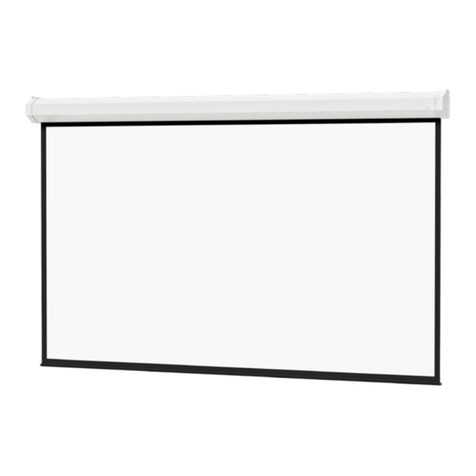

Elite Prime Vision Polar Star Series User manual

Rev041316-DR

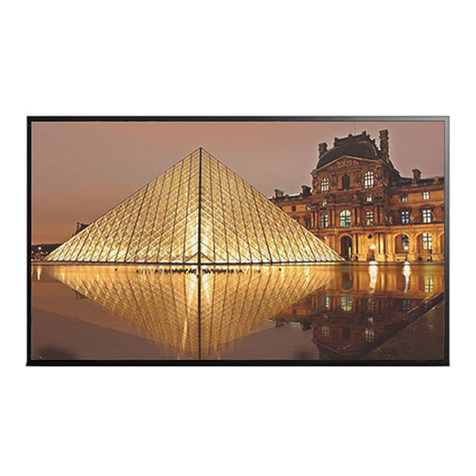

Ambient Light Rejecting Fixed Frame Screen

Polar

Thank you for choosing the

Elite Prime Vision,

included is our ISF certified

Polar Star

formulated for environments with minimal control over room lighting. It was designed to enhance picture

brightness, offer accurate

color fidelity, and improve contrast levels. The

educational facilities, conference rooms or any applications in which incident light is a factor.

In order for the Polar Star™

to maintain its projection qualities and o

below for proper maintenance and cleaning.

Use a dry microfiber cloth to remove dust from the screen’s surface.

When cleaning, use a damp microfiber cloth with warm water to remove any marks.

Never rub or app

ly pressure when cleaning the surface.

Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

In order to avoid damaging the screen, avoid touching it directly with your fingers, pens/pencils or

any other sharp or abrasive objects.

Hardware and Parts List

A. Frame Parts

x 6 pcs (4 top/bottom frame pcs + 2 side frame pcs)

B. Screen Material x

1 pc

C. Center joint

x 2 pcs

D. Elbow Joint

x4 pcs

E. Wall bracket x 4

pcs

F. wood screw

x 8 pcs

G. Hollow wall anchor

x 8 pcs

H. M5x15 screw

x 16 pcs

I. Center Support Bar x 1 -

J. Support joiner x 2 -

K. Fix Plates

x 60

www.EPVscreens.com

Ambient Light Rejecting Fixed Frame Screen

Polar

Star™ Series

User’s Guide

Elite Prime Vision,

Polar Star™ fixed frame projection screen!

Polar Star

™

, which is a reference quality front projection material precisely

formulated for environments with minimal control over room lighting. It was designed to enhance picture

color fidelity, and improve contrast levels. The

Polar Star™

is best for family rooms,

educational facilities, conference rooms or any applications in which incident light is a factor.

to maintain its projection qualities and o

ptimum performance, please refer to the list

below for proper maintenance and cleaning.

Use a dry microfiber cloth to remove dust from the screen’s surface.

When cleaning, use a damp microfiber cloth with warm water to remove any marks.

ly pressure when cleaning the surface.

Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

In order to avoid damaging the screen, avoid touching it directly with your fingers, pens/pencils or

any other sharp or abrasive objects.

Note:

sure all parts are

included in your

package before

pr

assemble your

Star™

projection screen.

x 6 pcs (4 top/bottom frame pcs + 2 side frame pcs)

1 pc

x 2 pcs

x4 pcs

pcs

x 8 pcs

x 8 pcs

x 16 pcs

2 pcs (depending on model/size)

4 pcs (depending on model/size)

x 60

- 180 pcs (depending on model/size)

1

The screen material

, which is a reference quality front projection material precisely

formulated for environments with minimal control over room lighting. It was designed to enhance picture

is best for family rooms,

educational facilities, conference rooms or any applications in which incident light is a factor.

ptimum performance, please refer to the list

When cleaning, use a damp microfiber cloth with warm water to remove any marks.

Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

In order to avoid damaging the screen, avoid touching it directly with your fingers, pens/pencils or

Note:

Please make

sure all parts are

included in your

package before

pr

oceeding to

assemble your

Polar

Star™

fixed frame

projection screen.

Rev041316-DR www.EPVscreens.com 2

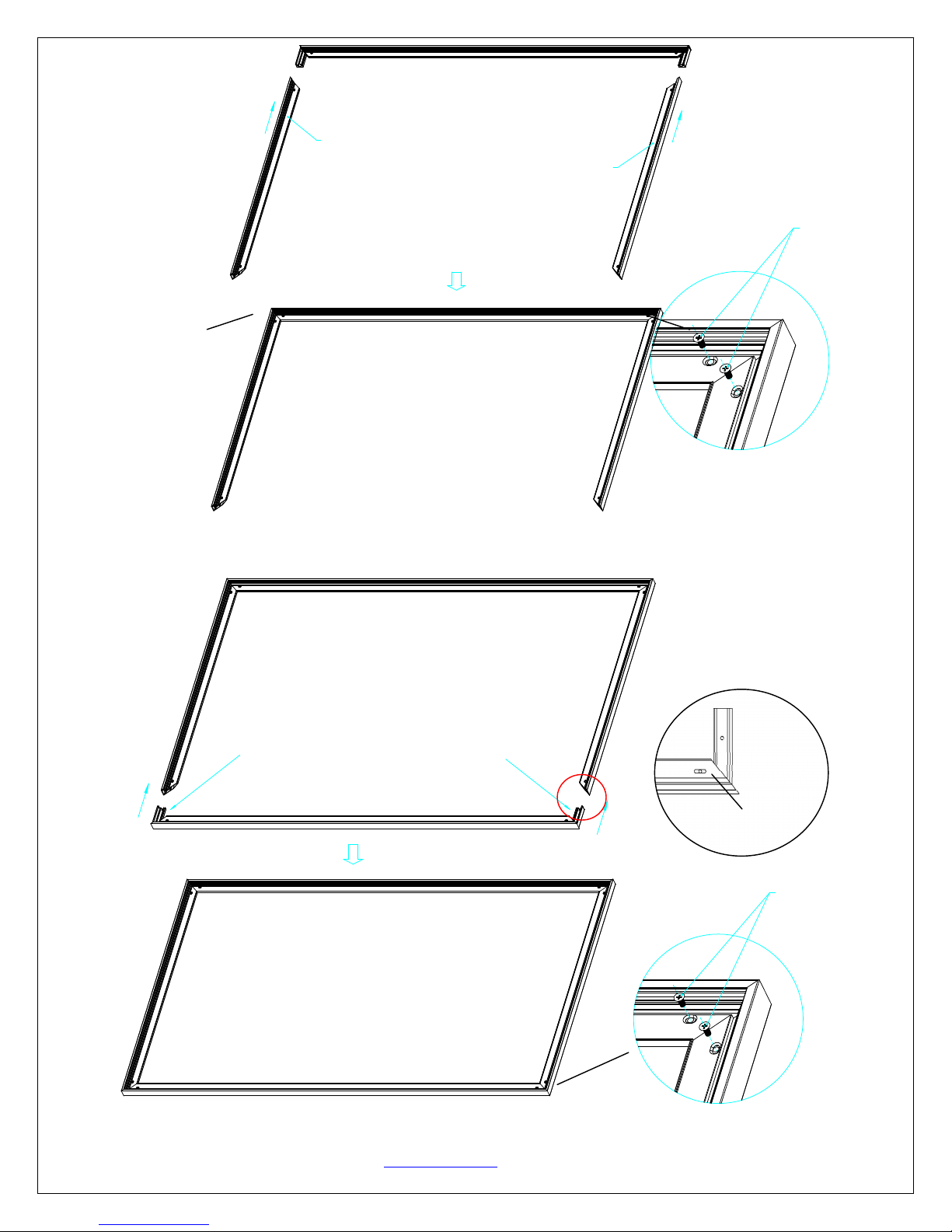

FRAME ASSEMBLY

1. Insert the center joint (c) connector to the horizontal frame piece with bevel connection and flat head,and then

fasten it with two M5x15 screws (h).

2. Insertthe other horizontal frame piece to thecenter joint connectorand then fasten it with twoM5x15 screws.

Note: a. 2 long frames should be assembled for a screen.

b. Do not tighten the screws completely until all frame pieces have been assembled correctly.

