M1XSP Installation Manual

Page 8

1. Connect the HAI OmniStat to the HVAC system per the instructions that came with the thermostat. After re-applying power

to the HVAC and OmniStat enter the Installer Setup Mode (see the HAI manual) and program as follows:

For OmniStat series 1:

A. Set the "Thermostat Address" to a value from 1 to 16. The first unit should be address 1. If multiple thermostats are installed,

each should be set to a consecutive address, starting at 1.

B. Set the "Communications Mode" to 300 Baud.

C. Set the "Display Options" to one of the options designated as "non-programmable" (4 thru 7). This is to disable the

thermostat's internal setback time schedules so they do not override the M1 Automation commands from the M1XSP.

An alternate method is to disable specific schedules by setting their times values to "----" (1 step past the 11:45pm time set).

D. Set the "Cool Setpoint Limit" and "Heat Setpoint Limit" if desired. Effectively, the thermostat will ignore any setpoint

commands sent to it that are outside these limits.

For OmniStat series 2:

A. Set the "Thermostat Address" to a value from 1 to 16. The first unit should be address 1. If multiple thermostats are installed,

each should be set to a consecutive address, starting at 1.

B. Set the "Communications Mode" to 2400 Baud.

C. Set the "System Options" to the option appropriate to the type of heat/cool system being connected.

D. Set the "Program Options" to either "None" or "Occupancy". This disables the thermostat's internal setback time schedules so

they do not override the M1 Automation commands from the M1XSP.

E. Set the "Cool Setpoint Limit" and "Heat Setpoint Limit" if desired. Effectively, the thermostat will ignore any setpoint

commands sent to it that are outside these limits.

