vbd ... Difference of base volume m

3

Vf... Tariff pulse counter of primary volume

Vbf ... Tariff pulse counter of base volume

Z ... Compression gas factor at measurement conditions

Zb... Compression gas factor at base conditions

miniELCOR

1

1 Introduction

1.1 Basic device description

The Gas-volume conversion device miniELCOR (hereinafter only “the device”)

is a measuring instrument designed for the conversion of the gas volume measure at

measurement conditions to volume at base conditions.

The information on the gas volume passing through is measured using the

impulse outputs of the gas meter. The gas temperature and pressure are measured

by integrated converters. The device calculates the ratio of compressibility factors of

gas using standard methods or a constant value is used.

The device has been constructed and approved pursuant to the EN 12405-1

standard as a conversion device type 1 (compact system) and can be supplied as a

T, PT, or PTZ conversion device.

From safety point of view device is constructed according to EN 60079-11 like

intrinsic safe.

It is manufactured and supplied in compliance with the following European

Parliament directives:

1994/9/EC Equipment and protective systems for use in potentially explosive

atmospheres

2004/108/EC Electromagnetic compatibility

2004/22/EC Directive on measuring instruments

Device is put onto market and into usage according to above mentioned

standards and is marked with CE mark.

The device is built in a casing with sturdy plastic with IP66 protection. It is

equipped with a graphic display and a 6-button keypad. Furthermore, it has impulse

inputs for the connection of a gas meter with LF or HF impulse output and binary

inputs. Device with FW version 4.xx and higher is suitable for connection via encoder

NAMUR or SCR. If applied encoder SCR the only miniELCOR SCR1 variant is

allowed. The binary inputs can work as check inputs to check the connection with a

gas meter or can have a different function, e.g. monitoring the conditions of safety

snap locks, doors, etc. The device has 4 available outputs. These can be configured

as impulse or binary outputs, or as data outputs for the CL-1 module. When using

this module, an analog current output can be realized.

The device is powered by a lithium battery. The life cycle of the battery is 6

years in the defined work mode. In the case of a battery power supply, one can also

use the impulse outputs. An external power supply source can be used in

applications with higher demands.

The device has a data archive of the measured values with an adjustable

structure and storing period. The binary archive stores changes on the binary inputs

and the occurrence of the monitored events (limits, etc.) Error conditions are stored

in an status archive. It is possible to program the storing of important quantities and

calculations and storage of some statistical values in the daily and monthly archive.

The archive has settings for service and metrology; in case of changes of settings,

the acts influencing the device parameters are recorded. The other logs are available

as well , see more in 7.3.

miniELCOR

2

For communication with its superior system, the device has a serial interface

RS-232 and RS-485. Various communication protocols installed in the device allow

easier connection to the SCADA systems. The device cooperates with common

phone, radio, GSM, and GPRS modems, and in case of an alarm condition, it can

initiate the connection.

The device can be enhanced by one non-metrology converter for measuring

pressure or temperature. This enhancement can be performed without breaking the

official mark on an already installed device.

1) Basic configuration of the device offers following inputs and outputs:

-analog input (pressure P - metrologic channel)

-analog input (temperature T - metrologic channel)

-4x digital input DI1 to DI4 (binary, pulse); input DI1 can be used for connecting

encoder NAMUR

-4x digial output DO1 to DO4 (binary, pulse, analog)

-communication channel RS485/RS232 for communication with suprordinate

systém

-input of external power supply

-option: connection one digital pressure or temperature transmiter EDTxx (as

nometrologic) to internal bus by help expansion board KP 065 08. This

enhancement can be accomplished by end user on already installed device

without breaching of metrological seal.

2) Device variant with SCR encoder ensures following inputs and

outputs:

-The same like at basic device variant ( see ad 1) however without possibility

of connection of digital transducer EDTxx

-1x input for SCR encoder connection by means of extention board KP 065 09

The device can be configured using the supplied SW [22] for PCs. This SW also

allows the readout, display and archive of both the immediate measured values as

well as the contents of the internal device archives.