3. Insert both elbowjoint connectors into the long horizontal frame and then fasten it with twoM5x15

screws(seeFig.1).Then insert the short frames and fasten them with screws (Fig.1.2).

Push Push

Joint

Long frame

( fig.1)

Flat head

bevel connection

Bevel connection

Flat head

×2

½ Long Frame

½ Long Frame Push

Horizontal Long Frame

M5x15 Screw

M5x15 screws

M5x15 screws

Rev041316-DR www.EPVscreens.com 3

Push

Push

( fig.2)

Insert the exposed ends of the joint connectors

into the short (vertical) frame and align the four

corners so that they meet at perfect right angles

4. Join all four frame parts together following the steps shown below. (Fig.2)

Note: When assembled, please push simultaneously the two ends of the long frames.

Push

Push

Short frame

Short frame

M5x15 screws

Screw

M5

×

15Screws

Screw

(Fig.1.1)

(Fig.1.2)

Rev041316-DR www.EPVscreens.com 4

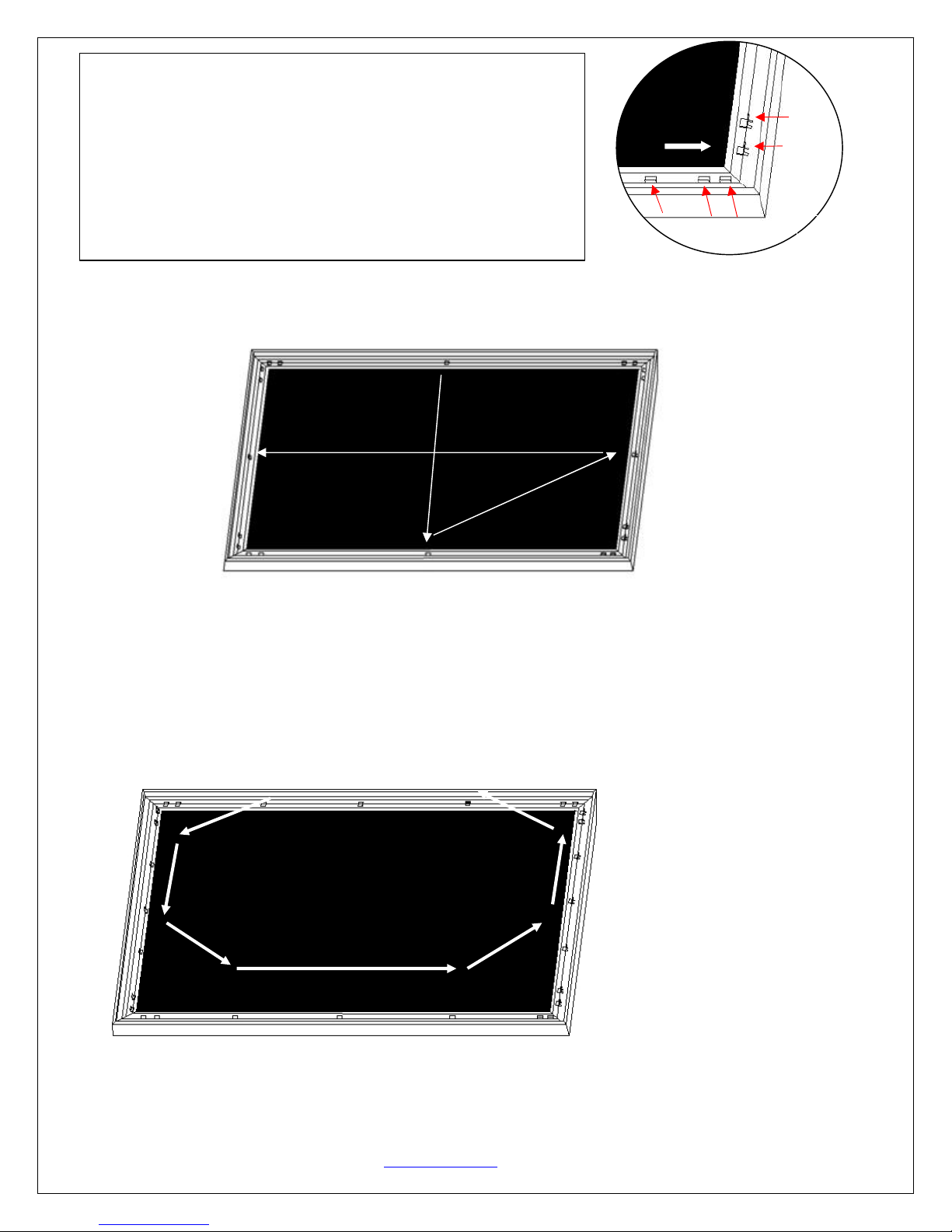

Attaching the Screen Material to the Frame

1. Make sure the screen material and frame are both lying face down on a clean, dry, and non-abrasive

surface.