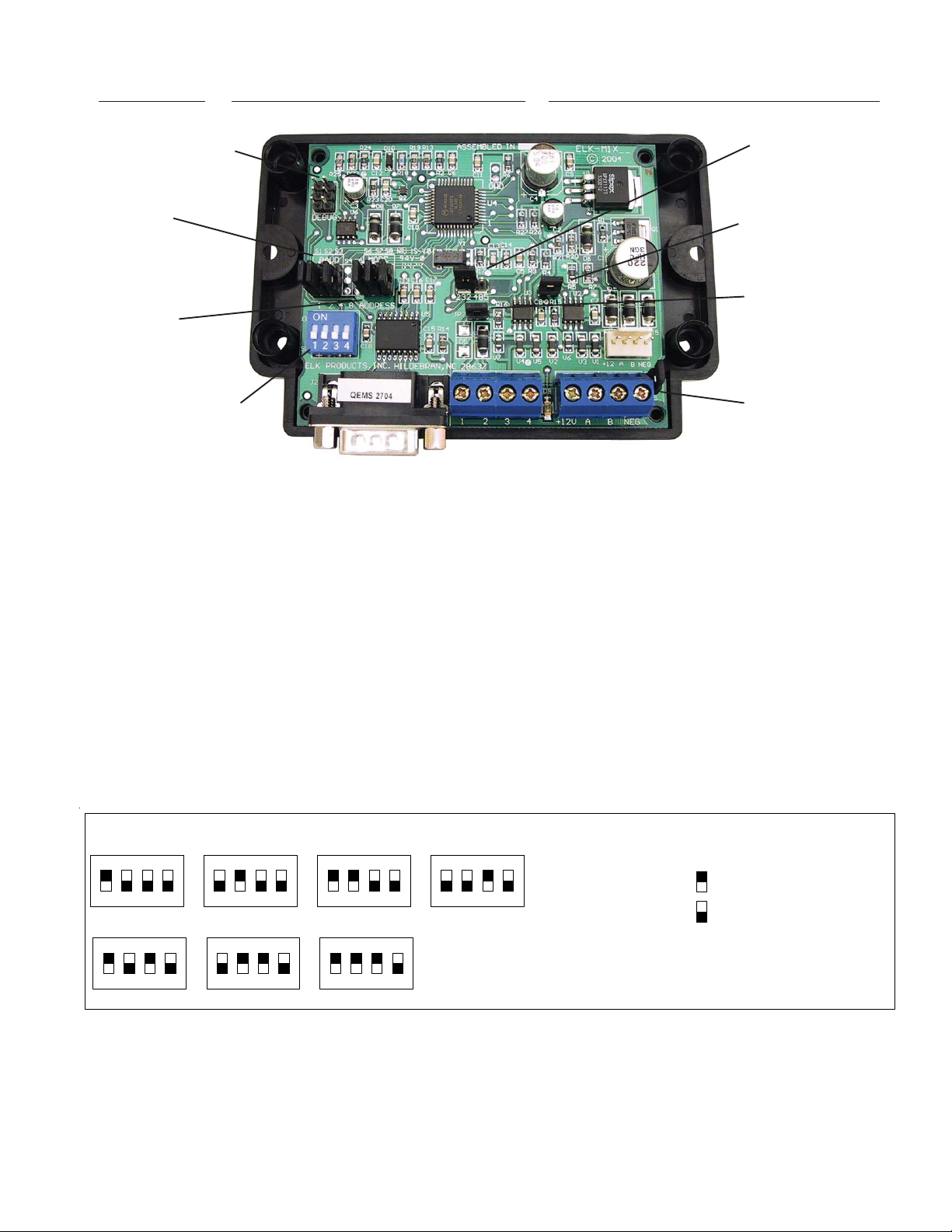

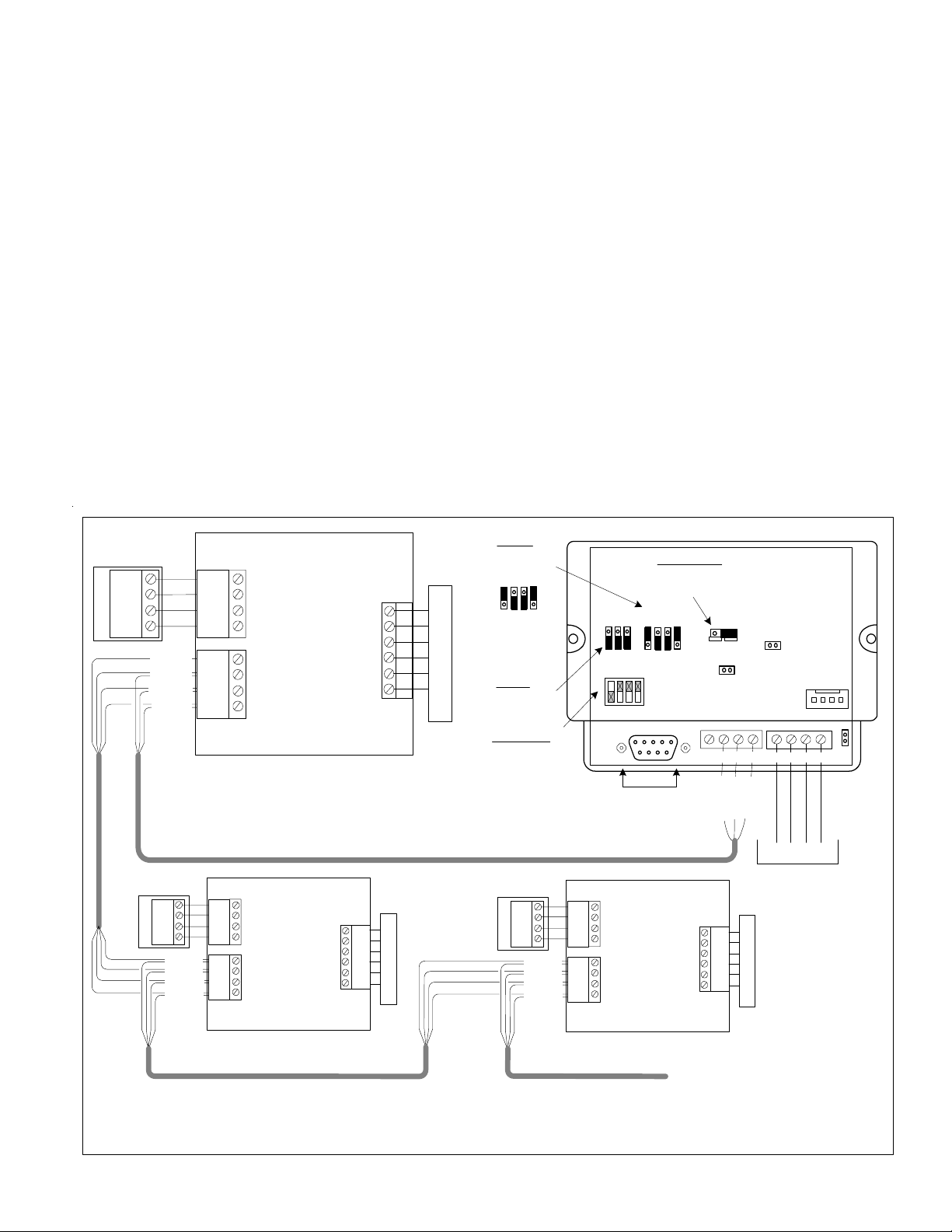

2. Install the ELK-M1XSP and set its data bus address from 1 to 4 using the 4-position dip switch. IMPORTANT: The data

bus address MUST be coordinated with the OmniStat address as follows:

The M1XSP data bus address MUST be 1 when connected to OmniStats addressed as 1, 2, 3, or 4.

The M1XSP data bus address MUST be 2 when connected to OmniStats addressed as 5, 6, 7, or 8.

The M1XSP data bus address MUST be 3 when connected to OmniStats addressed as 9, 10, 11, or 12.

The M1XSP data bus address MUST be 4 when connected to OmniStats addressed as 13, 14, 15, or 16.

* If M1XSPs are in use with other devices they will have to be changed to addresses other than 1 to 4.

Perform a M1 data bus enrollment after setting the M1XSP data bus address switches. Up to four (4) OmniStats may be

connected to a single M1XSP. Using four (4) M1XSPs a total of sixteen (16) OmniStats may be connected.

