Introduction ......................................................................3

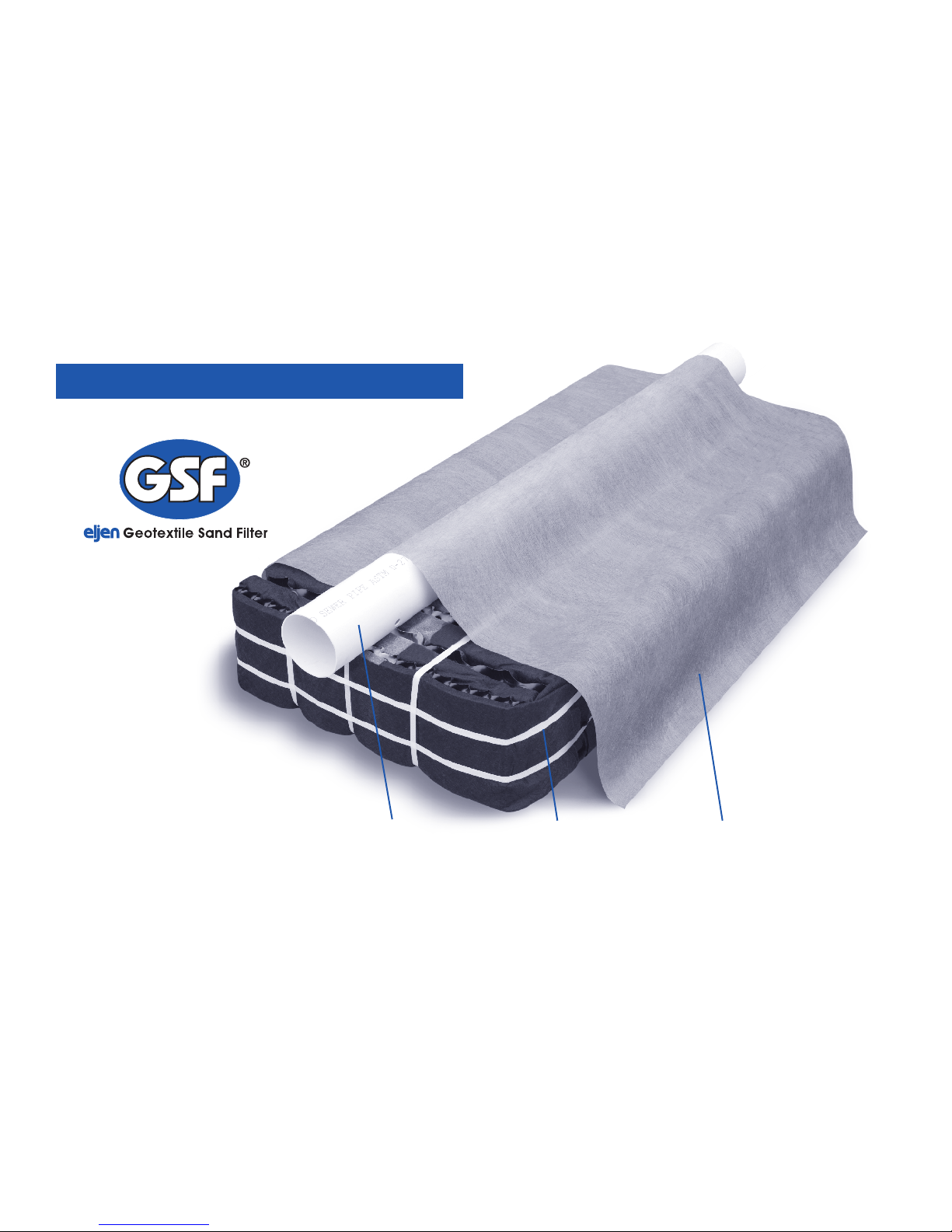

Eljen GSF System...............................................................3

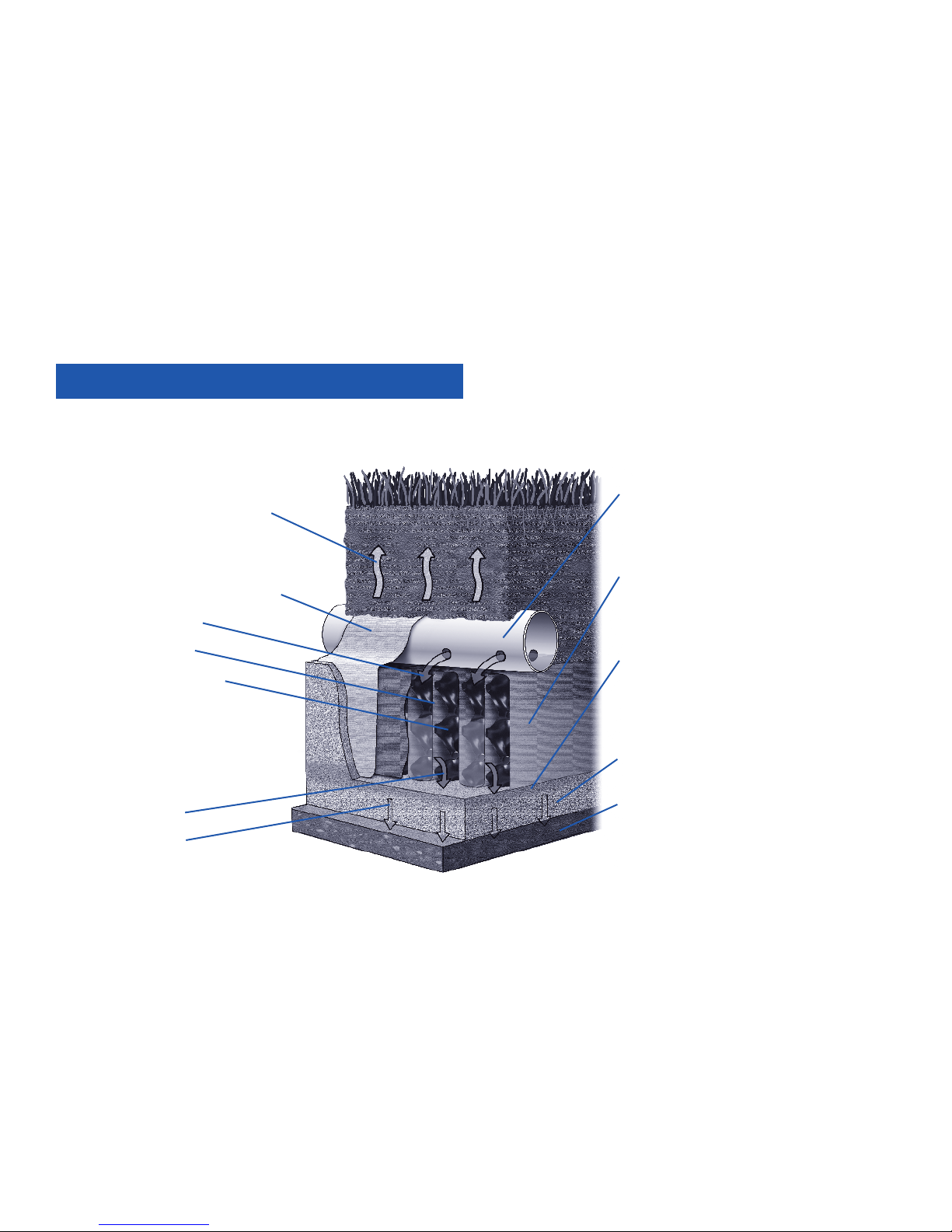

Eljen GSF System Description ............................................4

How the Eljen GSF System Works......................................4

Eljen GSF System Operation ..............................................5

Nature of Household Sewage ............................................6

The Eljen GSF Septic System..............................................6

The Septic Tank.................................................................7

Eljen GSF System Designs ..................................................8

.................................................9

Pumped Systems ...............................................................9

System Care and Maintenance ........................................10

Septic Tank Pumping.......................................................10

Potential System Problems...............................................11

Preventing System Problems ............................................12

Service and Maintenance Record ....................................14

Service and Maintenance Requirements ..........................14

Map of Your Septic System..............................................14

System Details.................................................................15

No one budgets for a septic system failure. A new residential

septic system can cost anywhere from $4,000 to more than

$20,000, or higher, to install. If the system is not maintained,

the soil around the system could become clogged causing

house. The bottom line is that rebuilding a failed septic sys-

tem is an expensive burden on the homeowner.

Preventing a septic system failure is easier and more afford-

able than it is to correct. By keeping harmful materials out of

the system and by pumping out the septic tank at least every

three years, the homeowner can protect their system against

premature failure. The minimum cost of having the septic

tank pumped is wise insurance to protect your home’s waste-

water system.

This Manitoba Owner’s Manual outlines the principles of

septic system operations and explains the basic maintenance

procedures that will lengthen the life of your system. If prop-

erly operated and maintained, your Eljen wastewater system

can provide many years of trouble-free service.

This manual applies to the Eljen GSF System in Manitoba.

IntroductionTable of Contents

2