2. Carefully unroll the material inside the frame. (Fig.3)

Please note the material will be noticeably smaller than the frame, as the material must be stretched to create a

sufficient amount of tension for perfect material flatness.

3. Attach the fix plates.

(1)

Stretch the material to the corner and insert the screen material’s edge in the groove of the frame. While

one hand holds the material in place the other hand snaps in the push plate (Fig.4-Fig.5).

(2) Begin by securing the four corners in the following sequence A→B→C→D (Fig.6).

(3) Insert the fix the plates as shown on Fig. 5. Fix plate ① is about 10cm away from the frame’s corner.

Fix plate ② is about 5cm away. (Fig.7)

(Fig. 6)

(Fig. 7)

Notes:

Make note of the label to help distinguish

the back and front side.

Unroll the screen material face down

Keep the screen material as close as possible

to the frame and do not allow it to scratch

against any part of the frame.

(Fig. 4)

Insert pushplate in

Screen material edge (Fig. 5)

Schematic

c

ross section of the

f

rame

Plate

Frame groove

A

B

C

D

(Fig.3)

Rev041316-DR www.EPVscreens.com 5

(4) Place a fix plate in the center of each side in the following orderE→F→G→H.(Fig.9)

(5) Next, fasten a fix plate on the center of each frame side in the following order

I→J→K→L→M→N→O→P as shown in Fig.10.

E

G

H

F

(Fig.9)

I

J

K

L M

N

O

P

Tip for attaching the last corner (D):

1. Position yourself left of location ①.

2. Pull the material to the corner of the frame with your hand while your left

hand snaps in the fix plate on location ①(the third red dot).

3. Then insert and snap in the fix plate on location②.

(Fig.10)

①

②

③

⑤

④

Pull

(Fig. 8)

Rev041316-DR www.EPVscreens.com 6

(6) Fasten the remainder of the fix plates in the empty locations in the red markings to complete attaching the screen

material. (Fig.11)

Center Support BarInstallation

1. Insert the support joiner into each end of the center support bar.

support joiner Center support bar

2. Insert the Center Support Barinto the upper top groove on the back of the frame(not the one where the fix

plate inserts) with the bottom end near the approximate center point of the frameand rotate it in at an angle so

that both ends of the bar are in alignment with the groove (see Fig. 17 below for details).

3. Slide the top end of the bar into the top center point of the frameto complete the center support bar

installation.This will provide added stability to your frame and added tension to the material.

Screen material edge

Fixed plate groove

(do not insert here)

Center Support Bar

(Fig. 17)

Remove

push

Center Support Bar

(Fig.11)