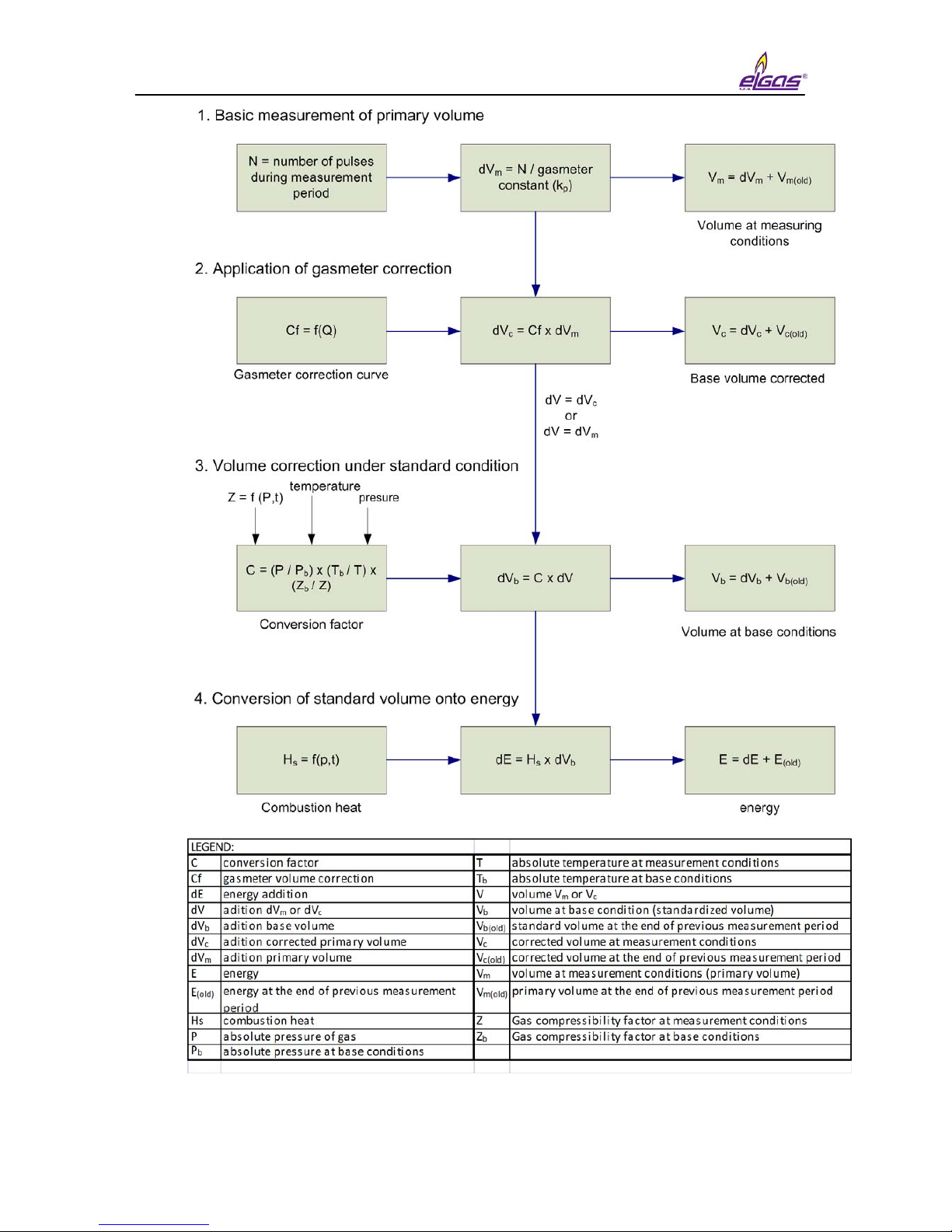

1.2 Function principle

1.2.1 Conversion using equation of state

The device obtains data on the gas flowing through via impulses (N) from an lf

or hf sensor located in the gas meter. The volume at the measuring conditions (V) is

calculated from the number of impulses (N) and gas meter constant (kp).