3. For OmniStat 2 series the M1XSP must be firmware updated to version 70.0.2 (or the latest 70.x.x version).

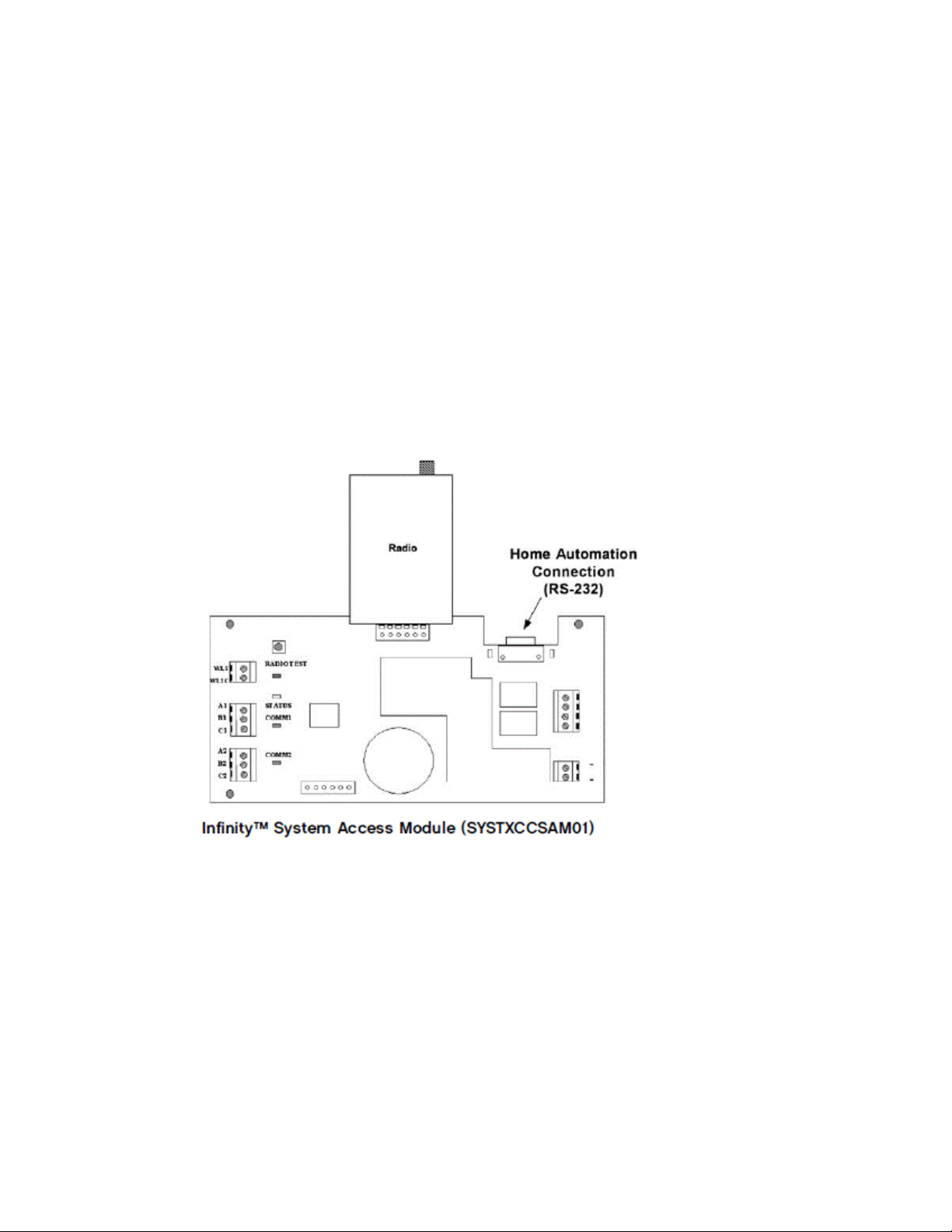

4. Set the M1XSP MODE jumpers to: S5=1, S6=0, S7=1, & S8=0If the M1XSP has jumper S4, set it to =1.

5. Set the M1XSP BAUD jumpers as follows:

On Omnistat 1 series the baud rate must be set for 300 baud: S1=1, S2=0, S3=0

On Omnistat 2 series we recommend setting to 2400 baud: S1=1, S2=1 S3= [see note below]

* Omnistat 2 series may alternatively be set to 300, 1200, or 9600 baud. (refer to back page)

NOTE: Baud Jumper S3 has a special purpose with OmniStat 2 series. The normal setting is S3=0. However, if it is set to

S3=1 the M1XSP will pass along thermostat data in the form of ASCII data to the Elk-M1. This has been a requested feature

by some customers. Refer to the ElkM1 ASCII Protocol document for addition details.