Diagonal models 135” and below use 1 x

Center Support Bar

Diagonal models above 135” require 2 x

Center Support Bars

Rev041316-DR www.EPVscreens.com 7

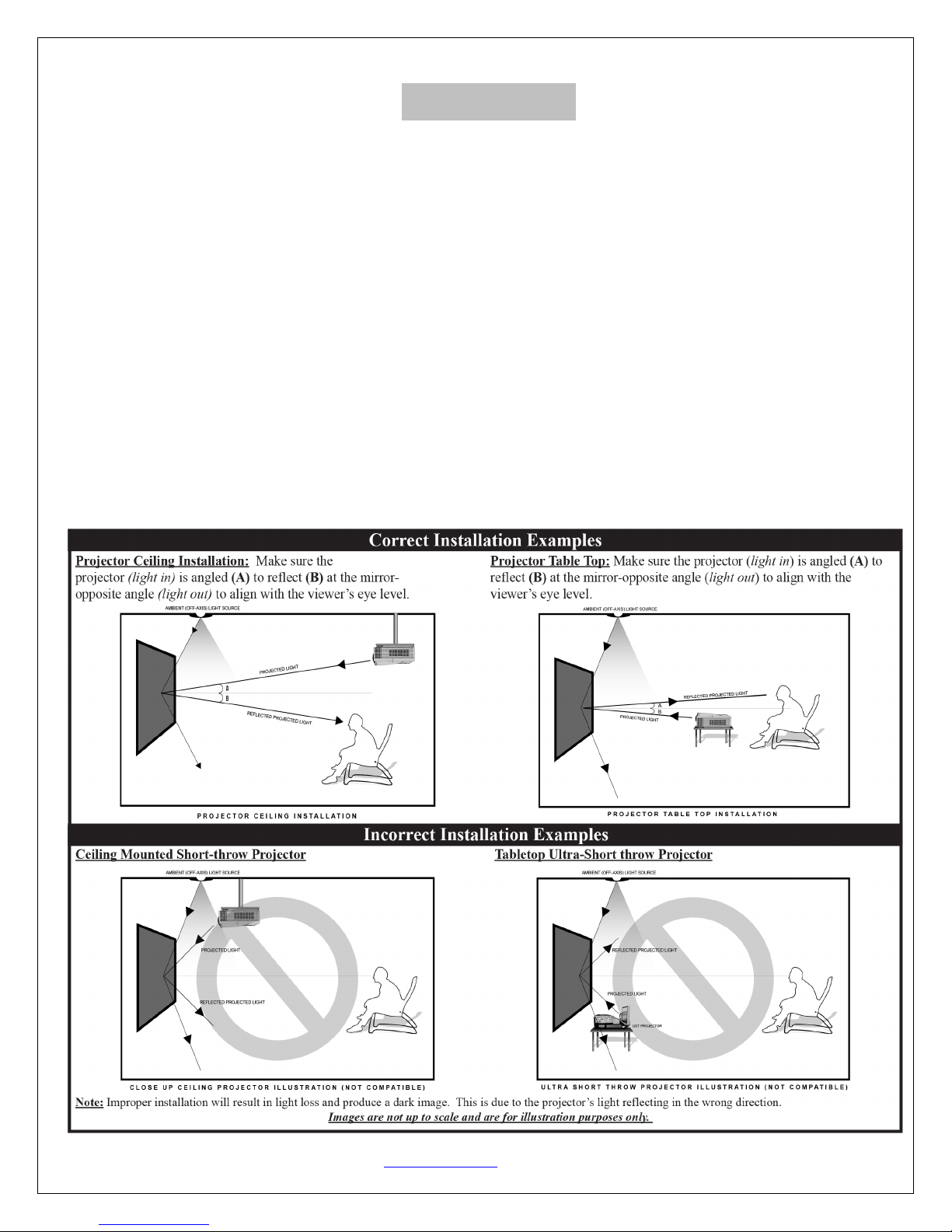

Notice to Installer:

Please use the following installation instructions to obtain superior optical performance from the

Polar Star™ Angular Reflective ALR (Ambient Light Rejecting) Screen.

•Angular-Reflective material is not compatible with ultra/short-throw projectors

•Minimum lens throw ratio 1.5x image width

•Ambient light must not come from the same direction as the projector

Since angular-reflective means that the projected image will reflect at the mirror-opposite angle, it

isimportant to position the projector so that the viewer will get the best possible image.

Step 1: Establish the general “eye level” of the viewers

Step 2: Set the appropriate projection level

Step 3: Adjust the screen height level and projection angle

Input Angle (A) = Output Angle (B) aligns with the viewer’s angle

Rev041316-DR

Installation

1.

Locate your desired installation location with a stud finder (recommended) and mark the

where the screen is to be installed

2. Drill a hole

with the proper bit size according to the wood screw

3. Line up the wall brackets

with the drilled holes on the installation location and screw them

Phillips screwdriver.

Note: Use 2 top

wall brackets on diagonal sizes

sizes 135” and above.

4.

Position the fixed frame screen o

center of the bottom frame

to secure the installation.

5. The design of the

wall brackets allow

feature of the installation design

as it allows

6.

Using both hands finish the installation by pushing the lower portion of the fixed frame screen into the

lower bracket as shown in Fig. 1

9

CAUTION

Please follow these instructions carefully to ensure proper maintenance and safety

1. When hanging the screen up, please make sure that no other objects such as power switches, outlets, furniture,

ladders, windows, etc. occupy the

space designated for your Fixed

2. Regardless if the screen is hung on or installed into the wall, make sure that the proper mounting anchors are

used and that the weight is supported appropriately by a strong and structurally sound surface j

and heavy picture frame should.