The device obtains other data on the gas flowing through from the temperature

and pressure converters – gas temperature (t) and absolute pressure at measuring

conditions (p). This data is used to calculate the conversion factor (C) which is

influenced also by these other factors: Absolute temperature at base conditions (Tb),

absolute pressure at base conditions (pb) and compressible factor of the gas at base

conditions (Zb).

miniELCOR

3

Volume at measuring conditions (operational volume):

V = N

kp

Ratio of compressibility factor:

K = Z

Zb

Conversion factor:

C = p * Tb*1

pb(t + 273.15) K

Volume at base conditions (standardized volume):

Vb= V * C

Gas compressibility factor expresses the deviation of properties of natural gas

from the properties of an ideal gas. By setting the parameters, it is possible to choose

a specific method for calculation of the compressibility factor pursuant to the standard

(AGA NX-19 mod, AGA8-G1, AGA8-G2, SGERG-88 or AGA8-92DC). A constant

compressibility value can be used for other gases besides natural gas. If the

pressure or temperature value gets out of the limits of validity of the chosen standard

for calculation of compressibility, the device calculates using a default compressibility

value.

The device calculates the gas flow from the impulse frequency on the input in

real time using mathematical filtration from the input signal.

Operational flow:

Q = ∆V / ∆t [m3/h]

Where: ∆V ............................ increment of operational volume

∆t ............................. time between the impulses with an accuracy

of one hundredth of a second

The value of the immediate flow displayed on the converter display is updated

every 10 seconds.

Standardized flow:

Qb= C * ∆V / ∆t [m3/h]

1.2.2 Error values of volumes at measuring conditions and

volumes at base conditions

For calculation during error conditions (i.e. in case of a converter error,

deviation of the quantity value from the working range, or device error), the device

has counters of the error volume at measuring conditions (Vs) and error volume at

base conditions (Vbs). These counters are interconnected with the pertinent counters

of volume at normal conditions.

A detailed description of device behavior during normal and error conditions is

in Article 4.4.

miniELCOR

4

1.2.3 Volume correction at measurement conditions

Device enables to compensate gasmeter error according to predefined

correction curve from gasmeter test certificate. This function and parameters Vccan

be activated only by manufacturer or by Acreditive service to ensure that used

gasmeter correction curve in dependance on flowrate Qmis valid within working

conditions.

Error of measurement is corrected by usage of function f(Qm). For corrected

volume is:

Vc = Vmx f(Qm)

where

Vc... Corrected volume at measurement conditions

Vm... Primary volume

Qm... Primary flowrate

Linear interpolation method is used for getting values between calibration

points. File with correction values is to be inserted into device with help of service

programme 22. Information about insertion of correction curve into device is logged

in setup archive.

The principle of volume calculation are seen on Fig. 1

Condition for usage of volume correction.

1. Correction is used only in case that gasmeter transmits at least 10 pulses

per second resulting in usage only HF sensors.

2. Under Qmin correction is not applied and over Qmax value of correction

coefficient given for Qmax will be used.

Conversion of volume on energy (*)

Device enables to calculate consumpted quantity of gas directly in energy form.

This conversion uses value of combustion heat Hs. Calculation is made with

adding of differences dVb( and dVbs) multiplied by actual value of combustion heat

Hs.

dE=Hsx dVb, dEs=Hsx dVbs

Two other counters ( energy counter E and estimated energy counter Es) are

dedicated for measurement in configurable energy units: MJ, kWh, Btu.

Note :

No conversion of absolute counter value (E or Es) is accomplished after

change of units. Following increases are added already respecting new units.

Principle diagram of energy calculation is drawn at Fig. 1

miniELCOR

5

Combustion heat Hs

To get correct conversion it is necessary to enter correct value of combustion

heat and relative conditions. Then device will make new conversion of relative

temperature for defined relative conditions and final value will be used for energy

calculation. In case of AGA8-92DC method combustion heat is not entered but

calculated directly from gas composition according to EN ISO 6976. For the other

methods value Hs(MJ/m3) must be entered manually and always under those

relative conditions:

combustion temperature/ temperature of gas = 25°C / 0 °C

miniELCOR

6

Fig. 1 Volume and energy calculations - Scheme

miniELCOR

7

1.3 Device dimensions

Fig. 2 Device dimensions

2 Device technical description

2.1 Device architecture

The device’s electronics are laid out on three basic boards.