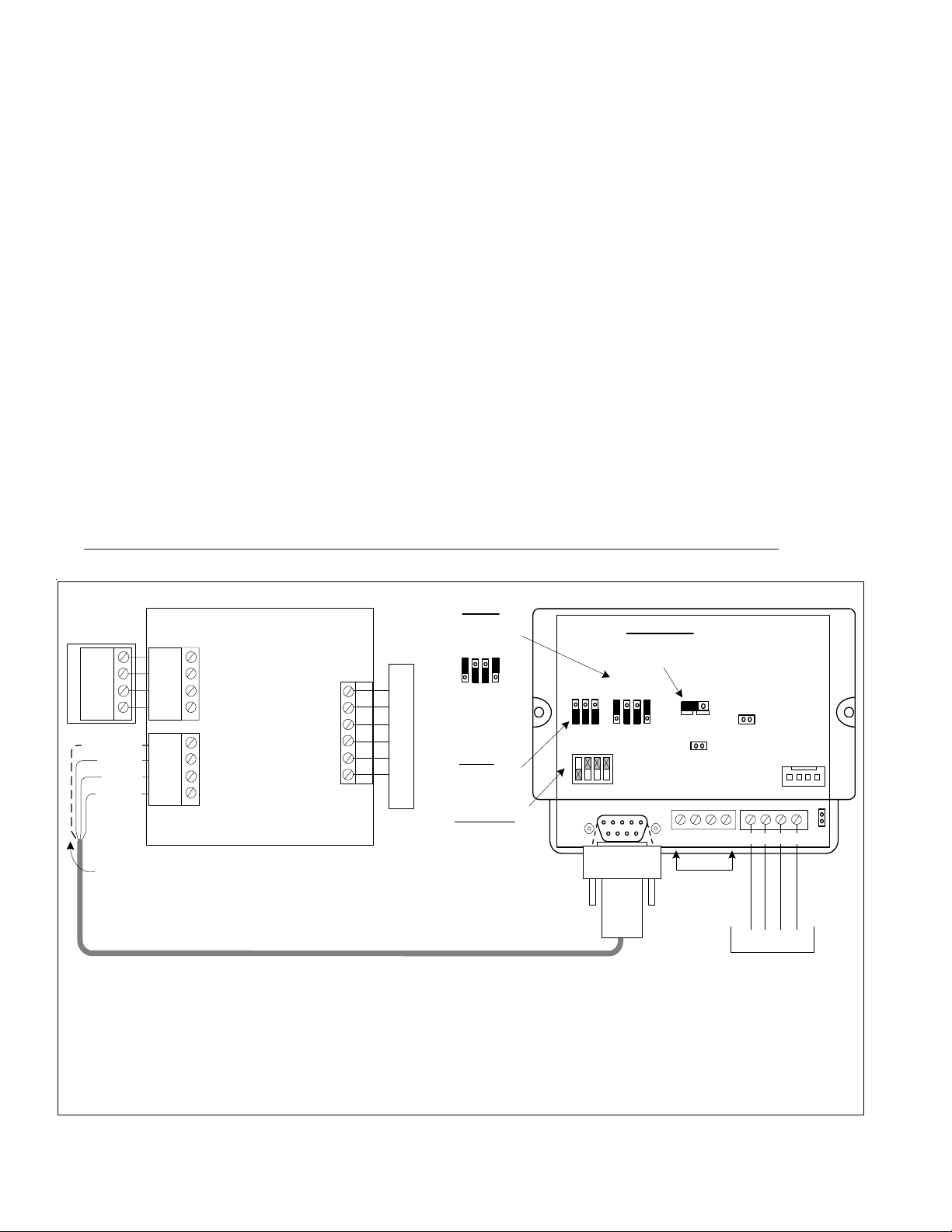

6. On the M1XSP set Jumper JP3 to the "232" position. Make certain that Jumper JP5 is ON. THIS IS VERY IMPORTANT!

7. Splice the ELK-W037A serial cable (supplied) with a four conductor cable running to the OmniStat. Max. length is 500ft.

On OmniStat 1 series splice the four conductor cable to the Black, Red, Green, and Yellow four pin flying lead cable.

On OmniStat 2 series remove the factory jumper between terminals N/C and Black, then connect the four conductor cable

coming from the M1XSP according to the wiring diagram.

8. On OmniStat 2 series REMOVE Jumper J8 from the back side of the unit (if present). THIS IS VERY IMPORTANT!

9. Plug the ELK-WO37A cable into the 9 pin connector on the M1XSP.

10. Using the ELK-RP Software, program steps a, b, & c below. Then test and verify operation using steps d and e.

a. Select the Automation Tab in ELK-RP and pick the Thermostat icon. Program a name for each valid Thermostat.

b. Select the Task icon. Program two tasks: Name the 1st Task "Economy Mode" and the 2nd "Comfort Mode".

c. Select Rules icon and create the following 4 rules.

Whenever [Area Name] Armed State Becomes Armed Away Whenever [Economy Mode] (Task 1) Is Activated

Then Activate [Economy Mode] (Task 1) Then Set [Thermostat 1] (TStat 1) Cooling Desired Temp to 85 degrees

Whenever [Area] Armed State Becomes Disarmed Whenever [Comfort Mode] (Task 2) Is Activated

Then Activate [Comfort Mode] (Task 2) Then Set [Thermostat 1] (TStat 1) Cooling Desired Temp to 70 degrees

d. From the M1 Keypad PRESS the ELK key followed by the RIGHT arrow key to access Menu 1 - View/Control Automation

Fncts. Press 6 for the Thermostat Temperature sub-menu, followed by Right arrow key. The Keypad should now display

the Name and current temperature from Thermostat (T01).

e. Go back and select the Tasks sub-menu, then select Economy Mode (Task 1). Press the # key to activate. When this

task is activated the thermostat cooling setpoint should go to 85 degrees. Confirm this on the Thermostat display.

HAI OmniStat 1 (RC) & OmniStat 2 Series (RS-232) Themostats