3. Frame parts are made of high quality velour

4. When not in use, cover over the screen with a furniture sheet to protect it from dirt, grime, paint or an

impurities.

5. When cleaning, use a damp soft cloth with warm water to remove any marks on the frame or screen surface.

6. Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

7. In order to avoid damaging the

screen, avoid touching it directly with your fingers, tools or any other sharp or

abrasive objects.

8. Spare Parts should be placed o

ut of reach of small children

For a local Elite

Prime Vision

www.EPVscreens.com

(Fig. 18)

www.EPVscreens.com

Locate your desired installation location with a stud finder (recommended) and mark the

where the screen is to be installed

.

with the proper bit size according to the wood screw

s included.

with the drilled holes on the installation location and screw them

wall brackets on diagonal sizes

below 135”, and use 3 top

wall brackets on diagonal

Position the fixed frame screen o

nto the top wall brackets as shown in Fig. 18

and push down at the

to secure the installation.

wall brackets allow

s theframe to slide

over them through its sides.

as it allows

your screen to be properly centered.

Using both hands finish the installation by pushing the lower portion of the fixed frame screen into the

9

.

Please follow these instructions carefully to ensure proper maintenance and safety

of

your

1. When hanging the screen up, please make sure that no other objects such as power switches, outlets, furniture,

space designated for your Fixed

-Frame screen.

2. Regardless if the screen is hung on or installed into the wall, make sure that the proper mounting anchors are

used and that the weight is supported appropriately by a strong and structurally sound surface j

3. Frame parts are made of high quality velour

-

surfaced aluminum and should be handled with care.

4. When not in use, cover over the screen with a furniture sheet to protect it from dirt, grime, paint or an

5. When cleaning, use a damp soft cloth with warm water to remove any marks on the frame or screen surface.

6. Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

screen, avoid touching it directly with your fingers, tools or any other sharp or

ut of reach of small children

in accordance with household safety guidelines.

Prime Vision

contact or Technical Support, please visit

www.EPVscreens.com

(Fig.19)

8

Locate your desired installation location with a stud finder (recommended) and mark the

drill-hole area of

with the drilled holes on the installation location and screw them

in using a

wall brackets on diagonal

and push down at the

over them through its sides.

This is an important

Using both hands finish the installation by pushing the lower portion of the fixed frame screen into the

your

Screen.

1. When hanging the screen up, please make sure that no other objects such as power switches, outlets, furniture,

2. Regardless if the screen is hung on or installed into the wall, make sure that the proper mounting anchors are

used and that the weight is supported appropriately by a strong and structurally sound surface j

ust as any large

surfaced aluminum and should be handled with care.

4. When not in use, cover over the screen with a furniture sheet to protect it from dirt, grime, paint or an

y other

5. When cleaning, use a damp soft cloth with warm water to remove any marks on the frame or screen surface.

screen, avoid touching it directly with your fingers, tools or any other sharp or

in accordance with household safety guidelines.