The bottom part of the casing contains the board of inputs and outputs

containing the battery and back-up battery and terminal box for connecting the

pressure and temperature sensors and any device inputs and outputs. The

connections related to the metrology function of the converter are protected by

covers which are secured with official mark.

Optionally, the input board can have an extension board for connecting an

additional digital pressure (EDT 23 type) or temperature (EDT 34 type) converter.

This additional digital converter communicates with the converter using the protocol

Modbus RTU interface RS-485.

Note:

If SCR encoder is required it can be arranged only by manufacturer

or by authorised service center. Those two subjects will ensure

appropriate labelling placed on housing.

miniELCOR

8

The lid of the housing contains a processor board which is protected by a cover

and secured by an official mark. The board cover has an opening for access to the

service switch. The service switch can be use to enable/disable the setting of the

device parameters using a service SW.

Fig. 3 Main parts of the device

2.2 Device power supply

2.2.1 Supply battery

The device is powered by a built-in battery (lithium) with a voltage rating of

3.6 V. The life cycle of the battery depends especially on the configuration of the

device, the frequency of communication, and the time the display is on. The

consumed capacity is calculated during the device’s activity and the capacity

decrement is recorded in its memory. The device will issue an alert to replace the

battery 90 days before the expected discharge (error messages E9 – see Table 8.

miniELCOR

9

Defined mode with life cycle of the supply battery of more than 5 years:

•Archiving period of the data archive 1 hr

•Communication with device 2 min/day

•Showing on the display 2 min/day

•Period of input impulses ≤10 Hz

•Measuring period 15 s

•Surrounding temperature 25 °C

•expansion board KP 065 09 ( SCR encoder ) is not used

If the device is operated with higher consumption than in the defined mode, it

is necessary to count on a more frequent replacement of the battery or use a network

power source.

2.2.2 Replacement of supply battery

. It is suitable to disconnect the discharged battery as soon as possible. While

the battery is being replaced, the device does not measure pressure or temperature,

but counts the incoming lf impulses (but does not convert the number of pulses, this

will be performed only when the supply battery is connected again) and insures that

the real time clock is running. The data stored in the device archives and parameter

settings will remain preserved.

Discharged batteries belongs at hazardous waste category. According to

OEEZ (2002/96/ES) directives and and other internal directives battery must not be

disposed together with household waste. Withdrawing duty is applied over

discharged battery.

2.2.3 Back-up battery

The battery ensures the back-up of important functions in case of discharge or

replacement of the supply battery. The back-up battery can be replaced in an

accredited service center after the official and security mark is broken (replacement

can not be performed in a potentially explosive atmosphere). It is necessary to use

the same type of battery. Only recommended type of battery may be used.

Due to correct calculation of remaining battery capacity after replacement it is

mandatory to reset this information with service SW tool [22].

Replacement of battery is allowed also at hazardous zone but only with

recommended type of battery.

miniELCOR

10

Defined mode for life cycle of back-up battery of 10 years

•Storing, temperature 25 °C

•Backed-up inputs (DI1 – DI4) not connected or connected contacts

disconnected

•Does not depend on the presence of the supply battery

Defined mode for life cycle of back-up battery of 4 years

•Backed-up inputs (DI1 – DI4) short-circuited

•Without powering battery

Self-discharging of batteries

The back-up and supply batteries are lithium. Their capacity drops due to self-

discharging. The recommended time frame for their replacement is 10 years, even if

the battery was never connected.

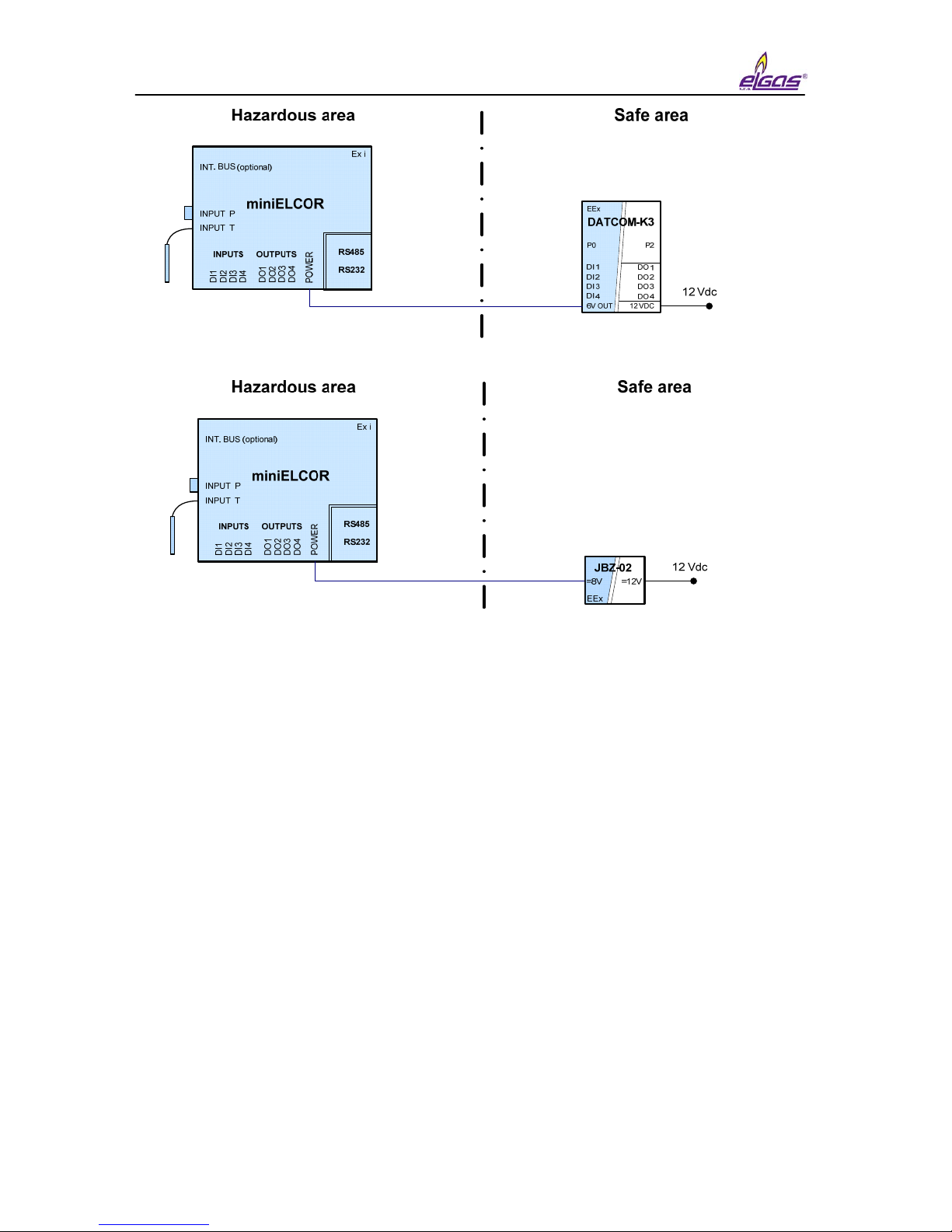

2.2.4 External power supply

Usage of external power supply is necessary in case of appliance of:

-NAMUR HF pulse input

-Binary output

-NAMUR encoder.

External power supply is recommended in case of increased current consumption

regimes like:

-frequent communicationi (more than once a day),

-frequent LCD displaying

-SCR encoder usage.

An approved intrinsically-safe source must be used for the external power

supply. In case a NAMUR type sensor is not connected to the device, one can use

the built-in sources of the communication modules DATCOM-Kx or sources JBZ-01,

JBZ-02.

If the NAMUR sensor is connected to the device, one must always use an

external power source JBZ-01 or JBZ-02.