contact or Technical Support, please visit

Table of contents

Other Elite Prime Vision Projection Screen manuals

Popular Projection Screen manuals by other brands

Philips

Philips BDL4230E/00 Service manual

Draper

Draper Access FIT Series Installation & operation instructions

Da-Lite

Da-Lite Cosmopolitan Electrol Instruction book

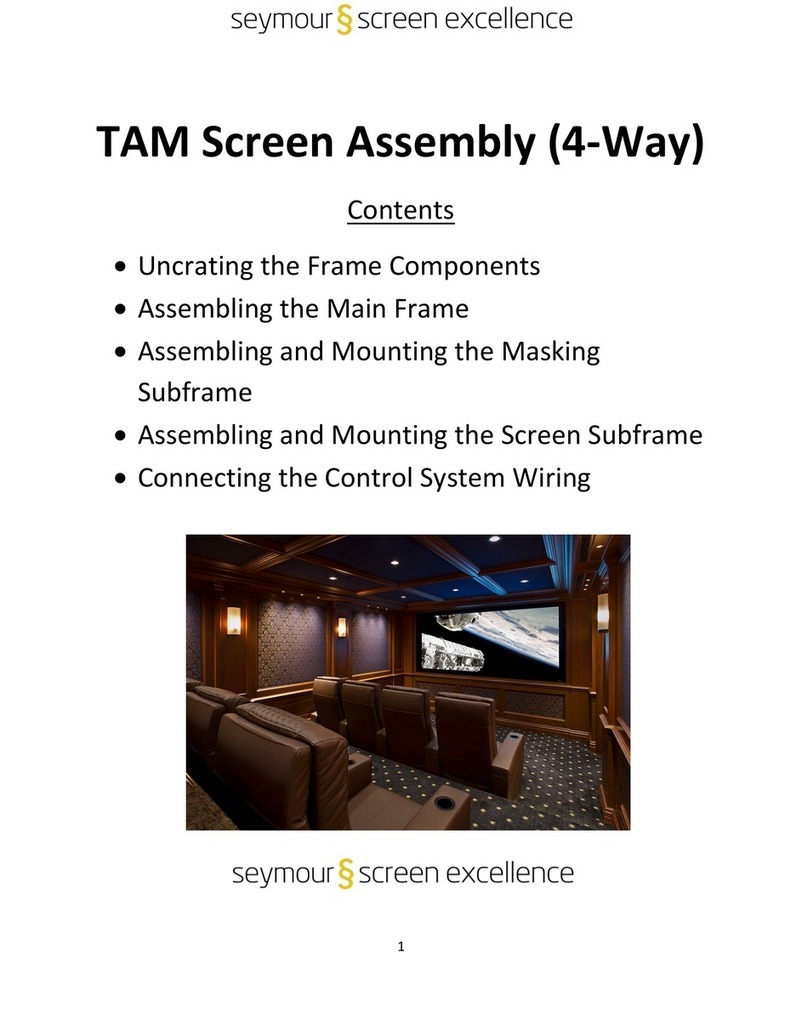

Seymour Screen Excellence

Seymour Screen Excellence TAM Assembly manual

Cima

Cima Below Ceiling ElectriScreen owner's manual