miniELCOR

11

Fig. 4 Examples of external power supply

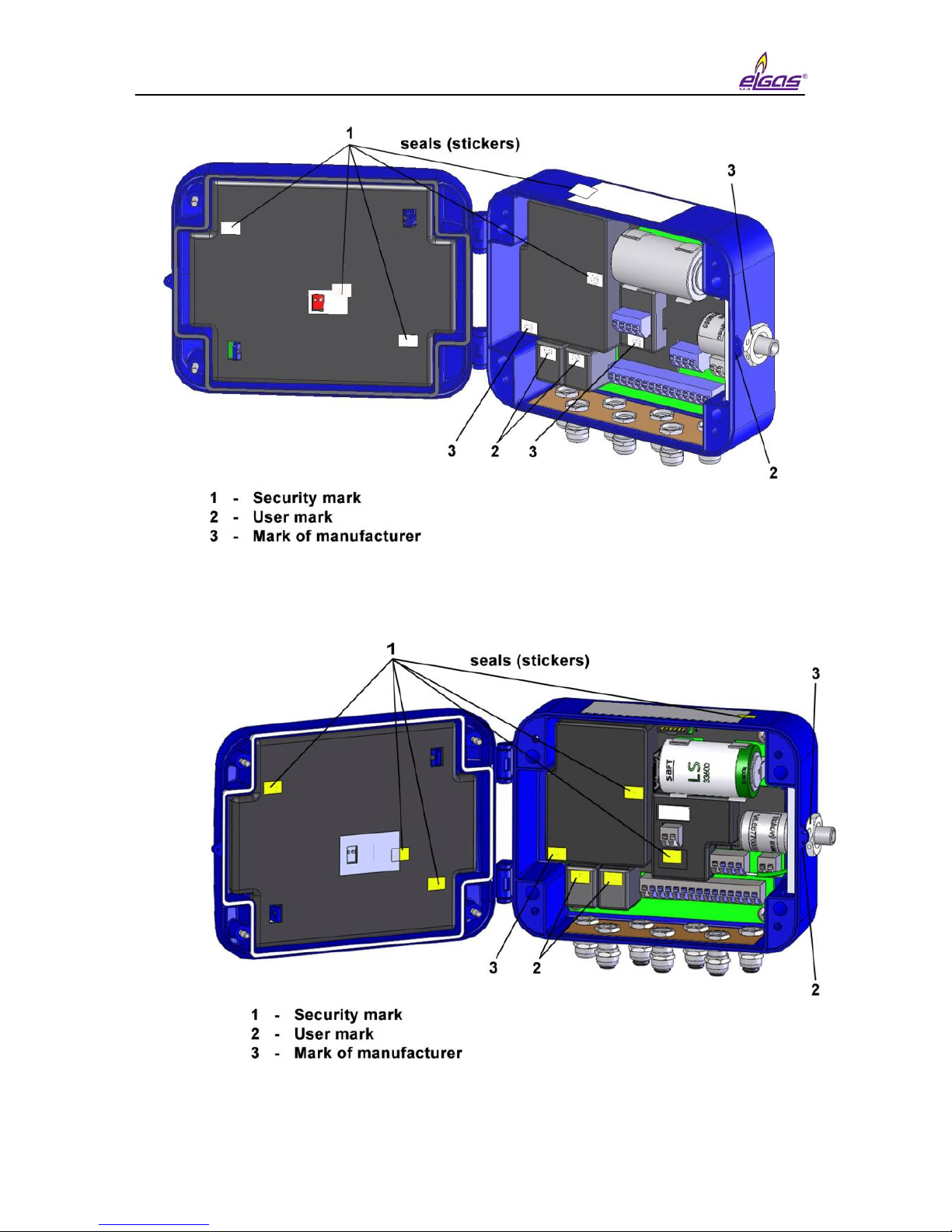

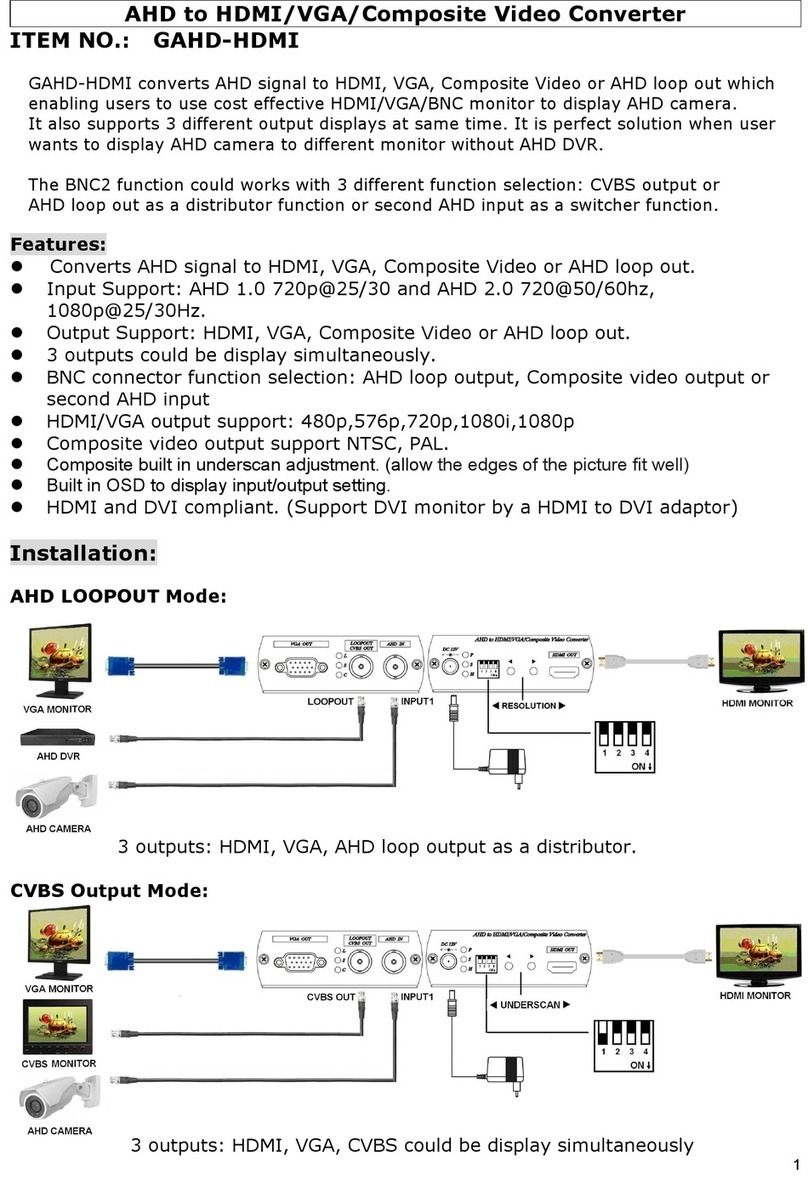

2.3 Security marks

Security marks located on the device indicate the technical condition of the

device regarding unauthorized handling.

Security mark of the manufacturer (metrology mark)

- its design is stipulated by the Approval certificate on the quality management

system for production, output control, and testing pursuant to Enclosure no. 2,

procedure D, ND no. 464/2005 Coll., issued by the Notified person no. 1383. Such

security mark has the same importance for the user as the so called Official mark

pursuant to the Act on Metrology.

In case such a mark is broken, the manufacturer does not guarantee that the

properties of the device are in compliance with the EC Certificate on type verification.

User mark

- control mark of the user (seals) as needed

Mark of manufacturer

- control mark of manufacturer as needed

miniELCOR

12

Fig. 5 Security marks (device without SCR encoder)

Fig. 6 Security marks of miniELCOR SCR

miniELCOR

13

2.4 Product label

Fig. 7 Product label English version

Fig. 8 Product label – original certification for ZONE 1

This manual suits for next models

1

Table of contents

Other Elgas Media Converter manuals

Popular Media Converter manuals by other brands

ASTRO

ASTRO U-911 operating manual

Baumer

Baumer HOG 220 Installation and operating instructions

Korenix

Korenix JetCon 1701GP-U user manual

Genie Security Solutions

Genie Security Solutions GAHD-HDMI manual

Imagine communications

Imagine communications Selenio 6800 HUC6800+C Installation and operation manual

ION

ION EZ Vinyl/Tape converter quick start guide

Polyend

Polyend Poly 2 Instructions of use

Task Lighting

Task Lighting LCDMXSD-D3-L manual

KTI

KTI KC-300DM series installation guide

Behringer

Behringer ULTRAGAIN PRO-8 DIGITAL ADA8000 user manual

CYP

CYP CPCD-3A Operation manual

Advantech Wireless

Advantech Wireless SSPBMg-C400-BRE Installation and operating manual