Kimex

Kimex 042-3 Series installation manual

ORION Images

ORION Images R4K Series Installation and user guide

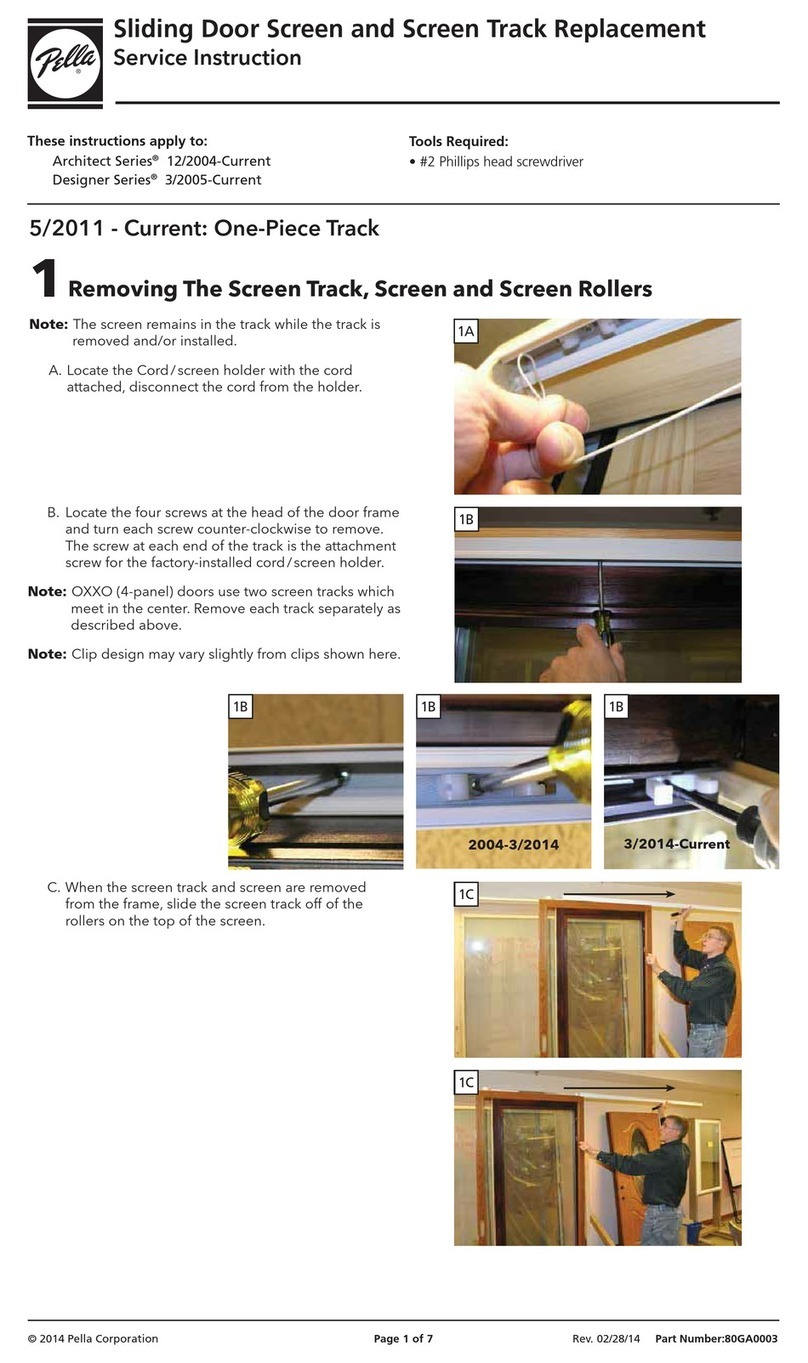

Pella

Pella architect series Service instruction

InFocus

InFocus SC-PU-60 Instruction book

Bei automation

Bei automation Laminar XL installation instructions

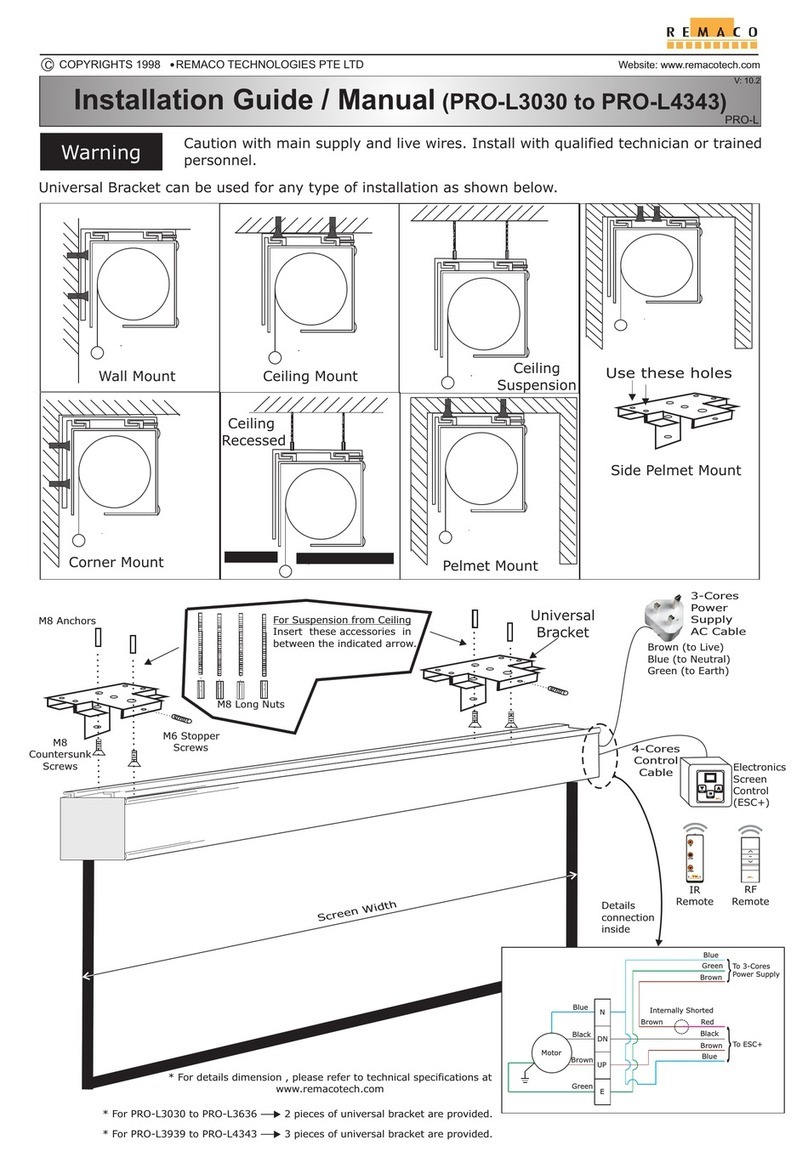

REMACO TECHNOLOGIES

REMACO TECHNOLOGIES PRO-L3030 manual

Derksen USA

Derksen USA GL150-MARATHON Installation and operating instructions